Escolar Documentos

Profissional Documentos

Cultura Documentos

Masonry Swimming Pool PDF

Enviado por

AilynTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Masonry Swimming Pool PDF

Enviado por

AilynDireitos autorais:

Formatos disponíveis

CBI 3125, 3321, 8412

September 2016

MASONRY SWIMMING POOLS

1 Masonry Swimming Pools

contents MASONRY SWIMMING POOLS

Masonry Swimming Pools ......................................................................................... 2 1. Planning • Finishes and details

1. Planning .............................................................................................................. 2 NZS 4441 Swimming Pool Design Standard and • Accommodation of lights, ladders, skimmer boxes

NZS 5826 Pool Water Quality govern the safe • Water circulation

2. Design ................................................................................................................. 2

operation of swimming pools and need to be consulted • Filtration

3. Regulations ......................................................................................................... 2 during the planning, design and construction of the • Safety – owner controlled access to pool enclosure

4. Land..................................................................................................................... 2 pool.

The size of the pool is naturally determined by

This information describes the construction of individual requirement but where cost or available

Specification .................................................................................................................. 3

a Swimming pool specially designed for “Firth space are the limiting factors then a 6m x 3.6m

5. Construction........................................................................................................ 3 Masonry” and includes full details of wall and floor pool is the smallest size recommended. With a

construction, reinforcing and drainage details. recommended water depth of 1.3m and 28,100 litres

6. Setting out ........................................................................................................... 3

Should it be desired to alter depth, structure or shape capacity, this pool is for swimmers only and is not

7. Excavation ........................................................................................................... 3 large or deep enough to take a springboard. Diving

outside the scope of this pamphlet or where adverse

8. Drainage .............................................................................................................. 3 site conditions exist, the services of a Structural boards are not recommended in pools less than 9m

Engineer should be sought, as each deviation will long and 2.4m deep.

a. Subgrade Drainage ........................................................................................ 3

present its own special requirements. The rectangular shape remains the most practical pool

b. Pool Drainage ................................................................................................ 3

Before constructing your pool, make a survey on the shape and is of course best suited to concrete block

9. Floor Construction .............................................................................................. 3 construction. However other shapes are possible.

following factors:

10. Blockwork ........................................................................................................... 3

• Paved areas and Pool Fencing (need to comply 3. Regulations

11. Grouting Cores .................................................................................................... 4

with the Fencing of Swimming Pools Act)

Determine the planning requirements by consulting

12. Fittings ................................................................................................................ 4 • Access to house the local territorial authority.

13. Curing .................................................................................................................. 4 • Access to toilet and dressing facilities

Swimming pools require a building consent. Some

14. Backfill ................................................................................................................ 4 • View of pool from house

authorities may require design calculations or

• View/privacy of pool from neighbours a producer statement from a Structural Engineer.

15. Coping ................................................................................................................. 4

• Shelter from wind Submit two copies of the building plans, showing

Interior Finish ............................................................................................................... 4 • Orientation to sun size of pool, details of construction, drainage and

• Shade from house, neighbours plumbing, site plan showing position of existing

16. Plastering ............................................................................................................ 4

building, swimming pool and distances to boundaries.

17. Painting ............................................................................................................... 4 • Relationship with garden, trees

• Location of pump/filter unit (consider the noise The basis for the structural design of this swimming

18. Plumbing ............................................................................................................. 4

made by the pump/filter) pool is AS/NZS 1170 - Structural Design Actions,

19. Paving .................................................................................................................. 4 • Connection to storm water drains NZS 4230 Design of Reinforced Concrete Masonry

Structures and NZS 4229 Concrete Masonry

20. Filtering ............................................................................................................... 4 • Access to water supply

Buildings not requiring Specific Design.

21. Electrical ............................................................................................................. 5 • Location of underground services

22. Fencing ................................................................................................................ 5 4. Land

2. Design

Consider the effects of the water table on pool

Wall to Floor Detail ..................................................................................................... 5 Consider: depth and under pool drainage. Consider access and

• Use manoeuvring space for excavator and methods of

Typical Step Detail ....................................................................................................... 6

• Size and shape soil disposal.

