Escolar Documentos

Profissional Documentos

Cultura Documentos

Restraint: FJ Restraint Flexible Expansion Joint

Enviado por

Al JameelTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Restraint: FJ Restraint Flexible Expansion Joint

Enviado por

Al JameelDireitos autorais:

Formatos disponíveis

RESTRAINT SYSTEMS www.romac.

com • 1-800-426-9341

FJ RESTRAINT

FLEXIBLE EXPANSION JOINT

MATERIAL SPECIFICATIONS

FJ RESTRAINT

USE: The FJ Restraint is a flexible ductile iron fitting, ™

developed to accommodate pipeline forces that result

in damaged pipe or loss of service. The FJ Restraint is

designed to compensate for expansion, contraction, ro- F L E X I B L E E X PA N S I O N J O I N T

RESTRAINT SYSTEMS

tation, bending and settlement of your pipeline all at the U.S. PATENT: 5,897,146

same time, with one fitting.

MATERIALS

CASTINGS: The Casing, Ball and Sleeve are cast of duc- MADE IN U.S.A.

tile (nodular) iron, meeting or exceeding ASTM SIZES 3 - 12"

A 536, Grade 65-45-12.

FLANGE ENDS: Flanges meet the dimensional require-

ments of ANSI Class 125 and 150 bolt circles.

MJ ENDS: Mechanical Joint ends meet the dimensional

requirements of either ANSI/AWWA C111/A21.11 or

ANSI/AWWA C153/A21.53 depending on size. Sizes 3" - 12"

NSF61 certified upon request.

MJ RESTRAINT: To securely fix MJ ends of the FJ Re-

straint, Romac Grip Rings or Roma Grip can be supplied.

CASING COVERS, 14 - 24 INCH: Protective polyethylene

LOCK RING: Series 400 stainless steel. Limits expansion debris cover.

and contraction of FlexiJiont up to maximum working

pressure. Standard MJ gasket is used with this fitting. COATINGS: The entire fitting is lined and coated with

See ANSI/AWWA C111/A21.11 for specifications. Transi- fusion bonded epoxy.

tion gaskets may be used for steel (IPS) pipe size PVC. PROTECTIVE SLEEVE: Polyethylene sleeve, 8 mils thick

RING GASKETS: Ring gaskets are made of dual durome- to cover entire FJ Restraint assembly after installation.

ter Ethylene Propylene Diene Methylene rubber (EPDM) Provided with flexible rubber bands to secure to pipe

compounded for water and sewer service. ends and FJ Restraint.

CASING COVERS, 3-12 INCH: Ethylene Propylene Diene PRESSURE: When properly installed the FJ Restraint can

Methylene (EPDM) compounded for water and sewer be used at working pressures up to 350 psi.

service.

