Escolar Documentos

Profissional Documentos

Cultura Documentos

Wsc2015 Tp10 PV TW Symbols Iso e Pre

Enviado por

Cristyan ReisTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Wsc2015 Tp10 PV TW Symbols Iso e Pre

Enviado por

Cristyan ReisDireitos autorais:

Formatos disponíveis

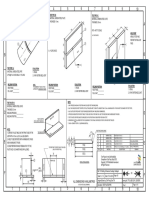

1 2 3 4 5 6

141 136 141 136

135

135 111 135

141

111 A

A

111

135 136

141

136

135 136 135

135

136 135

136

135 136 136

B 135

B

136 111

136

111

Welding Processes:

SMAW--111

GMAW--135

C FCAW--136 C

GTAW--141 136

135

135

135

Test Project for the 43rd WorldSkills

Competition in Sao Paulo, Brazil, 2015.

Copyright◎ 2015 Worldskills International

INSTRUCTIONS TO COMPETITORS All Rights Reserved.

D

D 1. TACK WELDS ARE TO BE MADE IN ANY POSITIONS USING ANY PROCESSES LISTED ON THE DRAWING. Skill: 10. Welding, Schweissen, Soudage

2. ALL TACK WELDS ARE TO BE MADE NOT LONGER THAN 15 mm AND MUST BE MADE ONLY ON THE OUTSIDE OF THE VESSEL. OR

3. ALL FILLET WELDS TO HAVE A LEG SIZE OF 10 mm WITH TOLERANCE (+2.0 mm/-0.0 mm). Scale: N. T. S Date: 14. June. 2013 Paper: A3

4. GRINDING WILL BE ALLOWED TO BE CARRIED OUT ONLY FOR TACK WELD, START/STOP AND INTERLAYER PASSES.OF THE WELDS.

Drawn/Designed by: Chih-Peng Chen TW Drawing No:WSC2015_TP10_TW_PV_SYMBOLS_ISO E

5. FINAL CLEANING MAY BE CARRIED OUT BY USING WIRE BRUSH.

Description: Pressure Vessel-Symbols Rev: Page:

Appd: Sign:

1 2 3 4 5 6

Você também pode gostar

- Oceans ViolãoDocumento3 páginasOceans ViolãoCristyan ReisAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- AnunciaçãoDocumento1 páginaAnunciaçãoCristyan ReisAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Oceanos OceansDocumento6 páginasOceanos OceansCristyan ReisAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Oceans AcoustDocumento3 páginasOceans AcoustCristyan ReisAinda não há avaliações

- Wsc2015 Tp10 Ss Us Isoe PreDocumento1 páginaWsc2015 Tp10 Ss Us Isoe PreCristyan ReisAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Wsc2015 Tp10 PV TW Symbols Iso A PreDocumento1 páginaWsc2015 Tp10 PV TW Symbols Iso A PreCristyan ReisAinda não há avaliações

- Wsc2015 Tp10 Ss Us Isoa PreDocumento1 páginaWsc2015 Tp10 Ss Us Isoa PreCristyan ReisAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Wsc2015 Tp10 TP Iso A Rev PreDocumento1 páginaWsc2015 Tp10 TP Iso A Rev PreCristyan ReisAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Wsc2015 Tp10 PV TW Assembly Iso A PreDocumento1 páginaWsc2015 Tp10 PV TW Assembly Iso A PreCristyan ReisAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Wsc2015 Tp10 PV TW Partslist Iso A PreDocumento1 páginaWsc2015 Tp10 PV TW Partslist Iso A PreCristyan ReisAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Wsc2015 Tp10 PV TW Assembly Iso e PreDocumento1 páginaWsc2015 Tp10 PV TW Assembly Iso e PreCristyan ReisAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Wsc2015 Tp10 Al TW Iso e PreDocumento1 páginaWsc2015 Tp10 Al TW Iso e PreCristyan ReisAinda não há avaliações

