Escolar Documentos

Profissional Documentos

Cultura Documentos

Spro 60 Facility Requirements Poster PDF

Enviado por

BrahimMedjberTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Spro 60 Facility Requirements Poster PDF

Enviado por

BrahimMedjberDireitos autorais:

Formatos disponíveis

TM ®

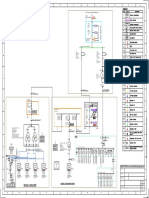

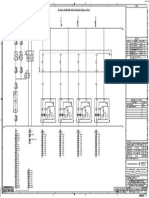

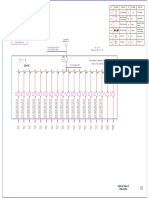

Chiller power panel

§

single phase

Transformer

(step-up or step-down)

Process station power panel

§

3-phase

sPro 60 SLS Center

§

separate from §

customer supplied/installed §

separate from chiller power

N2 process station power

§

4 models available from

3D Systems

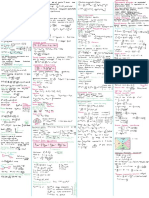

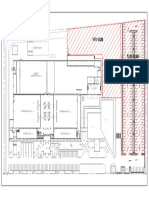

Room

3658 mm

Minimum Clearance Width Depth Height

N2 N2

1219 mm (48 in)

§

required if facility does not have 457 cm 366 cm 305 cm

240 VAC, 3-phase, 50/60 Hz, Room

15 ft 12 ft 10 ft

213 cm – 244 cm

1219 mm (48 in)

Access door

7 ft – 8 ft

Floor

CHILLER N2 supply Room area oxygen monitor

Facility Requirements

Bulk nitrogen tank Nitrogen dewars First floor installation Required

recommended

§ 4572 mm Vibration-free

Preferred

§

99.999% pure nitrogen 99.999% pure nitrogen

§

customer supplied/installed Uncarpeted

connect dewars with auto-switching §

§

option for high nitrogen demand sites § Level and flatness within 25.4 mm (1 in) below process station

manifold(s) to ensure constant N2 optional process station power shutoff

§ Distributed load-bearing capacity 0.024 bar (50 psf) on seven 100 mm (4 in) dia. pads

§

suitable for LaserForm Oven N2 supply supply during build safety interlock (3D Systems must

suitable for LaserForm Oven

§

N2 exhaust connect)

N2 supply safety interlock contact rating: 10 A

§

Atmosphere

Heating and air conditioning installed;

Room temperature controls

A/C not blowing on top of process station

Operating range: (16 to 27)° C; (60 to 80)° F

Nitrogen System Options 1, 2 or 3. Temperature Setpoint range: (18 to 24)° C; (65 to 75)° F

Stability: ± 2° C (± 5° F)

Non-condensing relative humidity No higher than 70%

Room air changes 4 per hour minimum

Maximum: 3516 W (12000 Btu/h)

Heat dissipation

Average: 2110 W (7200 Btu/h)

1016 mm (40 in) Atmospheric corrosives None

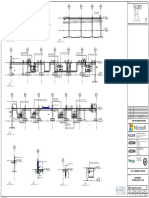

Nitrogen exhaust

TOP

3658 mm (12 ft)

§

¾ inch NPT male fitting at top of

Nitrogen inlet process station for exhaust hose

¼ inch NPT male fitting at top of §

exhaust to outside at Coolant Electrical

Nitrogen generator process station for inlet hose 1 in (25.4 mm) H2O

Process station input voltage (240 ± 5%) VAC, 3-phase, 50/60 Hz, 12.5 kVA

§

not suitable for LaserForm Oven Normal operating current (20 to 25) A

N2 supply Distilled water (only) Peak operating current 30 A

§

99.9% pure nitrogen

N2 N2 H2O H 2O

customer supplied

§

required for installation

§

On/Off breaker rating

Power cable (for 3-phase power)

Power cable circuit breaker wiring

40 A

4-conductor; wire size according to local electrical code

phase 1 to FD1-L1; phase 2 to FD1-L2; phase 3 to FD1-L3

do not use deionized water

§

or tap water §

The 3-phase power cable and cable gland (cord grip) are customer supplied and installed.

The cable feeds through the gland on the top of the process station.

