Escolar Documentos

Profissional Documentos

Cultura Documentos

137 33 Evaluation

Enviado por

ByronDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

137 33 Evaluation

Enviado por

ByronDireitos autorais:

Formatos disponíveis

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

Evaluation of Engineering Properties of a

Rigid Pavement Using Plaxis Software

B Suresh1, N Venkat Rao2

Assistant Professor, Department of Civil Engineering, Institute of Aeronautical Engineering, Dundigal,

Telangana, India1

Associate Professor, Department of Civil Engineering, Institute of Aeronautical Engineering, Dundigal,

Telangana, India2

ABSTRACT: The construction of foundations of most engineering structures requires adequate information about the

engineering properties of the soil and sub-soil condition of the area this is more important especially in the design and

construction of highways. Usually the subgrade strength of the soil is mostly expressed in terms of CBR (California

Bearing Ratio). Weaker subgrade essentially requires thicker layers whereasthe stronger subgrade works well with

thinner pavement layers. The pavement and the subgrade mutually must withstand the traffic volume. The present

paper focuses at investigating and establishing the sub-soil types and profile to determine the engineering

characteristics of the underlying soils. Representative soil samples are collected and analyzed in the laboratory for

geotechnical engineering standards. The laboratory investigations have been carried out on a number of soil samples

procured from different roadwork sites of proposed site. The site characterized by low volume rural roads where the

sustainable load is limited to 3tonns. The total length of road is 3350 meters passing through two villages. The load

bearing capacity of the pavement is analyzed using the Plaxis software and concluded regarding the stability and

deformation characteristics of the road.

KEYWORDS:subgrade strength, design and construction, bearing capacity, stress and strain deformation Plaxis

software

I. INTRODUCTION

The main characteristics of low volume rural roads that set them apart from more conventional highways are:

Rural Road Connectivity is important key component of Rural Development by Promoting access to economic and

social services and thereby generating increased agricultural incomes and productive employment opportunities in India

The development of the rural road has a high potential to influence economic development through supply side effects.

For example improved accessibility may lead to changes in crop types -from subsistence crops to cash crops – or to

improvements in health and education leading to more productive days work per year and a better skilled workforce

The paper attempts to understand and investigate the variations in sub-soil type and profile to determine the

geotechnical and engineering characteristics of the underlyingsoils by CBR test with moisture contents. Thus, various

soil samples with differentdensities and moisture content are to be calculated. A detailed analysis of results has to

becarried out to get this inference. Subgrade soil is the integral part of the road pavement structure which provides

support to the pavement. The subgrade and its different properties are very much important in the pavement design

structure. The major function of the subgrade is to provide the support to the pavement against traffic loading and for

this the subgrade should possess sufficient stability under adverse climate and heavy loading conditions.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1070

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

II. MATERIALS USED AND EXPERIMENTAL PROCEDURE

1. Sieve Analysis: A sample of approximately 1000grams was used for the test after washing and oven-dried.

The sieving was done by mechanical method using automatic shakers and a set of sieves.

2. Liquid Limit Determination: A liquid limit the sample isdetermined by using Casagrande apparatus

3. Aggregate Crushing Value: Two test were conducted aggregates crushing value is determinedby passing the

sample through 12.5mm and retained on 10mm IS Sieve are oven-dried at a temperature of 100 to 110oC for

4hrs and cooled.Aggregatecrushingvalue = x100

4. Aggregate impact value test: The mean of two observations, rounded to nearest whole number is reported as

the aggregate impact value. The specimen is passed through 12.5mm and retained on 10mm IS Sieve are oven-

dried at a temperature of 100 to 110oC for 4hrs and cooled.Aggregate impact value = ∗ 100%

III. LITERATURE REVIEW

Wang et.al (1972) made his study on the response of rigid pavements subjected to wheel loads. His theory was based

on krichoff’s plate theory. The stresses and deflections in the slab are computed by finite element model

Huang (1983) prolonged his study to the multiple slabs and different load transfer devices similar to ILLI-SLAB

model which is earlier developed by Tabatbaie and Barenberg in year (1980) the subgrade was considered as an elastic

half space and the contact between subgrade and slab was also considered

Tayabji et.al (1986)analyzedpavement resting on winkler foundation by using JSLAB which is similar to ILLI-SLAB.

He utilized plate elements to represents slab and a bounded or unbounded base

Helwany et.al (1998)identified the importance of finite element method in the analysis of three layer pavement system

subjected to various typeof loadings at different pressures this method is very much useful for observing responses of

pavements subjected to axle loads with different tyre pressures.

