Escolar Documentos

Profissional Documentos

Cultura Documentos

Tds Uk Mactex H Nov12

Enviado por

Felipe BabugiaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tds Uk Mactex H Nov12

Enviado por

Felipe BabugiaDireitos autorais:

Formatos disponíveis

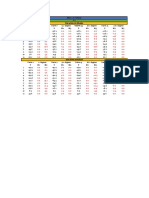

MACTEX H 09.1 13.1 15.1 20.1 25.1 33.1 35.1 40.1 45.1 50.1 55.1 60.1 70.1 75.

20.1 25.1 33.1 35.1 40.1 45.1 50.1 55.1 60.1 70.1 75.1 80.1 90.1

Mechanical and Hydraulic properties

Tensile strenght — CMD 7.5 8.7 9.8 11.5 12.5 15.5 14.1 16.5 18.0 21.0 23.0 25.3 30.0 31.8 34.0 38.0

according to EN ISO 10319

kN/m

-1.0 -0.8 -1.1 -1.2 -1.2 -1.5 -1.4 -1.7 -1.8 -2.0 -2.3 -2.5 -2.6 -3.0 -3.0 -3.7

F: 01865 774550

T: 01865 770555

Strain — CMD

7600 The Quorum,

% 65 65 65 65 70 70 70 70 70 70 75 75 75 75 75 75

according to EN ISO 10319 +13 +13 +13 +13 +14 +14 +14 +14 +14 +14 +15 +15 +15 +15 +15 +15

Tensile strength — MD 6.2 8.3 9.0 11.5 11.0 14.4 13.6 16.2 18.0 20.5 22.2 24.5 29.7 31.3 33.0 36.5

according to EN ISO 10319

kN/m

-0.8 -0.8 -1.0 -1.2 -1.1 -1.4 -1.4 -1.2 -1.8 -1.9 -2.2 -2.4 -2.6 -3.0 -3.0 -3.6

E: oxford@maccaferri.co.uk

Oxford Business Park, North,

Strain — MD 60 60 60 60 65 65 65 65 65 65 70 70 70 70 70 70

according to EN ISO 10319

%

Web: www.maccaferri.co.uk

+12

Maccaferri Ltd - Head Office

+12 +12 + 12 +13 +13 +13 +13 +13 +13 +14 +14 +14 +14 +14 +14

Garsington Road, Oxford, OX4 2JZ

CBR Static puncture resistance 1060 1150 1400 1600 1900 2200 2200 2600 2800 3180 3600 3950 4700 5000 5500 6400

according to EN ISO 12236

N

-106 -115 -140 -160 -190 -220 -220 -260 -280 -318 -360 -395 -470 -500 -550 -640

Dynamic puncture resistance 40 33 32 30 25 24 22 21 19 16 15 13 12 12 11 9

according to EN ISO 13433

mm

+8.0 +3.0 +4.0 +4.0 +4.0 +3.0 +3.0 +3.0 +3.0 +2.0 +3.0 +3.0 +3.0 +2.0 +2.0 +2.0

Perth:

Dublin:

Belfast:

Pyramidal puncture resistence 400 500

N - - - - - - - - - - - - - -

According to EN ISO 14574 -40 -50

Area offices

Permeability (normal to the plane)

T: 01 885 1662

l/(m2 sec) 110 105 100 90 86 75 70 52 43 36 33 30 29 28 25 23

according to EN ISO 11058

T: 01738 621317

-22 -20 -20 -20 -18 -15 -14 -12 -12 -12 -9 -9 -8 -8 -8 -8

T: 028 9026 2830

Opening pore size O90 100 90 80 80 70 70 65 65 65 65 65 65 65 65 65 50

according to EN ISO 12956 m

+25 +25 +25 +25 +20 +20 +20 +20 +15 +15 +15 +15 +15 +15 +15 +15

Energy absorption — CMD &MD 2.4 2.8 3.2 3.7 4.4 5.4 4.9 5.8 6.3 7.4 8.6 9.5 11.3 11.9 12.8 14.3

Kj/m2

Web: www.maccaferri.ie

according to EN ISO 10318 1.9 2.5 2.7 3.3 3.9 4.7 4.4 5.3 5.9 6.7 7.8 8.6 10.4 11.0 11.6 12.8