Typical Plan Layout...................................................................................................... 6 • Depth

Corner Detail of Steel Reinforcing.......................................................................... 7

Swimming Pool Planning Module ........................................................................... 8

1 Masonry Swimming Pools 2 Masonry Swimming Pools

SPECIFICATIONS The vertical rods are tied with black iron tie-wire 14. Backfill

to starters. Place horizontal reinforcing as the work

Backfill over subgrade drainage with free draining

proceeds. Clean mortar from cores at each course.

5. Construction b) Pool Drainage granular material or Pea metal. Do not overstress

It is essential that walls are kept true and plumb.

After completion of excavation, set main 38mm copper the walls by operating heavy equipment on the fill,

All work shall comply with the compliance documents

or PVC outlet drain in position. Levels should be or by impacting against them with large masses of

for the NZ Building Code, NZS 4210 Masonry 11. Grouting Cores

checked at this point to ensure the finished floor will moving earth.

Construction and NZS 4441 Swimming Pool

have a slight fall from all directions towards the outlet. Fill cores of each block in accordance with NZS

Design Standard.

Standard copper or PVC fittings are available with 4210. The grout shall be 17.5 MPa Firth Blockfill. 15. Coping

6. Setting Out manufacturer’s installation instructions. Note: It is especially important to ensure that the The coping (top edge of wall) should provide:

blockwork cores are free of mortar prior to grouting.

Mark out pool area using timber profiles and 9. Floor Construction • A visual edge to the pool

string lines. • A non-skid walking surface

Screed and compact levels and falls as required. 12. Fittings

Set tops of profiles level using dumpy level or water 100mm of free draining hardfill topped with 25mm • A handhold for swimmers

Box for or leave openings for fittings previously selected.

filled hose system. String lines marking outside of of 6.5mm down stabilised hardfill rolled with a Lay electrical cords prior to grouting. • A barrier to prevent surface water on surrounding

pool walls should be accurately placed and checked vibratory roller to produce a hard unyielding base surfaces from draining back into the pool adding

for squareness. for the slab. 13. Curing dirt and discoloration.

Peg out area to the excavated. Sides of excavation Lay 125mm thick reinforced concrete slab and integral Cure block walls for seven days under wet sacking

should be cut approximately 300mm larger all round reinforced wall footings. The floor and footings are to kept damp, before placing and compacting backfill.

than the outside wall dimension to allow for back be 20MPa Firth Readymix Concrete containing Xypex

filling and drainage. Indicate depths and where spoil is additives.

to be spread if not to be removed from site. Floor reinforcement consists of 663 HRC mesh sheets,

INTERIOR FINISH

cut, placed and lapped. Set reinforcing 50mm above

7. Excavation

hardfill. Support on 50mm plastic stools.

Allow access of at least 2.4m wide plus manoeuvring 16. Plastering Firth Concrete Paving Slabs

Wall footing consists of a thickening round the Firth Bricks (Focus)

room for digger and readymix concrete trucks. Inform If a plaster finish is desired allow for one bond coat

perimeter of the floor slab with additional reinforcing

excavator of location of underground services, and followed by a flanking coat of plaster and a finish coat Firth Interlocking Paving

and wall starter bars as detailed. Tie starter bars

their respective depths, before work commences. to give a total thickness of 15mm. Treated Timber

to HRC mesh with black iron tie-wires accurately

Hand trim bottom of excavation to desired level.

located to ensure that they match the hollow cores A neat easy to clean detail involves tiling the The essential features are:

of the concrete block walls. top 150mm of pool walls between coping and

8. Drainage Non slip

Cut reinforcing bars to lengths required using bolt plaster finish.

a) Subgrade Drainage

cutters and form bends to minimum radius of six For best results apply paint finish over Adequate drainage from paved areas