Hadi and Arfiadi (2001)according to them the design of rigid pavements based upon the two assumptions1) flexural

fatigue of the concrete base 2) erosion of subgradeby considering these two factors the most safe and economical

designs were achieved .

Long and Shatnawi(2011) studied on performance of rigid pavements and resolvedthe thick slab and lean concrete

layers beneath the pavement the deflection response and the formation of voids under the slab has no significant effect

on subgrade reaction

Jain (2013) he identified the suitability and need of flexible and rigid pavements to the various situations and he also

analysed the cost involved in the construction of rigid and flexible pavements he concluded the life span of rigid

pavement is much more than the flexible pavement.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1071

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

IV. EXPERIMENTAL RESULTS AND ANALYSIS

The following experiments were conducted for the evaluation of subgrade strength and also for the analysis of soil

properties, aggregate properties as follows

Grain size analysis of soil specimen

Sample

36-51 inches Test Number: 1

Depth:

USCS Soil Classification: SP

AASHTO Soil

A-3

Classification:

Particle weight %

IS % cumulative

S.no. size retained finer

sieve retained % retained

D(mm) (grams) N

1 100 100 0 0 0 100

2 63 63 0 0 0 100

3 20 20 0 0 0 100

4 10 10 0 0 0 100

5 4.75 4.75 14 1.4 1.4 98.6

6 2 2 0 0 1.4 98.6

7 1.18 1.18 128 12.8 14.2 85.8

8 0.6 0.6 136 13.6 27.8 72.2

9 0.425 0.425 118 11.8 39.6 60.4

10 0.3 0.3 322 32.2 71.8 28.2

11 0.15 0.15 216 21.6 93.4 6.6

12 0.075 0.075 28 2.8 96.2 3.8

Pan

Table.1Representing the details of sieves having larger opening sizes are placed above the ones having smaller opening

sizes.This sieves are sived by motorized sive shaker to gain the distribution of soil in each sive

Sieve Analysis of soil specimen

100

90

80

70

% finer

60

50

40

30

20

10

0

10 1 0.1 0.01

sieve size (mm)

Graph.1 Represents grading curve. Corresponding to 10% 30% and 60% fines. From this graph we can consider the

geotechnical p[arameters such as coefficient pof curvature and coefficient of uniformity.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1072

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

Grain Size Distribution Curve Results:

%

98.6 D10: 0.15 Cu: 2.83

Gravel:

% Sand: 351.8 D30: 0.3 Cc: 1.41

%

3.8 D60: 0.425

Fines:

Table.2 Represents diameter of particle size, coefficient of uniformity and coefficient of curvature of the specimen.

( ) ( . )

D10 = 0.15, D30 = 0.30, D60 = 0.425, Coefficient of curvature Cc = ( ; = Cc = 1.411, Coefficient

∗ ) . ∗ .

of uniformity Cu = = 2.83.According to the USCS Soil Classification system, the sample was poorly graded sand,

gravelly sand, with little or no fines. According to the AASTHO Soil Classification system the sample belongs to A-3

group with fine sand. The soil sample shows a Coefficient of curvature of 1.411, Coefficient of uniformity of 2.83 so it

is fine sand

Calculations of Liquid Limit Test

S.NO Determination Sample1 Sample2 Sample3 Sample4 Sample5

1 Weight of container + wet soil(gm) 47.76 49.13 47.53 47.77 48.14

2 Weight of container + dry soil(gm) 37.23 38.18 37.19 37.78 38.18

3 Loss of moisture 10.53 10.95 10.34 9.99 9.96

4 Weight of container (gm) 14.893 14.727 14.587 15.55 15.531

5 Weight of dry soil (gm) 22.337 23.453 22.603 22.230 22.649

6 Moisture content 33.03 31.82 31.38 31.00 30.54

7 Number of blows 35 30 26 24 20

Table.3Representing the details on calculations of liquid limit test for five soil samples from this we can gain the

percentage of moisture content for number of blows.

Flow curve

m

o 34

i 33

s 32

% 31

t

u 30

r

0 10 20 30 40

e

Number of blows

Graph.2 Represents a flow curve corresponding to 25 blows using casagrande apparatus from this graph we can gain

the otipum water content in the specimen

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1073

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

Calculations of Plastic Limit Test

S.NO Determination Sample1 Sample2 Sample3

1 Weight of container + weight of wet soil (gm) 41.00 38.007 37.925

2 Weight of container + weight of dry soil (gm) 34.34 33.387 33.585

3 Loss of moisture (gm) 6.66 4.62 4.340

4 Weight of container (gm) 15.773 14.156 16.580

5 Weight of dry soil (gm) 18.567 19.231 17.005

6 Weight of wet soil (gm) 25.227 23.851 21.345

7 Moisture content % 26.400 19.370 20.332

Table.4Representing the details on calculations of plastic limit test for three soil samples from this we can gain the

percentage of moisture content.

