Escolar Documentos

Profissional Documentos

Cultura Documentos

Bridge-Ch-5-Example On Slab Bridge EDITEDFINAL

Enviado por

kassahun kebedeTítulo original

Direitos autorais

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Bridge-Ch-5-Example On Slab Bridge EDITEDFINAL

Enviado por

kassahun kebedeDireitos autorais:

Design Of RC Superstructure A.

Y 2017

Example on Design of Slab Bridge

Design Data and Specifications

Superstructure consists of 10m slab, 36m box girder and 10m T-girder all simply supported.

Only the design of Slab Bridge will be used for illustration.

Roadway Grade = 1660.00 m, amsl (above mean sea level)

HWM = 1643.56 - Roadway grade dictates elevation of

superstructure and not minimum free board requirement.

I. Slab II. T-Girder III.Box-Girder

Clear span = 10m Clear span 10m Clear span = 36m

Road way width = 7.32m Road way width = 7.32m Road way width = 7.32m

Curb width = 0.8m Curb width = 0.80m Curb width = 0.80m

-Materials

Concrete: Class ‘A’ concrete: Cylinder strength f c’ = 28MPa [A5.4.2.1]

[A5.4.2.4]

Steel: fy = 400MPa

Es = 200GPa

Design method is Load and Resistance Factor Design (LRDF)

Reference: AASHTO LRFD Bridge Design Specifications, SI units, 2nd Edition, 2005.

Slab Bridge Design

WU dep’t of Civil Engineering Page 1

Design Of RC Superstructure A.Y 2017

1.Depth Determination [A2.5.2.6.3]

Minimum recommended depth for slabs with main reinforcement parallel to traffic is

Where S is the span, S=c/c of supports ≤ clear span + d, S=10+0.4/2+0.43/2=10.415m

Use D = 540 mm,

d= 540- F/2-25 = 499mm S=10.415m≤Clear span + d = 10000 + 499 = 10.499m Ok!

2. Live Load Strip Width [Art.4.6.2.3]

a) Interior Strip

i) One lane loaded: multiple presence factor included [C.4.6.2.3]

L1 is smaller of 10415 or 18000. W1 is the smaller of 8920 or 9000

L1 = 10415 W1 = 8920

ii) Multiple lanes loaded

W=Actual edge to edge width = 8920mm

NL = Int(clear roadway width/3600)

Use E=3256.63mm

Equivalent concentrated and distributed loads

Truck: P1’=35/3.2566=10.75; P2’ = 145/3.2566 = 44.52

Tandem: P3’=110/3.2566 = 33.78

Lane: w’ = 9.3/3.2566 = 2.856

b) Edge Strip Longitudinal edge strip width for a line of wheels [Art.4.6.2.1.4]

E= distance from edge to face of barrier + 300+1/4* interior strip width

E= 800 + 300+3256.63/4 = 1914.08mm > 1800mm

Use E=1800 mm

WU dep’t of Civil Engineering Page 2

Design Of RC Superstructure A.Y 2017

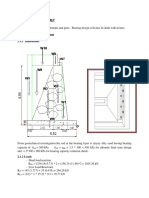

3. Influence Lines for Shear Force and Bending Moment

Slab bridges shall be designed for all vehicular live loads specified in AASHTO

Art 3.6.1.2, including the lane load [Art.3.6.1.3.3].

Influence Lines for Shear Force at "x" distance from end support

Influence Lines for Bending Moment at "x" distance from end

support

WU dep’t of Civil Engineering Page 3

Design Of RC Superstructure A.Y 2017

a) Inter Strip

i) Maximum Shear Force

This governs

Impact factor = 1+IM/100 = 1+33/100 = 1.33, not applied to lane load [Art.3.6.2.1]

