Escolar Documentos

Profissional Documentos

Cultura Documentos

Rivets and Joints

Enviado por

mahfuzul_haqueDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Rivets and Joints

Enviado por

mahfuzul_haqueDireitos autorais:

Formatos disponíveis

ILLUSTRATIVE PROBLEMS 59

ILLUSTRATIVE PROBLEMS.

3-1. Figure 3-6 shows a simple structural connection composed of two steel

straps held together by two bolts 1 in. in diameter. The upper strap is 3/s in. thick,

and the lower strap is '/2 in. thick. Both straps are 3 in. wide. Calculate the max-

imum unit stresses in shear, bearing, and tension caused by a pull P of 15,000 Ib.

Fig. 3-6 Bolted connection.

Solution: In each case we must calculate the size of the area resisting the pull.

By dividing this area into the pull P, we obtain the average unit stress.

5/iear. The bolt is in single shear. Hence, A, = 2(0.7854) = 1.57 in.2 and

15,000

9550 psi A/?s.

1.57

Bearing. The upper strap bears against the right side of each bolt, and the area

in bearing is presumed to be the bolt diameter times the thickness of the strap.

That area is (2)(1X0.375) = 0.75 in.2. The lower strap bears against the left side of

each bolt, and that bearing area is (2)(1)(0.5) = 1.0 in.2. Clearly, since each strap

is subjected to a pull of 15,000 Ib. the maximum stress will be exerted.on the small-

est of these two areas and is

15.000

= 20,000 psi A/is.

[—3 0.75

Tension. When either rivets or unfinished bolts are used in structural joints, the

hole is considered to be of'/» in. larger diameter than the rivet or bolt. The max-

imum tensile stress will be found in the upper strap, where the net resisting area is

smaller than in the lower strap. This area is (3.0 - 1.1251(0.375) = 0.703 in.-.

Hence

[—2 15.000

0.703

= 21.300 psi

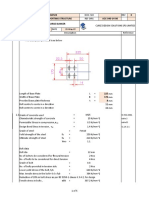

3-2. An ASTM A36 steel beam. W 21 x 62. is connected to a steel column.

Anx.

W 14 x 99. with 3/4-in.-diameter rivets, as illustrated in Fig. 3-7. All connecting

angles are 3/» in. thick. Calculate the allowable load R that may safely be trans-

mitted from the beam to the column through the bearing-type connection.

60 RIVETED AND WELDED JOINTS. THIN-WALLED PRESSURE VESSELS

/•Column ^Beam^

flange* i iJl

*"""

i

0(

5/i fe o< )O

ff/7^fes ex >o

(X "^ * 5JO;

1

\ —^ ex >0

H.O, o< (•O

n jMl ••_

1.4 r4»- -

0 11 0

0 0

I 1 - Fig. 3-7 Beam-to-column connection.

Solution: In order to determine the allowable load on this connection, we must

first find the allowable load on one rivet in shear, single or double, and in bearing.

In this connection, however, there are two groups of rivets which must be consid-

ered separately: group A of five rivets through the web of the beam and group B of

four rivets which connect the seat angle to the column flange. The two rivets fas-

tening the beam flange to the seat angle do not resist any vertical load and must be

disregarded.

From Table E-4 we find that the web of the W 21 x 62 beam is 0.40 in. thick.

The side angles are 3/« in. (0.375 in.) thick. The rivets through the beam web are in

double shear, in bearing against 0.40-in. web and two 3/»-in. angles.

Allowable load on one J/«-in. rivetjn group A (through beam web):

' V .'

In double shear (I7.5)(2)(0.442) = 15.47 kips

In bearing on 0.40-in. plate (43.5)(0.4)f—j = 13.05 kips «- Governs

In bearing on (2)(0.375^= 0.75 in. = 24.47 kips

• "*"' f, -

In group.5, the four rivets are in single shear, in bearing against one -Vs-in. angle

and also in bearing against the 3 /4in.-thick column flange.

Allowable load on one 3/4-in. rivet in group B (through seat angle):

In single shear (17.5X0.442) = 7.774 kips «- Governs

In bearing on f-in. angles. 43.5f -jrj (-T-J = 12.23 kips

In bearing on ?-in. flange = 24.47 kips

The total allowable load on the connection then is

Allowable load on 5 group A rivets = (5X13.05) = 65.25 kips

Allowable load on 4 group B rivets = (4)(7.74) = 30.96 kips

Total allowable load R on connection = 96.21 kips Ans.