Result of plastic limit test

Compute the average of the moisture contents to determine the plastic limit, PL

. . .

Plastic limit = = 22.034%

Plastic limit of the soil sample was 22.034%

Plasticity index = liquid limit – plastic limit = 31.38 – 22.034 = 9.346 < 10

Engineering Properties of Soils based on laboratory testing have been correlated to the liquid limit and plastic limits

test and these soil atterberg limits are used to classify a fine-grained soil according to the Unified Soil Classification

system and AASHTO system.

Here plasticity index (PI) = 9.346 and liquid limit (LL) =31.38

so the soil is CL-ML (ML-Inorganic silt and CL-Inorganic clay)

Calculations of California bearing ratio test for dynamic compaction

S NO Determination Sample 1 Sample 2 Sample3

1 Weight of mould + compacted soil 4912 4307 4149

2 Weight of compacted soil (Wt) 2015 1828 1737

3 Wet density γt = Wt/V 2.015 1.828 1.737

4 Container number 1 2 3

5 Weight of container + weight of wet soil (gm) 81.48 88.65 82.78

6 Weight of container weight of dry soil(gm) 75.84 80.06 73.680

7 Weight of water(gm) 5.64 8.59 4.10

8 Weight of container(gm) 15.108 11.280 13.940

9 Weight of dry soil(gm) 60.732 68.780 59.740

10 Water content (%) 8.497 11.102 13.219

11 Weight of wet soil (gm) 66.372 77.37 68.84

12 Dry density(gm/cc) 1.857 1.645 1.534

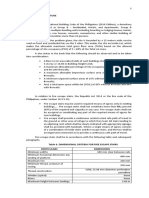

Table.5 Representing the Calculations for California bearing ratio test values for the three samples from this we can

gain the dry density of the soil specimen.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1074

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

California Bearing Ratio Test

Penetrati

Proving ring reading NO. standard load Average

on in Corrected load % of CBR

Division (Kg) CBR

mm

0

0.5 4 5 4

1 6 7 6

1.5 8 7 9

2 10 10 9

32. 2.5 2.3 2.3

2.5 14 13 13 35 32.5 1370 2.43%

5 5 7 7

3 15 13 14

4 15 13 14

3.8 3.8 3.6

5 16 16 15 80 80 75 2055 3.80%

9 9 4

7.5 19 20 23

10 24 23 25

12.5 28 27 28

Table.6Representing the detail Calculations for California bearing ratio test the penetration generally calculated for

2.5mm and 5mm penetration.

80

Percentage of California bearing ratio for sample 1 at 5 mm penetration =2055X 100 = 3.89

80

Percentage of California bearing ratio for sample 1 at 5 mm penetration =2055X 100 =3.89

78

Percentage of California bearing ratio for sample 1 at 5 mm penetration= X 100 =3.64

2055

Finally the average California bearing ratio test value at 5 mm penetration is calculated by taking the mean of three

samples and placed in (column 6)

. . .

Average California bearing ratio test value at 5 mm = = 3.80%

Result of California bearing ratio test

If the California bearing ratio value for 5 mm penetration exceeds that of 2.5mm, the test should be repeated if identical

results follow the California bearing ratio corresponding to 5 mm penetration should be taken for design so the

California bearing ratio test value of 5mm i.e.; 3.80% is considered for designing of pavement.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1075

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

Calculation for Aggregate Crushing Value

Test Number: 1

weight of sample 1000 grams

The

Net weight The fraction

sieve sizes of fraction Aggregate

of aggregate passing through

Aggregate retained crushing

S.NO in the 2.36mm IS

passing 2.36mm IS value

measure in sieve in grams

through sieve in (B/A*100)

grams (A) (B)

grams

12.5mm-

1 284 79 205 27.81

10mm

12.5mm-

2 269 63 206 23.42

10mm

Average Value 25.615

Table.7 Representing the I.S. sieve sizes for aggregates in mm the net weight of aggregates passing through 12.5 mm

I.S. sieve and retaining on 10 mm I.S. sieve is taken and curshing test is found for two samples

The mean of the crushing value obtained in the two tests is reported as the aggregate crushing value

. . .

