Escolar Documentos

Profissional Documentos

Cultura Documentos

What Is The Difference Between WBM and WMM With Respect To Civil Engineering

Enviado por

prasadnn2001Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

What Is The Difference Between WBM and WMM With Respect To Civil Engineering

Enviado por

prasadnn2001Direitos autorais:

Formatos disponíveis

What is the difference between WBM and WMM

with respect to civil engineering?

Details -

The differences between WBM and WMM are -

1. Components -

a. WBM -

i. Coarse Aggregates ( 90 mm - 45 mm for sub-base course) &

(63 mm - 4 mm & 53 mm - 22.4 mm for base course) Hand broken aggregate

can be used.

ii. Screenings - Stone/Gravel/Moorum - Fraction passing 75

micron sieve < 10 %, LL << 20 & PI << 6

iii. Binder Material - Fine grained material with PI << 6

b. WMM -

i. Aggregates need to be crusher run - Grading 1 (53 mm - 75

micron) for layer thickness greater ≥≥ 100 mm & Grading 2 for layer

thickness << 100 mm (26.5 mm - 75 micron)

ii. OMC varies between 2 % - 6%

2. Construction Sequence -

a. WBM - Each component is laid in a phased manner

i. Spreading of coarse aggregates by templates or motor graders,

and, and compaction using 80–100 kN roller

ii. Screening is applied in three or more successive layers, to fill

the voids in CA, accompanied with brooming & dry rolling (80–100 kN roller)

iii. Water is sprinkled & wet screenings are distributed evenly &

forced into the voids by brooming & rolling.

iv. Binding material is applied in two or more successive layers,

followed by sprinkling of water, and the resultant slurry is swept into the voids

by brooming & rolling (80–100 kN roller)

b. WMM - All components are pre-mixed in mixing plants

i. WMM is prepared in mixing plants, having MC slightly greater

than OMC, accounting for transit/evaporation losses

ii. Mix is spread by a self propelled paver finisher, and in case of

multi-layer construction bottom layer may be spread using motor graders.

iii. Rolling is done using roller having minimum static weight =

100 kN

TL;DR -

WMM is more expensive than WBM as

o it requires crusher run aggregates, whereas, larger sized hand broken

aggregates can be used in WBM

o it requires a mixing plant, a paver (to spread the WMM mix), & a

heavier roller (to compact the WMM mix). More construction equipment =

more $$$

Laying WBM is usually more labour intensive than WMM (which is why

WBM is preferred for rural roads of lower priority - ODR & VR)

WMM uses more closely graded material, in comparison with WBM, hence,

WMM is more durable and stable than WBM.

Components of WBM are laid in a phased/successive manner, whereas, all

components of WMM are mixed in a mixing plant before spreading of mix,

making the laying operation simpler & quicker (a paver being used for the

laying operation also helps)

WMM is easier to handle & compact in comparison with WBM, as the mix is

prepared in a mixing plant

Sources -

IRC 109 - 2015 (Guidelines for Wet Mix Macadam)

IRC 19 - 2005 (Standard Specifications & Code of Practice for Water Bound

Macadam)

MoRTH Specifications for Road & Bridge Works (5th Revision

Você também pode gostar

- Grading For Close Graded Granular MaterialDocumento7 páginasGrading For Close Graded Granular MaterialBilal A Barbhuiya100% (1)

- Vue - Js CheatSheetDocumento13 páginasVue - Js CheatSheetdorinadidAinda não há avaliações

- DBM Mix Design No.-1Documento81 páginasDBM Mix Design No.-1pujan patel100% (1)

- Painting of BridgesDocumento4 páginasPainting of Bridgesradhakrishnang100% (1)

- Original Ground Level-Ogl CompactionDocumento3 páginasOriginal Ground Level-Ogl CompactionCheng Engi100% (2)

- WBMDocumento19 páginasWBMAnshul Tiwari75% (4)

- Ac 133Documento7 páginasAc 133thirumalaichettiar100% (2)