VLL+IM=1.33*72.52+14.87 = 111.32

ii) Maximum bending Moment

Truck: MTr = 44.52(0.703+2.553) + 10.75(0.103) = 146.06 kNm

Tandom: MTa = 33.78(2.304*2) =155.66 kNm this →governs

Lane: MLn = 2.856*(1/2)*2.604*10.415 =38.73kNm

MLL+Im = 1.33*155.66+38.73 = 245.76kNm

b) Edge Strip

Because E= 1800mm, one lane loaded with a multiple presence factor of 1.2 will be

critical

4. Select resistance factor, φ [Art. 5.5.4.2.1]

WU dep’t of Civil Engineering Page 4

Design Of RC Superstructure A.Y 2017

Strength Limit States (RC) φ

Flexure & Tension 0.90

Shear & Torsion 0.90

Axial Compression 0.75

Bearing On concrete 0.70

Compression in strut and tie model 0.70

5. Select Load Modifiers, η1

Strength service fatigue

i) Ductility η0 0.95 1.0 1.0 [Art. 1.3.3]

ii) Redundancy ηR 1.05 1.0 1.0 [Art. 1.3.4]

iii) Importance ηI 1.05 1.0 1.0 [Art. 1.3.5]

η0 = ηR = ηI = 1.0

6. Select Applicable Load Combinations [Table 3.4.1-1]

Strength I U=η (1.25DC + 1.50DW + 1.75(LL+1M)+1.0FR+γTG TG

Service I U=1.0(DC+DW) +1.0(LL+IM) + 0.3(WS+WL+1.0FR

Fatigue U=0.75*(LL+IM)

7. Dead Load Force Effects

a) Interior Strip:- Consider a 1m Strip, ρcon=2400 kg/m3 [Table 3.5.1-1]

-3 3 2

WDC= (2400*9.81)* 10 kN/m * 0.54 m = 12.71kN/m

WDW = (2250*9.81)* 10-3 kN/m3 * 0.075m = 1.66kN/m2

75mm bituminous wearing surface, ρbit = 2250kg/m3 [Table 3.5.1-1]

VDC = ½ * 12.71*10.415 = 66.21kN/m VDW = ½ * 1.66*10.415 = 8.64kN/m

b) Edge Strip:

WU dep’t of Civil Engineering Page 5

Design Of RC Superstructure A.Y 2017

VDC = ½* 16.06*10.415 = 83.63kN/m

8. Investigate Service Limit State

i) Durability: Cover for main reinforcement steel for [Art. 5.12]

deck surface subjected to tire wear = 60mm

bottom of cast in-place slab = 25 mm

ηD = ηR = ηI = 1.0 η = 1.0

a) Moment –Interior Strip

M=1.0(172.34 + 22.51 + 245.76) = 440.61 kNm

Reinforcement:

Assume j=0.875 and fs = 0.6 fy = 0.6*400 = 240

b) Moment – Edge strip:

M=1.0(217.76 + 0 + 533.56) = 751.32kNm

ii) Control of Cracking [Art.5.7.3.4]

Components shall be so proportioned that the tensile stress in the mild steel

Reinforcement at the service limit state, fs, does not exceed fsa

Z – crack width parameter (N/mm) = 23000N/mm for severe exposure

WU dep’t of Civil Engineering Page 6

Design Of RC Superstructure A.Y 2017

dc depth of concrete measured from extreme tension fiber to center of bar located closest

there to. Clear cover used to compute dc≤50mm.

a) Interior strip

190 <394.6 Okay!

b) Edge Strip

140<418.98 Okay

A- Area of concrete having the same controid as the principal tensile reinforcement

and bounded by the surfaces of the cross-section and a line parallel to the neutral axis

divided by the number of bars (mm2), clear cover here also ≤ 50mm

The concrete is considered cracked if tensile stress in concrete ≥ 80% of the modulus of

rupture, [Art. 5.7.3.4&5.4.2.6

a) Interior Strip – check concrete tensile stress against 0.8fr

Mint = 440.61kNm/m

Now, steel stress should be calculated for elastic cracked section. The moment of inertia

of the composite transformed section should be used for the stress calculation

N=7, nAsprove = 7*4232.88 = 29630.16mm2 Equivalent concrete area

WU dep’t of Civil Engineering Page 7

Design Of RC Superstructure A.Y 2017

Determine x from ½*1000*x2 = 29630.16(499-x) x=144.87mm

Now Icr = 1/3*1000*144.873 + 29630.1(499-144.86)2 = 4.729*109 mm4/m.

