Escolar Documentos

Profissional Documentos

Cultura Documentos

Power Curber 5700C 25585 - Joystick Calibration Instructions

Enviado por

Phil B.Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Power Curber 5700C 25585 - Joystick Calibration Instructions

Enviado por

Phil B.Direitos autorais:

Formatos disponíveis

POWER CURBER

5700 – C &

OEM JOYSTICK P60268

CALIBRATION INSTRUCTIONS

DOCUMENT # 25585

7-25-07

The contents and specifications in this publication are subject to change without notice.

The contents of this publication are the sole property of Power Curbers, Inc. and

cannot be reproduced in any manner without prior written consent.

POWER CURBERS INC. DOCUMENT # 25585

i

Section Contents

Section 1............................................................................. Safety

Section 2...................................................Calibration of Joystick

Section 3........................................................... Trouble Shooting

Section 4...........................................Crawler Joystick Schematic

POWER CURBERS INC. DOCUMENT # 25585

ii

1.0 Safety

1.1. IMPORTANT SAFETY NOTICE functions of all controls before attempting to operate

the machine.

All equipment has limitations. Understand the speed,

WARNING: braking, steering, leveling, stability, and load

THE MACHINE OPERATOR IS RESPONSIBLE FOR characteristics of the machine before starting to

THE SAFE OPERATION OF THIS MACHINE AND FOR operate. Read the OPERATION MANUAL and ask

THE SAFETY OF PERSONS AROUND THE MACHINE! questions of your supervisor or trained technician

Before assembling, operating, cleaning, lubricating, until you know these limitations. Be sure you have

or adjusting this machine be sure to READ AND checked all of the controls in a safe area before

CAREFULLY FOLLOW THE INSTRUCTIONS IN THE starting to work.

OPERATION MANUAL AND MAINTENANCE

MANUAL! The manual is provided for your safety WARNING

and the safety of those around the machine.

Unauthorized alterations or modifications of the

This machine must be operated in accordance with machinery, or the use of unauthorized replacement

the OPERATION MANUAL, the SAFETY SIGNS on the parts can result in the creation of unanticipated

machine, and COMMON SENSE. hazards that could cause serious injury or death!

Do Not approach any potentially moving parts of the Written approval must be obtained from Power

machine while engine is running. Do Not operate the Curbers, Inc. before attempting any modification or

machine without all Safety Guards in place. Keep all alteration or using a replacement part not otherwise

Safety Signs clear and readable at all times. authorized by Power Curbers!

The manufacturer of this machine cannot be

responsible for any injury or any other damages

whatsoever when the machine is not used in

WARNING

accordance with the OPERATION MANUAL or the Never bypass or disconnect the machines'

SAFETY SIGNS on the machine. In such event, YOU Emergency Stop Circuit in ANY manner which will

ASSUME ALL RISKS OF THE OPERATION AND USE render it inoperative.

OF THIS MACHINE.

If this machine is not operated in accordance with WARNING

the OPERATOR'S MANUAL and the SAFETY SIGNS Before performing any maintenance on the machine

on the machine, the manufacturer and seller of this ensure that the machine is in a safe condition by

machine disclaim all express and implied warranties, performing the SAFETY SHUTDOWN PROCEDURE as

including any warranty of merchantability, or fitness, described below.

or otherwise with respect to any claim for property

damage or personal injury and expressly disclaim all To Perform Safety Shutdown Procedure:

remedies for any such claims.

The machine operator is responsible for identifying 1. Position the machine on flat and level ground.

and explaining any potential hazards to all persons 2. Side shift trimmer (if equipped) under machine completely,

around the machine regardless of their knowledge of and raise trimmer fully. Adjust the nuts on the vertical

the operation of the machine. You are responsible travel limit rods of each trimmer post so as to keep the

for insuring all persons understand any potential trimmer from being lowered. Refer to Sub-Section 7.5.2

hazards and consequences of any potential hazard if Trimmer Adjustments in the OPERATION MANUAL.

the Safety Signs or instructions are not followed.

Do Not operate this machine if you do not 3. Retract all mold or paver sideplates (if equipped) to their

understand all of the instructions in the OPERATION highest position.

