Escolar Documentos

Profissional Documentos

Cultura Documentos

7 Risk Management or Mismanagement

Enviado por

Woody Bil0 notas0% acharam este documento útil (0 voto)

13 visualizações61 páginasrisk management or mismanagement

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentorisk management or mismanagement

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

13 visualizações61 páginas7 Risk Management or Mismanagement

Enviado por

Woody Bilrisk management or mismanagement

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 61

As our coal industry moves into another boom

period for the resources sector – one issue is

paramount, and that is maintaining the health

and safety of our coal mine workers.

With the ever present reminder from the

media that no job is safe, our coal mine

workers thoughts are (understandably) not

100% on the job and now more than ever is

the time for all to be truly vigilant and to look

after your workmates.

Coal Mining Safety and Health Act 1999

coal mine worker means an individual who

carries out work at a coal mine and includes

the following individuals who carry out work

at a coal mine—

(a) an employee of the coal mine operator;

(b) a contractor or employee of a contractor.

Since the inception of risk based

legislation (1999-2001) risk management

has been the instrument widely used and

often abused by the coal owners’

representatives in an effort to

expediently get the job done with

minimal regards to the risk management

requirements of our legislation, and

more importantly the safety of our coal

mine workers.

More and more, mining management teams

are referring to other State and Federal OHS

laws with legal counsel as a stand points on

safety protocols regardless of the legislation

that governs our coal industry. This being the

Queensland Coal Mining Safety and Health Act

1999 & the Queensland Coal Mining Safety

and Regulation 2001. This has led to complex

and conflicting management systems being

developed and not adequately maintained.

To clarify any misunderstanding, the term

“management” encompasses those who

control and or give directions to coal mine

workers, for example; Supervisors, Open-Cut

Examiners, ERZ Controllers, Shift Supervisors,

Ventilation Officers, Mine Managers and Site

Senior Executives. All of whom make up part

of the mine management structure and have

the relevant competencies that permit them

to legally give direction and supervision.

We must never forget that the coal mining

safety and health legislation that we, in the

coal mining industry all must adhere to is

written on the blood of our fallen comrades

that have either been made incapacitated or

have lost their lives due to being exposed to

unsafe conditions that left them vulnerable to

the risks without adequate controls in place to

either remove or minimise the exposure to

the hazard.

Risk Assessments have become the catch

cry of the day, with acronyms such as

JSA’s, JSEA’s, SLAM’s, HIT’s, Take 5’s,

WRAC’s etc... These are all useful tools in

risk assessment, but only the initial

exercise in the process of ensuring an

acceptable level of risk is achieved.

How is the coal mine worker expected to

perform or understand his or her task safely, if

given to read and sign a risk assessment pro-

forma that does not outline the steps required

to perform the task safely, when the end

game after the risk assessment is to develop

an easy to understand work procedure with

identified existing and additional controls in

place?

The majority of coal mine

workers’ openly state that risk

assessments are only performed

to permit a risky task to proceed

with the onus of risk mitigation

placed squarely at the feet of the

coal mine worker.

A case in point was a mining company that

required the removal of product from an open-

cut operation. This operation was to be

performed adjacent to a known strata faulting

(being the failing high-wall). A JSA was

performed, hazards identified and soft controls

put in place. Unfortunately, the controls were

inadequate to the extreme. These being “keep

close watch on the high-wall whilst operating

under it and move away if rocks start to fall”.

The mines management had previously

identified this area as unstable, the mine’s

geologists had advised to cease operations in

this pit and had gone so far as to equate the

amount of material that would fall. Despite

these dire concerns, coal mine workers were

directed by their supervisors to work this area

as “a JSA had been done”.

The inevitable fall of earth occurred and

approximately 30,000 tonne dislodged and fell

onto a rear-dump truck trapping the coal mine

worker (who could be your Husband, Father,

Son, Brother, Uncle, Cousin or Mate) and

leaving him with a permanent metal rod in his

back to replace his broken spine - not the way

he would have intended to come home from

work!

In the foyer of any coal mine and their

corporate offices, there is the obligatory

safety and health policy. Inevitably,

these policies all profess the same

motherhood statements with one

invariably stating; compliance with

relevant legislation is paramount to the

operation.

How can this be when we have

numerous accidents and

incidents occurring daily at our

coal mines? Are the policies

just wall coverings? You would

like to think not.

