Escolar Documentos

Profissional Documentos

Cultura Documentos

LRAD 1000RX - Interface Protocol Rev G

Enviado por

ngdnamDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

LRAD 1000RX - Interface Protocol Rev G

Enviado por

ngdnamDireitos autorais:

Formatos disponíveis

REVISIONS

REV By DESCRIPTION SUMMARY OF CHANGES Date

G Lopez ENHANCEMENT ADDED MAXABEAM PROTOCOL 11/3/2010

NOTICE

This document contains proprietary and confidential information of LRAD CORPORATION, INC.

Use of this information is restricted to purposes of interest to LRAD CORPORATION, INC. The

information contained herein is to be neither copied nor disclosed to others, in whole or part,

without the prior written consent of LRAD CORPORATION, INC.

15378 Avenue of Science, San Diego, CA, 92128

Software and Communications Interface Control

Document – LRAD 1000RX

DOC. # 105328-00 REV

G

SHEET 1 of 23

Contents

1.0 Scope ...................................................................................................................................................3

2.0 General Description ............................................................................................................................3

3.0 System Description .............................................................................................................................3

3.1 PTSS Controller ..............................................................................................................................4

3.2 Axis Video Server ...........................................................................................................................4

3.3 Barix Audio Server ..........................................................................................................................4

3.4 LRAD Amps ....................................................................................................................................5

3.5 Lantronix Serial Server....................................................................................................................5

4.0 Communications Protocols .................................................................................................................5

4.1 PTSS Controller ..............................................................................................................................5

4.1.1 General Command Structure: ...................................................................................................5

4.1.3 Integers .....................................................................................................................................6

4.1.4 Control Characters ...................................................................................................................6

4.1.5 Error Codes ..............................................................................................................................6

4.1.7 Coordinate System ...................................................................................................................6

4.1.8 Commands and Responses .......................................................................................................7

4.2 LRAD Serial Attenuation Module (SAM) Protocol ......................................................................14

4.2.1 General Command Structure ..................................................................................................14

4.2.2 Control Characters .................................................................................................................15

4.2.3 Escape Character ....................................................................................................................15

4.2.4 List of Commands ..................................................................................................................15

4.2.5 Get ID Request Response Data Structure Definition .............................................................16

4.2.6 Status Response Sequence Structure ......................................................................................16

4.2.7 Definition of STATUSBITS ..................................................................................................17

4.2.8 LRC Checksum Calculation ...................................................................................................17

4.2.10 Communications Sequence Diagram .....................................................................................18

4.3 Camera Controls ............................................................................................................................18

4.4 Axis Video Streaming ...................................................................................................................19

4.5 Audio Streaming to the Barix ........................................................................................................19

5.0 Programming Notes ..........................................................................................................................19

6.0 Maxabeam Protocol ..........................................................................................................................20

7.0 Appendices ........................................................................................................................................23

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 2 of 23

San

1.0 Scope

This document describes the network architecture of the devices in the LRAD 1000-RX as well as the control

protocols for each of the devices in the system. The intended audience is and LRAD system integrator.

2.0 General Description

LRAD 1000-RX is an Acoustic Hailing Device integrated with a mechanical actuation system that allows for the unit

to be aimed and operated via a TCP/IP network connection. The unit consists of various hardware devices which

perform unique functions of the AHD. These hardware devices are connected on a network that is internal to the

LRAD 1000-RX unit.

3.0 System Description

The following photograph identifies the main elements of the LRAD 1000-RX unit.

Camera

Housing Axis Video

Server

Ethernet 6

Amplifier

Pack

Ethernet 2 Barix Audio

Server

Lantronix

Serial Server

Network

Base Switch

Electronics

Module

Ethernet 1

Moxa

Computer

Network

Router

Figure 1: LRAD 1000-RX Main Elements

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 3 of 23

San

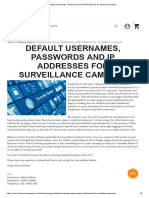

All of the elements of the LRAD 1000-RX are accessed through a single IP connection to the Pan/Tilt Unit

Electronics Module. This connection goes to a full featured hardware router which is set up to manage the network

connections to the devices in the LRAD. All of the devices on the LRAD‟s internal network can be accessed through

the LRAD‟s single external IP address as shown in the following network diagram:

Camera Housing Amplifier Pack

Axis Video Server. Lantronix Serial Server. Barix Audio Server.

Username: root Username: root Username: (none)

Password: atc Password: (no password) Password: (no password)

IP Address: 172.25.25.61 IP Address: 172.25.25.63 IP Address: 172.25.25.62

Subnet Mask: 255.255.255.0 Subnet Mask: 255.255.255.0 Subnet Mask: 255.255.255.0

Default Gateway: 172.25.25.1 Default Gateway: 172.25.25.1 Default Gateway: 172.25.25.1

Web Server Port: 80 DNS Server: 0.0.0.0 DNS Server: 0.0.0.0

RS-232 Serial Port: 4000 Web port: 80 Web Port: 80

Video Stream Port: 554 Com 1 Port (volume control): 100001 UDP Streaming Listen Port: 3030

Com 1 baud rate: 19200 RTP Receive Port: 4040

Com 2 Port (Maxabeam): 100002 Audio Stream Control Port: 12302

Com 2 baud rate: 9600

Ethernet 5

Ethernet 6 Ethernet 4

Network Switch

Ethernet 2

Base Electronics Module

Moxa Pan/Tilt Control Computer. Network Router.

Username: root Username: root

Password: atc Password: atc

IP Address: 172.25.25.60 IP Address: 192.168.1.140

Subnet Mask: 255.255.255.0 Subnet Mask: 255.255.255.0

Default Gateway: 172.25.25.1 Ethernet 3 Default Gateway: 192.168.1.1 Ethernet 1

DNS Server: 0.0.0.0 DNS Server: 0.0.0.0

Web Port: 80 Moxa Telnet Port: 21

Telnet Port: 21 Moxa FTP Port: 23

FTP Port: 23 Axis Web Server Port: 8061

Pan/Tilt Command Port: 10010 Axis Video Stream Port: 554 Laptop IP Address: 192.168.1.xxx

Axis RS-232 Port (camera): 4000 xxx is an available network address.

Barix Web Server Port: 8062

Barix RTP Port: 4040

Barix UDP Port: 3030

Barix Streaming Control: 12302

Lantronix Web Server Port: 8063

Lantronix COM1 (volume) Port: 10001

Lantronix COM2 (Maxa) Port: 10002

Figure 2: LRAD 1000-RX Network Architecture

The IP address of the PTSS Controller is fixed, therefore, the control PC‟s TCP/IP address must be set to the same

subnet as the PTSS controller in order to connect.

3.1 PTSS Controller

This device serves as the LRAD‟s network router and also runs the application that controls the Pan and Tilt

positioning system. All motion control, position feedback and pan/tilt system monitoring is performed by this

unit using it‟s unique protocol. This device is housed in the Pan/Tilt unit electronics module at the base of

the pan and tilt (see photo above).

3.2 Axis Video Server

This device converts the analog video from the integrated camera and streams the video across the IP

network in MJPEG or MPEG-4 format. This device contains an onboard serial port which is used to control

the camera functions, such as zoom, focus, etc. This device is housed in the IP camera enclosure.