- Is:4990-1993, Plywood For Concrete Shuttering Work - SpecificationDocumento22 páginasIs:4990-1993, Plywood For Concrete Shuttering Work - Specificationrpagarwal2100% (1)

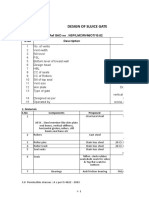

- Design of Vertical Type Drop On Permeable Foundation Hydraulic ParticularsDocumento17 páginasDesign of Vertical Type Drop On Permeable Foundation Hydraulic Particularsprasadnn2001Ainda não há avaliações

- SDB Volume-II 2nd Revision - AllDocumento970 páginasSDB Volume-II 2nd Revision - Allsrinivas palnati100% (1)

- 1offtake Gates DesignDocumento26 páginas1offtake Gates Designprasadnn2001Ainda não há avaliações

- PMB - Is 15462 - 2019Documento20 páginasPMB - Is 15462 - 2019vinayaka.vr100% (1)

- RE Wall ConstructionDocumento80 páginasRE Wall ConstructionV Venkata Narayana88% (8)

- BC Job MixDocumento3 páginasBC Job MixSOIGNE ENGINEERING CONSULTANTSAinda não há avaliações

- Atelier Clandestin 50 Special Dungeon RoomsDocumento27 páginasAtelier Clandestin 50 Special Dungeon RoomsEmma PileAinda não há avaliações

- Sieve Analysis of Wet Mix MacadamDocumento2 páginasSieve Analysis of Wet Mix Macadamjitendra100% (1)

- Marth 1800 PrestressingDocumento17 páginasMarth 1800 PrestressingRamesh100% (4)

- WMM Density ExamplesDocumento65 páginasWMM Density ExamplesV Venkata Narayana75% (8)

- What Is PQC PDFDocumento19 páginasWhat Is PQC PDFLASA VADODARAAinda não há avaliações

- Mistake in Bitumen Content Assessment in OGPC and SC in APDocumento14 páginasMistake in Bitumen Content Assessment in OGPC and SC in APPrakasam VemavarapuAinda não há avaliações

- Annexure 5.14 BC Mix DesignDocumento10 páginasAnnexure 5.14 BC Mix Designmiesty50% (2)

- En1991 1 4 SseDocumento30 páginasEn1991 1 4 Sseprasadnn2001Ainda não há avaliações

- Reasons For Cube FailureDocumento3 páginasReasons For Cube Failureharish chandra78% (9)

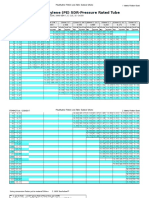

- Hdpe Pipe InformationDocumento21 páginasHdpe Pipe Informationprasadnn2001Ainda não há avaliações

- IS: 73 - 1992 Paving Bitumen - SpecificationDocumento7 páginasIS: 73 - 1992 Paving Bitumen - SpecificationKarthikeyan Vedi83% (6)

- Is 10262-2019 PDFDocumento44 páginasIs 10262-2019 PDFMaulik Panseriya100% (1)

- FDD-Sand Replacement MethodDocumento5 páginasFDD-Sand Replacement MethodRitesh Kumar100% (1)

- Analysis, Specification and Estimate On Road WorksDocumento71 páginasAnalysis, Specification and Estimate On Road WorksAnonymous BACdUNvPZ280% (5)

- WBM (Water Bound Macadam) RoadsDocumento13 páginasWBM (Water Bound Macadam) RoadssatishsajjaAinda não há avaliações

- M 30 Concrete Mix Design FinalDocumento10 páginasM 30 Concrete Mix Design FinalRakesh ReddyAinda não há avaliações

- Irc SP 139-2023Documento41 páginasIrc SP 139-2023anant11235Ainda não há avaliações

- Codes List For BridgesDocumento6 páginasCodes List For Bridgesagsanghani100% (6)

- Price Variation Bid Project Cost in HAMDocumento6 páginasPrice Variation Bid Project Cost in HAMUmesh Mishra100% (2)

