Escolar Documentos

Profissional Documentos

Cultura Documentos

Normand Ranger - Yard No. 290

Enviado por

Erwin Paulian SihombingDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Normand Ranger - Yard No. 290

Enviado por

Erwin Paulian SihombingDireitos autorais:

Formatos disponíveis

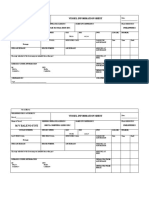

VS 490

AHTS

VS 490 AHTS Hull no. 290

Designed by Wärtsilä Ship Design Norway AS

(Vik Sandvik)

Delivered 2010 by Ulstein Verft AS

M/V “normand ranger” Built for Skrog 30 AS, to be assigned to

Solstad Shipping AS

Anchor Handling Tug Supply Vessel Large main diesel engines

Large capacity AHT winch

Equipment for safe work deck by means

of Multi Deck Handler

Anchor Recovery Frame at stern for

deploying and retrieval of anchors

VS 490 AHTS

M/V “NORMAND RANGER” is an Anchor Handling Tug M A IN D IM EN SION S

Supply Vessel designed by Vik Sandvik (Wärtsilä). The vessel is

propelled by two large diesel engines, one per side. The Length over all approx. 91,0 m

propeller power could be boosted by electric motors via Length between p.p. 79,35 m

reduction gear PTI, in operations where more propeller power Breadth moulded 22,0 m

is required. Depth to main deck 9,6 m

Draught max 7,95 m

There are different combinations how the propulsion can be run: TA N K CA PA CITIES

• Boost mode (full power at 750 rpm, including electric motors)

Fuel oil (MDO) 1210 m3

• Diesel Electric (DE) mode

Fresh water 1015 m3

• Diesel Mechanic (DM) mode Ballast water 2886 m3

• DP in diesel mechanic mode, good weather Liquid mud 650 m3

• DP in diesel mechanic mode, bad weather Dry bulk, cement; 4 off 291 m3

Urea 34 m3

Rig chain lockers; 4 off 649 m3

Main Activities

ORO tank capacity 1299 m3

• Anchor Handling Towing Winch, 500 t SWL,

three separate drums V ESSEL CA PA CITIES

• General supply services, including carrying liquid mud, brine,

and dry bulk Deadweight at max. draught 4019 tonnes

• Duties for standby and rescue operations Cargo deck area main deck 760 m2

• Fire fighting operations Main deck load 15 t/m2 from stern to 25 frame

10 t/m2 from 25 frame to 72 frame

M/V ”NORMAND RANGER” is an environmentaly friendly ship Gross tonnage, international 7480 GRT

in all respects. The ship is built according to Det Norske Veritas Net tonnage, international 2244 NRT

class Clean Design. Also, catalytic reactors for minimum NOx Max speed (at d= 6.0m) 18.5 knots

emissions are installed. A Green Passport complying with IMO Bollard pull approx. 280 tonnes

ship recycling scheme is issued. Environmental Regularity Number (ERN) 99, 99, 99

CLA SSIFICATION / FLA G

DnV 1A1, ICE C, Tug, Supply Vessel, OILREC, SF, E0,

DYNPOS-AUTR, CLEAN DESIGN, NAUT-OSV(A), COMF-V(3),

Standby Vessel (S), Fi-Fi I, TMON, BIS, DK(+), HL(2.8)

Flag: NOR

A N CE

VS 490 AHTS

“NORMAND RANGER” iis built with a hotel compliment with permanent • Spooling gears for the towing/working drums, max. sideload 60 tonnes

capacity for 58 persons. Low noise and vibration levels are recorded in the • Two chain pulling winches, max 5.3 t pull

accommodation. • Two secondary winches with dividing flange socket part

170 tonnes pull at 0 - 23 m/min

• Four state cabins with day-room and bedroom Capacity: approx. 1600m dia. 8 in. synthetic rope or 4000m 76 mm wire