Aggregate crushing value of the two samples obtained = = 25.615%

The aggregate crushing value for cement concrete pavement shall not exceed30% and the aggregate crushing value for

wearing surfaces shall not exceed 45%

Calculation For Aggregate Impact Value

Test Number: 1

weight of sample 500 grams

Net weight

sieve sizes of

of aggregate The fraction passing The fraction Aggregate

Aggregate

S.NO in the through 2.36mm IS retained 2.36mm impact value

passing

measure in sieve in grams (B) IS sieve in grams (B/A*100)

through

grams (A)

1 12.5 mm-10

354 44 310 12.42

mm

2 12.5 mm-10

368 56 312 15.21

mm

Average Value 13.815%

Table.8 Representing the I.S. sieve sizes for aggregates, the net weight of aggregates passing through 12.5 mm I.S.

sieve and retaining in 10 mm I.S. sieve is taken and inpact test is conducted on two specimens

The mean of the aggregate impact value obtained in the two tests is reported as the aggregate impact test value

. .

Aggregate impact value of the two samples are obtained = = 13.815%

The aggregate impact value for cement concrete pavement shall not exceed30% and the aggregate impact value for

wearing surfaces shall not exceed 45% TheAverage Calculated for Aggregate Impact Value was 13.815%.

The minimum wheel load for design of rural roads is considered to be 30KN or 3 tons and minimum tyre pressure

0.5MPa and maximum wheel load if any possibility of traffic consisting of mini-trucks and buses a design wheel load

of 50KN or 5.20 tons with minimum tyre pressure of 0.7MPa should be considered. As per IRC: SP: 62-2004.The

values of elastic modulus of concrete to be taken 3x104MPa, coefficient of thermal expansion of concrete is 10x10-6per

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1076

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

0

c and Poisson’s ratio of cement concrete is 0.15. As a research a test load of 100 Kilonewtons or 10 tons was applied

on rigid pavements

Total thickness of rigid pavement is 400 mm

Thickness of improved sub grade thickness 100mm (layer 1)

Thickness of Granular sub-base and compacted base of gravel 100mm thick (layer 2 and 3)

Thickness of Proposed CC PAVEMENT is 200mm thick (layer 4)

This road surface is designed to carry the design speed of 50 KMPH. The roadway width of 7.50 meters and carriage

way width of 3.75 meters Vertical curves are not required as the road is having plain embankment along the entire

length. Maximum Height of embankment of 0.50 meters PLAXIS is a finite element package that has been developed

specifically for the analysis of deformation and stability in geotechnical engineering projects. The simple graphical

input procedures enable a quick generation of complex finite element models and the enhanced output facilities

provides a detail presentation of computational results. The calculation itself is fully automated and based on robust

numerical procedures. The minimum clearance between the road face of the kerb and the outer edge of the wheel

should be 1.2 m and width of the wheel is as 0.86 m the figure the plates represented on the top layer of the pavement it

representing the

Plaxis analysis on the rigid pavementAssigning the rigid pavement layers with all material properties and a test load of

10 tons and the details of Rigid pavement layers are as follow thickness of improved sub grade thickness 100mm (layer

1) thickness of Granular sub-base and compacted base of gravel 100mm thick (layer 2 and 3) and thickness of Proposed

CC PAVEMENT 200mm thick (layer 4) the rigid pavement.

(a) (b) (c)

Fig 1(a) assigning input parameters of geotechnical properties using plaxis software (b) assigningpavement layers and

generation of mesh for the designed values of pavement(c) assigning test plates and stress points beneath the pavement

layers to view the deformation ,stress,strain after the test

(a) (b) (c)

Fig 2 (a)Two plates were selected and a uniform distributed load of -10KN is applied on the testplates (b)

assigninmgthe test load of -10KN to see the pavement properties (c) Represents the evaluation process of pavement

properties using Plaxis software

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1077

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

(a) (b) (c)

Fig 3 (a) Represents ultimate satisfactory result of the rigid pavement aster the evaluation process (b) Represents

minute deformation below the pavement layers due to the applied load of -10KN.(c) Represents satisfactory resultsin

stress and strain parameters of the pavement.

Fig 4 (a)Representing the minor displacement of pavement layers due the applied load of -10KN.

V. CONCLUSION

From the results and discussions of several tests conducted on the disturbed subsoil samples the California bearing ratio

test was recorded as 3.80%. Hence subgrade strength is poor according to the pavement design chart of IRC: SP: 72-

2007. The minimum wheel load for design of rural roads is considered as 30KN or 3 tons and the maximum wheel load

if any possibility of traffic consisting of mini-trucks and buses a design wheel load of 50KN or 5.20 tons to be

considered but as a research the test load of 100 Kilo Newton or 10 tons was applied on the rigid pavements using the

application of plaxis

The simple graphical input procedures enable a quick generation of complex finite element models and the enhanced

output facilities provides a detail presentation of computational results. The calculation itself is fully automated and

based on robust numerical procedures it is concluded that the Rigidpavement is away from zone of failure

REFERENCES

1. Ameri, M., Salehabadi, E.G., Nejad, F.M. and Rostami, “Assesment of Analytical Techniques of Flexible Pavements byFinite Element Method

and Theory of Multi-Layer System”,Journal Basic Applied Science Research, Vol.2, No.11, pp.11743-11748,2012.