- DESIGN OF PRESSURE VESSEL Full Report DEDocumento48 páginasDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (1)

- Check List Formate DLC & GSBDocumento2 páginasCheck List Formate DLC & GSBvinay rode100% (1)

- RE Wall-Construction Methodology-15-23Documento9 páginasRE Wall-Construction Methodology-15-23NITESH SINGH80% (5)

- Barcos de Concreto (Inf)Documento257 páginasBarcos de Concreto (Inf)hectorSTAinda não há avaliações

- Sjbit CIVIL-VI-HYDRAULIC-STRUCTURES-AND-IRRIGATION-DESIGN-DRAWIN-10CV65-NOTES PDFDocumento93 páginasSjbit CIVIL-VI-HYDRAULIC-STRUCTURES-AND-IRRIGATION-DESIGN-DRAWIN-10CV65-NOTES PDFprasadnn2001100% (2)

- Band Drain DesignDocumento11 páginasBand Drain Designprasadnn2001Ainda não há avaliações

- Band Drain DesignDocumento11 páginasBand Drain Designprasadnn2001Ainda não há avaliações

- 15 Profile CorrectionDocumento3 páginas15 Profile CorrectionAnish Panchal100% (1)

- Concrete Mix Design M25 PDFDocumento8 páginasConcrete Mix Design M25 PDFJEFFY JACOBAinda não há avaliações

- Methodology For Dry Lean Cement Concrete (D.L.C)Documento3 páginasMethodology For Dry Lean Cement Concrete (D.L.C)Anish Panchal100% (2)

- BBM Specification (227 229)Documento3 páginasBBM Specification (227 229)mayur_lanjewar100% (4)

- Hot Mix Plant Calibration, Laying & TestingDocumento55 páginasHot Mix Plant Calibration, Laying & Testingjaffna88% (17)

- Check List of PQCDocumento2 páginasCheck List of PQCkrishna67% (3)

- IRC SP 84 2014 Metal CrashBarrierDocumento11 páginasIRC SP 84 2014 Metal CrashBarrierbansal group100% (1)

- Wet Mix Macadam (WMM) Technical Specifications As Per MORTH and Indian StandardDocumento40 páginasWet Mix Macadam (WMM) Technical Specifications As Per MORTH and Indian StandardRAMPALLI GATTAIAH0% (1)

- Mix Design For Dry Lean ConcreteDocumento3 páginasMix Design For Dry Lean ConcreteKunal Paul100% (2)

- National Highways Authority of India.: Design Mix Summary of Semi Dense Bituminous Concrete (Grade-2)Documento37 páginasNational Highways Authority of India.: Design Mix Summary of Semi Dense Bituminous Concrete (Grade-2)Rahul Goyal100% (2)

- Mix Design M45 PDFDocumento6 páginasMix Design M45 PDFHarsh PatelAinda não há avaliações

- Design Mix M 30 PPC - CP2659-41Documento2 páginasDesign Mix M 30 PPC - CP2659-41Sathish AnandakumarAinda não há avaliações

- Short Notes On MoRTH - Embankment & Sub-BaseDocumento4 páginasShort Notes On MoRTH - Embankment & Sub-Basevino2424Ainda não há avaliações

- CTB Specification MORTH V RevDocumento4 páginasCTB Specification MORTH V RevL V Laxmipathi Rao100% (1)

- Mautic DocumentationDocumento33 páginasMautic DocumentationDVMSAinda não há avaliações

- Section 900 Quality Control For Road WorksDocumento24 páginasSection 900 Quality Control For Road WorksAmul Kotharkar73% (11)

- Six Month Training Report On Construction of Railway Overbridge PDFDocumento49 páginasSix Month Training Report On Construction of Railway Overbridge PDFGurpreet SinghAinda não há avaliações

- Is Premix Carpet Really Good For Roads in India?Documento9 páginasIs Premix Carpet Really Good For Roads in India?Prof. Prithvi Singh Kandhal100% (2)

- The Opportunities of Flexible HousingDocumento18 páginasThe Opportunities of Flexible HousingdrikitahAinda não há avaliações