3.3 Barix Audio Server

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 4 of 23

San

This device decodes a streamed digital audio file and sends the analog audio to the LRAD amplifiers for

playback through the LRAD unit. It is housed in the Head Unit Electronics Module.

3.4 LRAD Amps

The LRAD amplifiers boost the signal level of the audio that is streamed to the unit. They contain the Serial

Attenuation Module (SAM) which is used to set the volume level of the AHD as well as to monitor the health

of the amplifiers. The SAM is driven by one of the serial ports on the Lantronix Serial Server.

3.5 Lantronix Serial Server

The Lantronix Serial Server provides two serial ports that can be accessed via the network connection. Port

10001 is connected to the LRAD amplifiers and sends the serial communications commands used to

control and monitor the amplifiers. Port 10002 can be used to connect an optional accessory, such as a

Maxabeam Illuminator.

4.0 Communications Protocols

The LRAD 1000-RX contains various devices that can be controlled using each device‟s unique protocol. Control of

a device in an LRAD is achieved by reading and writing each device‟s protocols through the appropriate internet

socket connection. The programmer/integrator must set up these socket connections in their application to match

the IP addresses and ports for each LRAD unit. Each of the serial ports in the LRAD used to communicate with RS-

232 based devices, is also set up as an internet socket to which the serial data is written to and read from.

Hardware settings for the serial ports such as bit rate, flow control, etc. are preset at the factory and should not need

to be changed. For information on setting port hardware settings, consult the user manuals for the Lantronix and

Axis devices in the appendix.

4.1 PTSS Controller

The PTSS Controller performs all functions related to the mechanical positioning of the LRAD 1000-RX.

This device controls the motor drivers for the pan (azimuth) and tilt (elevation) axes and monitors the unit‟s

current position. These commands are read/written to the socket connection at port 10100 on the PTSS

controller‟s IP address.

4.1.1 General Command Structure:

Commands from the host to the pan and tilt shall be structured as follows:

1. Start of message character byte [SOM]

2. Message length byte [MSL]

3. Command number byte [CMD]

4. Command data (variable)

5. End of message character byte [EOM]

Valid commands or queries shall be responded to by the pan and tilt with the following structure:

1. Acknowledge byte [ACK]

2. Message length byte [MSL]

3. Command number byte [CMD]

4. Command data (variable)

5. End of message character byte [EOM]

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 5 of 23

San

NOTE: The host application must wait for a response from the PTSS controller before issuing another

command. The response times will vary depending on the command issued and on the state of the PTSS

controller.

Invalid commands or queries shall be responded to by the pan and tilt with the following structure:

1. Not acknowledge byte [NAK]

2. Message length byte [MSL]

3. Command number byte [CMD]

4. Error code byte [ERR]

5. End of message character byte [EOM]

With proper implementation of this protocol, NAKs should not appear during normal operation, however, the

host application should recognize a NAK and respond appropriately (i.e., retries, user notification, etc.).

4.1.2 Message Length [MSL]

The MSL byte denotes the length of the message starting with the command byte [CMD] and ending with

the [EOM] byte.

4.1.3 Integers

Integers are 1, 2, or 4 bytes in length, big-endian, two‟s complement signed integers, depending on the

allowable range for each variable. All multiple byte variables are big-endian ordered.

4.1.4 Control Characters

02h Start of Message [SOM]

03h End of Message [EOM]

06h Acknowledge [ACK]

15h Not Acknowledge [NAK]

4.1.5 Error Codes

70h Corrupted data packet

71h Invalid command

72h Invalid command data

73h Invalid position

74h Unit busy/move in progress

75h Soft limit

76h Hard limit

77h Hardware error

78h Other

4.1.6 Connection Timeout

The PTSS controller will automatically close the socket connection if a “Get Position and Move Status” (40h)

command is not received by the PTSS controller over a ten second period. The client application must

issue this command to the pan/tilt at least once every ten seconds in order to maintain the socket

connection. If the socket connection is closed due to this time out, the client application can re-open the

socket connection and continue operation.

4.1.7 Coordinate System

Positioning of the LRAD 1000-RX is achieved by rotating the hailing device through it‟s vertical and

horizontal axes. The vertical axis is referred to as the pan axis and has an allowable range of +/-210

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 6 of 23

San

degrees. The LRAD rotates right and left around this axis. The horizontal axis is referred to as the tilt axis

and has an allowable range of +/-95 degrees. The LRAD rotates up and down around this axis.

The LRAD 1000-RX can operate using two coordinate systems: Machine Absolute Coordinates and User

Offset Coordinates.

Machine Absolute Coordinates are constant for each LRAD. The Machine Zero position in the pan axis is

where the Acoustic Array is centered between the pan axis hard stops. The positive direction in the pan

axis would be in the direction that would move the field of view of the integrated camera to the right. The

Machine Zero position in the tilt axis is where the Acoustic Array is centered between the tilt axis hard stops.

The positive direction in the tilt axis would be in the direction that would move the field of view of the

integrated camera up.

The user has the ability to create a User Offset coordinate system that would reset the units zero

coordinates to a new position upto +/- 107 degrees from the Machine Zero position in the pan axis. This is

useful when trying to measure the angle between two targets or when it is desirable to align the machine‟s

zero position to a known direction, such as a compass heading. The LRAD can also be mounted in an

inverted position (i.e. hung upside down), and the inversion command will “offset” the pan and tilt axis

coordinates by inverting the axes‟ positive and negative directions.

ONCE DEFINED, LIMITS AND SETPOINTS ARE FIXED IN MACHINE ABSOLUTE COORDINATES.

THEY DO NOT CHANGE RELATIVE TO THE MACHINE WHEN USER OFFSETS OR THE INVERSION

BIT ARE CHANGED. WHAT CHANGE ARE THE USER COORDINATES OF THESE POINTS AND, IN

THE CASE OF A LIMIT, THE SIGNS OF THE ASSOCIATED COMMANDED TRAVEL DIRECTIONS.

SIMILARLY, INVERSION DOES NOT RELOCATE THE ORIGIN OF THE USER COORDINATE SYSTEM

RELATIVE TO THE MACHINE.

4.1.8 Commands and Responses

The following table lists all of the LRAD PTSS controller‟s user commands. A “Yes” in the “Affected by

Inversion?” column indicates that the PTSS controller will automatically invert the axes‟ coordinates so that

the programmer does not have to perform any of this conversion in the interface software. This means that

for example a user entered move command of -30 degrees in pan will result in the unit turning to the left by

30 degrees as long as the inversion state is set to match the installation of the unit. The column labeled

“User Offset/Absolute Coords.” denotes whether the coordinates passed by the command will be treated by

the machine as being relative to the Machine Absolute Coordinates or to the User Offset Coordinates set

using commands 29h or 2Ah.

User

Affected Offset/

Command Name by Absolute

Hex Description Inversion? Coords.

20h Jog (pan speed, tilt speed) Yes -

*Immediately accelerates to the entered speed(s)

pan speed = -125 to 125 parts of user-addressable maximum (see 44h)

tilt speed = -125 to 125 parts of user-addressable maximum (see 44h)

Responses:

[ACK],[MSL],[CMD],(pan speed), (tilt speed), [EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

21h Move to entered coordinates (pan angle, tilt angle) Yes Offset

*Immediately moves to the given coordinates at max acceleration and

speed.

