Escolar Documentos

Profissional Documentos

Cultura Documentos

What Is Incandescent Light Bulb

Enviado por

Cloudine IzonTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

What Is Incandescent Light Bulb

Enviado por

Cloudine IzonDireitos autorais:

Formatos disponíveis

What is Incandescent Light Bulb?

An incandescent light bulb, incandescent lamp or incandescent light globe is an electric

light with a wire filament heated to such a high temperature that it glows with visible light

(incandescence). The filament is protected from oxidation with a glass or fused quartz bulb that is

filled with inert gas or a vacuum. In a halogen lamp, filament evaporation is slowed by a chemical

process that redeposit metal vapor onto the filament, thereby extending its life.

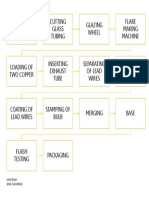

The light bulb factory has two production lines that eventually merge. One prepares for glass

bulb, the others makes what’s called the mount the electrical compounds go inside it.

CUTTING GLASS TUBING

At a start of the mount lines the machine cuts glass tubing into pieces of specific lengths. The cut

tubes lands on what’s glazing wheel.

GLAZING WHEEL

Runs them through a gas flame for about seven seconds. This heats the glass enough to smooth the

surface.

FLARE MAKING MACHINE

The glazed tubes now enter what’s called flare making machine. Which heats each tube until the

glass is malleable. Then stretches one end into a flare shape.

LOADING OF WIRE

The next machine loads two copper lead wires into the flare end.

INSERTING EXHAUST TUBE

Then it insert a thin glass cylinder called the exhaust tube.

A trip through series of progressively hotter flames softens the tube. A press the moves in to squash

them, encasing the wires in glass. At the same time, the machine makes tiny hole in the glass in-

between the wires. This is to later remove air from inside the ball. It’ll exits the exhaust tube

through this hole.

SEPARATING OF LEAD WIRES

Next, the machine separates the lead wire and forms the end into hooks. This fasten to the filament,

a thin wire called made of tungsten a type of metal that holds up well to heat.

COATING OF LEAD WIRES

The machine coats the lead wires in a liquid form of another metal, zirconium. This lengthens their

life span by making them more resistant to moisture inside the ball.

The bulbs are made of inexpensive type of glass called soda-lime glass.

STAMPING OF BULB

A machine stamps the top of each bulb with the voltage, wattage and company logo.

Opaque light bulbs are simple clear bulbs with an inside coating of synthetic silicon, a white

powder. The coating machine charges the bulbs to 30,000 volts combined with just the right

amount of heat, this electrical charge makes a thin layer of powder cling to the glass.

A series of flames evaporates moisture and bakes off impurities.

MERGING

As the two production lines merge, a bulb goes over each mount. Torches then fuse the flared end

of the mount to the neck of the bulb. Arms move in and mold the neck to fit inside the bulbs

aluminium base.

The next machine vacuums out all the air in the bulb and replaces it with pressurized argon gas.

This inert gas will resist heat build up, helping the filament last longer.

After bending the lead wires out of the way torches meld and seal off the glass exhaust tube locking

the argon gas inside.

The bulb would now be fully functional if connected to an electric current.

BASE

Needs a base in order to screw into socket of a light fixture. The base is made of aluminium.

FLASH TESTING

Repeated light ups using a higher voltage each time. This strengthens the filaments inside, making

it less likely to break during shipping.

Você também pode gostar

- Light BulbDocumento1 páginaLight BulbCloudine IzonAinda não há avaliações

- Background: The Duct Tape BookDocumento5 páginasBackground: The Duct Tape BookCloudine IzonAinda não há avaliações

- INTRODUCTIONDocumento1 páginaINTRODUCTIONCloudine IzonAinda não há avaliações

- INTRODUCTIONDocumento1 páginaINTRODUCTIONCloudine IzonAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- ASTM E 2611-17 Standard Test Method For Normal Incidence Determination of Porous MaterialDocumento14 páginasASTM E 2611-17 Standard Test Method For Normal Incidence Determination of Porous Materialcvazquez999100% (1)

- The Greatest Medical Discoveries of The MillenniumDocumento10 páginasThe Greatest Medical Discoveries of The MillenniumKatie JusayAinda não há avaliações