2. Beiabih, A.G. and Chandra, “Comparative Study ofFlexible and Rigid Pavements for Different Soil and Traffic Conditions”, Journal of the

Indian Roads Congress, Paper No.554, 2009.

3. Das, A,“Reliability Considerations of Bituminous Pavement Design by Mechanistic-Empirical Approach”, International Journal of Pavement

Engineering, Vol.9, No.1, pp. 19-31,2008.

4. Dilip, D., Ravi, P. and Babu,G, “System Reliability Analysis of Flexible Pavements”, Journal Transportation Engineering, Vol.139, No.10, pp.

1001-1009,2013.

5. Hadi, M.N.S. and Arfiadi, “Optimum Rigid Pavement Design by Genetic Algorithms”, Computers and Structures, Vol.1, No.5,2001.

6. Helawany, S., Dyer, J. and Leidy, J, “Finite Element Analyses of Flexible Pavements”, Journal of Transportation Engineering, Vol.124, No.5,

pp.491-499. International Journal of Latest Research in Science and Technology,ISSN:2278-5299 50, 1998.

7. Huang, Y.H. and Deng, X.J, “ Finite Element Analysis of Jointed Concrete Pavements”, Journal of Transportation Engineering, Vol.109,

No.5,pp.689-705,1983.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1078

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 1, January 2017

8. Long,B.andShatnawi, S, “Structural Evaluation of Rigid Pavement Sections, Road Materials and Pavement Design”, Vol.1, No.1, pp.97-

117,2011.

9. Subagio, B. Cahyanto, H., Rahman, A. and Mardiyah, S,“Multilayer Pavement Structural Analysis Using Method of Equivalent Thickness”,

Case Study: Jakarta-Cikampeck Toll Road , Journal of the Eastern Asia Society for Transportation Studies, Vol.6,pp.55-65,2005.

10. Tabatabaie,A.M. and Barenberg, “Structural Analysis of Concrete Pavements”, Transportation Engineering Journal, ASCE,

Vol.106,No.5,pp.832-849,1980.

11. IRC-SP- 72-2007 , “Guidelines for the Design of Flexible Pavements for Low Volume Rural Roads “,IRC,New Delhi

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0601137 1079

Você também pode gostar

- API RP 1102 SpreadsheetDocumento5 páginasAPI RP 1102 Spreadsheetdrramsay100% (4)

- BWA Overview Presentation: Clear Solutions For Water TreatmentDocumento10 páginasBWA Overview Presentation: Clear Solutions For Water TreatmentByronAinda não há avaliações

- L5CoachMentorReflectiveLog TemplateDocumento9 páginasL5CoachMentorReflectiveLog TemplateHadusssAinda não há avaliações

- Ring foundATIONDocumento8 páginasRing foundATIONShital PhapaleAinda não há avaliações

- 21 EffectDocumento9 páginas21 EffectDouli Génie CivilAinda não há avaliações

- Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocumento3 páginasNternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyAnonymous ELujOV3Ainda não há avaliações

- 291 EccentricallyDocumento7 páginas291 EccentricallybadisnoveAinda não há avaliações

- Soil Stabilization Using Plastics and Bottle StripsDocumento8 páginasSoil Stabilization Using Plastics and Bottle StripsPrathamesh NarkarAinda não há avaliações

- Stabilization of Subgrade With Waste Plastic As Stabilizer in Flexible PavementsDocumento6 páginasStabilization of Subgrade With Waste Plastic As Stabilizer in Flexible PavementsTime PassAinda não há avaliações

- Analysis of G+30 Highrise Buildings by Using Etabs For Various Frame Sections in ZoneIV and ZoneV PDFDocumento15 páginasAnalysis of G+30 Highrise Buildings by Using Etabs For Various Frame Sections in ZoneIV and ZoneV PDFK.ANISHAinda não há avaliações

- New Soil Stabilization Research PaperDocumento22 páginasNew Soil Stabilization Research PaperBhavsar NilayAinda não há avaliações

- INDIAN Steel TableDocumento9 páginasINDIAN Steel Tablekeshav langerAinda não há avaliações

- 135 Transverse BoxDocumento7 páginas135 Transverse BoxAnonymous b9fkTYfEoRAinda não há avaliações

- Glass Waste in Concrete Effect On Workability andDocumento10 páginasGlass Waste in Concrete Effect On Workability andimen.bourahlaAinda não há avaliações