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 7 of 23

San

pan angle = -32700 to 32700

tilt angle = -19000 to 19000

Responses:

[ACK],[MSL],[CMD],(pan angle), (tilt angle),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

22h Move to setpoint (setpoint number) No (Abs)

*Immediately moves to the entered setpoint coordinates at max

acceleration and speed.

setpoint number = 0 to 31

Responses:

[ACK],[MSL],[CMD],(setpoint number),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

23h Move incrementally by entered angles (pan angle, tilt angle) Yes -

*Immediately moves by the given angle at max acceleration and speed.

pan angle = -32700 to 32700

tilt angle = -19000 to 19000

Responses:

[ACK],[MSL],[CMD],(pan angle), (tilt angle),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

24h Go to home setpoint No (Abs)

*Immediately moves to setpoint 31 (home).

Responses:

[ACK],[MSL],[CMD],[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

25h Go to machine center No (Abs)

*Immediately moves to the machine center in Machine Coordinates.

Responses:

[ACK],[MSL],[CMD],[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

26h Save present position as setpoint (setpoint number) No (Abs)

*Assigns current pan and tilt angles to the given setpoint.

setpoint number = 0 to 31

Responses:

[ACK],[MSL],[CMD],(setpoint number),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

27h Save entered coordinates as setpoint (setpoint number, pan angle, tilt Yes Offset

angle)

*Assigns the entered coordinates as a setpoint.

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 8 of 23

San

setpoint number = 0 to 31

pan angle = -32700 to 32700

tilt angle = -19000 to 19000

Responses:

[ACK],[MSL],[CMD] ,(setpoint number),(pan angle), (tilt angle), [EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

28h Save present position as soft limit (soft limit axis and direction) Yes (Abs)

*Creates a soft limit at the present position for the axis and direction

given.

soft limit axis and direction: 00h= CCW, 01h=CW, 02h=DN, 03h=UP in

user coordinates [So if the inversion bit has been set via command

50h, then a value of 01h here makes the present position the limit of

positive rotation as specified by jog or vector commands, which are

in user coordinates. This is negative (CCW) rotation in the machine

absolute reference frame. Should the inversion bit then be cleared,

this limit would continue to apply to negative rotation in the machine

absolute reference frame, which would then also be negative rotation

in the user reference frame.]

Responses:

[ACK],[MSL],[CMD],(soft limit axis and direction),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

29h Save present position as offset center No (Abs)

*Assigns user coordinates of 0,0 to the present position of the unit. All

commands using offset coordinates will now use the present position

as the 0,0 position.

Note: The range of allowable pan and tilt offset centers is ±10700 and

±9500 from machine center respectively. The restricted range of pan

offsets ensures that the coordinates of accessible pan angles stay

within the range allowed by 2-byte signed integer representation. An

input which calls for offset center coordinate(s) beyond the allowable

limits is rejected as out of range.

Responses:

[ACK],[MSL],[CMD],[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

2Ah Offset origin of user coordinates incrementally by entered angles (pan Yes Offset

angle, tilt angle)

*Offsets the user coordinate origin by the given angle relative to

machine center.

pan angle = -21400 to 21400

tilt angle = -19000 to 19000

See the note in 29h above as to the ±10700 range of allowable pan

offsets.

Responses:

[ACK],[MSL],[CMD],(pan angle), (tilt angle),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 9 of 23

San

2Fh Save entered value as soft limit (soft limit axis and direction, angle) Yes Offset

*Assigns a given angle as the soft limit for an axis and direction.

soft limit axis and direction: 00h= CCW, 01h=CW, 02h=DN, 03h=UP in

user coordinates, as described in 30h below.

angle = -32700 to 32700 for pan axis

angle = -19000 to 19000 for tilt axis

Note: An input which calls for a soft limit beyond the machine limits is

interpreted and acknowledged as calling for the nearest allowable

value, in light of any existing offset. For example, a CW soft limit

input of 20000, when the machine is upright and has a user offset of

10000 in the pan axis, is acknowledged as an input of 12000, so that

input value plus offset sum to 22000, the machine pan maximum

limit.

Responses:

[ACK],[MSL],[CMD],(soft limit axis and direction),(angle),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

30h Read soft limit (soft limit axis and direction) Yes Offset

*Returns the soft limit setting for the entered axis and direction in User

Offset Coordinates.

soft limit axis and direction: 00h= CCW, 01h=CW, 02h=DN, 03h=UP in

user coordinates. [So if the inversion bit has been set via command

50h then the CW soft limit reported here is the user coordinate of the

soft limit associated with positive motion commands, which are in

user coordinates. This is negative (CCW) rotation of the pan axis in

the machine absolute reference frame.]

angle = -32700 to 32700 for pan axis

angle =-19000 to 19000 for tilt axis

Responses:

[ACK],[MSL],[CMD],(soft limit axis and direction),(angle),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

31h Read setpoint coordinates (setpoint number) Yes Offset

*Returns the coordinates for the entered setpoint number in User Offset

Coordinates.

setpoint number = 0 to 31

pan angle = -32700 to 32700

tilt angle = -19000 to 19000

Responses:

[ACK],[MSL],[CMD],(setpoint number),(pan angle), (tilt angle),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

32h Read offset angle No Abs

*Returns the location of the origin of user in machine absolute

coordinates

pan angle = -10700 to 10700

tilt angle = -9500 to 9500

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 10 of 23

San

Responses:

[ACK],[MSL],[CMD],(pan angle), (tilt angle),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

33h Read inverted status No -

*Returns the value stored for the machine‟s inversion status.

inv status: 00h = upright, 01h = inverted

Responses:

[ACK],[MSL],[CMD],(inv status),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

40h Get position and move status Yes Offset

*Returns machine movement status and position in User Offset

Coordinates.

move status: 00h = move complete, 01h = moving

pan angle = -32700 to 32700

tilt angle = -19000 to 19000

Responses:

[ACK],[MSL],[CMD] ,(move status),(pan angle),(tilt angle),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

41h Get machine status No -

*Returns additional machine status as shown.

Machine status = 32 bits (0= no, 1=yes)

Bit 0: Pan soft limit

Bit 1: Tilt soft limit

Bit 2: Pan limit switch asserted

Bit 3: Tilt limit switch asserted

Bit 4: Pan drive faulted

Bit 5: Tilt drive faulted

Bit 6: Pan motor stall (repeated position errors)

Bit 7: Tilt motor stall

Bit 8: Pan motor controller comms failed

Bit 9: Tilt motor controller comms failed

Bit 10: Fans on

Bit 11: Fan current present

Bits 12 to 19: Enclosure temperature (deg. C) -128 to 127

Bit 20: Internal IP port #1 ping response OK

Bit 21: Internal IP port #2 ping response OK

Bit 22: Internal IP port #3 ping response OK

Bit 23: Internal IP port #4 ping response OK

Bit 24: Internal IP port #5 ping response OK

Bit 25: Internal IP port #6 ping response OK

Bit 26: Internal IP port #7 ping response OK

Bit 27: Internal IP port #8 ping response OK

Bit 28: Pan encoder initialization error

Bit 29: Tilt encoder initialization error

Bits 30 to 31: Not used at the moment (zeroes)

Responses:

[ACK],[MSL],[CMD],(machine status),[EOM]

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 11 of 23

San

[NAK],[MSL],[CMD],[ERR],[EOM]

42h Read machine serial no and firmware rev No -

*Returns the serial number and revision of the machine as set by the

factory.

serial no: 8 printable characters

firmware rev: 8 printable characters

Responses:

[ACK],[MSL],[CMD],(serial no),(firmware rev),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

43h Perform reset and self test No -

*Restarts the PTSS controller application and performs self test.