NITROGEN NITROGEN §

Connect the power cable ground wire to the ground bus bar in the process station's

INLET EXHAUST Glycol power distribution enclosure.

COOLANT

OUTLET

+ Glycol

customer supplied

§

required for installation

§

100% ethylene glycol

§

source: McMaster Carr

PROCESS STATION

§

Connect the process station to a dedicated power circuit.

§

The electrical systems in the Vanguard SLS System process station and computer cabinet

meet U.S. and European standards for electrical noise suppression. If your facility power noise

levels exceed the applicable standard, install an isolation filter in series between the power

panel and the process station.

COOLANT

INLET

Process Station Facility Power Transformer

coolant mix A customer-supplied step-up or step-down transformer is required if the facility does not have

Coolant hoses 240 VAC, 3-phase, 50/60 Hz, 12.5 kVA power. 3D Systems stocks four transformers:

§

included with 3D Systems-supplied chiller

2 :1 Transformer Type 3D Systems Part No. Output

Step-up 5600-03538 208 to 240 VAC; 3-phase; 60 Hz

½ inch NPT male barbed Pushloc® fittings

§ coolant capacity

Room telephone Step-down 5600-03539 400 to 240 VAC; 3 phase; 50 Hz

1009 mm (40 in)

30 L (8 gal) §

recommended

Step-down (CE approved)

Step-down

5600-03539-EUR

5600-03768

400 to 240 VAC; 3 phase; 50 Hz

480 to 240 VAC; 3 phase; 60 Hz

§

customer supplied/installed

Coolant out §3D Systems customer support hotline

§

If you purchase a transformer from a supplier other than 3D Systems, specify a "delta-to-wye"

or "wye-to-wye" primary-to-secondary configuration.

1-800-793-3669 §

Connect the transformer secondary neutral to the transformer secondary ground.

Coolant in CAUTION: Do not connect the transformer secondary neutral to the process station ground.

Room temperature

CEILING A/C Air Conditioning max 27° C (80° F) setpoint and stability Chiller

§

required

§

set temperature between

18° C and 24° C (65° F and 75° F)

Part Finishing Area* §

These requirements only apply to the 3D Systems-supplied chiller.

suspend hoses

from ceiling

§

do not install vent directly

above process station

min 16° C (60° F) §

temperature should be constant to

±2° C (± 5° F)

Chiller Electrical

230 VAC, 60 Hz, single phase, 10 A

*see separate Part Finishing Facility Requirements drawing Facility power 200 VAC, 50 Hz, single phase, 10 A

N2 Step-up or step-down transformer

Wiring

240 VAC, 50 Hz, single phase, 10 A

May be required to modulate power

Ground wire cannot be used for neutral (return)

Nitrogen inlet and exhaust hoses 4572 mm (15 ft) NOTE: The single phase chiller power source must be separate from the 3-phase

process station power source.

§

drop down from ceiling Process station power cable

§

keep exhaust line as short as possible §

drop down from ceiling Chiller Coolant

Distilled water 2 parts Use only distilled water; do not use deionized water or tap water

§

route through cable gland at top of process station ®

H2O H2O Glycol 1 part 100% pure ethylene glycol (preferred) or DowFrost propylene glycol

§

connect to power distribution panel Coolant capacity 30 L (8 gal)

§

Coolant is customer-supplied and must be available at installation.

+ Glycol

§

100% pure ethylene glycol is available through McMaster-Carr in 1 and 5 gallon containers.

3126 mm (123 in) Request part no. 3190K246 (5 gal size—recommended).

To order, call 404-346-7000 (U.S. only) or see www.mcmaster.com

§

If local toxic chemical regulations do not permit use of ethylene glycol in the Vanguard

®

facility, use DowFrost propylene glycol manufactured by The Dow Chemical Company.

3048 mm (120 in)

N2 Nitrogen

Purity

Nitrogen line fittings

99.998%

Inlet: ¼ in NPT male; Exhaust: ¾ in NPT male

2730 mm (107.5 in)

Continuous flow 9 lpm (19 scfh) for length of build

Continous flow of 9 lpm (19 sc fh) plus

Purge flow

165 lpm (350 scfh) maintaining 1.03 bar (15 ps i) for 25 min

Exhaust Mus t exhaust to outside at pressure 0.0025 bar (1.0 in H2 O)

1050 mm (41.3 in) Week ly consumption

3 3

120 m (4240 ft ) of N2 gas based on 24 h/day operation with 7 purge cycles

2618 mm (103 in)

1996 mm (78.6 in)

§

Nitrogen supply and exhaust systems are customer supplied and installed.