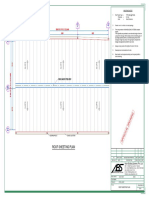

FJ RESTRAINT WITH FLANGED ENDS FJ RESTRAINT COMPONENTS

Casing Cover

Casing

Ball

Lockring

FJ RESTRAINT WITH MECHANICAL JOINT ENDS

Ball Gasket

Casing Gasket

Sleeve

8-14 JULY 01, 2017 • REV. 02/16/2018

www.romac.com • 1-800-426-9341 RESTRAINT SYSTEMS

FJ RESTRAINT

FLEXIBLE EXPANSION JOINT

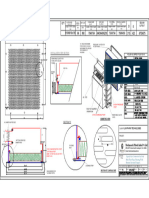

3" - 24" DIMENSIONS A FLANGED END A

FLANGE MJ MJ E

1

NOM OFFSET X X X TOTAL

A B C D E

EXPANSION ANGLE

RESTRAINT SYSTEMS

SIZE FLANGE FLANGE MJ D

L1 L1 L1 L2

4 24.7 24.1 23.5 11.2

8 35.7 35.1 34.5 22.2

3" 12 6.8 6.2 8.2 5.7 11.9 46.7 46.1 45.5 33.2 4.00 20.0°

16 57.7 57.1 56.5 44.2

20 68.7 68.1 67.5 55.2 A EXP

C

4 26.7 26.1 25.5 12.6

8 37.7 37.1 36.5 23.6 FL

4" 12 7.0 6.4 9.4 6.3 13.2 49.7 49.1 48.5 35.6 4.00 19.0° B MJ END

A

16 60.7 60.1 59.5 46.6 4

20 72.7 72.1 71.5 58.6 E

4 28.9 28.6 28.2 13.2 D

8 40.9 40.6 40.2 25.2

6" 12 7.9 7.5 11.9 7.4 15.6 52.9 52.6 52.2 37.2 6.26 18.0°

16 65.9 65.6 65.2 50.2

20 77.9 77.6 77.2 62.2

4 31.1 30.3 29.5 13.4

8 44.1 43.3 42.5 26.4 B

8" 12 8.8 8.0 14.4 8.7 18.1 57.1 56.3 55.5 39.4 6.26 17.0° C

ANGLEº

16 70.1 69.3 68.5 52.4

20 83.1 82.3 81.5 65.4

B

4 33.6 32.9 32.2 14.9 1 2

8 46.6 45.9 45.2 27.9

OFFSET

10" 12 9.3 8.6 16.9 10.1 20.7 60.6 59.9 59.2 41.9 6.26 16.0°

16 74.6 73.9 73.2 55.9

20 88.6 87.9 87.2 69.9

4 35.5 34.7 33.9 15.4

8 50.5 49.7 48.9 30.4 A FLANGED END A L2 A

12" 12 10.0 9.2 19.4 11.3 23.7 65.5 64.7 63.9 E 45.4 7.88 15.0° 1 3

7

16 80.5 79.7 78.9 60.4

D

20 95.5 94.7 93.9 75.4

4 42.9 43.0 43.1 21.0

8 55.9 56.0 56.1 34.0

14" 12 10.9 11.0 21.7 12.7 26.2 69.9 70.0 70.1 48.0 7.88 15.0°

16 84.9 85.0 85.1 63.0

20 99.9 100.0 100.1 78.0 A EXPANSION / 2 EXPANSION / 2

C L1

4 46.7 46.5 46.4 23.0 SECTION A-A

8 57.7 57.5 57.4 34.0 FLANGE X FLANGE

16" 12 11.7 11.7 24.1 14.0 28.6 72.7 72.5 72.4 49.0 9.44B 15.0°

MJ END

A L2 B

4

16 87.7 87.5 87.4 E 64.0 6

20 102.7 102.5 102.4 79.0 D

4 49.0 48.7 48.5 23.9

8 60.0 59.7 59.5 34.9

18" 12 12.5 12.3 26.3 15.1 30.9 74.0 73.7 73.4 48.9 9.44 15.0°

16 89.0 88.7 88.5 63.9

20 104.0 103.7 103.5 78.9

4 52.9 52.4 51.9 25.5 B L1

C

SECTION B-B

8 61.9 61.4 60.9

ANGLEº 34.5

20" 12 13.7 13.2 29.2 16.9 34.3 77.9 77.4 76.9 50.5 11.82 15.0° FLANGE X MJ

16 92.9 92.4 91.9 65.5 B

2

L2

5

B

1

20 107.9 107.4 106.9 80.5

OFFSET

4 56.2 55.8 55.4 26.5

8 64.2 63.8 63.4 34.5

24" 12 14.9 14.5 34.7 19.7 39.4 80.2 79.8 79.4 50.5 11.82 15.0°

16 95.2 94.8 94.4 65.5

20 110.2 109.8 104.4 80.5

Note: Dimension L1 Equals Midpoint of Expansion. L1