If these corporate safety and health

policies are to legally state the

intentions and beliefs of mining

companies then, the coal mining

safety and health legislation also

requires to be read and understood

if compliance is to occur.

One main requirement is the objects of the Act

being;

Coal Mining Safety and Health Act 1999

The objects of this Act are—

(a) To protect the safety and health of persons at

coal mines and persons who may be affected by

coal mining operations; and

(b) To require that the risk of injury or illness to any

person resulting from coal mining operations be

at an acceptable level.

This is done through the identification of

hazards and the controlling of risks involved in

every mining operation. A colleague of mine

once said;

“the hazard is the shark in the

swimming pool – the risk is

swimming with it”

The coal industry is very apt at identifying

hazards and consequences, but not very good

at ensuring the identified controls to obtain

an acceptable level of risk are in place prior to

the start of the task. Numerous risk

assessments are performed and (in some

cases) work procedures developed from the

outcomes of the risk assessments.

Once written they identify the additional

controls that are required to be in place

prior to the start of any mining operation

to achieve an acceptable level of risk,

these could include communication,

additional training, guarding, isolation,

barriers or gas levels etc...

Once written and made part of the safety

and health management system they

become a statute of law. In other words,

did you do what you said (in black and

white) you were going to do?

Unfortunately, this is just not the case in

numerous operations and accidents and

incidents continue to occur.

This leads to (in some cases) the issuance of

safety alerts, so as the rest of the mining

industry is aware and is given the opportunity

to be pro-active in ensuring a similar incident

at their operation does not occur. This is not

the case in reality though; reoccurrence of

similar incidents continues to occur at an

alarming rate.

This is on top of the current mining boom that

required additional management personal to

be placed in areas of operation with little to

no training given, just a desired outcome.

With this and combined with the loss of

corporate memory at well established mining

operations, has led to mismanagement of coal

mine workers safety.

Change Management or Management of Change?

In some cases the slightest change to performing

a routine task can have catastrophic results if not

identified and managed correctly. The legislation

requires that all mines manage any change in

their mining operation with assessment of what

the change may have on the task in relation to its

health and safety obligations to all coal mine

workers.

Coal Mining Safety and Health Act 1999

62 Safety and health management system

(3) The safety and health management system

must be adequate and effective to achieve an

acceptable level of risk by—

(g) if there is a significant change to the coal

mining operations of the coal mine—containing a

plan to immediately review the safety and health

management system so that risk to persons is at

an acceptable level.

Coal Mining Safety and Health Act 1999

64 Review of principal hazard management plans and standard operating

procedures

(1) This section applies if—

(a) a safety and health management system has been developed for a new coal mine; or

(b) it is proposed to change a safety and health management system at an

existing coal mine.

(2) The site senior executive must review the principal hazard

management plans and standard operating procedures in

consultation with coal mine workers affected by the plans

and operating procedures.

(3) The review under subsection (2) must take place—

(a) for a new coal mine—as soon as practicable after the start of coal mining operations; or

(b) for a change at an existing coal mine—before the change

happens.

A case in point that recently occurred with

regards to the failure of change being managed

and legislative requirements being met, was at an

underground coal mine in central Queensland.

The mine had identified that their gas analyser

was in need of an upgrade, so a job order was

placed to have an external agency come to the

mine to perform the upgrade. This upgrade

would mean that the tube bundle gas analyser

would be out of commission for at least 48hrs.

The mine did not identify that this was a

significant change to the mining

operation and had not developed a

contingency plan to deal with the

outage.

This is despite the legislative minimum

requirements that all sealed areas must

be monitored.

Coal Mining Safety and Health Regulation 2001

223 Monitoring and sampling mine

atmosphere

(1A) The safety and health management system

must also provide for sampling of the mine

atmosphere, using the mine’s gas monitoring

system, at each of the following places—

(a) The return airway from each unsealed waste,

idle workings and goaf area;

The end result (after a directive was issued by

the Industry Safety and Health Representative

to ensure an acceptable level of risk was

achieved) was that men were withdrawn from

the mine till a sampling regime was put in

place to comply with not only legislation but

also the mines principal hazard management

plan for spontaneous combustion.

It is the mismanagement of these serious safety

events as briefly described in both

aforementioned cases of legislative breaches that

have the ever present potential to continually

cause injuries and or multiple fatalities. It does

not require Nirvana for the minimum

requirements to ensure that the safety and

health of our coal mine workers is to be met.