1430 mm (56.3 in) §

If you plan to use the process station’s nitrogen supply for a LaserForm Oven, use liquid or

bottled nitrogen with a purity of at least 99.998%. The 99.9% nitrogen produced by nitrogen

559 mm generators is not sufficiently pure for metals processes.

(22 in)

FRONT

813 mm (32 in)

SIDE Fork lift slots

§

use 183 cm (6 ft) forks

§

do not lift from side

Preliminary © July 2009 by 3D Systems Corporation All Rights Reserved

Você também pode gostar

- Instant Assessments for Data Tracking, Grade 4: MathNo EverandInstant Assessments for Data Tracking, Grade 4: MathNota: 5 de 5 estrelas5/5 (2)

- Eternal Source of Light Divine - Document PDFDocumento2 páginasEternal Source of Light Divine - Document PDFMariana_Peimbe_1236100% (5)

- Allison Trans PDFDocumento748 páginasAllison Trans PDFoundilahmed100% (5)

- Thread Make-Up ProcedureDocumento5 páginasThread Make-Up ProcedureVova PanchenkoAinda não há avaliações

- Mcdowall - Ave Maris StellaDocumento3 páginasMcdowall - Ave Maris Stellariverfall0% (2)

- Manual 3306 Caterpillar PDFDocumento4 páginasManual 3306 Caterpillar PDFmuhammad aliAinda não há avaliações

- Timing Cover 190EDocumento8 páginasTiming Cover 190ESergio Belmar CrisostoAinda não há avaliações

- MDPE WORK PROCEDURE For GailDocumento59 páginasMDPE WORK PROCEDURE For GailSaravanan100% (1)

- Flight of The Bumble-Bee - For Cello and Piano PDFDocumento5 páginasFlight of The Bumble-Bee - For Cello and Piano PDFgilneiAinda não há avaliações

- Technical Description: Gas-Insulated, Metal-Enclosed Medium-Voltage SwitchgearDocumento19 páginasTechnical Description: Gas-Insulated, Metal-Enclosed Medium-Voltage SwitchgearNedyHortetlAinda não há avaliações

- E-1004 As-Built Resubmittal ABP 1-As-Built AR-1Documento1 páginaE-1004 As-Built Resubmittal ABP 1-As-Built AR-1Ace LangAinda não há avaliações

- Highland Drive Project Scope-Mountain Road, Becker County, July 20, 2022Documento1 páginaHighland Drive Project Scope-Mountain Road, Becker County, July 20, 2022Michael AchterlingAinda não há avaliações

- Ahw 10 103500 Ea 2373 00053 0002 Noy0000y0812 CH 02Documento8 páginasAhw 10 103500 Ea 2373 00053 0002 Noy0000y0812 CH 02Parag Lalit SoniAinda não há avaliações

- Metro MapDocumento1 páginaMetro MapTim HermansAinda não há avaliações

- Elétrico Odete - 2modelDocumento1 páginaElétrico Odete - 2model381138deAinda não há avaliações

- Ilide - Info Caterpillar Gas Engine 3516 Schematic Diagram PRDocumento2 páginasIlide - Info Caterpillar Gas Engine 3516 Schematic Diagram PRTamAinda não há avaliações

- 2019 System Map COVID-19 Stations FINALDocumento1 página2019 System Map COVID-19 Stations FINALwtopwebAinda não há avaliações

- ELECTRICODocumento1 páginaELECTRICOErwin Grimaldo Elera ContrerasAinda não há avaliações

- Circuit Energi MeterDocumento2 páginasCircuit Energi MeterYusuf PranotoAinda não há avaliações

- 4Documento4 páginas4Abstruse RonAinda não há avaliações

- Kinda Shizz (Score)Documento4 páginasKinda Shizz (Score)madmegdigital8753Ainda não há avaliações