Responses:

[ACK],[MSL],[CMD],[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

44h Set max speed (pan speed, tilt speed) No -

*Sets the maximum positioning speed (upto 60 deg/sec max.)

pan speed = 0 to 250 parts of factory maximum

tilt speed = 0 to 250 parts of factory maximum

Responses:

[ACK],[MSL],[CMD],(pan speed),(tilt speed),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

45h Set acceleration (pan accel, tilt accel) No -

*Sets the maximum positioning acceleration (upto 120 deg/sec/sec max

on pan and 60 deg/sec/sec max on tilt).

pan accel = 0 to 250 parts of factory maximum

tilt accel = 0 to 250 parts of factory maximum

Responses:

[ACK],[MSL],[CMD],(pan accel),(tilt accel),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

46h Read machine name No -

*Returns the stored name of the machine.

name: 8 printable characters

Responses:

[ACK],[MSL],[CMD],(name),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

47h Read machine speeds No -

*Returns pan and tilt axis maximum speed settings

pan speed = 0 to 250 parts of factory maximum

tilt speed = 0 to 250 parts of factory maximum

Responses:

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 12 of 23

San

[ACK],[MSL],[CMD],(pan speed),(tilt speed),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

48h Read machine accelerations No -

*Returns pan and tilt axis maximum acceleration settings

pan accel = 0 to 250 parts of factory maximum

tilt accel = 0 to 250 parts of factory maximum

Responses:

[ACK],[MSL],[CMD],(pan accel),(tilt accel),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

49h Get drive detail status No -

*Returns additional machine status as shown.

Detail Drive status = 32 bits (0= no, 1=yes)

One for each the pan and tilt axis

Bit 0: The peak drive current has been exceeded

Bit 1: The Elmo drive has detected a hard limit switch inhibit

Bit 2: The low limit switch has been triggered (pan CCW tilt Down)

Bit 3: The high limit switch has been triggered (pan CW tilt Up)

Bit 4: Drive speed tracking exceeded set limit, motor stalled

Bit 5: Drive position tracking exceeded set limit, motor stalled

Bit 6: Internal Elmo configuration error, drive fault

Bit 7: Power supply delivering too little voltage, drive fault

Bit 8: Power supply delivering too much voltage, drive fault

Bit 9: Short circuit in the drive or motor winding, drive fault

Bit 10: Drive temperature exceeded the limit, drive fault

Bit 11: Internal Elmo stack overflow error, drive fault

Bit 12: Internal Elmo CPU error, drive fault

Bit 13: The motor is powered but not moving, motor stalled

Bit 14: The position limit exceeded set limit, motor stalled

Bit 15: Can not start the motor, motor stalled

Bit 16: Internal Elmo program error, drive fault

Bit 17: Stopped by limit, drive fault

Bit 18-31 unused, 0

Responses:

[ACK],[MSL],[CMD],(pan drive status),(tilt drive status),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

4Ah Read machine deceleration (pan decel, tilt decel) No -

*Returns pan and tilt axis maximum deceleration settings

pan decel = 0 to 250 parts of factory maximum

tilt decel = 0 to 250 parts of factory maximum

Responses:

[ACK],[MSL],[CMD],(pan decel),(tilt decel),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

4Bh Set deceleration (pan decel, tilt decel) No -

*Sets the maximum positioning deceleration (upto 120 deg/sec/sec max

on pan and 60 deg/sec/sec max on tilt).

pan decel = 0 to 250 parts of factory maximum

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 13 of 23

San

tilt decel = 0 to 250 parts of factory maximum

Responses:

[ACK],[MSL],[CMD], (pan decel),(tilt decel),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

50h Set/clear pan and tilt axis inversion No -

*Sets User Coordinates for upright or inverted mounting.

inv status: 00h = upright, 01h = inverted

Responses:

[ACK],[MSL],[CMD],(inv status),[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

51h Clear offset center No Abs

*Returns unit to Machine Absolute Coordinate system.

Responses:

[ACK],[MSL],[CMD],[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

60h Clear all setpoints No Abs

*Clears saved coordinates for setpoints 0 to 31.

Responses:

[ACK],[MSL],[CMD],[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

61h Clear all soft limits No Abs

*Returns all soft limits to default positions of +/-95 degrees in tilt and +/-

210 degrees in pan.

Responses:

[ACK],[MSL],[CMD],[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

65h Immediate stop No -

*Immediately stops any move in progress

Responses:

[ACK],[MSL],[CMD],[EOM]

[NAK],[MSL],[CMD],[ERR],[EOM]

4.2 LRAD Serial Attenuation Module (SAM) Protocol

The SAM module is an RS-232 device that is connected to the Lantronix Ethernet to Serial converter. This

device is used to set the volume level of the LRAD hailing device and to read the status of the amplifiers.

Commands for the SAM are written to/read from the socket connection at port 10001 on the PTSS

controller‟s IP address.

4.2.1 General Command Structure

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 14 of 23

San

The general structure of the SAM communications protocol is described below.

From the host to the SAM:

Data Format Bytes

STX 02h 1

Command XXh

Data see special mute/unmute cases

LRC XXh

ETX 03h

Transfers from the host to the SAM will always start with a unique STX (Start of Text) 02H character.

From the SAM to the host:

Data Format Bytes

STX 02h 1

ACK 06h 1

Command XXh 1

see STATUS_RESPONSE_SEQUENCE and

Data GET_ID_REQUEST data definitions

LRC XXh 1

ETX 03h 1

Transfers from the SAM to the host will always start with an STX character and an ACK (acknowledge) 06H

character. The last received command will be returned by the SAM, followed by the current status response

data.

4.2.2 Control Characters

02h Start of Message [SOM]

03h End of Message [EOM]

06h Acknowledge [ACK]

15h Not Acknowledge [NAK]

1Bh Escape Character [ESC]

4.2.3 Escape Character

All zero values and payload bytes that match control characters must be escaped by adding the escape

character 1Bh prior to transmitting the conflicting data byte and setting Bit-7 of the conflicting byte. For

example zero values are not transmitted or received, but are escaped with the two byte sequence: 1Bh,

80h. This action must be performed on all payload bytes, including the LRC. The ESC sequence must be

removed from any command or response prior to calculating the LRC.

4.2.4 List of Commands

The following are the commands that are recognized by the SAM.