SECTION C-C

See page 8-16 for weights. MJ X MJ

JULY 01, 2017 8-15

RESTRAINT SYSTEMS www.romac.com • 1-800-426-9341

FJ RESTRAINT

FLEXIBLE EXPANSION JOINT

FLANGE x FLANGE FLANGE x MJ MJ x MJ

NOM. APPROX. APPROX. APPROX. LIST

SIZE OFFSET *LENGTH / PART NUMBER WT (lbs.) *LENGTH / PART NUMBER WT (lbs.) *LENGTH / PART NUMBER WT (lbs.) PRICE

4.0 24.67 / 221-01-0314 97 24.07 / 221-03-0314 93 23.47 / 221-02-0314 95

8.0 35.67 / 221-01-0325 110 35.07 / 221-03-0325 106 34.47 / 221-02-0325 108

3” 12.0 46.67 / 221-01-0336 123 46.07 / 221-03-0336 119 45.47 / 221-02-0336 121 POA

RESTRAINT SYSTEMS

16.0 57.67 / 221-01-0347 136 57.07 / 221-03-0347 132 56.47 / 221-02-0347 134

20.0 68.67 / 221-01-0358 149 68.07 / 221-03-0358 145 67.47 / 221-02-0358 147

4.0 26.66 / 221-01-0416 138 26.06 / 221-03-0416 128 25.46 / 221-02-0416 133

8.0 37.66 / 221-01-0427 155 37.06 / 221-03-0427 145 36.46 / 221-02-0427 150

4” 12.0 49.66 / 221-01-0439 173 49.06 / 221-03-0439 163 48.46 / 221-02-0439 168 POA

16.0 60.66 / 221-01-0450 189 60.06 / 221-03-0450 179 59.46 / 221-02-0450 184

20.0 72.66 / 221-01-0462 207 72.06 / 221-03-0462 197 71.46 / 221-02-0462 202

4.0 28.92 / 221-01-0617 215 28.55 / 221-03-0617 200 28.18 / 221-02-0617 208

8.0 40.92 / 221-01-0629 245 40.55 / 221-03-0629 230 40.18 / 221-02-0629 237

6” 12.0 52.92 / 221-01-0641 274 52.55 / 221-03-0641 260 52.18 / 221-02-0641 267 POA

16.0 65.92 / 221-01-0654 307 65.55 / 221-03-0654 292 65.18 / 221-02-0654 299

20.0 77.92 / 221-01-0666 336 77.55 / 221-03-0666 321 77.18 / 221-02-0666 329

4.0 31.07 / 221-01-0818 331 30.27 / 221-03-0818 303 29.47 / 221-02-0818 317

8.0 44.07 / 221-01-0831 372 43.27 / 221-03-0831 344 42.47 / 221-02-0831 358

8” 12.0 57.07 / 221-01-0844 414 56.27 / 221-03-0844 386 55.47 / 221-02-0844 400 POA

16.0 70.07 / 221-01-0857 456 69.27 / 221-03-0857 428 68.47 / 221-02-0857 442

20.0 83.07 / 221-01-0870 498 82.27 / 221-03-0870 470 81.47 / 221-02-0870 484

4.0 33.61 / 221-01-1020 466 32.91 / 221-03-1020 428 32.21 / 221-02-1020 447

8.0 46.61 / 221-01-1033 520 45.91 / 221-03-1033 482 45.21 / 221-02-1033 501

10” 12.0 60.61 / 221-01-1047 578 59.91 / 221-03-1047 541 59.21 / 221-02-1047 559 POA

16.0 74.61 / 221-01-1061 637 73.91 / 221-03-1061 599 73.21 / 221-02-1061 618

20.0 88.61 / 221-01-1075 695 87.91 / 221-03-1075 657 87.21 / 221-02-1075 676

4.0 35.48 / 221-01-1221 630 34.68 / 221-03-1221 561 33.88 / 221-02-1221 596

8.0 50.48 / 221-01-1236 708 49.68 / 221-03-1236 640 48.88 / 221-02-1236 674

12” 12.0 65.48 / 221-01-1251 787 64.68 / 221-03-1251 718 63.88 / 221-02-1251 752 POA