- Canalización y AlimentadoresDocumento9 páginasCanalización y AlimentadoresLEONEL VILCAAinda não há avaliações

- DIAGRAMA UNIFILAR IE-DU-01 Ver 2Documento1 páginaDIAGRAMA UNIFILAR IE-DU-01 Ver 2Mane VazAinda não há avaliações

- Map CityDocumento1 páginaMap CityMian Channu Campus100% (1)

- Annapolis River WatershedDocumento1 páginaAnnapolis River WatershedPietersmaAinda não há avaliações

- A.104-Basement Floor PDFDocumento1 páginaA.104-Basement Floor PDFdothi aiuyenAinda não há avaliações

- JW Pump Curve - F3514g-F3524g-F3524gsiDocumento1 páginaJW Pump Curve - F3514g-F3524g-F3524gsikman548Ainda não há avaliações

- Block-1 Siss-4MwDocumento1 páginaBlock-1 Siss-4Mwahmad alregebAinda não há avaliações

- SAP16P: Absolute Maximum Ratings Electrical CharacteristicsDocumento6 páginasSAP16P: Absolute Maximum Ratings Electrical Characteristicsr_cristiAinda não há avaliações

- Formulaire GMRT 1Documento1 páginaFormulaire GMRT 1martaAinda não há avaliações

- Noite Feliz Mateus CarraroDocumento41 páginasNoite Feliz Mateus CarraroAna Carolina SoaresAinda não há avaliações

- Irrigation Water PointDocumento15 páginasIrrigation Water PointWING HONG FUNGAinda não há avaliações

- JMPGuitars 18W Xtra TMB LayoutDocumento1 páginaJMPGuitars 18W Xtra TMB LayoutRenan Franzon GoettenAinda não há avaliações

- Claudare Stree T: Not For ConstructionDocumento1 páginaClaudare Stree T: Not For Constructionfehmeen zehraAinda não há avaliações

- Technics Su-Vz320 Amplifier SCHDocumento1 páginaTechnics Su-Vz320 Amplifier SCHasca barbesAinda não há avaliações

- Column DetailsDocumento1 páginaColumn DetailsLubangakene BrianAinda não há avaliações

- Bala 10 Plates Rev 01 FORMAT 001 000Documento1 páginaBala 10 Plates Rev 01 FORMAT 001 000Oscar MarinAinda não há avaliações

- ToneDocumento1 páginaToneNguyễn Quang TrânAinda não há avaliações

- Variations: Tema LentoDocumento8 páginasVariations: Tema Lentojoaquin6panisseAinda não há avaliações

- Rimsky Korsakov TheFlightOfTheBumbleBeeDocumento6 páginasRimsky Korsakov TheFlightOfTheBumbleBeesyslsomAinda não há avaliações

- MathDocumento1 páginaMathassal2007faisalAinda não há avaliações

- Discussion EntropyDocumento4 páginasDiscussion EntropyAyuni MokhtarAinda não há avaliações

- Tambourin: From Le Triomphe de La République, Ou Le Camp de GrandpréDocumento4 páginasTambourin: From Le Triomphe de La République, Ou Le Camp de GrandpréPat FrederickAinda não há avaliações

- Instalasi Air Kotor, Air Bekas, Dan Oil Trap + (Posisi Biotech Opsi 1) - DitandatanganiDocumento1 páginaInstalasi Air Kotor, Air Bekas, Dan Oil Trap + (Posisi Biotech Opsi 1) - DitandatanganiOis HarefaAinda não há avaliações

- Bala 08 Plates - Rev - 01 FORMAT - 001 000Documento1 páginaBala 08 Plates - Rev - 01 FORMAT - 001 000Oscar MarinAinda não há avaliações

- GR Cheat Sehe 8Documento2 páginasGR Cheat Sehe 8Sophia VentAinda não há avaliações

- AA1164 3-Way NFB Switch Mod PDFDocumento1 páginaAA1164 3-Way NFB Switch Mod PDFjosemfcAinda não há avaliações

- PL 1102.a Sistem SW LayoutDocumento1 páginaPL 1102.a Sistem SW LayoutjendrikoAinda não há avaliações