Simply put, there is a prescribed and well proven

way of achieving these minimums and the

industry, as a whole, is just not consistently

making the grade.

Coal Mining Safety and Health Regulation 2001

Part 2 Safety and health management system

6 Basic elements

A coal mine’s safety and health management system

must provide for the following basic elements—

(a) risk identification and assessment;

(b) hazard analysis;

(c) hazard management and control;

(d) reporting and recording relevant safety and health

information and data.

There are often two main areas that are

contributively linked to the failures

investigated, both of them being

controllable and yet many times ignored.

These being the lack of communication

and the involvement by those that are

required to perform and or affected by

the task.

Step by step the coal mining safety

and health legislation and associated

standards spell out the requirements

that (as a minimum) are to be

achieved in developing a procedure

to safely perform a task.

Coal Mining Safety and Health Act 1999

14 Meaning of standard operating procedure

A standard operating procedure at a coal mine is

a documented way of working,

or an arrangement of facilities, at the coal

mine to achieve an acceptable level of risk,

developed after consultation with coal mine

workers.

Firstly, identify the hazards in the task

required to be accomplished and the

impact the task may have on other areas

of the operation. This is the risk

assessment stage, to be performed with

no preconceived outcomes and by an

independent thinking facilitator.

The end of this stage

does not imply the

task can be begin

Secondly, the involvement of those

who will be required to perform the

task along with technical support

from their respective coal mine

management and or external

assistance.

Coal Mining Safety and Health Act 1999

13 Meaning of consultation

Consultation with coal mine workers is

discussion between the site senior

executive or supervisors and affected

coal mine workers about a matter with

the aim of reaching agreement about the

matter.

Coal Mining Safety and Health Regulation 2001

Standard operating procedures

10 Developing standard operating procedures

(1) The site senior executive must ensure the following steps

are taken in developing standard operating procedures for

managing and controlling hazards at the mine—

(a) the site senior executive must consult with a cross-section

of the mine’s coal mine workers involved in carrying out a

task under the proposed standard operating procedure to

identify the hazards associated with the task and ways of

controlling the hazards;

Once the hazards involved in the task have been

identified, then the assessment process takes into

account the existing controls in place at the mine to

classify the risk through the ranking process.

Coal Mining Safety and Health Act 1999

18 Meaning of risk

(1) Risk means the risk of injury or illness to a person

arising out of a hazard.

(2) Risk is measured in terms of consequences and

likelihood.

The end of this stage

does not imply the

task can be begin

Now that the assessment process has

identified the level of risk in performing the

task, perseverance must be given to achieving

the “ALARA” principle, being As Low As

Reasonably Achievable. Emphasis being on

achievable (and acceptable) to the coal mine

workers that are required to perform the

desired task safety.

Coal Mining Safety and Health Act 1999

29 What is an acceptable level of risk

(1) For risk to a person from coal mining operations to be at

an acceptable level, the operations must be carried out so

that the level of risk from the operations is—

(a) within acceptable limits; and

(b) as low as reasonably achievable.

(2) To decide whether risk is within acceptable limits and as

low as reasonably achievable regard must be had to—

(a) the likelihood of injury or illness to a person arising out of

the risk; and

(b) the severity of the injury or illness.

Some tasks require additional

controls to be put in place to ensure

an acceptable level of risk, these

additional controls are then added to

the assessment and the task re-

ranked to make certain that ALARA

has been achieved.

The end of this stage

does not imply the

task can be begin

From the identified controls and the required additional

controls, a procedure can then be drafted.

Coal Mining Safety and Health Regulation 2001

Standard operating procedures

10 Developing standard operating procedures

(1) The site senior executive must ensure the following steps

are taken in developing standard operating procedures for

managing and controlling hazards at the mine—

(b) the site senior executive must prepare a draft standard

operating procedure and give a copy of it to the coal mine

workers with whom the site senior executive consulted;

During this period, the additional controls

must be assigned to a responsible person to

make certain they are implemented prior to

the commencement of the task. Not, as in

many cases just ink on a page. These

additional controls could be as simple as

limiting access or extra roof support. Once the

draft procedure is written then the following

legislative requirements apply.