Name Description Bytes Command

SAM will return name

GET_ID_REQUEST and revision 1 FEh

SAM will return current

volume level,

GET_STATUS_REQUEST temperature, voltage 1 FDh

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 15 of 23

San

SET_MUTE_STATE_REQUES SAM will mute the

T (MUTE, TRUE) amplifiers 2 FCh 01h

SET_MUTE_STATE_REQUES SAM will un-mute the

T (MUTE, FALSE) amplifiers 3 FCh 1Bh 80h

SAM will set the

volume of the Where: XXh =

SET_ATTENUATION_REQUE amplifiers to the two's

ST, ATTENUATION_VALUE (-1 specified setting complement -1

TO -100) between -1 and -100 2 FBh XXh to -100

SAM will set the

SET_ATTENUATION_REQUE volume of the

ST, ATTENUATION_VALUE (0) amplifiers to 0 3 FBh 1Bh 80h

SAM will increase the

volume of the

INCREMENT_ATTENUATION_ amplifiers by one

REQUEST increment 1 FAh

SAM will decrease the

volume of the

DECREMENT_ATTENUATION amplifiers by one

_REQUEST increment 1 F9h

4.2.5 Get ID Request Response Data Structure Definition

The response to the GET_ID_REQUEST command will have the following structure:

Byte Value

1 „A‟

2 „T‟

3 „C‟

4 „L‟

5 „R‟

6 „A‟

7 „D‟

8 „S‟

9 „A‟

10 „M‟

11 „,‟

12 „V‟

13 VERSION_MAJOR

14 „.‟

15 VERSION_MINOR

16 BUILD_LETTER

4.2.6 Status Response Sequence Structure

The response to the GET_STATUS_REQUEST command will have the following structure when the

attenuation value is between -1 and -100:

Byte Value

1 ATTENUATION (-1 TO -100)

2 STATUSBITS

3 5VOLTATCMSB

4 5VOLTADCLSB

5 12VOLTATCMSB

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 16 of 23

San

6 12VOLTADCLSB

7 48VOLTATCMSB

8 48VOLTADCLSB

9 DEVICETEMPERATUREADCMSB

10 DEVICETEMPERATUREADCLSB

The response to the GET_STATUS_REQUEST command will have the following structure when the

attenuation value is Zero or Muted:

Byte Value

1 1Bh

2 80h

3 STATUSBITS

4 5VOLTATCMSB

5 5VOLTADCLSB

6 12VOLTATCMSB

7 12VOLTADCLSB

8 48VOLTATCMSB

9 48VOLTADCLSB

10 DEVICETEMPERATUREADCMSB

11 DEVICETEMPERATUREADCLSB

4.2.7 Definition of STATUSBITS

bit 0 nGPIO4 (value is 0 when input is high)

bit 1 nGPIO5 (value is 0 when input is high)

bit 2 Reserved

bit 3 Reserved

bit 4 Reserved

bit 5 Reserved

bit 6 Reserved

bit 7 Mute State (1=muted, 0=unmuted)

4.2.8 LRC Checksum Calculation

The checksum is calculated by XOR‟ing Bytes starting with the first command after the STX Byte and

ending at the last data Byte. The STX and Bytes is not included in the LRC checksum, the ACK byte is

included in the LRC. If all Command and Data Bytes are XOR‟ed and the result is then XOR‟ed with the

LRC byte, the result should be zero.

4.2.9 Operational Ranges

All voltage values coming from the SAM should be within +/- 5% of nominal. Amplifier temperatures above

90C will cause the amplifiers to shut down.

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 17 of 23

San

4.2.10 Communications Sequence Diagram

Control LRAD-R

Interface Control Module

User clicks "connect"

button, serial port is

opened and serial I/O

GetIdentificationRequest()

parameters are set.

GetIdentificationResponse()

ID not OK ID OK

Not connected Connected

User sends

"update" request. GetStatusRequest()

GetStatusResponse()

User sends

"mute" request. SetMuteStateRequest()

SetMuteStateResponse()

User sends

volume control

setting. SetAttenuationRequest()

SetAttenuationResponse()

User sends

"increment

volume" request. IncrementAttenuationRequest()

IncrementAttenuationResponse()

User sends

"decrement

volume" request. DecrementAttenuationRequest()

DecrementAttenuationResponse()

4.3 Camera Controls

The LRAD 1000-RX is configured with a SONY FCB-EX 980S camera which can be controlled via RS-232

VISCA commands (“VISCA” is a trademark of Sony Corporation). The control commands for the camera

are written to/read from the socket connection at port 4000 of the PTSS controller‟s IP address, which is

forwarded to the built in serial port of the Axis video server.

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 18 of 23

San

A full documented description of the VISCA protocol can be found on pages 39 to 57 of the Sony FCB-EX

980S camera manual, “fcb-ex980-ac4g100121.pdf”

4.4 Axis Video Streaming

The video stream from the LRAD camera can be accessed using a web browser to run the Axis Media

Control applet. This applet can be reached by pointing a browser to the ip address and port of the Axis

server‟s web portal: 10.1.6.99:8061. The first time a user connects to this address, an ActiveX control will

be installed on the user‟s browser.

Optionally, the video stream can be decoded using an IP to analog converter, such as an Axis 292 Video

Decoder.

In addition, MJPEG and MPEG-4 streams can be displayed in a developer‟s application. For more

information on this, consult the Axis 282 Server Manual and the Axis Media Control Manual in the appendix.

4.5 Audio Streaming to the Barix

The Barix device in the LRAD receives and decodes streamed digital audio files in MP3 format. All

hardware settings for this device are set at the factory and do not need to be changed. While this device

contains a volume control as well as other audio controls, they should not be used or altered, since this

could adversely affect the acoustic performance of the AHD. MP3 files written to the socket connection to

Barix device, port 8062 on the PTSS controller, will be automatically played through the LRAD‟s acoustic

array.

In order to stream live audio through a microphone, the audio at the control computer should be converted

into MP3 format. An application such as LAME encoder can be used for this task and is included in ATC‟s

API.

For more information on the streaming protocol for the Barix, please consult the Barix Audio Streaming

Protocol document in the appendix.

5.0 Programming Notes

Since all of the devices in the LRAD use flash memory for storage of persistent parameters, such as soft limits, port

addresses, etc., it is not recommended that these parameters be written unnecessarily, since flash memory does

not have an infinite number of write cycles. Applications should store each device‟s settings in a local file as well,

for backup purposes.

In order to protect the LRAD‟s acoustic array, the unit should be stowed with the face of the array pointing down in

order to avoid dirt and moisture buildup on the grill covering the acoustic drivers. Users should be reminded to stow

the LRAD when exiting the control application or when the system is idle for a long period of time.

Since the LRAD is a very efficient loudspeaker, there will be an audible hiss coming from the array when the SAM is

at full volume and no audio is being streamed to the device. The hiss will be reduced as the volume is decreased.

It is recommended that the LRAD be automatically muted or the volume turned down when no audio is being

played.

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 19 of 23

San

6.0 Maxabeam Protocol

The Maxabeam spotlight has an RS-232 connection to an Ethernet to Serial network server found at port

10002.