16.0 80.48 / 221-01-1266 865 79.68 / 221-03-1266 796 78.88 / 221-02-1266 830

20.0 95.48 / 221-01-1281 943 94.68 / 221-03-1281 874 93.88 / 221-02-1281 908

4.0 42.88 / 221-01-1427 832 42.98 / 221-03-1427 776 43.08 / 221-02-1427 804

8.0 55.88 / 221-01-1440 909 55.98 / 221-03-1440 853 56.08 / 221-02-1440 881

14” 12.0 69.88 / 221-01-1454 993 69.98 / 221-03-1454 937 70.08 / 221-02-1454 965 POA

16.0 84.88 / 221-01-1469 1,082 84.98 / 221-03-1469 1,026 85.08 / 221-02-1469 1,054

20.0 99.88 / 221-01-1484 1,171 99.98 / 221-03-1484 1,115 100.08 / 221-02-1484 1,143

4.0 46.42 / 221-01-1629 1,090 46.42 / 221-03-1629 1,034 46.42 / 221-02-1629 1,062

8.0 57.42 / 221-01-1640 1,166 57.42 / 221-03-1640 1,110 57.42 / 221-02-1640 1,138

16” 12.0 72.42 / 221-01-1655 1,270 72.42 / 221-03-1655 1,214 72.42 / 221-02-1655 1,242 POA

16.0 87.42 / 221-01-1670 1,374 87.42 / 221-03-1670 1,318 87.42 / 221-02-1670 1,346

20.0 102.42 / 221-01-1685 1,477 102.42 / 221-03-1685 1,421 102.42 / 221-02-1685 1,449

4.0 48.98 / 221-01-1830 1,307 48.74 / 221-03-1830 1,259 48.50 / 221-02-1830 1,283

8.0 59.98 / 221-01-1841 1,394 59.74 / 221-03-1841 1,346 59.50 / 221-02-1841 1,370

18” 12.0 73.98 / 221-01-1855 1,505 73.74 / 221-03-1855 1,457 73.50 / 221-02-1855 1,481 POA

16.0 88.98 / 221-01-1870 1,625 88.74 / 221-03-1870 1,577 88.50 / 221-02-1870 1,601

20.0 103.98 / 221-01-1885 1,744 103.74 / 221-03-1885 1,696 103.50 / 221-02-1885 1,720

4.0 52.90 / 221-01-2032 1,755 52.40 / 221-03-2032 1,667 51.90 / 221-02-2032 1,711

8.0 61.90 / 221-01-2041 1,844 61.40 / 221-03-2041 1,756 60.90 / 221-02-2041 1,800

20” 12.0 77.90 / 221-01-2057 2,004 77.40 / 221-03-2057 1,916 76.90 / 221-02-2057 1,960 POA

16.0 92.90 / 221-01-2072 2,153 92.40 / 221-03-2072 2,065 91.90 / 221-02-2072 2,109

20.0 107.90 / 221-01-2087 2,303 107.40 / 221-03-2087 2,215 106.90 / 221-02-2087 2,259

4.0 56.22 / 221-01-2433 2,402 55.82 / 221-03-2433 2,290 55.42 / 221-02-2433 2,349

8.0 64.22 / 221-01-2441 2,503 63.82 / 221-03-2441 2,391 63.42 / 221-02-2441 2,447

24” 12.0 80.22 / 221-01-2457 2,704 79.82 / 221-03-2457 2,592 79.42 / 221-02-2457 2,648 POA

16.0 95.22 / 221-01-2472 2,893 94.82 / 221-03-2472 2,781 94.42 / 221-02-2472 2,837

20.0 110.22 / 221-01-2487 3,081 109.82 / 221-03-2487 2,969 109.42 / 221-02-2487 3,025

* Length shown is nominal, or shipped length Larger Sizes Available Upon Request

TO ORDER: Specify Part Number and contact Romac Quotations Department

EXAMPLE: For a 3" Flange to Flange FJ Restraint with an offset of 4" Order: 221-01-0314