Coal Mining Safety and Health Regulation 2001

Standard operating procedures

10 Developing standard operating procedures

(c) if the coal mine workers agree with the draft standard operating

procedure, the site senior executive must prepare it as the final

standard operating procedure;

(d) if the coal mine workers do not agree with the draft standard

operating procedure—

(i) for a disagreement that is not about a legal or technical matter—the

site senior executive must decide the disagreed matter and prepare

the final standard operating procedure; or

(ii) for a disagreement that is about a legal or technical matter—the

site senior executive must—

(A) obtain further information or advice, including, for

example, from a person having the necessary qualifications

and experience to give the advice or from a recognised text

on the matter; and

(B) after consulting with the workers about the information or

advice, prepare a further draft standard operating

procedure and give a copy of it to the workers; and

(C) if the workers disagree with the further draft—decide the

disagreed matter and prepare the final standard operating

procedure;

(e) the site senior executive must include the final standard

operating procedure in the mine’s safety and health

management system.

(2) The site senior executive must ensure—

(a) the final standard operating procedure accords with—

(i) all matters agreed, under this section, between the site

senior executive and coal mine workers; and

(ii) the site senior executive’s decision, under this section,

on any disagreed matters; and

(b) a record is kept of the disagreed matters.

(3) In developing the standard operating procedure, the

site senior

executive must—

(a) use a risk assessment process recognised by the

mining industry as an acceptable process for

identifying and controlling hazards; and

(b) have regard to the methods of controlling the

hazard stated in the database kept by the chief

executive under section 280(1)(a)(i) of the Act.

(4) If, at the commencement of this section, the

mine has a standard operating procedure for

managing and controlling a particular hazard at

the mine.

Arguments proliferate regarding the intent of

the legislation with regards to the

development of standard operating

procedures. The renaming of work procedures

such to a mine operating procedure (MOP) is

one of the current miscreant acts being

performed by mining management in a vain

attempt to abrogate their legal obligations

and the involvement of affected coal mine

workers.

A work procedure is to be an easy to

understand, accessible and documented way

of working, developed after consultation with

the affected coal mine workers regardless of

what title it is given, be it a JSA, JSEA, SLAM,

HIT, Take 5, WRAC or a Box of Frogs etc..., and

is subject to the legislative requirements prior

to being implemented as part of the mines

safety and health management system.

Coal Mining Safety and Health Act 1999

32 Cooperation to achieve objects of Act

(1) This Act seeks to achieve cooperation between coal operators, site

senior executives and coal workers to achieve the objects of the Act.

(2) Cooperation is an important strategy in achieving the objects of the

Act and is achieved—

(a) at an industry level by—

(i) the establishment of the coal mining safety and health advisory

council under part 6; and

(ii) the appointment of industry safety and health representatives

under part 8; and

(b) at coal mine level by—

(i) the election of site safety and health representatives under part 7;

and

(ii) the process of involving coal mine workers in the management of

risk.

Corporate and senior coal mining

management espouse that their

operations aim for implausible

targets such as “Zero Harm”, “A safe

workplace that is injury and fatality

free” or “Target Zero”.

Implausible due to constant non compliance

to not only the coal mining safety and health

legislation but also their corporate charters,

health, safety & environment policies and the

mine’s safety and health management

system. Only through trust, communication,

training, involvement and consistency at all

levels of the business can mining operations

attempt to reach these goals.

Consequently, as the coal industry

progresses into a new year of economic

uncertainty – safety must maintain its

economic viability. History has shown

that when the profits are being eaten

into, spending on safety is one of the first

to suffer cost cuts under the guise of

returns for the share holder.

I for one have not seen many share holders

working at the coal face, the real share holders

are the men and women who mine Queensland

coal.

It is these people that rightly deserve to expect

that they will return home each working shift in

the same physical and psychological condition

that they arrived to work that shift.

Você também pode gostar

- PWC Financial Institution Continuous Cost ManagementDocumento40 páginasPWC Financial Institution Continuous Cost ManagementhellowodAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- For Peer Review: Theory and Language of Climate Change CommunicationDocumento18 páginasFor Peer Review: Theory and Language of Climate Change CommunicationUsman AliAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Responsible Use of Media and Information and Evolution of MediaDocumento35 páginasResponsible Use of Media and Information and Evolution of MediaERICKA GRACE DA SILVAAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Chapter 2 Review of Related Literature and StudiesDocumento7 páginasChapter 2 Review of Related Literature and StudiesRJ Gabuya100% (2)