MANUAL.

4. Extend the right rear post straddle leg fully.

If there are any instructions or operations which you

do not understand, before you operate the machine, 5. Turn the front crawler fully left.

call Power Curbers at (704) 636-5871.

6. Begin to lower the machine, while keeping the machine

1.2. PERSONNEL SAFETY level both front to rear and side to side, until the mold or

CONSIDERATIONS paver touches the ground evenly or until the machine posts

have lowered as far as possible.

WARNING: 7. Raise machine approximately 6 inches.

Your safety and the safety of those around you 8. Place all machine controls in their OFF, STOP, or

depends upon your using care and judgment in STANDBY positions, and stop the engine. Refer to Section

operating this machine. Know the positions and

POWER CURBERS INC. DOCUMENT # 25585

1

7.4 "To Stop the Machine" in the OPERATION SAFE RENDERING of the machine by other means prior

MANUAL. to performing any maintenance. While alternative

positioning of the machine and its' accessories can be

9. Place four (4) jack stands under the machine as outlined accomplished in many ways, Power Curbers Inc. cannot

below. These jack stands should be rated at no less than 5 anticipate every possible procedure or circumstance that

tons each. might involve a potential hazard. Before proceeding with

any operation in which to render the machine safe, you

I. Under the right front corner of machine frame just to

must first satisfy yourself that the procedures and

the rear of the right side trimmer lift post assembly. mechanisms you have chosen are safe for you and other

II. Under the right rear post straddle leg inner tube as persons around the machine

close as possible to the inside of the right rear crawler. In

the event that the inner straddle leg tube needs to be

removed for service, then the alternate jack stand location

would be at the end of the outer straddle leg tube.

III. Under the left rear corner of the machine.

(a) For machines equipped with the standard rigid

mold mount, this position would be under the rearmost

machine frame cross member, as close as possible to the

inside of the left rear crawler.

(b) For machines equipped with the optional

hydraulically adjustable mold mount offset, this position

would be under the rearmost adjustable offset outer side

shift tube, as close as possible to the inside of the left rear

crawler. In the event that the adjustable offset needs to be

removed, first remove the mold and then lower the machine

until all three suspension post are fully collapsed.

IV. Under the steering cylinder mount arm, where it is

welded to the underside of the machine frame just to the

rear of the left front post assembly.

10. Start the engine, place the Servo System switch in the ON

position, and lower the machine evenly onto the jack stands

by using the amplifier JOG switches. DO NOT retract the

machine posts so that the crawlers come off the ground, but

rather leave the crawlers "lightly touching" the ground.

11. Extend the mold or paver sideplates (if equipped) so that

they are "lightly touching" the ground.

12. Extend the conveyor shift cylinder fully or until the load

end of the conveyor comes to rest on the ground.

13. If the conveyor load end is not already on the ground, tilt

the conveyor so that the load end of the conveyor is

lowered and comes to rest on the ground.

14. Return the Servo System switch to the OFF position and

stop the engine.

15. Remove ignition key and tag ignition switch as "Down for

Maintenance - Do Not Start".

16. Bleed the air from the hydraulic oil tank. See Illustration

Figure 4.5 Hydraulic Tank Air Bleed in the MAINTENANCE

MANUAL.

IMPORTANT NOTE: In the event that the engine,

hydraulic or electrical systems required to perform the

SAFETY SHUTDOWN PROCEDURE as outlined above

are inoperative, then it is your responsibility to ensure a

POWER CURBERS INC. DOCUMENT # 25585

2

2.0 Calibration of Joystick

1. The engine must not be running during calibration. The pumps and joystick must be connected before continuing. You must

use an ammeter that is capable of measuring at least 3 amps set the joystick. Note: Measuring voltage is NOT an accurate means

of calibrating this joystick.

Crawler Joystick P60268

Rotate MAX

adjustment

screw 30

turns

counter-

clockwise

Rotate

THRESH

adjustment

screw 30 turns

counter-

clockwise.