Você também pode gostar

- Social Psychology Key TermsDocumento1 páginaSocial Psychology Key Termsmahfuzul_haqueAinda não há avaliações

- 612 Chapter 9 Static-Force Analysis: T RXFDocumento1 página612 Chapter 9 Static-Force Analysis: T RXFmahfuzul_haqueAinda não há avaliações

- Mining Company Sorted Share ProfileDocumento1 páginaMining Company Sorted Share Profilemahfuzul_haqueAinda não há avaliações

- Truss AnalysisDocumento12 páginasTruss Analysismahfuzul_haqueAinda não há avaliações

- Eutectic Metal Simulation AnalysisDocumento16 páginasEutectic Metal Simulation Analysismahfuzul_haqueAinda não há avaliações

- Steel Stat 2014Documento1 páginaSteel Stat 2014mahfuzul_haqueAinda não há avaliações

- Lexmark User Guide PDFDocumento182 páginasLexmark User Guide PDFmahfuzul_haqueAinda não há avaliações

- Triangular BCC Structural Analysis-Static 1-1Documento15 páginasTriangular BCC Structural Analysis-Static 1-1mahfuzul_haqueAinda não há avaliações

- Eggplant Cooking RecipeDocumento1 páginaEggplant Cooking Recipemahfuzul_haqueAinda não há avaliações

- Thursday, October 18, 2018 - Progress Campus Bridge - 1 PM - 4 PMDocumento1 páginaThursday, October 18, 2018 - Progress Campus Bridge - 1 PM - 4 PMmahfuzul_haqueAinda não há avaliações

- GD&T ExamDocumento15 páginasGD&T Exammahfuzul_haqueAinda não há avaliações

- Exercise Two Beam Machine Design-Static 1-1Documento9 páginasExercise Two Beam Machine Design-Static 1-1mahfuzul_haqueAinda não há avaliações

- Simulation of Eutectic Metal AlloyDocumento12 páginasSimulation of Eutectic Metal Alloymahfuzul_haqueAinda não há avaliações

- Basic Beam Static 2 1Documento16 páginasBasic Beam Static 2 1mahfuzul_haqueAinda não há avaliações

- Solid 3D-Static 1-1Documento12 páginasSolid 3D-Static 1-1mahfuzul_haqueAinda não há avaliações

- Exercise2 A Pin Joint and A Roller Support-Static 1-1Documento15 páginasExercise2 A Pin Joint and A Roller Support-Static 1-1mahfuzul_haqueAinda não há avaliações

- Exercise2 A Pin Joint and A Roller Support-Static 1-1Documento15 páginasExercise2 A Pin Joint and A Roller Support-Static 1-1mahfuzul_haqueAinda não há avaliações

- 3 D Truss Exercise 6.18-Static 3-1 Right ResultDocumento17 páginas3 D Truss Exercise 6.18-Static 3-1 Right Resultmahfuzul_haqueAinda não há avaliações

- Problem 6.31 Truss-Static 1-1reportDocumento18 páginasProblem 6.31 Truss-Static 1-1reportmahfuzul_haqueAinda não há avaliações

- 3 D Truss Exercise 6.18-Static 3-1 Right ResultDocumento16 páginas3 D Truss Exercise 6.18-Static 3-1 Right Resultmahfuzul_haqueAinda não há avaliações

- Truss Problem 10Documento12 páginasTruss Problem 10mahfuzul_haqueAinda não há avaliações

- Basic Beam Analysis Example2Documento11 páginasBasic Beam Analysis Example2mahfuzul_haqueAinda não há avaliações

- Truss Problem 10Documento12 páginasTruss Problem 10mahfuzul_haqueAinda não há avaliações

- Truss Problem 6.1 Johnston and Beer Book-Static 1-1Documento15 páginasTruss Problem 6.1 Johnston and Beer Book-Static 1-1mahfuzul_haqueAinda não há avaliações

- Truss Problem 10Documento15 páginasTruss Problem 10mahfuzul_haqueAinda não há avaliações

- Machine Design-Static 1-1Documento13 páginasMachine Design-Static 1-1mahfuzul_haqueAinda não há avaliações

- Exercise2 A Pin Joint and A Roller Support-Static 1-1Documento15 páginasExercise2 A Pin Joint and A Roller Support-Static 1-1mahfuzul_haqueAinda não há avaliações

- Truss AnalysisDocumento14 páginasTruss Analysismahfuzul_haque100% (1)