Steel stress over n, fs/n = M(d-x)/Icr =(440.61*106*354.13)/(4.729*109) = 32.99MPa

fs=7*32.99=230.93MPa≤0.6fy

Now, fsa can be computed:

fs = 230.93≤fsa = 240Mpa OK!

b) Edge Strip

Medge = 751.32KNm/m

½*750*X2 = 7*4882.93(749-x) x = 219.655mm<250mm Curb height

WU dep’t of Civil Engineering Page 8

Design Of RC Superstructure A.Y 2017

Icr = 1/3*750*(219.655)3 + 7*4882.93(749-219.655)2 = 12.227*109mm4

fs/n = M(d-x)/Icr = 751.32x106*(749-219.655)/12.227x109) = 32.53Mpa

fs = 7*32.53Mpa=227.71Mpa

fs<fsa Ok!

iii) Deformations

Deflection and camber calculations shall consider dead load, live load, erection loads,

concrete creep and shrinkage.

[Art. 5.7.3.6.2]

Immediate (instantaneous) deflections may be computed taking the moment of inertia as

either the effective moment of inertia, Ie or the gross moment of inertia, Ig

The long-term deformation (due to creep and shrinkage) may be taken as the immediate

deflection multiplied by the following factor

3.0-1.2(A’s/AS)≥1.6 if immediate deflection is calculated using Ie.

if immediate deflection is calculated using Ig.

a) Dead Load Camber:

Total dead load of the bridge and the whole bridge cross-section is considered

WDC = 12.71*8.62+(2.53+0.59+0.23)*1.8*2=121.62KN/m

WDW=1.66*7.32

Ma – actual maximum moment (Nmm)

fr – modulus of rupture

yt – distance from N.A to extreme tension fiber (mm)

WU dep’t of Civil Engineering Page 9

Design Of RC Superstructure A.Y 2017

fr = 0.63 = 0.63 = 3.33Mpa,

Location of N.A,

Since the section does not crack under DL, Ig should be used

Chamber 4*4.53=18.12mm upward

b) Live Load Deflection (Optional) [Art.2.5.2.6.2]

Use design truck alone or design lane plus 25% of truck load. [Art. 3.6.1.3.2]

When design truck is used alone, it should be placed so that the distance between its resultant

and the nearest wheels is bisected by span centerline. All design lanes should be loaded.

MDC+DW+LL+IM = 1813.79+1.33*146.06*3.2566*2*1.0 = 3079.04KNm>Mcr

Multiple presence factor

Design Truck Load

First load, P=385.7KN,a=8.78,b=1.635m,X=4.48m

WU dep’t of Civil Engineering Page 10

Design Of RC Superstructure A.Y 2017

Second load, P=385.7,a = x = 4.48m, b = 5.935m

Third load, P=93.1kKN,a=10.235,b=0.18m,X=5.935

(ΔLL+IM)1=1.75+3.83+0.003=5.583<<13mm Ok!

Design Lane Load +25% of design Truck Load:

W=9.3*2*1=18.6kN/m

ΔLL+IM=1.33+1.48+2.79mm<<13.02mm Ok!

Tandem Load

Single concentrated tandem load at mid-span (spaced at zero meter)

P=1.33*220*2*1 = 585.2KN

With average Ie over the entire span used instead of Ie at section of maximum moment as

done here, smaller deflection would result. The contribution of compression steel is also

neglected. For these reasons, live load deflections are made optional in AASHTO.

9. Investigate Fatigue Limit State.

U=0.75(LL+IM), IM=15%

Fatigue load shall be one design truck with 9m axle spacing.

Maximum moment results when the two from axles are on the span and the rear axle is out of

span.

a) Tensile Live Load stress:

One lane loaded E=4298.2mm

WU dep’t of Civil Engineering Page 11

Design Of RC Superstructure A.Y 2017

fs max = 7*5.58 = 39.05 Mpa

b) Reinforcing Bars:

The stress range in straight reinforcement bars resulting from fatigue load

combination shall not exceed.

ff=145-0.33fmin+55(r/h)

ff-is stress range fmin-minimum LL stress, where there is stress reversal=0 for our case

r/h=0.3

ff=145-0.33(0)+55(0.3)=161.5Mpa

fmax<ff Ok!

40.66<161.5 ok!

10. Investigate Strength Limit State

i) Flexure: Equivalent Rectangular stress Distribution [Art. 5.7.2.2.2]

a) Interior strip

Mu=ηΣγiQI=1.05[1.25MDC + 1.5MDW + 1.75MLL +IM+γTGMTG]

For simple span bridges, temperature gradient effect reduces gravity load effects.