Step 2, Reset

2. Locate the “MAX” adjustment potentiometer and rotate adjustment screw counter clockwise 30 turns. Note: The

potentiometer has a slip clutch to prevent over tightening and to prevent oversetting. Repeat the same adjustment for the

“THRESHOLD” potentiometer.

POWER CURBERS INC. DOCUMENT # 25585

3

Key switch

ON

Press switch to

POWER position

to energize

console. Do not

start engine.

Step 3, Power ON

3. Energize the console but do not start the engine.

Place joystick in

STOP position

Place

CRAWLER/

VIBRATORS

switch to ON

Step 4, Stop position

4. Place the crawler-vibrator switch to the ON position. Turn the joystick knob to the STOP position. Note: The engine

must be off when calibrating the joystick.

POWER CURBERS INC. DOCUMENT # 25585

4

Disconnect wire on

“A” terminal.

Connect ammeter

lead to wire.

Connect other

ammeter lead

to “A”

terminal.

Step 5, Connect Ammeter

5. Adjust the ammeter leads and settings to read up to 3 amps (not volts). Disconnect the “A” terminal wire. Connect one

ammeter lead to “A” terminal and the “A” wire to the other lead of the ammeter. Refer to your ammeter manual for

proper operation and safety information.

POWER CURBERS INC. DOCUMENT # 25585

5

Rotate Joystick

to full

FORWARD

position.

Step 6, Joystick

6. Rotate joystick knob to full FORWARD position.

POWER CURBERS INC. DOCUMENT # 25585

6

First, adjust

“THRESH”

until ammeter

reads .350

amps or 350

mA.

Next, adjust

“MAX” until

ammeter

reads 1.250

amps or 1250

mA.

Step 7, Adjustment

7. Adjust the “THRESHOLD” potentiometer (approximately 13 turns clockwise) until the ammeter reads 0.350 amps (350

mA). Next, adjust the “MAX” potentiometer (approximately 14 turns clockwise) until the ammeter reads 1.250 amps (or

1250 mA). Note: The screws should not need to be rotated more than 20 turns.

8. The remaining steps are for checking proper adjustments. Keep ammeter connected.

POWER CURBERS INC. DOCUMENT # 25585

7

Rotate

joystick to

minimum

FORWARD

position and

read ammeter

Step 9, Minimum

9. Turn the joystick knob to minimum FORWARD position. The current reading should be 0.300~0.350 amps. If the

correct setting has not been reached, re-adjust the “THRESHOLD” potentiometer to get the minimum setting within

range. This should require less than one turn.

Rotate joystick

to FORWARD

position and

read ammeter.

Step 10, Max adjustment

10. Turn joystick knob to full FORWARD position. Check the current reading to be approximately 1200~1350 mA. If the

correct setting has not been reached, re-adjust the “MAX” potentiometer to within the range. This should require less

than one turn of the screw.

POWER CURBERS INC. DOCUMENT # 25585

8

“A” Terminal

Coat adjusting

screws with

silicone caulk

“A” Wire

Step 11, Terminal

11. Disconnect the ammeter and reconnect the “A” wire.

12. Coat the adjusting screws with silicone caulk to secure the screws.

POWER CURBERS INC. DOCUMENT # 25585

9

3.0 Trouble Shooting

- If the “THRESHOLD” setting is too low, then you will have to turn the joystick further to get the pump to start. If the

setting is too high, then the pump will start at too high a speed.

- If “MAX” is too low, then the pump will not reach full speed. If the reading is too high, then the coil may be damaged.

- Again check to see that the current range is between 350 to 1200 mA when rotating joystick knob.

- 5700 – C’s with Network Extension and 5700 Super B’s with Micro, are calibrated by the micro.

- Conveyor joysticks can be calibrated the same way. Conveyor UP is equivalent to the crawler FORWARD position.

- If the speed range in FORWARD does not seem to be the same in REVERSE then, the joystick pot may be miss-

centered.

Joystick

Pot

Step 12, Joystick Pot

- If machine moves in only one direction (only forward or only reverse) then, the switch contacts may be damaged. The

joystick should be replaced.