To prevent the possibility of ground water pressure diameters. Lay concrete slab in one continuous plastered blockwork. Adequate fall away from pool edge 1:50 is

lifting the pool out of the ground when empty, lay operation without any construction joints. Compact

a 100mm perforated plastic pipe or equivalent system recommended.

concrete into position and screed with falls to main 17. Painting

round the perimeter of pool footing and one cross outlet. Finish surface with steel trowel. Main outlet

The masonry blockwork can be painted with chlorinated 20. Filtering

line under the deepest part of the pool linking the fitting must be properly bonded into concrete for

perimeter drain. rubber or 100% acrylic paint. Painting applied in An efficient filter is essential for proper pool

water tightness. Flood slab with water as soon as

accordance with the manufacturer’s specification. maintenance.

it has hardened. Keep slab wet for seven days for

Discharge the subgrade drainage system to an outfall Particular attention to the surface preparation of

full curing. Types available are:

or elsewhere but never the pool outlet drain. Ensure the blockwork or plaster finish is important because

adequate falls. Total underslab area should be covered defects such as blistering or peeling could occur.

10. Blockwork • Sand Filter

with a 100mm layer of free draining hardfill. If it is not

• D E Type Filter

possible to discharge the subgrade drainage system Blockwork is laid by building the corners first and 18. Plumbing

by gravity, fit a hydrostatic pressure release valve working towards the centre of the wall with each • Cartridge Filter

All pipe work and installation of plumbing systems

to floor. However, even where outfall is available a block levelled lengthwise and crosswise and aligned • Ozone Water Purification

to be in accordance with the NZ Building Code.

recommended safety measure would be to still fit a along a string. The first course of the blocks on the

footing are threaded around starter bars and laid in Filteration and water recirculation equipment shall

hydrostatic release valve. 19. Paving be of approved type and installed in accordance with

a full mortar bed, with only the face shell bedding for

All variety of materials for pool area paving is manufacturer’s instructions.

the upper courses.

available, such as:

3 Masonry Swimming Pools 4 Masonry Swimming Pools

21. Electrical The gate must open outwards and have a latching typical step detail

device not less than 1.2m above finished ground

All work shall be done by a registered electrician to

level. The gate must automatically shut with the latch

comply with the Electrical Regulations.

operating from a stationary start at a position of D16 Firth Bullnose capping

150mm from the closed position. 150sq glazed ceramic tiles

22. Fencing

Fencing around the pool is required by the Territorial Details

Authority and has to comply with the Fencing of

The drawings in this document have been developed

Swimming Pools Act. For full information contact

assuming the following limitations. Where the

your Territorial Authority. In brief, the fence must

operating conditions are outside these limitations seek

enclose the pool area. The fence must be at least

professional engineering advice.

1.2m high measured from the ground level outside 300 rise

of the fence. The distance between ground tread

• No surcharge exists around the pool edge

D12 L bars

level and the bottom of the fence must not at 400cs

exceed 100mm. • Maximum depth of the pool is 1.4m D10 nosing bar

Fences shall be built so to prevent climbing from • The pool is below ground D12

at 400cs

the outside. All horizontal fence members must • The pool will be predominantly full with water. If left Hardwall plaster finish

be on the inside of the fence and spaced 900mm or for long periods empty, there is a possibility that with selected paint finish over

more apart. Space between vertical paneling, boards, drying shrinkage could cause cracking.

2 D12 at 400cs

bars or other such material must not exceed 100mm

at any point. • The maximum length or width is 6.4m

D16 horizontal bar 400 lap

3 coats mulseal coating

ot similar waterproof coating

Marley Novaflow drain

laid below floor level

Excavated cut 100mm below foundation

D10 at 300 cs

wall to floor detail

T

typical plan layout

Bullnose paver on Mortar

6400 min. recommended length for swimming

45mm Firth capping Selected ceramic tile surround

Sand Bedding D16 top course in Firth 20.16

Firth paving around

open end bond beam blocks

pool provides non-slip

Selected paint over plaster finish Top eye ball jet surface and free

Free Drainage

4000 min. side for swimming

drainage

granular backfill

D12 vertical bars placed

in centre of core at 400 cs.