Because temperature gradient may not always be there, assume γTG=0

Mu=1.05 [1.25(172.34) + 1.5(22.51) + 1.75(245.76)] = 713.23kNm/m

Mu = φAsfyd(1-0.588 ρfy/f’c)

D=540-32/2-25 = 499mm

Ρ = 0.0086 >ρmin = 0.03*f’c/fy = 0.03*28/400=0.0021

As = 0.0086*1000*499=4291.4mm2

Use

b) Edge Strip

Mu=ηΣγiQI=1.05[1.25(217.76) +0+ 1.75(533.56)+0) = 1266.22KN/m

WU dep’t of Civil Engineering Page 12

Design Of RC Superstructure A.Y 2017

D=540 + 250 – 32/2-25 = 749mm

ρ=0.00904>ρmin

As =ρbd = 0.0086*750*749=5082.19mm2

ii) Shear

Slab bridges designed in conformance with AASHO, Art 4.6.2.3 may be considered

satisfactory for shear. Art. 4.6.2.3deals with approximate method of analysis of slab bridges

using equivalent strip method.

But if longitudinal tubes are placed in the slab as in pre stressed concrete, and create voids

and reduce the cross section, the shear resistance must be checked.

iii) Distribution Reinforcement: The amount of bottom transverse reinforcement may be

taken as a percentage of the main reinforcement required for positive moment as

a) Interior strip:

Transverse reinforcement = 0.175*4347.34mm2 = 745.6mm2

b) Edge strip:

Transverse reinforcement = 0.1715 * 5063.8 mm2 = 868.44mm2

WU dep’t of Civil Engineering Page 13

Design Of RC Superstructure A.Y 2017

iv) Shrinkage& Temperature Reinforcement: Reinforcement for shrinkage &

temperature stresses shall be provided near surfaces of concrete exposed to

daily temperature changes. The steel shall be distributed equally on both sides

a) Interior Strip:

m, transverse.

2.1 LIMIT STATES

GENERAL

Bridges shall be designed for specified limit states to achieve the objectives of

constructability, safety, and serviceability, with due regard to issues of inspectibility,

economy, and aesthetics, as specified in Chapters 3 – 11.

Regardless of the type of analysis used, Equation 2.1 shall be satisfied for all specified force

effects and combinations thereof. Equation 2.1 below is the basis of the LRFD methodology.

Each component and connection shall satisfy Equation 2.1 for each limit state, unless

otherwise specified. For service and extreme event limit states, resistance factors shall be

taken as 1.0, except for bolts, for which the provisions of Chapter 8: Bridge Details apply.

All limit states shall be considered of equal importance.

i i Qi Rn = Rf (2.1)

Where:

i = D R I 0.95 (2.2)

for loads for which a minimum value of i is appropriate:

i = 1 1.0 (2.3)

D R I

WU dep’t of Civil Engineering Page 14

Design Of RC Superstructure A.Y 2017

Where: i = load modifier: a factor relating to ductility, redundancy, and operational

importance

i = load factor: a statistically based multiplier applied to force effects

Qi = force effect

= resistance factor: a statistically based multiplier applied to nominal resistance

(see chapters 5,6,7 8, 10 and 12).

Rn = nominal resistance

D = a factor relating to ductility, as specified below

R = a factor relating to redundancy as specified below

I = a factor relating to operational importance as specified below

Rf = factored resistance: Rn

Ductility, redundancy, and operational importance are significant aspects affecting the margin

of safety of bridges. Whereas the first two directly relate to physical strength, the last

concerns the consequences of the bridge being out of service. The grouping of these aspects

on the load side of Equation 2.1 is, therefore, arbitrary. However, it constitutes a first effort at

codification. In the absence of more precise information, each effect, except that for fatigue

and fracture, is estimated as ±5 percent, accumulated geometrically, a clearly subjective

approach. With time, improved quantification of ductility, redundancy, and operational

importance, and their interaction and system synergy, shall be attained, possibly leading to a

rearrangement of Equation 2.1, in which these effects may appear on either side of the

equation or on both sides.