- How Trust Leads To Online Purchase Intention Founded in Perceived Usefulness and Peer CommunicationDocumento16 páginasHow Trust Leads To Online Purchase Intention Founded in Perceived Usefulness and Peer CommunicationHương ThanhAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Vulnerabilidad SismicaDocumento142 páginasVulnerabilidad SismicaEd Jr ATAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Courseworkbbmf 2093 Jun 19Documento9 páginasCourseworkbbmf 2093 Jun 19bubbleteaAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Mba Iii ProjectDocumento70 páginasMba Iii ProjectmanojAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Principles of Risk Management and Insurance 13th Edition Rejda Solutions ManualDocumento36 páginasPrinciples of Risk Management and Insurance 13th Edition Rejda Solutions Manualoutlying.pedantry.85yc100% (23)

- 5 IciciDocumento2 páginas5 IciciSagar SoniAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Low Back Pain Among Nurses in Slovenian Hospitals: Cross-Sectional StudyDocumento8 páginasLow Back Pain Among Nurses in Slovenian Hospitals: Cross-Sectional StudyMerieme SafaaAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- TLE-026-Home Economics Literacy Module 9Documento19 páginasTLE-026-Home Economics Literacy Module 9Ivy Chezka HallegadoAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Jurnal Dinda SalsabilaDocumento13 páginasJurnal Dinda SalsabilaFebrianti NatasyaAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Risk Analysis in Engineering Risk AnalysDocumento408 páginasRisk Analysis in Engineering Risk AnalysShuyuan LuAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Anti Fraud PolicyDocumento17 páginasAnti Fraud PolicyKailash KhandeliaAinda não há avaliações

- Fire Policy 1Documento2 páginasFire Policy 1caleb99Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- BSBOPS504 Student Project Portfolio - Jacob Lloyd JonesDocumento21 páginasBSBOPS504 Student Project Portfolio - Jacob Lloyd JonesBui An100% (5)

- Global Risks Report 2017Documento76 páginasGlobal Risks Report 2017Mike MaguireAinda não há avaliações

- GE 10 Environmental Science: Prepared By: Marygrace P. Sanopal, LPTDocumento17 páginasGE 10 Environmental Science: Prepared By: Marygrace P. Sanopal, LPTVERGIE LAPINIGAinda não há avaliações

- Monash University - Overview PDFDocumento5 páginasMonash University - Overview PDFKartika WeningtyasAinda não há avaliações

- Independent Equity Research: How We Do It, and Why It Matters To InvestorsDocumento12 páginasIndependent Equity Research: How We Do It, and Why It Matters To InvestorsPutnam InvestmentsAinda não há avaliações

- D3.12 - SYNER-G Fragility Curves For All Elements at RiskDocumento145 páginasD3.12 - SYNER-G Fragility Curves For All Elements at RiskMohammad AL HaririAinda não há avaliações

- Plum Consulting Valuation of Public Mobile Spectrum at 825 845 MHZ and 870 890 MHZDocumento29 páginasPlum Consulting Valuation of Public Mobile Spectrum at 825 845 MHZ and 870 890 MHZsanjeevk05Ainda não há avaliações

- TR Biomedical Equipment Servicing NC IIDocumento68 páginasTR Biomedical Equipment Servicing NC IIRinmawiiAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Safety and Environmental Standards For Fuel Storage Sites: Process Safety Leadership Group Final ReportDocumento44 páginasSafety and Environmental Standards For Fuel Storage Sites: Process Safety Leadership Group Final ReportKumar JitendraAinda não há avaliações

- Portfolio Management ServicesDocumento83 páginasPortfolio Management Servicesragipanidinesh6206Ainda não há avaliações

- CP For Covid&EREIDDocumento118 páginasCP For Covid&EREIDAriane joy Rodrigueza100% (1)

- CP6 Strategic Business Plan Comprehensive Executive SummaryDocumento32 páginasCP6 Strategic Business Plan Comprehensive Executive SummaryMohamed Ibrahim ElagibAinda não há avaliações

- IEC 61511 Based Design For Gas Detection Systems Monitoring Hydrocarbon Storage Tank SystemsDocumento16 páginasIEC 61511 Based Design For Gas Detection Systems Monitoring Hydrocarbon Storage Tank Systemsarsil5840Ainda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

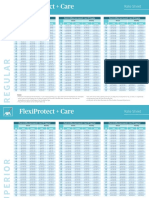

- Flexi+Care Rate SheetDocumento3 páginasFlexi+Care Rate SheetNeil MijaresAinda não há avaliações