Top eye ball jet

3 coats mulseal

1.4m max Firth 20.16 and cut out side of

or similar coating Fall 1 in 50

2 D12 bars block at each vertical bar position

so that the base can be cleaned Bottom return jet

600 laps 200mm from bottom

D16 at 400 cs horizontally out before cores filled

in Firth 20.16 open end

bond beam blocks

400

Hydrostatic valve

Marley Novaflow drain 125 Top eye ball jet

and pool drain set

around perimeter 100 in depression

and below floor level 850 3

663 mesh in centre of slab Pool light positioned

Excavated cut in 1000 300 2

D12 at 300 cs to shine away from

original ground pool side sitting area Step 1

Position skimmer to face

prevailing wind

5 Masonry Swimming Pools 6 Masonry Swimming Pools

corner detail of steel reinforcing swimming pool planning module

Firth 20.15 corner bond beam Using block module draw outline of swimming pool showing position of steps, skimmer, lights, filter, jets

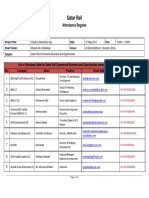

NAME

ADDRESS

D16 horizontal bar

to horizontal

at 400cs tied to

vertical bars

600 lap

bars D16 vertical bar

to corners

D12 at 400 cs placed in

centre of core

Firth 20.16 open end bond

beam blocks

400 block size Scale 1:50

7 Masonry Swimming Pools 8 Masonry Swimming Pools

SUSTAINABILITY : THE FIRTH CONCRETE & CONCRETE MASONRY SUSTAINABILITY LIFECYCLE

■

✔ Environmentally compliant manufacturing plants ■

✔ Most wash water returned from construction sites For more on Firth’s

■

✔ Surplus water and some aggregates recycled ■

✔ Highly durable, low maintenance buildings and no rot contribution to building a

■

✔ Low transport impacts ■

✔ High degree of noise control sustainable tomorrow

■

✔ Leftover concrete returned from construction sites ■

✔ Inherent fire resistance today, visit www.firth.co.nz

■

✔ Passive solar heated thermal mass makes completed buildings ■

✔ Overall longer effective building life or call us on 0800 347 841

more energy-efficient ■

✔ Demolished concrete can be recycled as hard fill or aggregate for our free brochure.

© Copyright Firth 2016

0800 FIRTH 1 (347 841)

www.firth.co.nz

Você também pode gostar

- DWN 1285227077 Design and Construction Process For Swimming PoolsDocumento39 páginasDWN 1285227077 Design and Construction Process For Swimming PoolsAli Syaputra100% (1)

- The Design, Construction, Operation and Maintenance of Public Swimming PoolsDocumento52 páginasThe Design, Construction, Operation and Maintenance of Public Swimming PoolsEdin UgarakAinda não há avaliações

- Construction and Specification Considerations For Swimming Pool PDFDocumento17 páginasConstruction and Specification Considerations For Swimming Pool PDFArshdeep KaurAinda não há avaliações

- 5 U 46Documento18 páginas5 U 46Edin UgarakAinda não há avaliações

- Federation Project Agreement: ConformedDocumento7 páginasFederation Project Agreement: ConformedEdin UgarakAinda não há avaliações

- Aes Ccstudy EidDocumento3 páginasAes Ccstudy EidEdin UgarakAinda não há avaliações

- Lecture Notes 2012 Dda2132 CHP 3a Deep Foundation PDFDocumento21 páginasLecture Notes 2012 Dda2132 CHP 3a Deep Foundation PDFJayachandra PelluruAinda não há avaliações

- EjetjtDocumento45 páginasEjetjtEdin UgarakAinda não há avaliações

- MATERIALS FBC Swimming Pools FinalDocumento138 páginasMATERIALS FBC Swimming Pools FinalGonzalo Gomez CastilloAinda não há avaliações