WU dep’t of Civil Engineering Page 15

Você também pode gostar

- Design of Box CulvertDocumento17 páginasDesign of Box CulvertSanket Diwate100% (12)

- Retaining Wall Design To ProkonDocumento6 páginasRetaining Wall Design To ProkonIMJ JAinda não há avaliações

- 3 M H Stone Masonry Retaining Wall Design Sheet - ModifiedDocumento9 páginas3 M H Stone Masonry Retaining Wall Design Sheet - ModifiedEngr Amir Jamal QureshiAinda não há avaliações

- Abutment Design Example PDFDocumento17 páginasAbutment Design Example PDFEng Venance Masanja100% (1)

- Design of Girder Type BridgeDocumento21 páginasDesign of Girder Type Bridgekartick sanati100% (1)

- Construction Schedule With S-CurveDocumento23 páginasConstruction Schedule With S-CurveJp Gallardo100% (2)

- Gravity Retaining Wall - VakapalliDocumento10 páginasGravity Retaining Wall - VakapalliD.V.Srinivasa RaoAinda não há avaliações

- 25m Single Lane Bridge Design Calculations Latest PDFDocumento16 páginas25m Single Lane Bridge Design Calculations Latest PDFshafiullahAinda não há avaliações

- Culvert and Bridge Material.Documento221 páginasCulvert and Bridge Material.Godana Tadicha100% (1)

- Suggested Procedure For Earthquake AnalysisDocumento4 páginasSuggested Procedure For Earthquake AnalysisThomas John Doblas AgrabioAinda não há avaliações

- CAPES Sample ResumeDocumento1 páginaCAPES Sample ResumesprokonoinoiAinda não há avaliações

- Gravity Retaining Wall - VakapalliDocumento6 páginasGravity Retaining Wall - VakapalliD.V.Srinivasa RaoAinda não há avaliações

- Design of Deck SlabDocumento5 páginasDesign of Deck Slabjignesh shahAinda não há avaliações

- Rebar ArrangmentDocumento116 páginasRebar ArrangmentJesusBlasVitangcol100% (2)

- Single Lane BridgesDocumento55 páginasSingle Lane Bridgeshsword7Ainda não há avaliações

- 06 SP05Documento192 páginas06 SP05erosAinda não há avaliações

- Instrument Signal LineDocumento62 páginasInstrument Signal Linedewking198875% (4)

- Counterfort Retaing Wall of 6 M Height Design & CostDocumento20 páginasCounterfort Retaing Wall of 6 M Height Design & CostDavid CruzaleguiAinda não há avaliações

- Slab Bridge Design ExampleDocumento16 páginasSlab Bridge Design ExampleShita Alemie100% (6)

- CH-3 Pile FoundationsDocumento85 páginasCH-3 Pile FoundationsDejene Ambese100% (1)

- Bridge CH 5 Example On Slab BridgeDocumento16 páginasBridge CH 5 Example On Slab BridgeHabhaile Asfaw83% (6)

- Design of Slab BridgeDocumento20 páginasDesign of Slab BridgeAshish Karki82% (11)

- Design of Cantilever Retaining WallDocumento2 páginasDesign of Cantilever Retaining WallRamilArtatesAinda não há avaliações

- Design of Bridge StructuresDocumento220 páginasDesign of Bridge StructuresVimalSharma100% (7)

- Bridge Engineering Final Examination PaperDocumento3 páginasBridge Engineering Final Examination PaperKaushal KumarAinda não há avaliações

- Abutment DesignDocumento112 páginasAbutment Designmasudulamin14Ainda não há avaliações

- Example - Slab Bridge PDFDocumento7 páginasExample - Slab Bridge PDFRefisa Jiru100% (4)

- Solid Slab Bridges: Advantages, Disadvantages and PrinciplesDocumento10 páginasSolid Slab Bridges: Advantages, Disadvantages and PrinciplesAmbrishAinda não há avaliações

- Dead Load Calculation For RCC T-Girder DeckDocumento3 páginasDead Load Calculation For RCC T-Girder Deckvasu7900100% (1)

- Bridge DesignDocumento129 páginasBridge DesignDaniel KariukiAinda não há avaliações

- 1 - Slab Bridge Final April23 - 2014Documento11 páginas1 - Slab Bridge Final April23 - 2014teweldeAinda não há avaliações