- Wsc2015 Tp10 Al TW Iso A PreDocumento1 páginaWsc2015 Tp10 Al TW Iso A PreCristyan ReisAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- Catalog Ore Tent or ADocumento24 páginasCatalog Ore Tent or ACristyan ReisAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- PQR Procedure Qualification Record Krishna SteelDocumento2 páginasPQR Procedure Qualification Record Krishna SteelHarshit Adwani100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- How Do I Set Up My TIG Welder?: Owner's ManualDocumento2 páginasHow Do I Set Up My TIG Welder?: Owner's ManualenricoAinda não há avaliações

- Welding Procedure For BOXNR Wagon (WPS)Documento8 páginasWelding Procedure For BOXNR Wagon (WPS)Shekher NikhilAinda não há avaliações

- List of Welding Procedures.: Client: Emirates Aluminium Company Limited. Gmmos Job #: 801-4690Documento6 páginasList of Welding Procedures.: Client: Emirates Aluminium Company Limited. Gmmos Job #: 801-4690ravi00098Ainda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Qualification of Welding Procedure Specification FCDocumento14 páginasQualification of Welding Procedure Specification FCmister pogi100% (4)

- Böhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Documento1 páginaBöhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Thanh TamAinda não há avaliações

- WIS5 - HandoutDocumento319 páginasWIS5 - HandoutReza FakhrizalAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Megaflo He Installation ManualDocumento36 páginasMegaflo He Installation ManualnicehornetAinda não há avaliações

- API 577 QuestionsDocumento14 páginasAPI 577 QuestionsabdoAinda não há avaliações

- Welding McqsDocumento3 páginasWelding McqsSaqib AshfaqAinda não há avaliações

- Gas Metal Arc WeldingDocumento16 páginasGas Metal Arc WeldingIhsan1991 YusoffAinda não há avaliações

- Filler Metal Selection Guide: Cronacast-211 Ni-Rod-55Documento9 páginasFiller Metal Selection Guide: Cronacast-211 Ni-Rod-55Vijaya BaraniAinda não há avaliações

- Tesda Multiple ChoiceDocumento8 páginasTesda Multiple ChoiceAira Ronquillo67% (3)

- Manual Overlay WeldingDocumento8 páginasManual Overlay Weldingcarlmac6183% (6)

- Aws B2.1-001 PDFDocumento10 páginasAws B2.1-001 PDFAli SASSIAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Redis Construction Afrika welding history reportDocumento4 páginasRedis Construction Afrika welding history reportengsam777Ainda não há avaliações

- Data Film IIWDocumento2 páginasData Film IIWelektromekanik 2014Ainda não há avaliações

- DAILY PIPELINE PROGRESS REPORTDocumento1 páginaDAILY PIPELINE PROGRESS REPORTheri_prasetyadiAinda não há avaliações

- Technical Manual Goodman MBR PDFDocumento27 páginasTechnical Manual Goodman MBR PDFElenilson SampaioAinda não há avaliações

- Fakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaDocumento5 páginasFakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaHairul Effendy Ab MaulodAinda não há avaliações

- Miller - Joint Design and Weld TypeDocumento8 páginasMiller - Joint Design and Weld Typed_beachboyzAinda não há avaliações

- Automation Catalogue EngDocumento100 páginasAutomation Catalogue EngYan FerizalAinda não há avaliações

- Tig WeldingDocumento12 páginasTig WeldingSridhar ChowdaryAinda não há avaliações

- Electric Boosting IIDocumento7 páginasElectric Boosting IICarlos Cabezón LozaAinda não há avaliações

- Welding PracticeDocumento6 páginasWelding PracticeOscar RodriguezAinda não há avaliações

- FG - ReCooler HP Generation 5 - Installation and Maintenance - Installation-Maintenance - UNDocumento24 páginasFG - ReCooler HP Generation 5 - Installation and Maintenance - Installation-Maintenance - UNIanosi SorinAinda não há avaliações

- 3L Filters CompleteDocumento66 páginas3L Filters CompleteHugo Ruiz100% (1)

- Electric Boiler BrochureDocumento4 páginasElectric Boiler BrochuredeztruktorAinda não há avaliações

- Api 577 Q 114Documento31 páginasApi 577 Q 114Mohammed YoussefAinda não há avaliações

- FCU Celling Daikin CatalogueDocumento20 páginasFCU Celling Daikin CatalogueTuyen NguyenAinda não há avaliações