Trasmissivity at 20 kPa

1x10-7 m2/s - - - - - - - - - - - - - -

F: 01 885 1601

according to EN ISO 12958

F: 01738 442283

F: 028 9026 2849

Physical properties - typical

Polymer raw material high tenacity polypropylene

2

Mass per unit (EN ISO 9864) g/m 90 110 120 135 150 170 180 200 220 250 280 300 350 370 400 500

mm (2 kPa) 0.6 0.7 0.8 0.90 1.0 1.1 1.2 1.2 1.3 1.4 1.6 1.6 1.7 1.8 2.0 2.5

Thickness (EN ISO 9863-1) mm (20 kPa) 0.5 0.6 0.7 0.7 0.8 0.8 0.9 1.0 1.1 1.2 1.4 1.4 1.5 1.6 1.7 2.0

mm (200 kPa) 0.4 0.4 0.5 0.5 0.6 0.6 0.7 0.8 0.9 1.0 1.2 1.3 1.3 1.4 1.5 1.7

E: dublin@maccaferri.ie

Material to be covered in one month after the istallation. Predicted to be durable in natural soils (4<ph<9) at a temperature <25 °C for a

Durability minimum of 25 years

E: perth@maccaferri.co.uk

E: belfast@maccaferri.co.uk

13253,

13250,

NOTE:

figures

Nonwoven

request.

Standards.

Harmonised

needlepunched

F+S, R+S, F+R.

13254,

13251,

against patent infringement.

according

and thermocalendered.

available on request.

Oxford, Perth, Belfast

These data are statistic

container are available on

Loading plan by truck and

Intermediate grades are

to

European

accept any liability for any loss or

conditions in which it may be used

the best of our knowledge accurate,

are beyond our control, we do not

but since the circumstances and

reserves the rigth to modify the

information contained herein are to

standard characteristics of the

following intended uses: F,

13256, 13257, 13265 for the

high tenacity polypropylene

The fabrics are CE marked

use of such information nor we do

results directly or indirectly from the

damage, however arising, which

product without any notice. The

of the products, the manufacturer

treatment

manufactured with virgin

fibers assembled by a

geotextiles

process of the technical characteristics

For the optimisation and improvement

13255,

13252,

according to EN 13249,

offer any warranty or immunity

D, R, F+D, F+S+D, F+R+S,

NEEDLEPUNCHED & THERMOCALENDERED NONWOVEN GEOTEXTILES

MACTEX H

UK / TDS / MacTex H Rev: 11, Nov 2012

TECHNICAL DATA SHEET

Você também pode gostar

- Wallap Part 2Documento11 páginasWallap Part 2Nizar HalabiAinda não há avaliações

- Analog and Digital Circuits Laboratory: Analog Experiment: Common Source AmplifierDocumento11 páginasAnalog and Digital Circuits Laboratory: Analog Experiment: Common Source AmplifierSanjai SenthilAinda não há avaliações

- Komatsu Hydraulic Excavator Pc300hd 6 Shop ManualDocumento20 páginasKomatsu Hydraulic Excavator Pc300hd 6 Shop Manualvivian100% (45)

- NMB Brushless DC CatalogDocumento20 páginasNMB Brushless DC Catalogมนต์ชัย บุญธนลาภAinda não há avaliações

- Analysis ReportDocumento30 páginasAnalysis ReportSolomon Ndugwa BalemeziAinda não há avaliações

- Appendix 4Documento7 páginasAppendix 4Rammiris ManAinda não há avaliações

- Wallap Part 3Documento11 páginasWallap Part 3Nizar HalabiAinda não há avaliações

- Esquematico Sansung S8 G950FDocumento119 páginasEsquematico Sansung S8 G950Fjjooseful100% (4)

- WCB Excavator Spare Parts Slewing Bearing Slewing Circle Slewing RingDocumento24 páginasWCB Excavator Spare Parts Slewing Bearing Slewing Circle Slewing RingWCB BEARING0% (1)

- Malaci ColDesDocumento57 páginasMalaci ColDesokechukwu1benjaminAinda não há avaliações

- Spek Potain MC205Documento16 páginasSpek Potain MC205Indra RahmadhaniAinda não há avaliações

- VulkanCoupling (Wartsila)Documento37 páginasVulkanCoupling (Wartsila)Denisse100% (2)

- 1974 MECL Integrated Circuits Series A Vol4 PDFDocumento624 páginas1974 MECL Integrated Circuits Series A Vol4 PDFjalmeida88Ainda não há avaliações