- Glass Waste in Concrete: Effect On Workability and Compressive StrengthDocumento9 páginasGlass Waste in Concrete: Effect On Workability and Compressive StrengthJenny ValderramaAinda não há avaliações

- Effect of Recycled Coarse Aggregate On Concrete PropertiesDocumento9 páginasEffect of Recycled Coarse Aggregate On Concrete PropertiesJumah Musdif TheirAinda não há avaliações

- Damage Assessment of RCC Bridge Deck by Impulse Response TechniqueDocumento8 páginasDamage Assessment of RCC Bridge Deck by Impulse Response TechniqueNatarajan SaravananAinda não há avaliações

- Stabilization of Lateritic Soil Subgrade Using Cement, Coconut Coir and AggregatesDocumento8 páginasStabilization of Lateritic Soil Subgrade Using Cement, Coconut Coir and AggregatesF.a.AlfredThomAinda não há avaliações

- Soil Stabilization Using Nano-Materials For Rural Roads-A Case StudyDocumento4 páginasSoil Stabilization Using Nano-Materials For Rural Roads-A Case StudyzahraaAinda não há avaliações

- 75 Determination PDFDocumento7 páginas75 Determination PDFAngelito RamosAinda não há avaliações

- 12 Steady PDFDocumento12 páginas12 Steady PDFMichael ZhaoAinda não há avaliações

- 143 Manoj Journal MB PDFDocumento12 páginas143 Manoj Journal MB PDFAnonymous ELujOV3Ainda não há avaliações

- An Experimental Study On Smart Transparent ConcreteDocumento10 páginasAn Experimental Study On Smart Transparent ConcreteBEYENA GEDEFAAinda não há avaliações

- 11 Ijirset Ggbs-FinalDocumento10 páginas11 Ijirset Ggbs-FinalShri swamiAinda não há avaliações

- Seismic Analysis and Design of Building Structures in STAAD ProDocumento9 páginasSeismic Analysis and Design of Building Structures in STAAD ProboyAinda não há avaliações

- Pavement Rehabilitation Using Thin White ToppingDocumento9 páginasPavement Rehabilitation Using Thin White ToppingRedminote3 LokAinda não há avaliações

- Buckling Analysis of Plate Element Subjectedto in Plane Loading Using Ansys PDFDocumento10 páginasBuckling Analysis of Plate Element Subjectedto in Plane Loading Using Ansys PDFMahmoudHelalAinda não há avaliações

- V. Raghul, N. Uma MaheswariDocumento7 páginasV. Raghul, N. Uma MaheswariamokeAinda não há avaliações

- Ball Joint DesignDocumento8 páginasBall Joint DesignRatnakar PatilAinda não há avaliações

- Analysis and Design of Suspension Cable BridgeDocumento5 páginasAnalysis and Design of Suspension Cable BridgeNhel AlbrechtAinda não há avaliações

- 80 Abrasion PDFDocumento6 páginas80 Abrasion PDFايات علي احمدAinda não há avaliações

- Highway and Transportation Engineering Lab Manual: June 2016Documento28 páginasHighway and Transportation Engineering Lab Manual: June 2016deepak khudaniaAinda não há avaliações

- The Effect of Degree of Saturation On The Bearing Capacity of Shallow FoundationDocumento9 páginasThe Effect of Degree of Saturation On The Bearing Capacity of Shallow Foundationmsaelfeky1Ainda não há avaliações

- Dynamic Analysis of Machine Foundation-INFODocumento8 páginasDynamic Analysis of Machine Foundation-INFOjakeer7Ainda não há avaliações

- Study of Structural Behaviour of Box Girder BridgesDocumento6 páginasStudy of Structural Behaviour of Box Girder BridgesIJRASETPublicationsAinda não há avaliações

- Seismic Analysis of Multi-Storey Building Resting On Flat Ground and Sloping GroundDocumento10 páginasSeismic Analysis of Multi-Storey Building Resting On Flat Ground and Sloping Groundankit yogiAinda não há avaliações

- Performance of Self Compacting Concrete With Partial Replacement of Cement With Nano-SilicaDocumento6 páginasPerformance of Self Compacting Concrete With Partial Replacement of Cement With Nano-SilicaIJRASETPublicationsAinda não há avaliações

- Pro118. Effect of Different Types of Steel Fibers OnDocumento10 páginasPro118. Effect of Different Types of Steel Fibers OnMritunjay YadavAinda não há avaliações

- 119 Effect PDFDocumento11 páginas119 Effect PDFnikola1popovi1Ainda não há avaliações

- 213 - Mech 008 PDFDocumento4 páginas213 - Mech 008 PDFananthAinda não há avaliações