- Computation of Dead LoadsDocumento10 páginasComputation of Dead LoadsSyrille Reyes75% (4)

- Design of BridgesDocumento64 páginasDesign of BridgesSukhwinder Singh Gill89% (9)

- Chapter 3 Inelastic Redistribution of MomentsDocumento6 páginasChapter 3 Inelastic Redistribution of MomentsMesfin DerbewAinda não há avaliações

- Design of A Slab Bridge On Abeya River A PDFDocumento13 páginasDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- Bridge Design BS 5400Documento4 páginasBridge Design BS 5400aldeto71100% (1)

- RC Solid Slab Bridge DesignDocumento34 páginasRC Solid Slab Bridge DesignChhour CEAinda não há avaliações

- Deck Design - Slab Bridge Jan 11 - 2017Documento11 páginasDeck Design - Slab Bridge Jan 11 - 2017eph100% (1)

- BOX Culvert Load DetailsDocumento7 páginasBOX Culvert Load Detailsragalwar100% (1)

- Design of Deck SlabDocumento8 páginasDesign of Deck SlabHussein AlkafajiAinda não há avaliações

- SLRB Deck Slab DesignDocumento8 páginasSLRB Deck Slab Designpaaji100% (1)

- Design of T Beam BridgeDocumento32 páginasDesign of T Beam BridgeAshish ShresthaAinda não há avaliações

- Design of PierDocumento11 páginasDesign of PierNaveen Yadav100% (6)

- Analysis of Deck Slab and Tee Beam of A BridgeDocumento59 páginasAnalysis of Deck Slab and Tee Beam of A Bridgenidhisasidharan100% (2)

- Bridge Design Report - Docx 150Documento17 páginasBridge Design Report - Docx 150nephembaniAinda não há avaliações

- Tech Spec Flow OrificeDocumento63 páginasTech Spec Flow OrificeSHIVAJI CHOUDHURY100% (1)

- T Girder Bridge Deck Diaphragm-20 MDocumento14 páginasT Girder Bridge Deck Diaphragm-20 MAmitabha DebAinda não há avaliações

- 4 Masonry Abutment DesignDocumento4 páginas4 Masonry Abutment DesignAlemie Shita100% (1)

- Materials: Slab Bridge DesignDocumento13 páginasMaterials: Slab Bridge DesignephremAinda não há avaliações

- RC Slab Bridge DecksDocumento24 páginasRC Slab Bridge DecksKeyur Patel100% (1)

- Design of Super StructureDocumento30 páginasDesign of Super StructureHemraj Raj100% (16)

- Detail Design of Bridges and StructuresDocumento61 páginasDetail Design of Bridges and StructuresEyoel Ashagre33% (3)

- Planning and Preliminary Design of BridgeDocumento22 páginasPlanning and Preliminary Design of BridgeBCE 2074 B Teacher0% (1)

- Prestress 2Documento14 páginasPrestress 2princesaleemAinda não há avaliações

- DESIGN AqueductDocumento37 páginasDESIGN AqueductGarg Tj71% (7)

- Design of Bridges Using Limit State by IRC-112 CodeDocumento45 páginasDesign of Bridges Using Limit State by IRC-112 CodeTIRTH100% (1)

- Bridge Design - Reinforced Concrete Bridge Deck Design To BS 5400Documento11 páginasBridge Design - Reinforced Concrete Bridge Deck Design To BS 5400Lavanyan Satchithananthan100% (1)

- Slab Girder BridgeDocumento42 páginasSlab Girder BridgeAslam Saifi100% (2)

- Pont Dalle en Béton Armé (Solid Slab Bridge) I. Hypothèse StructureDocumento5 páginasPont Dalle en Béton Armé (Solid Slab Bridge) I. Hypothèse Structureken koemhongAinda não há avaliações

- Solid Slab Bridge PDFDocumento20 páginasSolid Slab Bridge PDFMen Keo RathaAinda não há avaliações

- Design Example RC Slab PDFDocumento19 páginasDesign Example RC Slab PDFnabinniraulaAinda não há avaliações

- Design of Slab BridgesDocumento6 páginasDesign of Slab BridgesAwadh E. AjeelAinda não há avaliações