• Eighteen one-bed cabins • Spooling device for secondary winches, side load 23 tonnes

• Eighteen two-bed cabins • One rope reel, capacity: 1500 m of 90 mm dia. wire

• Hospital • One pennant winder, cap. 200 m dia. 76 mm wire

• Galley and separate scullery

• Mess (34 seats), two day rooms Shark Jaws, Towing Pins and Centering Devices

• Dry provision, cooler, and freezer rooms • Two Shark jaws, SWL 800 tonnes

• Meeting room and offices • Loose spooling sheave secured by the shark jaws, 100 t

• Changing room, laundry, gymnasium • Two sets Towing pins with locking arm of folding type, Ø512 mm

• Engine control room on Main deck Stroke: 1600 mm. Pull down force: 60 tonnes (30 t/pin)

• Two Centering devices, working width: 2 m

Deck Cranes • Twin stern rollers, dia. 4000mm, each 4000mm, total length 8000mm,

• Two knuckle boom shipboard / harbour cranes, 6 t at 3-16 m outreach, MWL: 750 tonnes on each roller. Cones only: Weldox 400

12 t at 3-11 m. • Anchor Recovery Frame (ARF), roller dia. 1680 mm,

• Multi Deck Handler (MDH), SWL 42 t, remote controlled travelling roller width 7010 mm, height from deck 6310 mm

crane, arranged for movement along the cargo rails Pulling force 1962 kN at max 60o circumference

Dry bulk plant Lifesaving and Rescue Equipment

• Four tanks, each 72.8 m3 / 175 tonnes • Six off life rafts, each 35 persons

• Twin BHS compressors, capacity 27 m3/min, 6.0 bar • MOB boat, 25 knots w. 10 persons onboard

• Air driers, dew point 4 degr. C. • Telescopic single-point davit for MOB

• Two segregated loading/discharge systems • Rescue scoop

• Dust cyclones and collector tanks

Sanitary Supply and Discharge System

Liquid Cargo Discharge Systems • Two UV sterilizers

• Two fresh water pumps, 150 m3/h – 9 bar, centrifugal type, hydr. • Vacuum sewage plant

• Two ORO/brine pumps, 100 – 24, eccentric screw type, hydr. • Sewage treatment plant, USCG approved

• Two ballast / DW pumps, 150/75 – 9/2.25, centrifugal type, el. • One reverse osmosis fresh water maker, 25t / 24h

• Two fuel oil pumps, 150 – 9, twin spindle screw type, hydr. • One fresh water generator, 12t / 24h

• Two ORO/mud pumps, 100 – 24, eccentric screw type, hydr.

• Agitators for mud/brine tanks, hydraulic drive Machinery / Propulsion System

• Tank cleaning system for mud/brine tanks • Two main engines, each of MCR 8000 kW at 750 rpm

• Flowmeters for FO, FW, brine, DW • Two shaft alternators, each 3000 kW / 3750 kVA at 720 rpm

• Two electric propulsion motors, frequency converter controlled,

Side Thrusters each 1500 ekW, 1200 rpm.

• Two super silent tunnel thrusters fwd., 1000 kW, controlable pitch • Two generator engines, each of 2188 kW / 2725 kVA at 1800 rpm

• Retractable azimuth thruster with nozzle fwd., 830 kW, controlable pitch • Two main propellers, cpp, each 9500 kW, dia. 4200 mm,

• Two tunnel thrusters aft, 880 kW, controlable pitch speed 150 rpm

All thrusters are frequency converter controlled • Exhaust SCR-catalysts for main engines and generator engines

• Emergency generator, 465 kW at 1800 rpm

Roll Damping System

• Two roll reduction tanks, U-configuration Oil Purification Plant

• Two FO separators, self cleaning, automatic

Manoeuvering/Positioning • Two LO separators, self cleaning, automatic

• Dynamic Positioning System DnV AUTR, IMO Class II. • Two mobile hydraulic oil separators