- 英展电子秤说明书Documento32 páginas英展电子秤说明书FrankAinda não há avaliações

- 2021.05.29 - Martinetto T22-726 Man - CE e Collaudo ENGDocumento9 páginas2021.05.29 - Martinetto T22-726 Man - CE e Collaudo ENGEdomAinda não há avaliações

- Method Statement Form: Project: MS No. Revision: 00 Date: Company: Location of Activity (Attach Sketches As Necessary)Documento6 páginasMethod Statement Form: Project: MS No. Revision: 00 Date: Company: Location of Activity (Attach Sketches As Necessary)ShahdeoAinda não há avaliações

- 1cge 4Documento29 páginas1cge 4JUAN PABLO GUERRERO JIMENEZAinda não há avaliações

- Quality ManagementDocumento24 páginasQuality Managementabhimanyu ratheeAinda não há avaliações

- Print Untuk Ujian - Mv. Arawana - Loading ManualDocumento11 páginasPrint Untuk Ujian - Mv. Arawana - Loading ManualtperkapalanAinda não há avaliações

- Ceeiel: U S. KnyDocumento7 páginasCeeiel: U S. KnyFlorin NiteAinda não há avaliações

- Cim 312CR: Full Bore Ball Valve - PN 32 - Type T12 - Aluminium Butterfly Handle - DZR Brass CRDocumento2 páginasCim 312CR: Full Bore Ball Valve - PN 32 - Type T12 - Aluminium Butterfly Handle - DZR Brass CRDaniel B. BalmoriAinda não há avaliações

- M/s. Jai Mata Di Energy System (JMES) VPO:-Narodra, District: Lachhamangarh, Siker - 332311Documento10 páginasM/s. Jai Mata Di Energy System (JMES) VPO:-Narodra, District: Lachhamangarh, Siker - 332311Ravi KumarAinda não há avaliações

- Al Imam Akbar UTS at HomeDocumento6 páginasAl Imam Akbar UTS at HomeDaniel Sevala 1407112344Ainda não há avaliações

- Magnetic Coupling Torque Vs Air GapDocumento4 páginasMagnetic Coupling Torque Vs Air GapDallie KurniawanAinda não há avaliações

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocumento8 páginasWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195Ainda não há avaliações

- Ilovepdf MergedDocumento100 páginasIlovepdf Mergedfrancis sebastian lagamayoAinda não há avaliações

- Piso 1 A 7 (T, M) C-1 Iteración de Diseño Curve 1 Curve 13Documento4 páginasPiso 1 A 7 (T, M) C-1 Iteración de Diseño Curve 1 Curve 13Fernando Sandoval siesquenAinda não há avaliações

- Apc Materials Properties PDFDocumento1 páginaApc Materials Properties PDFnamyefAinda não há avaliações

- Ma SeriesDocumento6 páginasMa Seriesruiz sumarAinda não há avaliações

- Planta EchanterDocumento34 páginasPlanta EchanterHernando Fang PedrozaAinda não há avaliações

- Lab 2Documento18 páginasLab 2Dodiya NikunjAinda não há avaliações

- Brochure - CLMS - Copper Cable Lug R1 PDFDocumento1 páginaBrochure - CLMS - Copper Cable Lug R1 PDFMuthu KumarAinda não há avaliações

- Calculation of Service Life: Load DataDocumento4 páginasCalculation of Service Life: Load Datarafael rodarteAinda não há avaliações

- Multitrack SNW RangeDocumento2 páginasMultitrack SNW RangeSergejjjAinda não há avaliações

- TABLE 1.10 Limiting Effect Cable Short-Circuit Currents 208 Volts, Three PhaseDocumento23 páginasTABLE 1.10 Limiting Effect Cable Short-Circuit Currents 208 Volts, Three PhaseJuan Carlos Perez ParraAinda não há avaliações

- Marconi - 110012 - Intact StabilityDocumento42 páginasMarconi - 110012 - Intact StabilityNikola DjordjevicAinda não há avaliações

- Miniature Circuit Breakers: Breaking Capacities Tripping CharacteristicsDocumento9 páginasMiniature Circuit Breakers: Breaking Capacities Tripping CharacteristicsEzeldeen AgoryAinda não há avaliações

- Product Design Features:: 12MVR100TADocumento1 páginaProduct Design Features:: 12MVR100TAtodorr80Ainda não há avaliações

- Debit Aliran Metode RationalDocumento3 páginasDebit Aliran Metode RationalAnggun Vita MutiaraAinda não há avaliações

- Maintenance: Printed in FranceDocumento3 páginasMaintenance: Printed in FranceRonald OngAinda não há avaliações