- Swimming Pool Construction GuideDocumento48 páginasSwimming Pool Construction GuideKeri Mason100% (3)

- The World Bank: Bosnia and Herzegovina Sarajevo Waste Water Project (P090675)Documento4 páginasThe World Bank: Bosnia and Herzegovina Sarajevo Waste Water Project (P090675)Edin UgarakAinda não há avaliações

- Project Name: Project Information Document (Pid) Appraisal StageDocumento7 páginasProject Name: Project Information Document (Pid) Appraisal StageEdin UgarakAinda não há avaliações

- Pool Design Guidelines Jan 2014 Final PDFDocumento64 páginasPool Design Guidelines Jan 2014 Final PDFEdin Ugarak100% (1)

- 115 K 12 HK 12 KDocumento9 páginas115 K 12 HK 12 KEdin UgarakAinda não há avaliações

- Humphreys PolymercompositesDocumento10 páginasHumphreys PolymercompositesroopeshdesaiAinda não há avaliações

- The World Bank: Sarajevo Waste Water Project (P090675)Documento6 páginasThe World Bank: Sarajevo Waste Water Project (P090675)Edin UgarakAinda não há avaliações

- SessionDocumento41 páginasSessionEdin Ugarak83% (6)

- Integrated Safeguards Datasheet Appraisal Stage I. Basic InformationDocumento6 páginasIntegrated Safeguards Datasheet Appraisal Stage I. Basic InformationEdin UgarakAinda não há avaliações

- The World Bank: Bosnia and Herzegovina Sarajevo Waste Water Project (P090675)Documento5 páginasThe World Bank: Bosnia and Herzegovina Sarajevo Waste Water Project (P090675)Edin UgarakAinda não há avaliações

- Annex 1-2Documento198 páginasAnnex 1-2Edin UgarakAinda não há avaliações

- Annex 1-2Documento198 páginasAnnex 1-2Edin UgarakAinda não há avaliações

- 25 June 2015Documento4 páginas25 June 2015Edin UgarakAinda não há avaliações

- Sheet1 Installation Progress TrackerDocumento2 páginasSheet1 Installation Progress TrackerEdin UgarakAinda não há avaliações

- Annex 1-2Documento198 páginasAnnex 1-2Edin UgarakAinda não há avaliações

- 05 OdsDocumento4 páginas05 OdsEdin UgarakAinda não há avaliações

- 05 OdsDocumento4 páginas05 OdsEdin UgarakAinda não há avaliações

- Inspection List 2.1 Installation of The Rails: Dome-Measurement Level RailsDocumento45 páginasInspection List 2.1 Installation of The Rails: Dome-Measurement Level RailsEdin UgarakAinda não há avaliações

- Inspection List 2.1 Installation of The Rails: Dome-Measurement Level RailsDocumento45 páginasInspection List 2.1 Installation of The Rails: Dome-Measurement Level RailsEdin UgarakAinda não há avaliações

- 05 OdsDocumento4 páginas05 OdsEdin UgarakAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Academic PortfolioDocumento23 páginasAcademic PortfolioAhmed Kadry OmarAinda não há avaliações

- Language & Identity: Engendering A Fifth Age in (West) African Architecture by Godson Egbo (2007)Documento5 páginasLanguage & Identity: Engendering A Fifth Age in (West) African Architecture by Godson Egbo (2007)Bukka_TrustAinda não há avaliações

- Organic Architecture Imre Makovecz Report of Cheen 3Documento23 páginasOrganic Architecture Imre Makovecz Report of Cheen 3Chin SingsonAinda não há avaliações

- BCA Fire Protection Guide PDFDocumento81 páginasBCA Fire Protection Guide PDFMaan LeungAinda não há avaliações

- Seville: My Seville in Two Days Packed ItineraryDocumento11 páginasSeville: My Seville in Two Days Packed ItinerarymirelafgAinda não há avaliações