- PQC Cracks Repair 1Documento3 páginasPQC Cracks Repair 1Deven PatleAinda não há avaliações

- WBM Vs WMMDocumento1 páginaWBM Vs WMMYashika Jain100% (16)

- Short Paneled Concrete Pavement - A Better Alternative Solution For Sustainability On ADocumento47 páginasShort Paneled Concrete Pavement - A Better Alternative Solution For Sustainability On ArajibchattarajAinda não há avaliações

- Detail Methodology of Premix Carpet Road in NepalDocumento2 páginasDetail Methodology of Premix Carpet Road in NepalSudip Shrestha50% (2)

- Slip Form and Fixed Form PaversDocumento63 páginasSlip Form and Fixed Form PaversShubham Pawar100% (1)

- Auramix 400Documento2 páginasAuramix 400manish lakhanpal50% (2)

- Technical Justification For Anchor Beam - Terminal SlabsDocumento1 páginaTechnical Justification For Anchor Beam - Terminal SlabsSudeep Joshi100% (1)

- DLCDocumento14 páginasDLCvijayAinda não há avaliações

- DSR Cost IndexDocumento3 páginasDSR Cost Indexతేజ చొల్లంగి100% (3)

- Cross Sectional Elements of A RoadDocumento16 páginasCross Sectional Elements of A RoadRamanarayanSankritiAinda não há avaliações

- Brick Test ReportDocumento1 páginaBrick Test Reportsudugouda100% (2)

- Morth 2900 Pipe CulvertsDocumento5 páginasMorth 2900 Pipe CulvertsRamesh100% (3)

- Methodology For Wet Mix MacadamDocumento11 páginasMethodology For Wet Mix MacadamRAMPALLI GATTAIAHAinda não há avaliações

- Transportation, Spreading, Compaction and Finishing:: Plants, Equipment and Machinery For Wet Mix MacadamDocumento6 páginasTransportation, Spreading, Compaction and Finishing:: Plants, Equipment and Machinery For Wet Mix MacadamRAMPALLI GATTAIAHAinda não há avaliações

- Element of Water Resource Engineering K.N Duggal DamsDocumento3 páginasElement of Water Resource Engineering K.N Duggal Damsprasadnn2001Ainda não há avaliações

- InfoDocumento1 páginaInfoprasadnn2001Ainda não há avaliações

- Compressive Strength Test Register For M - 30 Grade of Concrete (Illustrative Format For Acceptance Criteria)Documento10 páginasCompressive Strength Test Register For M - 30 Grade of Concrete (Illustrative Format For Acceptance Criteria)prasadnn2001Ainda não há avaliações

- Broad-Crested WeirDocumento11 páginasBroad-Crested Weirprasadnn2001Ainda não há avaliações

- Proforma C: Enroute Habitations Name / ChainageDocumento7 páginasProforma C: Enroute Habitations Name / Chainageprasadnn2001Ainda não há avaliações

- Rivas Filter DesignDocumento5 páginasRivas Filter Designprasadnn2001Ainda não há avaliações

- Foundations On Black Cotton Soil PDFDocumento4 páginasFoundations On Black Cotton Soil PDFprasadnn2001Ainda não há avaliações

- 02conversion TableDocumento3 páginas02conversion TableravirainbowAinda não há avaliações

- Asce702w - Asce 7-02 Code Wind Analysis ProgramDocumento37 páginasAsce702w - Asce 7-02 Code Wind Analysis Programprasadnn2001Ainda não há avaliações

- Natural Flow CalculatorDocumento18 páginasNatural Flow Calculatorprasadnn2001Ainda não há avaliações

- Aashhto LRFD 2007 - Concrete Deck Design: HC 17,5 CM OKDocumento7 páginasAashhto LRFD 2007 - Concrete Deck Design: HC 17,5 CM OKprasadnn2001Ainda não há avaliações