POWER CURBERS INC. DOCUMENT # 25585

10

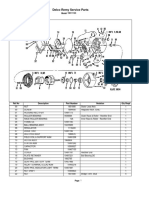

Crawler Joystick Schematic

POWER CURBERS INC. DOCUMENT # 25585

11

Você também pode gostar

- Technical - Manual Clarity v5 PDFDocumento230 páginasTechnical - Manual Clarity v5 PDFМаксим Остапенко100% (1)

- Om 57C PDFDocumento220 páginasOm 57C PDFPhil B.100% (4)

- Celect Codes: A Complete List of All Celect Fault Codes For The Cummins EcmDocumento3 páginasCelect Codes: A Complete List of All Celect Fault Codes For The Cummins EcmEduardo TorresAinda não há avaliações

- 2-2-14 Tier 4i Engine Troubleshooting Cheat SheetDocumento8 páginas2-2-14 Tier 4i Engine Troubleshooting Cheat SheetKevine Khaled100% (3)

- Seb Du 1340106Documento585 páginasSeb Du 1340106Biswajit DasAinda não há avaliações

- RPM Tech LM220 Parts Catalog s0300 Pmef 2676 and More Rev2Documento100 páginasRPM Tech LM220 Parts Catalog s0300 Pmef 2676 and More Rev2Phil B.Ainda não há avaliações

- PC700-8 Uess15301 1208Documento24 páginasPC700-8 Uess15301 1208LTATECNICOAinda não há avaliações

- 00 GEN-IMAN EXC HMG 6KW 10KW Manual PDFDocumento24 páginas00 GEN-IMAN EXC HMG 6KW 10KW Manual PDFjrincon26Ainda não há avaliações

- MM 57C PDFDocumento114 páginasMM 57C PDFPhil B.50% (2)

- 800A, 800AJ SN 0300183033 To PresentDocumento612 páginas800A, 800AJ SN 0300183033 To PresentBrian BobbAinda não há avaliações

- Dl420a Om en (#10001 - 2012)Documento236 páginasDl420a Om en (#10001 - 2012)Abdelrahman100% (3)

- Damien Elite C-7Documento3 páginasDamien Elite C-7m43238Ainda não há avaliações

- C12 Manual PDFDocumento256 páginasC12 Manual PDFKrunoslav100% (3)

- 2009 10 20 PDF KOMTRAX Troubleshoot Guide 68411 PDFDocumento35 páginas2009 10 20 PDF KOMTRAX Troubleshoot Guide 68411 PDFphankhoa83-1Ainda não há avaliações

- TA35 & TA40 Articulated Dumptruck Maintenance Manual: Click Here For Table ofDocumento488 páginasTA35 & TA40 Articulated Dumptruck Maintenance Manual: Click Here For Table ofKot878100% (2)

- Chieftain 2200 3 DeckDocumento1 páginaChieftain 2200 3 DeckSrinivas NandikantiAinda não há avaliações

- Cone Crushers: C-1540 C-1540RS C-1550Documento8 páginasCone Crushers: C-1540 C-1540RS C-1550brajesh123Ainda não há avaliações

- Operation and Maintenance Manual of SD22 ShantuiDocumento230 páginasOperation and Maintenance Manual of SD22 ShantuiDaniel Loaiza89% (19)

- MV Cable Sizing CalculationDocumento1 páginaMV Cable Sizing Calculationsureshbabum85Ainda não há avaliações

- 5-Lighting System Inspection ReportDocumento5 páginas5-Lighting System Inspection ReportAldrin TaghapAinda não há avaliações

- ASC110 Tier 2 Service ManualDocumento314 páginasASC110 Tier 2 Service ManualJaya Abadi100% (3)

- Fault Code 800101 Emergency Stop Fault 2017Documento14 páginasFault Code 800101 Emergency Stop Fault 2017Justice Machiwana50% (2)

- General Spec Sheet Power Crusher PC 1270Documento2 páginasGeneral Spec Sheet Power Crusher PC 1270ion_zloteaAinda não há avaliações

- Manual Power ScreenDocumento11 páginasManual Power ScreenMichael EstupiñanAinda não há avaliações