Position reference systems: • USCG approved oily water separator, 2 m3/h , 5 ppm

Two DGPS (1 off DPS 200 + 1 off DPS 132), laser reference system,

hydro acoustic reference units HiPap 350 with remote op. gate valve Fire Fighting System

spare ND 500 gate valve for HPR • Water mist total flooding system for engine room

• Water mist local protection system

Navigation / Communication

• S-band ARPA radar and X-band ARPA radar Fire Fighting I system for External Fires

• Digital chart system ECDIS • Two Fire Fighter I pumps, capacity each 1700 m3 – 14 bar, incl.

• Radio installation according to GMDSS – area A3 • Self protection water spray system

• Mini-M, Fleet-77

• V-Sat communication antenna Video and Monitoring System

• TV satellite antenna • Extensive CCTV system

• 25 cameras, six off 17” monitors

Deck Winches

• Two combined windlass / mooring winches. Chain 54 mm dia. K3 Electric Equipment

• Two tugger winches, 24 t pull at 0 - 22 m/min. • Main switchboards LLC 690 V - 60 Hz

• Two capstans aft, 14 t pull • Switchboards 440 V, 230 V

• Emergency switchboard

Towing / anchor handling winch of waterfall type • ULSTEIN COM® common distribution of automatic telephone, data

Towing / anchor handling winch of waterfall type with remote control network, and satellite TV antenna signal to all offices and cabins

system

• One declutchable anchor handling drum 500 tonnes with dividing flange Preparations

socket part. Capacity: 6100 m of 76 mm dia. wire Reinforcements and preparations for later installation of :

Brake holding load: 500 tonnes on 1st layer • A-frame, SWL 250 tonnes

• Spooling gear for the AH drum, max. sideload 60 tonnes • Offshore crane, 1200 tonnes m

• Two declutchable towing / working drums Also: ROV switchboard, 2 x 1500 kVA transformers

Capacity: 3600 m of 76 mm dia. wire + 3% tolerance

Brake holding load: 750 tonnes on 1st layer

www.ulsteingroup.com

ULSTEIN VERFT AS

Ulstein Verft AS is one of the world’s foremost suppliers of advanced vessels;

primarily anchor handling tug supply vessels, platform supply vessels and specialised

and multifunctional vessels. The shipyard serves as the Ulstein Group’s development

base for the detail design and assembling of capital and equipment intensive

specialised vessels and is the Group’s most important expertise base for carrying out

projects.

ULSTEIN GROUP

Ulstein Group is a world-leading brand, and supplier of products and services

within ship design, shipbuilding, power & control systems and aftermarket. With

many group companies forming an integrated value chain, Ulstein has the ability

to integrate and control the strategic components of a project - from idea to vessel

in operation. The Group has about 800 employees, subsidiaries in 9 countries, with

head office in Ulsteinvik, Norway.

CONTACT

Ulstein Verft AS

NO-6067 Ulsteinvik

NORWAY

Tel: + 47 7000 8000

www.ulsteingroup.com

April 22, 2010 12:38 PM

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- SBT LNG 07 v1Documento10 páginasSBT LNG 07 v1Erwin Paulian SihombingAinda não há avaliações

- Certification and Verification of Pipelines: Offshore Service Specification DNV-OSS-301Documento60 páginasCertification and Verification of Pipelines: Offshore Service Specification DNV-OSS-301Erwin Paulian SihombingAinda não há avaliações

- DNV Rules For Woodenships 1970Documento146 páginasDNV Rules For Woodenships 1970Erwin Paulian Sihombing0% (1)

- Mooring Rules Operations SPMBerthsDocumento10 páginasMooring Rules Operations SPMBerthsErwin Paulian SihombingAinda não há avaliações

- NSTM Chapter 582 Mooring TowingDocumento150 páginasNSTM Chapter 582 Mooring Towingvzagkas50% (2)