- Analysis of Bridge 18 M Span ReportDocumento2 páginasAnalysis of Bridge 18 M Span Reportashishphadke1972Ainda não há avaliações

- Design and Detailing of Approach SlabsDocumento1 páginaDesign and Detailing of Approach SlabsIsaac Mureithi MainaAinda não há avaliações

- Design of Reinforced Slab & Deck Girder Bridge-AASHTODocumento39 páginasDesign of Reinforced Slab & Deck Girder Bridge-AASHTOWaqas AnjumAinda não há avaliações

- Bahirdar University Bahirdar Institute of Technology Faculty of Civil and Water Resources Engineering Structural Design Mini ProjectDocumento18 páginasBahirdar University Bahirdar Institute of Technology Faculty of Civil and Water Resources Engineering Structural Design Mini ProjectYONAS GOSAAinda não há avaliações

- Bridge Design Chapter 1Documento19 páginasBridge Design Chapter 1Eng-Mohamed Ahmed AbdiAinda não há avaliações

- Insights Into Sustainable EngineeringDocumento24 páginasInsights Into Sustainable Engineeringcmanning17Ainda não há avaliações

- LGS Dry Partition - Mr. MuraokaDocumento5 páginasLGS Dry Partition - Mr. Muraokanaam9Ainda não há avaliações

- Mohd Razswan Bin Rus: Contact InfoDocumento4 páginasMohd Razswan Bin Rus: Contact InfoPelajar NIK MUHAMAD NOR SYAZANIS BIN NIK SYARMANAinda não há avaliações

- Vendor Document Requirement List: Mechanical 17Documento64 páginasVendor Document Requirement List: Mechanical 17Yonsi OyonAinda não há avaliações

- Hydro Culv 21Documento10 páginasHydro Culv 21rungekutasaAinda não há avaliações

- Mechanical Systems and Vehicle EngineeringDocumento8 páginasMechanical Systems and Vehicle EngineeringGeleta BekeleAinda não há avaliações

- Es 200 Easy - Pintu Geser OtomatisDocumento8 páginasEs 200 Easy - Pintu Geser OtomatisLivian TeddyAinda não há avaliações

- Engr0400 ResumeDocumento2 páginasEngr0400 Resumeapi-456443818Ainda não há avaliações

- Facade Renewal of Generalštab BuildingDocumento26 páginasFacade Renewal of Generalštab BuildingEmilija NikolicAinda não há avaliações

- Implementation of Lean Construction Techniques For Minimizing The Risks Effect On Construction ProjectDocumento49 páginasImplementation of Lean Construction Techniques For Minimizing The Risks Effect On Construction ProjectJohn PaulAinda não há avaliações

- Case Studies of EPPDocumento6 páginasCase Studies of EPPPrajwol ShresthaAinda não há avaliações

- MTechCE MadrasDocumento64 páginasMTechCE MadrasMd Zeeshaan100% (1)

- IS 16172 2014 Coupler Splice BarDocumento16 páginasIS 16172 2014 Coupler Splice BarMayank KumarAinda não há avaliações

- Level of Service AssessmentDocumento29 páginasLevel of Service AssessmentAngel NaldoAinda não há avaliações

- BIMDocumento8 páginasBIMMuhd ZulFadliAinda não há avaliações

- DN400Documento32 páginasDN400ersivarajAinda não há avaliações

- Optimizing A Beverage Can Production Line by MaterDocumento7 páginasOptimizing A Beverage Can Production Line by MaterAnonymous jSNHYv0UdAinda não há avaliações

- SOE Chartered Engineer Application FormDocumento16 páginasSOE Chartered Engineer Application FormRaymond Man PTMEAinda não há avaliações

- BSPP - Training MaterialsDocumento410 páginasBSPP - Training MaterialsMegadeth ShawonAinda não há avaliações

- Curriculum Vitae Osama Mohammed ElmardiDocumento8 páginasCurriculum Vitae Osama Mohammed ElmardifrancischanwathAinda não há avaliações

- Multi Choice Tech 1 AnswerDocumento20 páginasMulti Choice Tech 1 AnswerquyennqAinda não há avaliações

- Oc CDC Ref Guide WebDocumento32 páginasOc CDC Ref Guide WebDimitar YovchevAinda não há avaliações