- QJ341 HydraulicDocumento48 páginasQJ341 HydraulicJustice Machiwana100% (4)

- ISC 2013 Physics Paper 1 Theory Solved Paper PDFDocumento30 páginasISC 2013 Physics Paper 1 Theory Solved Paper PDFeltytanAinda não há avaliações

- Finlay I-130 Engine Fault ReportedDocumento4 páginasFinlay I-130 Engine Fault ReportedLuis Antonio Vega ParangueoAinda não há avaliações

- E-7 CE MANUAL Rev.1Issue.2 PDFDocumento155 páginasE-7 CE MANUAL Rev.1Issue.2 PDFnylsk8100% (5)

- P2 & P3 Piston Pumps TrainingDocumento114 páginasP2 & P3 Piston Pumps TrainingCésar Cusi Lazo100% (2)

- 1001 1501 Dumper Manual NEUSONDocumento134 páginas1001 1501 Dumper Manual NEUSONEdgar David Huallpamaita100% (1)

- Manual de Operación y Mantenimiento D65EX PDFDocumento351 páginasManual de Operación y Mantenimiento D65EX PDFKarlos Ramirez100% (1)

- ASC110-150MrCT3 ENDocumento10 páginasASC110-150MrCT3 ENDavid Apaza HurtadoAinda não há avaliações

- 374f (XWL)Documento12 páginas374f (XWL)Daryl Ivan Arce MarinAinda não há avaliações

- Criba Powertrack 800. - EspecificacionesDocumento10 páginasCriba Powertrack 800. - EspecificacionesLuis Eduardo Corzo Enriquez50% (2)

- V7000 Unified Problem Determination Guide 04Documento314 páginasV7000 Unified Problem Determination Guide 04Giuseppe RomanazziAinda não há avaliações

- Power Curber: 727 Bendix Drive PO Box 1639 Salisbury, NC USA 28146-1639 Tel. 704-636-5871 Fax. 704-633-8140Documento111 páginasPower Curber: 727 Bendix Drive PO Box 1639 Salisbury, NC USA 28146-1639 Tel. 704-636-5871 Fax. 704-633-8140BrunoAinda não há avaliações

- Series 90 Axial Piston PumpDocumento92 páginasSeries 90 Axial Piston PumpDave100% (1)

- Group 7: Hydraulic Components: Service ManualDocumento204 páginasGroup 7: Hydraulic Components: Service ManualJose Manuel Barroso PantojaAinda não há avaliações

- HST Series Cone Crusher: ManualDocumento24 páginasHST Series Cone Crusher: ManualDenAinda não há avaliações

- 06 Travel Drive 2plus2Documento23 páginas06 Travel Drive 2plus2MACHINERY101GEAR67% (3)

- Manual Issue 2 NewDocumento96 páginasManual Issue 2 NewSport Diet Music SDMAinda não há avaliações

- 22ma33d PZ PDFDocumento37 páginas22ma33d PZ PDFSantiago Fuentes Dos Reis0% (2)

- 623CT Sales Specification NewDocumento19 páginas623CT Sales Specification NewDaniel Alejandro Navarro Jara100% (1)

- 379,398,399 D and A REV1Documento167 páginas379,398,399 D and A REV1Roland LamoureuxAinda não há avaliações

- AP 240 enDocumento6 páginasAP 240 enJoão GuardadoAinda não há avaliações

- 1412TP 204 204Documento8 páginas1412TP 204 204Muhammad UmairAinda não há avaliações

- Power Curber: 727 Bendix Drive PO Box 1639 Salisbury, NC USA 28146-1639 Tel. 704-636-5871 Fax. 704-633-8140Documento358 páginasPower Curber: 727 Bendix Drive PO Box 1639 Salisbury, NC USA 28146-1639 Tel. 704-636-5871 Fax. 704-633-8140Jose Manuel Barroso PantojaAinda não há avaliações

- Hyundai R290LC 7 Crawler Excavator Service Repair ManualDocumento648 páginasHyundai R290LC 7 Crawler Excavator Service Repair ManualcodeyAinda não há avaliações