- Publication List Classification AND Related Services: APRIL 2011Documento18 páginasPublication List Classification AND Related Services: APRIL 2011Erwin Paulian SihombingAinda não há avaliações

- SNV2007 Karine Savreux 22Documento10 páginasSNV2007 Karine Savreux 22Erwin Paulian SihombingAinda não há avaliações

- LR Guidance For LifeboatsDocumento6 páginasLR Guidance For LifeboatsPan Karas XtraAinda não há avaliações

- Exxon MESQAC 2010Documento55 páginasExxon MESQAC 2010G_ARVALIS8470100% (1)

- Brosurclass 1Documento2 páginasBrosurclass 1Erwin Paulian SihombingAinda não há avaliações

- Loadline SurveyDocumento10 páginasLoadline SurveyRachana Chandra0% (1)

- EEDI Guidance Notes For Clients v2.0 - tcm155-232077Documento18 páginasEEDI Guidance Notes For Clients v2.0 - tcm155-232077Erwin Paulian SihombingAinda não há avaliações

- Revised Marpol Annex Vi: NO Technical Code 2008Documento10 páginasRevised Marpol Annex Vi: NO Technical Code 2008Erwin Paulian SihombingAinda não há avaliações

- 85 Inf 4Documento3 páginas85 Inf 4Erwin Paulian SihombingAinda não há avaliações

- Propulsi - Minggu 5Documento19 páginasPropulsi - Minggu 5Erwin Paulian SihombingAinda não há avaliações

- B1b StabilityDocumento17 páginasB1b StabilityDarwin Neil MoranoAinda não há avaliações

- IntroductionDocumento29 páginasIntroductionErwin Paulian SihombingAinda não há avaliações

- Previa AT Full SpecDocumento6 páginasPrevia AT Full SpecErwin Paulian SihombingAinda não há avaliações

- Project Guide Wartsila38Documento186 páginasProject Guide Wartsila38Erwin Paulian Sihombing50% (2)

- Abrasives Sand Steel Abrasive CostDocumento3 páginasAbrasives Sand Steel Abrasive CostRio HandokoAinda não há avaliações

- Engine Selection Guide-MANDocumento294 páginasEngine Selection Guide-MANlgbrangelAinda não há avaliações

- KiwilDocumento8 páginasKiwilErwin Paulian SihombingAinda não há avaliações

- Cover AmandemenDocumento3 páginasCover AmandemenErwin Paulian SihombingAinda não há avaliações

- HeaterDocumento12 páginasHeaterErwin Paulian SihombingAinda não há avaliações

- RWO Folder Oily Water SepDocumento4 páginasRWO Folder Oily Water SepErwin Paulian SihombingAinda não há avaliações

- Firepump PrintDocumento4 páginasFirepump PrintErwin Paulian SihombingAinda não há avaliações

- Vs - e (Ballast Hendra)Documento2 páginasVs - e (Ballast Hendra)Erwin Paulian SihombingAinda não há avaliações

- Compressed AirDocumento5 páginasCompressed AirErwin Paulian SihombingAinda não há avaliações

- Oily Water Bilge System Pump - ONDocumento5 páginasOily Water Bilge System Pump - ONErwin Paulian SihombingAinda não há avaliações

- KS091302 Week01A Course OverviewDocumento19 páginasKS091302 Week01A Course OverviewErwin Paulian SihombingAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Trading Ships of The South China Sea - ShipbuildingDocumento29 páginasTrading Ships of The South China Sea - ShipbuildingmrohaizatAinda não há avaliações

- Offshore Patrol Vessel For CCGDocumento87 páginasOffshore Patrol Vessel For CCGParbati SahaAinda não há avaliações

- Analisis Stabilitas Kapal Eagle ValleryDocumento7 páginasAnalisis Stabilitas Kapal Eagle Valleryakmal nagibAinda não há avaliações