8-16 JULY 01, 2017

Você também pode gostar

- Basic Wellhead School 01Documento47 páginasBasic Wellhead School 01Agung Doank Yess100% (6)

- Material List and Cost EstimateDocumento23 páginasMaterial List and Cost EstimateHein Zin HanAinda não há avaliações

- Lateral Torsional Buckling: Icon LegendDocumento3 páginasLateral Torsional Buckling: Icon LegendAl JameelAinda não há avaliações

- Asme Sec Ix-WpqDocumento47 páginasAsme Sec Ix-WpqKaushal Sojitra100% (1)

- ZealCon uPVC Doors and Window System Company ProfileDocumento55 páginasZealCon uPVC Doors and Window System Company ProfileFahad Lodhi100% (3)

- Basic Surface Wellhead SchoolDocumento47 páginasBasic Surface Wellhead SchoolIWCF IADC100% (2)

- Seal-Lock Apex: All Pressure EnvironmentsDocumento8 páginasSeal-Lock Apex: All Pressure EnvironmentsHunter100% (1)

- Samaila Consultant Limited: Culvert No. Location DateDocumento8 páginasSamaila Consultant Limited: Culvert No. Location Dateebed_meleck100% (2)

- KSL Apex SPR PRNT 6-04 RedDocumento8 páginasKSL Apex SPR PRNT 6-04 RedChandra SimarmataAinda não há avaliações

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Column-C1 SIZE: - (9"X15") Column - C2 SIZE: - (9"X15") : Schedule of FootingsDocumento1 páginaColumn-C1 SIZE: - (9"X15") Column - C2 SIZE: - (9"X15") : Schedule of FootingsPrabal Sethi100% (1)

- Plating Specifications - General InformationDocumento24 páginasPlating Specifications - General InformationStas ZabarskyAinda não há avaliações

- 1 150, 50, 280 & Lever Lock 280 & Lever LockDocumento46 páginas1 150, 50, 280 & Lever Lock 280 & Lever LocksanachAinda não há avaliações

- Repair Liner ConnectionDocumento6 páginasRepair Liner ConnectionwalterAinda não há avaliações

- (381611313) BOQ EarthworkDocumento39 páginas(381611313) BOQ EarthworkAshish SadaAinda não há avaliações

- 5024 - Wire Rope Sling Inspection Form PDFDocumento1 página5024 - Wire Rope Sling Inspection Form PDFAgung NugrohoAinda não há avaliações

- Precast Wall PanelsDocumento9 páginasPrecast Wall Panelschandanes100% (1)

- BS648-1964 Weights of Building Materials PDFDocumento50 páginasBS648-1964 Weights of Building Materials PDFJeff Anderson Collins71% (7)

- Specification - For - GRP - Pipe - and - Fittings - R3Documento18 páginasSpecification - For - GRP - Pipe - and - Fittings - R3RickAinda não há avaliações

- RR RC Din 19569 4 - Bs 7775 en r3 0 PDFDocumento8 páginasRR RC Din 19569 4 - Bs 7775 en r3 0 PDFEdney DavidAinda não há avaliações

- BS 08515-2009: Rainwater Harvesting Systems - Code of PracticeDocumento52 páginasBS 08515-2009: Rainwater Harvesting Systems - Code of PracticeAl JameelAinda não há avaliações

- Annexd1 - Infrastructure Works Grand BoisDocumento25 páginasAnnexd1 - Infrastructure Works Grand BoisAl Jameel100% (1)

- Gas Piping Building Services 1Documento21 páginasGas Piping Building Services 1abinayaAinda não há avaliações

- Installation Guide For Sure-Seal Drip Edge: 1-1/2" SS RING Shank NailDocumento2 páginasInstallation Guide For Sure-Seal Drip Edge: 1-1/2" SS RING Shank NailConstantin GubavuAinda não há avaliações