- QQS Valuation No 8 - 22-08-2016Documento16 páginasQQS Valuation No 8 - 22-08-2016Francois EhlersAinda não há avaliações

- Pagal, J. As#2 MW AmDocumento14 páginasPagal, J. As#2 MW AmJayson PagalAinda não há avaliações

- Dosti Realty Quality Management SystemDocumento129 páginasDosti Realty Quality Management Systemsanjay vidhateAinda não há avaliações

- Andhra Pradesh Buildings Schedule of Rates 2017-18Documento291 páginasAndhra Pradesh Buildings Schedule of Rates 2017-18Jagadeesh PondugalaAinda não há avaliações

- Irc Special PublicationsDocumento8 páginasIrc Special PublicationsP KAinda não há avaliações

- Studio-Vi Installation of Upvc Window/DoorDocumento6 páginasStudio-Vi Installation of Upvc Window/DoorMananshAinda não há avaliações

- Cold Weather ConcreteDocumento3 páginasCold Weather ConcreteKwang Sun100% (1)

- Miami Beach Art Deco District - Preservation and Development Plan - Early 1980sDocumento78 páginasMiami Beach Art Deco District - Preservation and Development Plan - Early 1980sMiami Design Preservation LeagueAinda não há avaliações

- Requirements of A Good PartitionDocumento11 páginasRequirements of A Good PartitionShraddha Bahirat100% (1)

- 08.4 Building Utilities Mechanical Systems 11 10 2021Documento5 páginas08.4 Building Utilities Mechanical Systems 11 10 2021Divina Luiza FantonialAinda não há avaliações

- IN436706 - IFFCO Palm Jumeirah Villa - Inspection Dec 13, 2018Documento6 páginasIN436706 - IFFCO Palm Jumeirah Villa - Inspection Dec 13, 2018PatrichAinda não há avaliações

- Building Construction 1 - 5 - Floors Vaults PDFDocumento33 páginasBuilding Construction 1 - 5 - Floors Vaults PDFDamjanAinda não há avaliações

- Ilovepdf MergedDocumento62 páginasIlovepdf MergedYcen Santiago0% (1)

- TrenchSystem ConcastWebCatalogDocumento26 páginasTrenchSystem ConcastWebCataloggemotorresAinda não há avaliações

- Finishing Works Method Statement For Building ConstructionDocumento14 páginasFinishing Works Method Statement For Building ConstructionElxao XanAinda não há avaliações

- Project 120 Chicago and Yoko Ono - Construction Release - FINALDocumento5 páginasProject 120 Chicago and Yoko Ono - Construction Release - FINALCrainsChicagoBusinessAinda não há avaliações

- Hydraulic Cement Uses and Types GuideDocumento25 páginasHydraulic Cement Uses and Types GuideKristan JayAinda não há avaliações

- Generic Design TASDocumento14 páginasGeneric Design TASAbinash100% (1)

- Tekla Structural Designer 2023 Us Codes ReferenceDocumento264 páginasTekla Structural Designer 2023 Us Codes ReferenceKevin James BenitezAinda não há avaliações

- Death and ArchitectureDocumento3 páginasDeath and ArchitectureAhins UpretiAinda não há avaliações

- 2393.502 - Proposed Ground and First Floor PlansDocumento1 página2393.502 - Proposed Ground and First Floor PlansDanny NguyenAinda não há avaliações

- CAST STONE TRADITIONAL RANGEDocumento28 páginasCAST STONE TRADITIONAL RANGEMalisa StefanovicAinda não há avaliações

- Construction Log BookDocumento27 páginasConstruction Log BookdominicnicolasbaltazarAinda não há avaliações

- Analysis and Design of Prestressed Concrete Box Girder BridgeDocumento25 páginasAnalysis and Design of Prestressed Concrete Box Girder BridgeChitharanjan VishnukripalAinda não há avaliações

- 18-II.8 Protection of Tower FootingDocumento4 páginas18-II.8 Protection of Tower Footingashok10577Ainda não há avaliações