ASCII Command: Maxa Beam Function:

Beam on, off, level:

BL Beam on low (with 3 second warm-up on high)

BN or B1 Beam on normal (with 3 second warm-up on high)

BH Beam on high

BI Beam intensity increments one level; cycles in the order low, normal, high, low,

normal, high... (no effect if beam off or in strobe mode)

BO or B0 Beam off

B1M Beam on, to setting stored by B0M (strobe settings will be the last used)

B0M Beam off, storing current beam setting (low, normal, high or strobe) in the

searchlight‟s volatile (power-on-dependent) memory

Zoom:

ZI Zoom in

ZO Zoom out

ZS Zoom stop

ZR+ Zoom rate increases

ZR- Zoom rate decreases

ZRS Zoom rate stops changing and is stored in the searchlight's non-volatile memory

Go to zoom positions:

(For these commands, the servo moves to the indicated position at its fastest mechanically possible rate)

GS Go to full programmed spot position (100%)

GF Go to full programmed flood position (0%)

GI Go to programmed initial position

Gxx Go to position xx% of travel, where xx is two digits, from 00 to 99 inclusive

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 20 of 23

San

ASCII Command: Maxa Beam Function:

Strobe:

(Strobe-on commands include 3 second warm-up on high if beam was previously off)

SRxx Strobe on at rate (frequency) of xxHz, where xx is two digits, from 01 to 31 inclusive

S1 Strobe on at frequency and duration stored in searchlight, or settings last used since

power-up if different

S0 Strobe off, return to previous non-strobe beam state

S5 Strobe on at 5Hz

S10 Strobe on at 10Hz

S25 Strobe on at 25Hz

S49 or S50 Strobe on at 49Hz (overrides 31Hz limit)

SPxx Set strobe percentage (duration) to xx%, where xx is two digits, from 03 to 63

inclusive

(The following two values are loaded into local memory at power-up)

SSR Store current strobe rate in searchlight‟s non-volatile memory

SSP Store current strobe percentage in searchlight‟s non-volatile memory

(The following strobe commands have no effect unless strobe is on)

SF+ Strobe frequency increases

SF- Strobe frequency decreases

SFS Strobe frequency stops changing and is stored in light's non-volatile memory

SD+ Strobe duration increases

SD- Strobe duration decreases

SDS Strobe duration stops changing and is stored in light's non-volatile memory

Program spot, flood, initial positions:

PZI Zoom in, overriding stored spot limit position

PZO Zoom out, overriding stored flood limit position

PZS Zoom stop

(The following three commands store the current position, given the noted restrictions, in the light's non-volatile

memory)

PZIM Store zoom-in maximum (programmed spot position; cannot be closer than ≈5° to

flood position)

PZOM Store zoom-out maximum (programmed flood position; cannot be closer than ≈5° to

spot position)

PZIP Store initial position (cannot be outside the range from spot to flood)

PRFS Restore factory settings (spot, flood and initial positions)

Write feedback:

WBL Send the beam level/state back to the controller (as "Off", "Off Low-Voltage ", "Low",

"Normal", "High", or "Strobe")

WZP Send the zoom position, as percent of total travel, where 100% = programmed spot

and 0% = programmed flood

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 21 of 23

San

ASCII Command: Maxa Beam Function:

Write feedback, cont‟d:

(The following two commands report the current local values, which may not be the values stored in the light’s

non-volatile memory)

WSR Send the strobe rate/frequency in Hz

WSP Send the strobe percentage/duration

WTMP Send the circuit board temperature (in Celsius), signed if negative

WV# Send the interface's firmware version number

Echo commands:

(After executing each of these commands, the searchlight replies back with: the literal command entered (lower-

case letters are translated to upper-case), <cr><lf>) (with no commas or spaces)

EBO Beam off

EBL Beam on low (with 3 second warm-up on high if previously off)

EBH Beam on high

ERxx Beam on strobe (with 3 second warm-up on high if previously off), at xxHz, where xx

is two digits, from 01 to 20 inclusive

EPxx Set strobe percentage (duration) to xx%, where xx is two digits, from 03 to 63

inclusive

EZxx Zoom to position xx% of travel, where xx is two digits, from 00 to 99 inclusive

ESPT Zoom to full programmed spot position (100%)

Echo write commands:

(After executing each of these commands, the searchlight replies back with: the literal command entered (lower-

case letters are translated to upper-case), the information as indicated below, <cr><lf>) (with no commas or

spaces)

EWBS Write the beam state, as one digit, where 0=off, 1= off low-voltage, 2=low, 3=high,

4=strobe, 5=malfunction

EWZP Write the zoom position (percent of total travel), as three digits, from 000 (flood) to

100 (spot)

EWSR Write the current (local memory) strobe rate, in Hz, as two digits

EWSP Write the current (local memory) strobe percentage, as two digits

EWTM Write the circuit board temperature (in Celsius), as three digits, signed if negative

EWV# Write the interface‟s firmware version number, as three digits, the middle one being

a decimal point

Notes:

Port settings: 9600 baud rate, 8 data bits, 1 stop bit, no parity, no flow control.

Port settings can be changed at port 8063 using a web browser if needed.

Commands are not case-sensitive, but must be terminated by carriage-return (ASCII 13); line-feed (ASCII 10) is

ignored. Otherwise, non-exact matches are replied to with “Invalid”. When power is initially applied to the

searchlight, the servo moves to the programmed initial-on position, without the beam being activated, and

"SL<cr><lf>" is sent to the controller.

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 22 of 23

San

7.0 Appendices

See attached files:

fcb-ex980-ac10121.pdf : Sony Camera user‟s manual and VISCA protocol document

Axis 282 Server Manual.pdf: User‟s manual for Axis 282 Video Server

Axis Media Control Manual.pdf: User‟s manual for Axis Media Control software

Barix Audio Streaming Protocol.pdf: Barix Streaming Device‟s audio streaming protocol document

UDS 200_UG.pdf: User‟s manual for Lantronix Serial Port Server

15378 Avenue of Science, San DOC. # 105328-00 REV

Diego, CA 92128

G

SHEET 23 of 23

San

Você também pode gostar

- User Manual, Lrad-100xDocumento20 páginasUser Manual, Lrad-100xFelipe Benedetti Direccion Seccional Huila Defensa CivilAinda não há avaliações

- TERMADocumento22 páginasTERMAИванИванов100% (1)

- User Manual: R&S GB4000V Audio UnitDocumento61 páginasUser Manual: R&S GB4000V Audio UnitMarcin BogdanAinda não há avaliações

- Cobham 400991 mk3 PDFDocumento114 páginasCobham 400991 mk3 PDFIvo CastroAinda não há avaliações

- (M1200T) DataSheet EN 160610 V1.0Documento12 páginas(M1200T) DataSheet EN 160610 V1.0phuongnt1710Ainda não há avaliações

- Jotron 7000 SeriesDocumento4 páginasJotron 7000 SeriesZoheir Redouane Zahzah100% (1)

- Hytera SmartDispatch-Net Feature Book V4.0Documento20 páginasHytera SmartDispatch-Net Feature Book V4.0tanajm60Ainda não há avaliações

- UHF Digital/Analog Mobile Transceiver Service Manual: Vertex Standard LMR, IncDocumento31 páginasUHF Digital/Analog Mobile Transceiver Service Manual: Vertex Standard LMR, IncIng Marco Antonio Hernandez LimaAinda não há avaliações

- Tech Manual TR-7550 VBDocumento3 páginasTech Manual TR-7550 VBseptemberzeroadyAinda não há avaliações

- Rm-rm2-Hvm V Uhf ModemDocumento2 páginasRm-rm2-Hvm V Uhf Modemducchinh1001Ainda não há avaliações

- RCMS2900 Series 2Documento7 páginasRCMS2900 Series 2Wildan YogaAinda não há avaliações

- Philips Pm5580Documento6 páginasPhilips Pm5580IoannisMakris100% (1)

- Logo Motion Edition B InternetDocumento188 páginasLogo Motion Edition B InternetlhinobuAinda não há avaliações

- RSM970S1 En7 PDFDocumento110 páginasRSM970S1 En7 PDFmuhammad arif sulaimanAinda não há avaliações

- Harmonic XOS Advanced Media ProcessorDocumento3 páginasHarmonic XOS Advanced Media ProcessorRobertAinda não há avaliações