- 09 Vacuum MeasurementDocumento44 páginas09 Vacuum MeasurementRamakrisnna GunasegaranAinda não há avaliações

- In Situ Electromagnetic (Eddy Current) Examination of Nonmagnetic Heat Exchanger TubesDocumento5 páginasIn Situ Electromagnetic (Eddy Current) Examination of Nonmagnetic Heat Exchanger Tubesruben carcamoAinda não há avaliações

- Controllable Pitch PropellersDocumento2 páginasControllable Pitch PropellersAnkit DedhiyaAinda não há avaliações

- Assembly Manual: 18 Watt Tube Guitar Amp KitDocumento71 páginasAssembly Manual: 18 Watt Tube Guitar Amp Kitandrea772Ainda não há avaliações

- QCS Section 22Documento12 páginasQCS Section 22hvacsriniAinda não há avaliações

- g3 Air System AbaDocumento15 páginasg3 Air System Aba08088338Ainda não há avaliações

- Cathode Ray TubeDocumento12 páginasCathode Ray Tubeashley_rodrigues_20Ainda não há avaliações

- HiSpeed DXi Operator ManualDocumento254 páginasHiSpeed DXi Operator Manualnery castro100% (1)

- 3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Documento2 páginas3 Gardner Denver Compressor Bulletin 13-9-209 - 2nd - 9-03Sebastian SalazarAinda não há avaliações

- Copley TPK 2007Documento15 páginasCopley TPK 2007MatthewAinda não há avaliações

- BMW CODES Bavarian ToolDocumento29 páginasBMW CODES Bavarian ToolOctavio Maciel100% (1)

- Akira 14hs9n 3y01Documento15 páginasAkira 14hs9n 3y01Su BarkahAinda não há avaliações

- BRG200R - OPERATOR MANUAL - 74098521N - EnglishDocumento82 páginasBRG200R - OPERATOR MANUAL - 74098521N - EnglishSvilen PopovAinda não há avaliações

- Ed Gray Motor Generator Under Free Energy Circuits - 6229Documento1 páginaEd Gray Motor Generator Under Free Energy Circuits - 6229scribdsanduAinda não há avaliações

- PMT Tpmz0001eDocumento138 páginasPMT Tpmz0001eamit281276Ainda não há avaliações

- Introducing The PyrazoDocumento13 páginasIntroducing The PyrazoVuk DrobnjakAinda não há avaliações

- Illuminating Seals, Square Design: Subject To Change - 2018/07Documento3 páginasIlluminating Seals, Square Design: Subject To Change - 2018/07Vikk SuriyaAinda não há avaliações

- FWC Air Cooled Exchanger PDFDocumento49 páginasFWC Air Cooled Exchanger PDFdinakaranpatelAinda não há avaliações

- Variable Vol Fundamentals PDFDocumento11 páginasVariable Vol Fundamentals PDFSharon LambertAinda não há avaliações

- Electronic SwitchesDocumento28 páginasElectronic Switchesgame masterAinda não há avaliações

- 2-And 3-Way Cartridge Closed Loop Control Valve Type .WRCE... /SDocumento24 páginas2-And 3-Way Cartridge Closed Loop Control Valve Type .WRCE... /SPatrick ByronAinda não há avaliações

- TL Audio Classic Series 479645Documento14 páginasTL Audio Classic Series 479645Nicolas ZuluagaAinda não há avaliações

- UT Level II QuestionsDocumento28 páginasUT Level II QuestionsMahade Hasan Dipu100% (6)

- Vacuum TubeDocumento25 páginasVacuum TubeGilberto ManhattanAinda não há avaliações

- Steve MARKS Toroidal Power Unit: Interview With Haok Durban (Marks' Assooiate) (Part 1)Documento93 páginasSteve MARKS Toroidal Power Unit: Interview With Haok Durban (Marks' Assooiate) (Part 1)Nikol DenisAinda não há avaliações

- Boiler InterviewDocumento16 páginasBoiler InterviewSachin PatelAinda não há avaliações

- Service Manual Viasonix PletismógrafoDocumento33 páginasService Manual Viasonix PletismógrafodhcastanoAinda não há avaliações

- HAN-L5 2S 058V2-WiringDocumento1 páginaHAN-L5 2S 058V2-WiringonealAinda não há avaliações