- SBECCLAYOUTDocumento1 páginaSBECCLAYOUTjedzekiel05Ainda não há avaliações

- Circuitos Eléctricos: Christian Lorenzo Carreon SilvaDocumento68 páginasCircuitos Eléctricos: Christian Lorenzo Carreon SilvaENIC-AITCGAinda não há avaliações

- SWR UpdatedDocumento1 páginaSWR Updatedram prasad meenaAinda não há avaliações

- Single Line Diagram Gardu Induk Indarung V: 158 5R1 5TB1 5J1 5W1 5W/5U1 5K1 5Z2 5Z1Documento1 páginaSingle Line Diagram Gardu Induk Indarung V: 158 5R1 5TB1 5J1 5W1 5W/5U1 5K1 5Z2 5Z1Silver SoulAinda não há avaliações

- 115/13.8kV TRANSFORMER (T602) PROTN. SET-1 PANEL-1 +TRPA.21Documento1 página115/13.8kV TRANSFORMER (T602) PROTN. SET-1 PANEL-1 +TRPA.21Anonymous BZQOJwWIh6Ainda não há avaliações

- CARegions 060816Documento1 páginaCARegions 060816BayAreaNewsGroupAinda não há avaliações

- M500 EeDocumento1 páginaM500 Eeapi-3711045Ainda não há avaliações

- V1a TR 20002Documento4 páginasV1a TR 20002bambangAinda não há avaliações

- Voltages / LoadingDocumento1 páginaVoltages / LoadingErick Vazquez PachecoAinda não há avaliações

- Site Layout FO KIK-CCTV-ARIF - New Rev4Documento1 páginaSite Layout FO KIK-CCTV-ARIF - New Rev4Adi PriyapurnatamaAinda não há avaliações

- Redes de Agua Potable Ok (1) - ModelDocumento1 páginaRedes de Agua Potable Ok (1) - ModelJHON KCOMTAinda não há avaliações

- Glacier Bay NPPDocumento1 páginaGlacier Bay NPPapi-19487128Ainda não há avaliações

- 9572-109-PVC-B-XXX (SHT-1) - R0 - Grde Slab LVL - 09042020Documento1 página9572-109-PVC-B-XXX (SHT-1) - R0 - Grde Slab LVL - 09042020MRITYUNJOY DUTTAAinda não há avaliações

- Transformer /175W Line Safety Line: MotorDocumento1 páginaTransformer /175W Line Safety Line: Motororo plataAinda não há avaliações

- CCTV Location - STA1400WANAMARTADocumento1 páginaCCTV Location - STA1400WANAMARTAAdi PriyapurnatamaAinda não há avaliações

- M3SD K003 Gen Hyd01 C DTL 0049 0Documento1 páginaM3SD K003 Gen Hyd01 C DTL 0049 0Shreyas ChawaleAinda não há avaliações

- P4 SLD 2019 PLIRE - Recover-ModelDocumento1 páginaP4 SLD 2019 PLIRE - Recover-ModelMd Shamim RezaAinda não há avaliações

- Building Face Line: Proposed Work For Mr. Sanjay Shinde, Anita Super Shopee at Khanapur, Dis. - SangliDocumento1 páginaBuilding Face Line: Proposed Work For Mr. Sanjay Shinde, Anita Super Shopee at Khanapur, Dis. - SangliRoyal JadhavAinda não há avaliações

- Exquistion Data SystematicDocumento1 páginaExquistion Data SystematicBrahimMedjberAinda não há avaliações

- 3d Systems Sls Material Selection Guide Usen 2017-10-24 WebDocumento2 páginas3d Systems Sls Material Selection Guide Usen 2017-10-24 WebBrahim MedjberAinda não há avaliações

- How To Select A Pump-By Majid HamedyniaDocumento72 páginasHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- 3d Systems Sls Material Selection Guide Usen 2017-10-24 WebDocumento2 páginas3d Systems Sls Material Selection Guide Usen 2017-10-24 WebBrahim MedjberAinda não há avaliações

- View ContentDocumento16 páginasView ContentBrahimMedjberAinda não há avaliações

- Hey There Sorry To Fool U: This Way I Can Download For FreeDocumento3 páginasHey There Sorry To Fool U: This Way I Can Download For FreeBrahimMedjberAinda não há avaliações