- 74 16 A ComparativeDocumento7 páginas74 16 A ComparativeSanjeev Kr. ThakurAinda não há avaliações

- Diagrid Structure Square in Plan - PushoverDocumento5 páginasDiagrid Structure Square in Plan - Pushovermaikol cantorAinda não há avaliações

- Shift in Position of Centre of Mass and Centre of Rigidity With Change in Symmetry of A BuildingDocumento6 páginasShift in Position of Centre of Mass and Centre of Rigidity With Change in Symmetry of A Buildingnaveenpnaidu1Ainda não há avaliações

- 114 - A ComparativeDocumento12 páginas114 - A ComparativePradeep MeganathanAinda não há avaliações

- Analysis of Rigid Pavement Joints Under Different Shoulder TypesDocumento7 páginasAnalysis of Rigid Pavement Joints Under Different Shoulder TypesIJRASETPublicationsAinda não há avaliações

- Articulo 1Documento8 páginasArticulo 1Abelino Vargas TenjoAinda não há avaliações

- A Study Report On Flexible Pavement Construction in VidishaDocumento4 páginasA Study Report On Flexible Pavement Construction in VidishaIJRASETPublicationsAinda não há avaliações

- 247 64 IJIRSET Paper TemplateDocumento8 páginas247 64 IJIRSET Paper TemplateshinthantAinda não há avaliações

- 9368 11590 1 PB PDFDocumento7 páginas9368 11590 1 PB PDFmamayo magzAinda não há avaliações

- 24 Production 009 NewDocumento8 páginas24 Production 009 NewjovaniAinda não há avaliações

- Effect of Gradation and Particle Size On Correlations Between DCP Index (ASTM D6951 - 03) and Relative Density For SandDocumento7 páginasEffect of Gradation and Particle Size On Correlations Between DCP Index (ASTM D6951 - 03) and Relative Density For SandJose GonzalezAinda não há avaliações

- Flexible Pavement Modelling Using Kenlayer: Dr. Amin ChegenizadehDocumento13 páginasFlexible Pavement Modelling Using Kenlayer: Dr. Amin ChegenizadehEman MousaAinda não há avaliações

- 48 EffectDocumento7 páginas48 EffectMalik RizwanAinda não há avaliações

- Effect of Woven Polyester Geotextile On The Strength of Black Cotton SoilDocumento7 páginasEffect of Woven Polyester Geotextile On The Strength of Black Cotton SoilSaleh HassanAinda não há avaliações

- Influence of Hoarding Frame On Response of RC Framed Host StructureDocumento9 páginasInfluence of Hoarding Frame On Response of RC Framed Host StructureGaurav PawarAinda não há avaliações

- 1.study of R.C.C. T-Beam Bridge With SkewDocumento6 páginas1.study of R.C.C. T-Beam Bridge With SkewsujupsAinda não há avaliações

- Akhil PDFDocumento6 páginasAkhil PDFSachin BorseAinda não há avaliações

- 111 Pushover NewDocumento8 páginas111 Pushover NewBenedicta OllaAinda não há avaliações

- A Study On Translucent Concrete and It's PropertiesDocumento7 páginasA Study On Translucent Concrete and It's PropertiessehunAinda não há avaliações

- IJIRSETDocumento9 páginasIJIRSETQasim KhanAinda não há avaliações

- Influence of Geometric Dimensions in Screening Efficiency of Geofoam Crumb Rubber Infilled TrenchDocumento6 páginasInfluence of Geometric Dimensions in Screening Efficiency of Geofoam Crumb Rubber Infilled TrenchIJRASETPublicationsAinda não há avaliações

- Elastic, Plastic and Yield Design of Reinforced StructuresNo EverandElastic, Plastic and Yield Design of Reinforced StructuresAinda não há avaliações

- PavimentosDocumento15 páginasPavimentosByronAinda não há avaliações

- Strategic MamagementDocumento4 páginasStrategic MamagementByronAinda não há avaliações

- Maskana 7212Documento26 páginasMaskana 7212ByronAinda não há avaliações

- EverFEv101Manual PDFDocumento34 páginasEverFEv101Manual PDFByronAinda não há avaliações

- New Constitutive Material: Models in RSDocumento8 páginasNew Constitutive Material: Models in RSByronAinda não há avaliações

- Japanese Geotechnical SocietyDocumento17 páginasJapanese Geotechnical SocietyByronAinda não há avaliações

- MaterialsDocumento9 páginasMaterialsByronAinda não há avaliações

- Phicometro 2Documento5 páginasPhicometro 2ByronAinda não há avaliações

- The Development of A Machine Vision Assisted, Teleoperated Pavement Crack SealerDocumento10 páginasThe Development of A Machine Vision Assisted, Teleoperated Pavement Crack SealerByronAinda não há avaliações