- Installation Instructions: Alignment, Sleeve Seating and Torque Wrench Use Are Critical To Coupling OperationDocumento2 páginasInstallation Instructions: Alignment, Sleeve Seating and Torque Wrench Use Are Critical To Coupling OperationcakendriAinda não há avaliações

- DF Hua Canon Hu003192 Muchka v01Documento42 páginasDF Hua Canon Hu003192 Muchka v01Jose VillalobosAinda não há avaliações

- S01-1 General Informations (G)Documento10 páginasS01-1 General Informations (G)juanAinda não há avaliações

- Word Debit Aliran Metode RationalDocumento9 páginasWord Debit Aliran Metode RationalAnggun Vita MutiaraAinda não há avaliações

- TS B3 SeriesDocumento4 páginasTS B3 SeriesGuadalupe CondoriAinda não há avaliações

- Turbine Flow MeterDocumento33 páginasTurbine Flow MeterPandeyAinda não há avaliações

- SM-T385 SVC MANUAL (Phonelumi - Com)Documento145 páginasSM-T385 SVC MANUAL (Phonelumi - Com)Rudy ATAinda não há avaliações

- Stainless StudsDocumento4 páginasStainless StudsNestramiAinda não há avaliações

- TDS - WIT PE 500 - RebarDocumento3 páginasTDS - WIT PE 500 - RebarDattatray GosaviAinda não há avaliações

- Megohmmeter MMG500Documento130 páginasMegohmmeter MMG500Iacobescu LaurentiuAinda não há avaliações

- DF Hua Canon Hu003102 Aymasurco v01Documento40 páginasDF Hua Canon Hu003102 Aymasurco v01Wilson ThiagoAinda não há avaliações

- GIECK Formula Ire Technique ADocumento5 páginasGIECK Formula Ire Technique ABENOVEROAinda não há avaliações

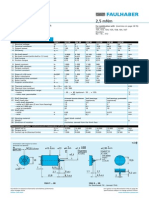

- Faulhaber DatasheetDocumento5 páginasFaulhaber DatasheetMuhammad SharifAinda não há avaliações

- 5.modification of Starter Operated 10 MT EOT - ConceptDocumento18 páginas5.modification of Starter Operated 10 MT EOT - ConceptIndranil DasguptaAinda não há avaliações

- BINH-MINH de inDocumento16 páginasBINH-MINH de inphong phong1998Ainda não há avaliações

- Output Beban Hidup 250kgDocumento672 páginasOutput Beban Hidup 250kgwahyuAinda não há avaliações

- 8.1 Fis em RebarDocumento51 páginas8.1 Fis em RebarJeyasingh GopalakrishnanAinda não há avaliações

- MAN106Documento297 páginasMAN106Luz Analía Valdez Candia75% (4)

- KR - MV5 - R410A - 220VMFL67474052 - 20170728 - Al ISO PDFDocumento441 páginasKR - MV5 - R410A - 220VMFL67474052 - 20170728 - Al ISO PDFFelipe Babugia0% (1)

- KR - Multi V S - R410A - 5060Hz - HP - EU - MFL67474032 - 0CVM0-03A (Jan.2017) PDFDocumento147 páginasKR - Multi V S - R410A - 5060Hz - HP - EU - MFL67474032 - 0CVM0-03A (Jan.2017) PDFFelipe BabugiaAinda não há avaliações

- KR SCAC (R410A 50,60Hz) HP Inverter Brazil MFL69982107 0CSL0-01A (July.2017) PDFDocumento91 páginasKR SCAC (R410A 50,60Hz) HP Inverter Brazil MFL69982107 0CSL0-01A (July.2017) PDFFelipe BabugiaAinda não há avaliações

- KR - MV IDU - WallMountedUnit (4series) - R410A - 5060Hz - Global - MFL55028426W - 0CVP0-01A (Mar.2017) PDFDocumento62 páginasKR - MV IDU - WallMountedUnit (4series) - R410A - 5060Hz - Global - MFL55028426W - 0CVP0-01A (Mar.2017) PDFFelipe BabugiaAinda não há avaliações

- Guidelines For Coheseive Parameters Ebook 3Documento11 páginasGuidelines For Coheseive Parameters Ebook 3arkan1976Ainda não há avaliações

- Kla DeterminationDocumento23 páginasKla DeterminationJokanoe LertAinda não há avaliações

- Induction FurnaceDocumento16 páginasInduction FurnaceMURSELIM ALIAinda não há avaliações