- Lop Free WaterDocumento2 páginasLop Free WaterVicentiu Alexandru Grama100% (2)

- ABS Thickness Measurement Requirement For Ship in Operation PDFDocumento2 páginasABS Thickness Measurement Requirement For Ship in Operation PDFMohd Fouzi AbdullahAinda não há avaliações

- NA Problems 1Documento3 páginasNA Problems 1siddarth amaravathi100% (1)

- NA QB Numerical 2010-092023Documento40 páginasNA QB Numerical 2010-092023Apoorv SinghAinda não há avaliações

- Ship ParticularsDocumento1 páginaShip ParticularsPerdanaAinda não há avaliações

- Design of The Anchoring EquipmentDocumento14 páginasDesign of The Anchoring Equipmentnarendra_katdareAinda não há avaliações

- Management For The Safe Operation of Ships: Regulation 1Documento3 páginasManagement For The Safe Operation of Ships: Regulation 1didoniphicAinda não há avaliações

- Incident at Sea (Word File)Documento10 páginasIncident at Sea (Word File)Dappaa ZahrAinda não há avaliações

- Data Kapal LNG Dan LPGDocumento68 páginasData Kapal LNG Dan LPGDaniel WeeksAinda não há avaliações

- Kapal Tanker TRGDocumento4 páginasKapal Tanker TRGDWI NDARUAinda não há avaliações

- AHTS HAILEY SARAH (5150 HP - 65 Tons - DP1)Documento3 páginasAHTS HAILEY SARAH (5150 HP - 65 Tons - DP1)Fajar SetiawanAinda não há avaliações

- Framing ConstructionDocumento12 páginasFraming ConstructionTruculent TrinoyAinda não há avaliações

- Draught Survey An Introduction and Principles AISIDocumento99 páginasDraught Survey An Introduction and Principles AISIArdiansyah Pratama100% (3)

- HMC Equipment - 01Documento16 páginasHMC Equipment - 01abaoub atefAinda não há avaliações

- Vessel Information SheetDocumento6 páginasVessel Information SheetJhun EspinaAinda não há avaliações

- Chapter 102 Naval Ship Technology Hull Structures and Ship Equipment 2013Documento301 páginasChapter 102 Naval Ship Technology Hull Structures and Ship Equipment 2013Mogie Talampas100% (1)

- Sailing Manual IntermediateDocumento22 páginasSailing Manual IntermediateEmilAinda não há avaliações

- Battleship Row Card Printing Tool v2Documento49 páginasBattleship Row Card Printing Tool v2Doug BirtlesAinda não há avaliações

- A Family Sailboat: William W. AtkinDocumento3 páginasA Family Sailboat: William W. AtkinFer IbáñezAinda não há avaliações

- HovercraftDocumento23 páginasHovercraftankita_friends100Ainda não há avaliações

- Fentek Catalogue Sept02 Part 43995Documento14 páginasFentek Catalogue Sept02 Part 43995Doan TuấnAinda não há avaliações

- Engleza MarinareascaDocumento26 páginasEngleza MarinareascaPetrache BogdanAinda não há avaliações

- United Federation of Planets: Federation Commander Master Ship ChartDocumento9 páginasUnited Federation of Planets: Federation Commander Master Ship ChartEdmundBlackadderIVAinda não há avaliações

- Bridge ChecklistsDocumento13 páginasBridge ChecklistsfernshaAinda não há avaliações

- Phase 2 - LAW - SS 2Documento1.355 páginasPhase 2 - LAW - SS 2LAUKIK SINGH PADIYARAinda não há avaliações

- Power Failure DrillDocumento2 páginasPower Failure DrillAbu Syeed Md. Aurangzeb Al Masum100% (1)

- 04-NAC-Initial Transverse Stability (180514) - StudentDocumento23 páginas04-NAC-Initial Transverse Stability (180514) - StudentGilles MathieuAinda não há avaliações