- Ak 100Documento46 páginasAk 100Er Vishnu SharmaAinda não há avaliações

- Camargo E. Millimeter-Wave GaN Power Amplifier Design 2022Documento339 páginasCamargo E. Millimeter-Wave GaN Power Amplifier Design 2022bryam vargasAinda não há avaliações

- Smart Com 150 Manual English V5 - 14 PDFDocumento121 páginasSmart Com 150 Manual English V5 - 14 PDFRafaelAinda não há avaliações

- AR9287Documento3 páginasAR9287Marriaga RonaldAinda não há avaliações

- DMR Repeater - Back-To-back Application Notes - R2.0Documento27 páginasDMR Repeater - Back-To-back Application Notes - R2.0A&A LABORATORIOAinda não há avaliações

- LNL X2220 DatasheetDocumento2 páginasLNL X2220 DatasheetDewytt Jhordan Cordoba CubillosAinda não há avaliações

- Service Manual VX 21002200 Series VHFDocumento44 páginasService Manual VX 21002200 Series VHFRubem A S FigueiraAinda não há avaliações

- 1501-102 - Circuit Pack DescriptionDocumento102 páginas1501-102 - Circuit Pack Descriptionalek nowal100% (2)

- Sonet: Quick ReferenceDocumento8 páginasSonet: Quick ReferenceNguyen Anh DucAinda não há avaliações

- AGS 20 L - Rev1Documento35 páginasAGS 20 L - Rev1carlosslvnAinda não há avaliações

- HP ProBook 6560b - FoxConn Cure DIS Rev 0Documento52 páginasHP ProBook 6560b - FoxConn Cure DIS Rev 0amitintime4uAinda não há avaliações

- Short User Manual 578140Documento20 páginasShort User Manual 578140YogithaAinda não há avaliações

- TS101 Advanced User Manual Updated1Documento21 páginasTS101 Advanced User Manual Updated1Shubham AcharyaAinda não há avaliações

- Dialog R242 PlatformArchitecture v1.1Documento128 páginasDialog R242 PlatformArchitecture v1.1qazxc vbnmAinda não há avaliações

- MOD-13-1538 V10.11-001 Release Note Issue 1.0 PDFDocumento21 páginasMOD-13-1538 V10.11-001 Release Note Issue 1.0 PDFNilson DinizAinda não há avaliações

- SRT 1C Slide CollectionDocumento302 páginasSRT 1C Slide CollectionGerencia de Ingeniería VenezuelaAinda não há avaliações

- EVB Schematic For RK3399ProDocumento36 páginasEVB Schematic For RK3399ProChu Tiến Thịnh100% (1)

- PNMSJ Java CatalogDocumento4 páginasPNMSJ Java CatalogAHMEDKAMAL2011100% (1)

- ZR800Z10 V2 2009-07-21Documento130 páginasZR800Z10 V2 2009-07-21jabril jabrilAinda não há avaliações

- 72 Operation ManualDocumento136 páginas72 Operation ManualChristopher M ChenAinda não há avaliações

- Leonidas Datasheet v3 PDFDocumento2 páginasLeonidas Datasheet v3 PDFSebastian RentschAinda não há avaliações

- Ds Nemo Outdoor LTE Altair TerminalsDocumento3 páginasDs Nemo Outdoor LTE Altair TerminalsjuanahumadaAinda não há avaliações

- ALC EthDocumento130 páginasALC EthtutenoAinda não há avaliações

- 383942-28 EnDat 2-2 enDocumento20 páginas383942-28 EnDat 2-2 enRefaat RaslanAinda não há avaliações

- Wavestar Dacs 4/4/1 Introduction and O&M: Patrick Wu Qacc &tsoDocumento38 páginasWavestar Dacs 4/4/1 Introduction and O&M: Patrick Wu Qacc &tsoDaiAnShengAinda não há avaliações

- Newtec MDM9000 Satellite Modem r3.3 DatasheetDocumento4 páginasNewtec MDM9000 Satellite Modem r3.3 DatasheetarzeszutAinda não há avaliações

- Nokia DMR38 1Documento134 páginasNokia DMR38 1Hugh TranAinda não há avaliações

- Sop VR10Documento53 páginasSop VR10didiAinda não há avaliações

- NV10 TRB 3.3Documento234 páginasNV10 TRB 3.3Juan perezAinda não há avaliações

- Manual Modulo HS-2 Megaplex 2100Documento34 páginasManual Modulo HS-2 Megaplex 2100Alejandro Vera SolisAinda não há avaliações

- Dell Brochure PDFDocumento2 páginasDell Brochure PDFUmbraSeriiAinda não há avaliações

- Telefire ADR-3000 Brochure PDFDocumento2 páginasTelefire ADR-3000 Brochure PDFJoseph BoshehAinda não há avaliações

- Autoranging Combiscope pm3370bDocumento478 páginasAutoranging Combiscope pm3370bjohn doeAinda não há avaliações

- Universal Reporting Guide - 164Documento62 páginasUniversal Reporting Guide - 164Luis Chavez AdalidAinda não há avaliações

- Transmode TS Series 6p ADocumento6 páginasTransmode TS Series 6p Aasdf2012Ainda não há avaliações

- 1 Sonet 101 2014-03Documento8 páginas1 Sonet 101 2014-03Carlos Sulca NeiraAinda não há avaliações

- Products: Base - Repeaters Mobiles Radios Portable Radios Nexedge P25 NexedgeDocumento1 páginaProducts: Base - Repeaters Mobiles Radios Portable Radios Nexedge P25 NexedgeCoyne GibsonAinda não há avaliações

- SLR 1000 Data Sheet PDFDocumento2 páginasSLR 1000 Data Sheet PDFBao Quoc MaiAinda não há avaliações

- Acer Aspire 5742 Series-Gateway NV55C Series (PEW71 LA-6582P)Documento48 páginasAcer Aspire 5742 Series-Gateway NV55C Series (PEW71 LA-6582P)Geoffrey M. Gitau0% (1)

- 2 2 HardwareDescription PDFDocumento80 páginas2 2 HardwareDescription PDFCao Hồng MinhAinda não há avaliações

- Triple Play: Building the converged network for IP, VoIP and IPTVNo EverandTriple Play: Building the converged network for IP, VoIP and IPTVAinda não há avaliações

- FY100 FY101 FY400 FY600 FY700 FY800 FY900: Communication ManualDocumento28 páginasFY100 FY101 FY400 FY600 FY700 FY800 FY900: Communication ManualMandeep BoparaiAinda não há avaliações

- DC1010 DC1020 DC1030 DC1040: Communication ManualDocumento28 páginasDC1010 DC1020 DC1030 DC1040: Communication ManualGubski Gubatayao100% (1)

- LTE Local Traffic Offlloading (SDR LR23)Documento28 páginasLTE Local Traffic Offlloading (SDR LR23)paulo.ferreira.flcAinda não há avaliações

- Sprui 35Documento35 páginasSprui 35TSAinda não há avaliações

- 3GPP TS 35.205: Technical SpecificationDocumento15 páginas3GPP TS 35.205: Technical SpecificationngdnamAinda não há avaliações

- KHD-400 스펙Documento2 páginasKHD-400 스펙ngdnamAinda não há avaliações

- Ắc quy Long - KPH100-12ANDocumento2 páginasẮc quy Long - KPH100-12ANngdnamAinda não há avaliações