- Ultimate Limit State Design of Ship StructuresDocumento256 páginasUltimate Limit State Design of Ship StructuresProrok NemanjaAinda não há avaliações

- Cbse Sample Paper 2023 Class 10Documento11 páginasCbse Sample Paper 2023 Class 10Garvit BhelAinda não há avaliações

- Material Safety AvabexDocumento4 páginasMaterial Safety Avabexfs1640Ainda não há avaliações

- 1b. PET - RawMaterials-SAMEA March 2008Documento29 páginas1b. PET - RawMaterials-SAMEA March 2008Muhammad Noman MehboobAinda não há avaliações

- Kuliah-7&8 Pengelolaan Lapangan Migas - Reservoir EvaluationDocumento15 páginasKuliah-7&8 Pengelolaan Lapangan Migas - Reservoir EvaluationAly RasyidAinda não há avaliações

- Study of Effect of Potassium Bisulphite As A Food PreservativeDocumento14 páginasStudy of Effect of Potassium Bisulphite As A Food PreservativeAntarctic SaverAinda não há avaliações

- 2.3. External Waterproofing SystemsDocumento2 páginas2.3. External Waterproofing SystemsKrishna SankarAinda não há avaliações

- Understanding PH MeasurementDocumento10 páginasUnderstanding PH MeasurementAnnisa Novita Putri SiregarAinda não há avaliações

- Class 12 Chemistry Syllabus 2023-24Documento3 páginasClass 12 Chemistry Syllabus 2023-24Rooh KSHIVAinda não há avaliações

- The Chemistry of Cooking and Cleaning - Ellen RichardsDocumento106 páginasThe Chemistry of Cooking and Cleaning - Ellen RichardsSandra Mian100% (2)

- Protect Rubber Goods To Prevent Failure: Tears ProtuberanceDocumento2 páginasProtect Rubber Goods To Prevent Failure: Tears ProtuberancePedro SarmientoAinda não há avaliações

- The Calvin CycleDocumento4 páginasThe Calvin CycleVerena Raga100% (1)

- Master AlloysDocumento8 páginasMaster AlloysAsif AliAinda não há avaliações

- What Is Wave Soldering Temperature Profile A Comprehensive Guide To SolderingDocumento13 páginasWhat Is Wave Soldering Temperature Profile A Comprehensive Guide To SolderingjackAinda não há avaliações

- One-Dimensional Compressible Flow in Variable AreaDocumento6 páginasOne-Dimensional Compressible Flow in Variable AreaswatiAinda não há avaliações

- Silva2019 Article OptimizationOfLycopeneExtractiDocumento11 páginasSilva2019 Article OptimizationOfLycopeneExtractilunosicaAinda não há avaliações

- 62f PDFDocumento20 páginas62f PDFMohsenAinda não há avaliações

- Strengthening MechanismsDocumento17 páginasStrengthening Mechanismspkn_pnt9950Ainda não há avaliações

- High Efficiency Transformation of Escherichia Coli With PlasmidsDocumento6 páginasHigh Efficiency Transformation of Escherichia Coli With PlasmidsAnthony TeeAinda não há avaliações

- REACH Annex XVII Status 1904Documento21 páginasREACH Annex XVII Status 1904MarkChenAinda não há avaliações

- Bulk Electronic Structure of SrTiO3: Experiment and TheoryDocumento10 páginasBulk Electronic Structure of SrTiO3: Experiment and Theoryhoehoe1234Ainda não há avaliações

- Ger 3751a Understanding Diagnosing Repairing Leaks h20 Gen Stator WindingsDocumento28 páginasGer 3751a Understanding Diagnosing Repairing Leaks h20 Gen Stator Windingsnareshvkkd100% (1)

- Plant Pathology Fst3Documento19 páginasPlant Pathology Fst3Alishba SherazAinda não há avaliações

- Spectrometry FinalDocumento57 páginasSpectrometry FinalAastha SahuAinda não há avaliações

- 2-Heptanol MSDS: Section 1: Chemical Product and Company IdentificationDocumento5 páginas2-Heptanol MSDS: Section 1: Chemical Product and Company Identificationa d e eAinda não há avaliações

- SLV General Introduction To Welding TechnologyDocumento35 páginasSLV General Introduction To Welding TechnologyMohammad Sobhan RajabiAinda não há avaliações

- Electro-Etching Made EasyDocumento52 páginasElectro-Etching Made Easyedhykoes100% (1)