- Wa380 5Documento12 páginasWa380 5alsief1951100% (3)

- OmegaDocumento2 páginasOmegaATHOLSCHWARZAinda não há avaliações

- Komatsu D375A-5 PDFDocumento12 páginasKomatsu D375A-5 PDFtechnical trainer 011cAinda não há avaliações

- Brochure Abg7820b Abg8820b t3 en 21 20000048 CDocumento12 páginasBrochure Abg7820b Abg8820b t3 en 21 20000048 CKurniawan100% (1)

- Technical Data 214403246Documento214 páginasTechnical Data 214403246Jhoersino TurpoAinda não há avaliações

- Service and Maintenance Manual: Models 600A 600AJDocumento342 páginasService and Maintenance Manual: Models 600A 600AJHari Hara SuthanAinda não há avaliações

- RCI510 Setup PDFDocumento10 páginasRCI510 Setup PDFDaniel Castillo PeñaAinda não há avaliações

- J-1175 Dual Power Jaw Crusher: SpecificationDocumento8 páginasJ-1175 Dual Power Jaw Crusher: SpecificationAndrey L'vovAinda não há avaliações

- 1021F-1121F 20050GB PDFDocumento24 páginas1021F-1121F 20050GB PDFnksiavash0% (1)

- Om K1024898e (dx140w)Documento309 páginasOm K1024898e (dx140w)Diego Mauricio Zapata Garcia50% (2)

- 1300 Maxtrak PDFDocumento409 páginas1300 Maxtrak PDFMihai PopaAinda não há avaliações

- Centralne Smarowanie Twin-3Documento48 páginasCentralne Smarowanie Twin-3slawny77Ainda não há avaliações

- PC45MR 5 - PC55MR 5 PDFDocumento20 páginasPC45MR 5 - PC55MR 5 PDFreno andriawanAinda não há avaliações

- REP REP REP REP Repair Manual Air Manual Air Manual Air Manual Air ManualDocumento19 páginasREP REP REP REP Repair Manual Air Manual Air Manual Air Manual Air ManualManuals CE & AgAinda não há avaliações

- E7 Hydraulic Diagram-ESDocumento2 páginasE7 Hydraulic Diagram-ESCésar A. Chacón100% (1)

- z45-25j Mantenimiento 2Documento255 páginasz45-25j Mantenimiento 2jonny david martinez perezAinda não há avaliações

- Operator'S Manual: WheelloaderDocumento94 páginasOperator'S Manual: WheelloaderMichael AkhramovichAinda não há avaliações

- Manual Powertrak 750Documento7 páginasManual Powertrak 750JG Ramirez MAinda não há avaliações

- Cummins: Fault Code: 363 PID: P0251, S251 SPN: 1076 FMI: 7Documento6 páginasCummins: Fault Code: 363 PID: P0251, S251 SPN: 1076 FMI: 7Enrrique LaraAinda não há avaliações

- Operation PDFDocumento86 páginasOperation PDFOscar LosadaAinda não há avaliações

- RPM Tech LM220 Snow Blower BrochureDocumento4 páginasRPM Tech LM220 Snow Blower BrochurePhil B.Ainda não há avaliações

- SB-16-034 COE Hydroboost Reservoir Fluid OverflowDocumento8 páginasSB-16-034 COE Hydroboost Reservoir Fluid OverflowPhil B.Ainda não há avaliações

- RPM Tech LM220 Brochure 01 2020 en SourcewellDocumento4 páginasRPM Tech LM220 Brochure 01 2020 en SourcewellPhil B.Ainda não há avaliações

- SB-16-027 J08E Rocker Arm Torque Bolt Change Workshop Manual CorrectionDocumento4 páginasSB-16-027 J08E Rocker Arm Torque Bolt Change Workshop Manual CorrectionPhil B.Ainda não há avaliações

- SB-16-015 11MY-17MY Conventional DCU Software UpdateDocumento3 páginasSB-16-015 11MY-17MY Conventional DCU Software UpdatePhil B.Ainda não há avaliações