- Hey There Sorry To Fool U: This Way I Can Download For FreeDocumento2 páginasHey There Sorry To Fool U: This Way I Can Download For FreeBrahimMedjberAinda não há avaliações

- DocuDocumento1 páginaDocuBrahimMedjberAinda não há avaliações

- MineDocumento1 páginaMineBrahimMedjberAinda não há avaliações

- Etnyre Centenial A 130 12Documento19 páginasEtnyre Centenial A 130 12Juan Gonzalez0% (1)

- Toro Riding Mower LX460 13ax60rg744 Owners ManualDocumento36 páginasToro Riding Mower LX460 13ax60rg744 Owners ManualFrank Dreistadt0% (1)

- ML C 525a C525amm44Documento9 páginasML C 525a C525amm44Sawan KumarAinda não há avaliações

- Ac & DC Uninterruptible Power Supply Systems and D.C. Back-Up Power Supply SystemsDocumento31 páginasAc & DC Uninterruptible Power Supply Systems and D.C. Back-Up Power Supply SystemsKthiri WaelAinda não há avaliações

- AD1865Documento12 páginasAD1865slobodan.jovanovic.jaAinda não há avaliações

- Trn-Se-Sk 1613 BS Ii Cat PDFDocumento379 páginasTrn-Se-Sk 1613 BS Ii Cat PDFrejaul6hossainAinda não há avaliações

- 106105163Documento1.044 páginas106105163Amandeep SinghAinda não há avaliações

- Keep Forklift Operators WarmDocumento2 páginasKeep Forklift Operators WarmEdgardo Isrrael Heredia SolanoAinda não há avaliações

- MVSSDocumento2 páginasMVSSManuel RoblesAinda não há avaliações

- ND3361 Lesson 01 Products Sep 14Documento40 páginasND3361 Lesson 01 Products Sep 14Josel ArevaloAinda não há avaliações

- Cable Breakout Units: Fibre Optic SolutionsDocumento2 páginasCable Breakout Units: Fibre Optic SolutionsEhsan RohaniAinda não há avaliações

- Vimar EIKON EVO Brochure Reduced PDFDocumento100 páginasVimar EIKON EVO Brochure Reduced PDFKyriacos EllesAinda não há avaliações

- Internal Arc Testing of MV Switchgear IEC 62271200 Part TwoDocumento4 páginasInternal Arc Testing of MV Switchgear IEC 62271200 Part TwoMohammed MadiAinda não há avaliações

- Volvo 2010 Supplement v70 08 Xc70 08 s80 07 Wiring DiagramDocumento20 páginasVolvo 2010 Supplement v70 08 Xc70 08 s80 07 Wiring DiagramTina100% (40)

- 5100 ManualDocumento33 páginas5100 ManualamenstoAinda não há avaliações

- Variable Refrigerant FlowDocumento15 páginasVariable Refrigerant FlowHoward RoarkAinda não há avaliações

- Max 3420 eDocumento23 páginasMax 3420 eGabriel CotignolaAinda não há avaliações

- Aeroplane 01.2020Documento108 páginasAeroplane 01.2020Maxi RuizAinda não há avaliações

- Electric Drives and Static Control: ObjectivesDocumento3 páginasElectric Drives and Static Control: ObjectivesSairaj VanaparthiAinda não há avaliações

- Herrenknecht Raise Boring Rig Rbr400Vf: Powerful Shaft BoringDocumento2 páginasHerrenknecht Raise Boring Rig Rbr400Vf: Powerful Shaft BoringvcampurojasAinda não há avaliações

- Master Parts Manual For All Kent Redline Air ToolsDocumento32 páginasMaster Parts Manual For All Kent Redline Air ToolsFernandoAinda não há avaliações

- Product Overview: NCP1014: High Voltage Switching Regulator For Offline SMPSDocumento2 páginasProduct Overview: NCP1014: High Voltage Switching Regulator For Offline SMPSSegundo Santiago Cardenas VasquezAinda não há avaliações

- Badger Airbrush AccessoriesDocumento6 páginasBadger Airbrush AccessoriesZim ZumAinda não há avaliações

- Manual contrAA 800 enDocumento140 páginasManual contrAA 800 enHumberto GuzmanAinda não há avaliações