- 3 D Truss Exercise 6.18-Static 3-1 Right ResultDocumento16 páginas3 D Truss Exercise 6.18-Static 3-1 Right Resultmahfuzul_haqueAinda não há avaliações

- Truss Problem 6.1 Johnston and Beer Book-Static 1-1Documento15 páginasTruss Problem 6.1 Johnston and Beer Book-Static 1-1mahfuzul_haqueAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- ME Elective 1 Engine Friction LubricationDocumento7 páginasME Elective 1 Engine Friction LubricationrickyAinda não há avaliações

- External FrictionDocumento2 páginasExternal FrictionRo AnAinda não há avaliações

- Atena TheoryDocumento330 páginasAtena Theorypassion777Ainda não há avaliações

- Rules of MixtureDocumento33 páginasRules of Mixtureperlan1234100% (1)

- Calculation For IPE200Documento10 páginasCalculation For IPE200HaymanAHMEDAinda não há avaliações

- Ansys ManualDocumento31 páginasAnsys Manualpriyadharshini natarajanAinda não há avaliações

- Simple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Documento5 páginasSimple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Bißék ŚílwàlAinda não há avaliações

- Young's Modulus of Strut Materials (39Documento6 páginasYoung's Modulus of Strut Materials (39Newton ShikderAinda não há avaliações

- Connection Surge Bin Supp Beam1Documento5 páginasConnection Surge Bin Supp Beam1Venkatesh HebbarAinda não há avaliações

- Peng2019 PDFDocumento7 páginasPeng2019 PDFRoja AllampallyAinda não há avaliações

- Mechanics of Deformable Bodies Final ExamDocumento4 páginasMechanics of Deformable Bodies Final ExamMichael Mendez OfficialAinda não há avaliações

- Beams Reinforced For TensionDocumento13 páginasBeams Reinforced For TensionChristian ActerAinda não há avaliações

- Seismic Design of BridgesDocumento20 páginasSeismic Design of BridgesIon PusculitaAinda não há avaliações

- Material Hardness Conversion TableDocumento3 páginasMaterial Hardness Conversion TableJessicalba LouAinda não há avaliações

- ANSYS Mechanical APDL Feature ArchiveDocumento490 páginasANSYS Mechanical APDL Feature ArchiveNicolás Reyes GonzálezAinda não há avaliações

- Guidelines For Nonlinear Analysis of Bridge StructuresDocumento4 páginasGuidelines For Nonlinear Analysis of Bridge StructuresMichael HiiAinda não há avaliações

- Seismic Design of Timber StructuresDocumento60 páginasSeismic Design of Timber StructuresSairam Venkat100% (1)

- Crack Width Calculation for ColumnDocumento3 páginasCrack Width Calculation for ColumnNadira PervinAinda não há avaliações

- Chapter 3. Failure of MaterialsDocumento20 páginasChapter 3. Failure of MaterialsVishal ShuklaAinda não há avaliações

- Perhitungan Volume Semen Untuk PaperDocumento3 páginasPerhitungan Volume Semen Untuk PaperSkolastikaPradiptaAinda não há avaliações

- D6364 PDFDocumento5 páginasD6364 PDFIndira BanerjeeAinda não há avaliações

- Behnam Et Al-2017-The Structural Design of Tall and Special BuildingsDocumento17 páginasBehnam Et Al-2017-The Structural Design of Tall and Special BuildingsKepian Hussein DraboAinda não há avaliações

- Plasticity Measurement of Clays and Ceramic BodiesDocumento3 páginasPlasticity Measurement of Clays and Ceramic BodiesHector RamírezAinda não há avaliações

- Theoretical Calculation of Strain Hardening ExponentDocumento4 páginasTheoretical Calculation of Strain Hardening ExponentRavi TejaAinda não há avaliações

- Geosynthetic Encased ColumnDocumento10 páginasGeosynthetic Encased Columnakdce01Ainda não há avaliações

- Assignment 2 2021Documento3 páginasAssignment 2 2021jonAinda não há avaliações

- Civil Engineering 2016 - Set-2-Watermark - pdf-72 PDFDocumento7 páginasCivil Engineering 2016 - Set-2-Watermark - pdf-72 PDFSkull CrusherAinda não há avaliações

- Web Bearing and Buckling Resistance of Steel BeamsDocumento10 páginasWeb Bearing and Buckling Resistance of Steel BeamsChris FindlayAinda não há avaliações

- Precast Beam Bridge Example AASHTODocumento347 páginasPrecast Beam Bridge Example AASHTOAhmed NurulAinda não há avaliações