- Information Handling Services, 2000 November 09, 2000 12:03:29Documento3 páginasInformation Handling Services, 2000 November 09, 2000 12:03:29ByronAinda não há avaliações

- Manual TimerDocumento2 páginasManual TimerByronAinda não há avaliações

- Lock Maiolo Savonarola MachiavelliDocumento22 páginasLock Maiolo Savonarola MachiavelliHeliogabolusAinda não há avaliações

- Example of Presentation Planning Document 1uf6cq0Documento2 páginasExample of Presentation Planning Document 1uf6cq0Wilson MorenoAinda não há avaliações

- Maya Evaluating InterfacesDocumento6 páginasMaya Evaluating InterfacesChristopher WalkerAinda não há avaliações

- States of Matter LessonDocumento4 páginasStates of Matter Lessonapi-280793165Ainda não há avaliações

- Risk LogDocumento1 páginaRisk LogOzu HedwigAinda não há avaliações

- Student Material CN Version - 2017.11.10Documento25 páginasStudent Material CN Version - 2017.11.10Jagaddeesha BRAinda não há avaliações

- Biogas Technology Suppliers Directory 2018: Internati NalDocumento6 páginasBiogas Technology Suppliers Directory 2018: Internati NalRazvan PetricaAinda não há avaliações

- Q3 - Summative Test2 - Statprob 2022 2023Documento2 páginasQ3 - Summative Test2 - Statprob 2022 2023Christian Lloyd ReandinoAinda não há avaliações

- PQA824 ManualDocumento100 páginasPQA824 ManualElkin AguasAinda não há avaliações

- Business Design Thinking - Nguyễn Quang MinhDocumento39 páginasBusiness Design Thinking - Nguyễn Quang MinhbuikimhoangoanhtqkAinda não há avaliações

- What Happens To The 3-Phase Motor When 1 Out of 3 Phases Is Lost?Documento3 páginasWhat Happens To The 3-Phase Motor When 1 Out of 3 Phases Is Lost?miretade titoAinda não há avaliações

- Analysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabDocumento3 páginasAnalysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabMesfinAinda não há avaliações

- Metal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatDocumento13 páginasMetal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatbluexpectroAinda não há avaliações

- Rail Inspection Vehicle Using Ir Sensor and Spot Marking SystemDocumento63 páginasRail Inspection Vehicle Using Ir Sensor and Spot Marking SystemNarayananNanuAinda não há avaliações

- A Research Paper On DormitoriesDocumento5 páginasA Research Paper On DormitoriesNicholas Ivy EscaloAinda não há avaliações

- RH 120eDocumento8 páginasRH 120eSawadogo Gustave NapinguebsonAinda não há avaliações

- Timing Chain InstallationDocumento5 páginasTiming Chain InstallationToriTo LevyAinda não há avaliações

- Oracle Pac 2nd KeyDocumento48 páginasOracle Pac 2nd KeyKrishna Kumar GuptaAinda não há avaliações

- Mechatronics Course PlanDocumento3 páginasMechatronics Course PlanMohammad Faraz AkhterAinda não há avaliações

- BUCA IMSEF 2021 Jury Evaluation ScheduleDocumento7 páginasBUCA IMSEF 2021 Jury Evaluation SchedulePaulina Arti WilujengAinda não há avaliações

- Definition, Scope and Nature of EconomicsDocumento29 páginasDefinition, Scope and Nature of EconomicsShyam Sunder BudhwarAinda não há avaliações

- Loading and Hauling Dump Truck: DumperDocumento2 páginasLoading and Hauling Dump Truck: DumperRJAinda não há avaliações

- Renaissance QuestionsDocumento3 páginasRenaissance QuestionsHezel Escora NavalesAinda não há avaliações

- Heat ExchangerDocumento5 páginasHeat Exchangersara smithAinda não há avaliações

- (LS 1 English, From The Division of Zamboanga Del SurDocumento17 páginas(LS 1 English, From The Division of Zamboanga Del SurKeara MhieAinda não há avaliações

- Coding Prony 'S Method in MATLAB and Applying It To Biomedical Signal FilteringDocumento14 páginasCoding Prony 'S Method in MATLAB and Applying It To Biomedical Signal FilteringBahar UğurdoğanAinda não há avaliações

- Job No. 25800: Quebrada Blanca Fase 2Documento1 páginaJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozAinda não há avaliações

- Certification Roadmap 11-30-16Documento1 páginaCertification Roadmap 11-30-16Cristian Gavilanes MontoyaAinda não há avaliações