- 6fm100e XDocumento2 páginas6fm100e XhaiaicAinda não há avaliações

- Call Recording SolutionsDocumento4 páginasCall Recording SolutionsngdnamAinda não há avaliações

- Security Architecture and Procedures For 5G SystemDocumento194 páginasSecurity Architecture and Procedures For 5G SystemKostas MoraitisAinda não há avaliações

- LogRhythm Software Installation Guide 7.4.4 RevADocumento117 páginasLogRhythm Software Installation Guide 7.4.4 RevAngdnamAinda não há avaliações

- Tactical Backpack-A50008943enwDocumento4 páginasTactical Backpack-A50008943enwngdnamAinda não há avaliações

- Default Usernames, Passwords and IP Addresses For Surveillance CamerasDocumento8 páginasDefault Usernames, Passwords and IP Addresses For Surveillance CamerasngdnamAinda não há avaliações

- LogRhythm Software Upgrade Guide 7.4.4 RevBDocumento89 páginasLogRhythm Software Upgrade Guide 7.4.4 RevBngdnamAinda não há avaliações

- Plaquette Hub de Communication Acel 4pages EN V2Documento4 páginasPlaquette Hub de Communication Acel 4pages EN V2ngdnamAinda não há avaliações

- XDM V9.1 R1 Release NotesDocumento30 páginasXDM V9.1 R1 Release NotesngdnamAinda não há avaliações

- MPM 10 100 User Manual 1503305994Documento57 páginasMPM 10 100 User Manual 1503305994ngdnamAinda não há avaliações

- LogRhythm Schema Dictionary and Guide RevBDocumento226 páginasLogRhythm Schema Dictionary and Guide RevBngdnamAinda não há avaliações

- Operator Manual Compass Standard 22 and Standard 22 CompactDocumento54 páginasOperator Manual Compass Standard 22 and Standard 22 CompactngdnamAinda não há avaliações

- CP R81.10 Gaia AdminGuideDocumento520 páginasCP R81.10 Gaia AdminGuidengdnamAinda não há avaliações

- CP 6000 7000 Appliances GettingStartedGuideDocumento50 páginasCP 6000 7000 Appliances GettingStartedGuidengdnamAinda não há avaliações

- Brocade G620 Hardware Installation GuideDocumento97 páginasBrocade G620 Hardware Installation GuidengdnamAinda não há avaliações

- Arista Usermanual - EOS Version 4.28.1F DOC-03495-22Documento3.855 páginasArista Usermanual - EOS Version 4.28.1F DOC-03495-22ngdnamAinda não há avaliações

- Dell EMC Unity™ Family Security Configuration Guide - v5.1Documento66 páginasDell EMC Unity™ Family Security Configuration Guide - v5.1ngdnamAinda não há avaliações

- LightSoft UM ETSI A00 V4.2R1 en PDFDocumento1.200 páginasLightSoft UM ETSI A00 V4.2R1 en PDFngdnamAinda não há avaliações

- 4352 Operator Unit 130-626.NG002Documento101 páginas4352 Operator Unit 130-626.NG002AbhijithAinda não há avaliações

- Priorities For Access To HealthDocumento25 páginasPriorities For Access To HealthsvpadillaAinda não há avaliações

- TM - A5ck, CC, CM - y PDFDocumento102 páginasTM - A5ck, CC, CM - y PDFslipargolokAinda não há avaliações

- Generic TWS600S Service ManualDocumento113 páginasGeneric TWS600S Service ManualWise So100% (2)

- Optical Fiber Communication 06EC7 2: Citstudents - inDocumento4 páginasOptical Fiber Communication 06EC7 2: Citstudents - inShailaja UdtewarAinda não há avaliações

- Lewmar Marine Equipment Guide Ed 14Documento224 páginasLewmar Marine Equipment Guide Ed 14Renato Fonseca100% (1)

- Growth of Escherichia Coli in A 5 Litre Batch Fermentation VesselDocumento15 páginasGrowth of Escherichia Coli in A 5 Litre Batch Fermentation VesselAs'ad Mughal100% (2)

- ANTENASDocumento10 páginasANTENASGreo HernandezAinda não há avaliações

- TIBCO Hawk Rulebase Standard GuidelinesDocumento9 páginasTIBCO Hawk Rulebase Standard GuidelinesAshish ShrivastavaAinda não há avaliações

- Diff BW CBO and RBODocumento2 páginasDiff BW CBO and RBORamreddy BollaAinda não há avaliações

- Leading Architect and Enabler in Digital SocietyDocumento31 páginasLeading Architect and Enabler in Digital SocietyRifki NugrahaAinda não há avaliações

- GEO ExPro V11i6Documento104 páginasGEO ExPro V11i6OsmanAinda não há avaliações

- Supervisory Setpoint Control (SSC) : I/A Series SystemDocumento46 páginasSupervisory Setpoint Control (SSC) : I/A Series SystemMiguel Angel GiménezAinda não há avaliações

- Anern Integrated Solar Garden Light-201604Documento1 páginaAnern Integrated Solar Garden Light-201604Godofredo VillenaAinda não há avaliações

- Software: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsDocumento8 páginasSoftware: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsBrandi DaleAinda não há avaliações

- Position PaperDocumento3 páginasPosition Paperapi-178099475100% (1)

- BTW-ST300MW Pure Sine Wave Inverter ManualDocumento15 páginasBTW-ST300MW Pure Sine Wave Inverter ManualCarlos ZubietaAinda não há avaliações

- Instrumentation For Measurement of Roof Convergence in Coal MinesDocumento9 páginasInstrumentation For Measurement of Roof Convergence in Coal MinessamratAinda não há avaliações

- A6Documento67 páginasA6Ashraff AudiAinda não há avaliações

- Profile Measurement Full ReportDocumento16 páginasProfile Measurement Full ReportAman RedhaAinda não há avaliações

- 90 61 085 Transportation ValvesDocumento18 páginas90 61 085 Transportation ValvesarrikanAinda não há avaliações

- Optimized Design of A Bagasse Dryer System For The Sugar IndustryDocumento6 páginasOptimized Design of A Bagasse Dryer System For The Sugar IndustryTJ BolorAinda não há avaliações

- Grade 2 SasmoDocumento8 páginasGrade 2 SasmoThích Toán HọcAinda não há avaliações

- Web Content Management SystemsDocumento30 páginasWeb Content Management SystemsTharmi KAinda não há avaliações

- LiquidlevelDocumento24 páginasLiquidlevelAnu Raj Anu RajAinda não há avaliações

- Surface Finish StandardDocumento3 páginasSurface Finish StandardvinodmysoreAinda não há avaliações

- Press Working OperationsDocumento23 páginasPress Working OperationsKanagaraj Ganesan100% (1)

- Invoice Cod Invoice Cod: Agen Pos Agen PosDocumento4 páginasInvoice Cod Invoice Cod: Agen Pos Agen Poswahids0204Ainda não há avaliações

- 009-1137-00 HST-SMRTD Savant Smart Host Tech SpecDocumento6 páginas009-1137-00 HST-SMRTD Savant Smart Host Tech Specferna2420Ainda não há avaliações

- Civil Engineering Interview QuestionsDocumento12 páginasCivil Engineering Interview Questionsjadgug100% (1)