- SB-16-022 11MY-14MY Conventional Burner Atomizer Repair ProcedureDocumento15 páginasSB-16-022 11MY-14MY Conventional Burner Atomizer Repair ProcedurePhil B.Ainda não há avaliações

- SB-16-006 11MY-16MY Conventional Rear Spring Pad LooseDocumento11 páginasSB-16-006 11MY-16MY Conventional Rear Spring Pad LoosePhil B.Ainda não há avaliações

- SB-15-035 13MY-16MY COE Seat Bolt Loose or MissingDocumento6 páginasSB-15-035 13MY-16MY COE Seat Bolt Loose or MissingPhil B.Ainda não há avaliações

- SB-15-032 P2030 Workshop Manual CorrectionDocumento34 páginasSB-15-032 P2030 Workshop Manual CorrectionPhil B.Ainda não há avaliações

- High Frequency Modeling of Transformer Using Black Box Frequency Response AnalysisDocumento7 páginasHigh Frequency Modeling of Transformer Using Black Box Frequency Response AnalysisJosAinda não há avaliações

- LCD TV: Service ManualDocumento44 páginasLCD TV: Service ManualDaniel Norberto DemariaAinda não há avaliações

- Annual Report 2012: ERTMS/GSM-R & Panel of Telecom ExpertsDocumento65 páginasAnnual Report 2012: ERTMS/GSM-R & Panel of Telecom ExpertsMoyGar2014100% (1)

- Precision Magnetics Analyzer - 3260B: Technical Data SheetDocumento4 páginasPrecision Magnetics Analyzer - 3260B: Technical Data SheetBABAKAinda não há avaliações

- HSHV385K GTPDocumento4 páginasHSHV385K GTPAkshita JainAinda não há avaliações

- DX DiagDocumento13 páginasDX DiagBernardus WasitaAinda não há avaliações

- Current Electricity - Answer KeyDocumento8 páginasCurrent Electricity - Answer KeyADITYA SINGHAinda não há avaliações

- Trimble Gps in STDocumento65 páginasTrimble Gps in STMohamedAlAmineAinda não há avaliações

- Electonic Devices - S. SharmaDocumento116 páginasElectonic Devices - S. SharmaRatsihAinda não há avaliações

- EN1I6190Documento112 páginasEN1I6190Mahmoud El-abdAinda não há avaliações

- 2006 June Phy3 MsDocumento13 páginas2006 June Phy3 MsSharifahHafizahAl-jufAinda não há avaliações

- Autonomous Robot BookletDocumento6 páginasAutonomous Robot BookletAnonymous L7XrxpeI1zAinda não há avaliações

- Lg+29ln450b,+450u,+457b,+457u+ch +la31r+led+tvDocumento35 páginasLg+29ln450b,+450u,+457b,+457u+ch +la31r+led+tvСтоян ДимитровAinda não há avaliações

- Square Wave GeneratorDocumento6 páginasSquare Wave GeneratorRahul KunduAinda não há avaliações

- Thyristor - CaledonDocumento4 páginasThyristor - CaledonIDA HAMIDAHAinda não há avaliações

- HEDTD CL444 101 C1gDocumento2 páginasHEDTD CL444 101 C1gJaimecolina2004Ainda não há avaliações

- GILL Capacity Analyser Owners ManualDocumento16 páginasGILL Capacity Analyser Owners ManualBrunoAinda não há avaliações

- M SCD enDocumento204 páginasM SCD enMosargt ArgAinda não há avaliações

- Formula Manipal ReportDocumento25 páginasFormula Manipal Reportsiddhartha180987100% (9)

- Vacuum Pump Project PresentationDocumento5 páginasVacuum Pump Project PresentationAlexandru Robert DumbravăAinda não há avaliações

- The Electric Motor IIDocumento6 páginasThe Electric Motor IIGray Fox GarcíaAinda não há avaliações

- Alternador Delco Remy 24 VCD 100 Amo.19011153Documento2 páginasAlternador Delco Remy 24 VCD 100 Amo.19011153JoséLuisRodríguezSánchezAinda não há avaliações

- FDDGDocumento3 páginasFDDGaliffpadziAinda não há avaliações