- Asce702w - Asce 7-02 Code Wind Analysis ProgramDocumento37 páginasAsce702w - Asce 7-02 Code Wind Analysis Programprasadnn2001Ainda não há avaliações

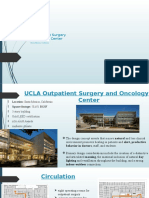

- UCLA Outpatient Surgery: and Oncology CenterDocumento24 páginasUCLA Outpatient Surgery: and Oncology CenterKaushiki Kamboj0% (1)

- AC O& M City Mall Version 1.0Documento12 páginasAC O& M City Mall Version 1.0yewminyun6098Ainda não há avaliações

- Mcafee Endpoint Security Suites Comparison Chart: Quick Reference CardDocumento2 páginasMcafee Endpoint Security Suites Comparison Chart: Quick Reference CardSven HedinAinda não há avaliações

- SOFiSTiK - Reinforcement - For - Autodesk - Revit - 1 - 2 PDFDocumento18 páginasSOFiSTiK - Reinforcement - For - Autodesk - Revit - 1 - 2 PDFDavid Carballo RetanaAinda não há avaliações

- Network Management by Sweksha Srivastava: A Project Report OnDocumento35 páginasNetwork Management by Sweksha Srivastava: A Project Report OnMonikaAinda não há avaliações

- Navicat enDocumento195 páginasNavicat enadyro12Ainda não há avaliações

- Framework For Stormwater Quality Management in SingaporeDocumento8 páginasFramework For Stormwater Quality Management in SingaporeVitor NinaAinda não há avaliações

- 3DMark06 Tes 1Documento156 páginas3DMark06 Tes 1ngototae100% (2)

- CIVIL B Tech Projects - IIT KanpurDocumento2 páginasCIVIL B Tech Projects - IIT Kanpurjayaram miryalaAinda não há avaliações

- Msi ms-7329 Rev 1.0 SCH PDFDocumento39 páginasMsi ms-7329 Rev 1.0 SCH PDFJimmys959Ainda não há avaliações

- Global Ip Office Technical Bulletin 212Documento13 páginasGlobal Ip Office Technical Bulletin 212kaylia123Ainda não há avaliações

- Roofplan and Doors ScheedueDocumento1 páginaRoofplan and Doors ScheedueSamille GarciaAinda não há avaliações

- ReferencesDocumento0 páginaReferencesDavid Aguilar BerriosAinda não há avaliações

- Osln PDFDocumento183 páginasOsln PDFAbdallah TebibAinda não há avaliações

- Pre-Chamber RegulatorDocumento3 páginasPre-Chamber RegulatorfahadullahAinda não há avaliações

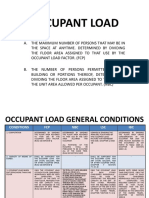

- 02 - Occupant Load General ConditionsDocumento5 páginas02 - Occupant Load General ConditionsLean Liganor100% (1)

- NEU - Statement of PurposeDocumento2 páginasNEU - Statement of PurposeAkash WaradeAinda não há avaliações

- Kss 82 Cread Cwrite enDocumento67 páginasKss 82 Cread Cwrite enEl BeppeAinda não há avaliações

- DS1847 Dual Temperature-Controlled NV Variable Resistor I2C PDFDocumento17 páginasDS1847 Dual Temperature-Controlled NV Variable Resistor I2C PDFJuan Gil RocaAinda não há avaliações

- InfiniBox With EMC VPLEX Best Practice GuideDocumento28 páginasInfiniBox With EMC VPLEX Best Practice GuideKamal ChowdhuryAinda não há avaliações

- Everspring Sm103 ManualDocumento4 páginasEverspring Sm103 ManualLokanatha ReddyAinda não há avaliações

- Catalogue - Floor Trims GuideDocumento57 páginasCatalogue - Floor Trims GuideFloorkitAinda não há avaliações

- An In-Depth Look Into The Win32 PE File Format - Matt Pietrek 2002Documento30 páginasAn In-Depth Look Into The Win32 PE File Format - Matt Pietrek 2002Alex Beldner100% (1)