- VSL Data Sheets Bonded SlabDocumento5 páginasVSL Data Sheets Bonded SlabKamal AlkurdiAinda não há avaliações

- VSL Data Sheets Bonded SlabDocumento5 páginasVSL Data Sheets Bonded SlabHugo LeãoAinda não há avaliações

- SS 08Documento1 páginaSS 08eno khanAinda não há avaliações

- Seal CoolerDocumento2 páginasSeal CoolerJulio Adolfo López Portocarrero100% (1)

- Reflex Level Gauges Rev 1Documento5 páginasReflex Level Gauges Rev 1mehdi HKAinda não há avaliações

- Especificaciones Compresor Centac C700Documento2 páginasEspecificaciones Compresor Centac C700Ascencio RubenAinda não há avaliações

- GPT 1-15 LineBackerDocumento4 páginasGPT 1-15 LineBackerazadeazAinda não há avaliações

- Gate Valve Standard FeaturesDocumento3 páginasGate Valve Standard Featuresعزت عبد المنعمAinda não há avaliações

- Royal Model Flushometer: BG U XYV YJ YKDocumento1 páginaRoyal Model Flushometer: BG U XYV YJ YKMohammed BasheeruddinAinda não há avaliações

- Control Valves: Model C000 Globe Style Main Valve Model CA000 Angle Style Main ValveDocumento4 páginasControl Valves: Model C000 Globe Style Main Valve Model CA000 Angle Style Main ValveAnderson SiqueiraAinda não há avaliações

- Installation Guide For Securedge 3000 XT: #9 X 1-1/2" Ss Screw W/ WasherDocumento2 páginasInstallation Guide For Securedge 3000 XT: #9 X 1-1/2" Ss Screw W/ WasherConstantin GubavuAinda não há avaliações

- 02 - SIDE CONN BOTTOM OP-ModelDocumento1 página02 - SIDE CONN BOTTOM OP-ModelAshfaqAinda não há avaliações

- Imi PBM - Pb-Af3 - 2022Documento2 páginasImi PBM - Pb-Af3 - 2022ariesca.instrumentacionAinda não há avaliações

- T-Pattern Globe Valves PDFDocumento16 páginasT-Pattern Globe Valves PDFandistwn99Ainda não há avaliações

- 501/453/RAC/L: Cable Gland Selection TableDocumento2 páginas501/453/RAC/L: Cable Gland Selection TablesedcAinda não há avaliações

- Catalog Cast Steel Swing Check ValveDocumento4 páginasCatalog Cast Steel Swing Check ValvezahoorAinda não há avaliações

- 320C-USN Tactical 320CC-USN Rappel Belt: A E D L P RDocumento2 páginas320C-USN Tactical 320CC-USN Rappel Belt: A E D L P RKyle YangAinda não há avaliações

- Bay Sect VillanuevaDocumento2 páginasBay Sect VillanuevaRafaela VillanuevaAinda não há avaliações

- Keys-3001 en 10032639Documento2 páginasKeys-3001 en 10032639Janos NagyAinda não há avaliações

- Installation Guide For Securedge 3000: #9 X 1-1/2" Ss Screw W/ WasherDocumento2 páginasInstallation Guide For Securedge 3000: #9 X 1-1/2" Ss Screw W/ WasherConstantin GubavuAinda não há avaliações

- Boquillas para Torre de EnfriamientoDocumento3 páginasBoquillas para Torre de EnfriamientoAnonymous Lb4hrlAf7VAinda não há avaliações

- Chesterton 891Documento2 páginasChesterton 891aiindustriyahoocoidAinda não há avaliações

- 3 - CompTJ TypicalDetailsDocumento8 páginas3 - CompTJ TypicalDetailsdougAinda não há avaliações

- Slrsebp: Mason Industries, IncDocumento2 páginasSlrsebp: Mason Industries, Incgenas7265Ainda não há avaliações

- CT WKM Ball Dynaseal 310Documento1 páginaCT WKM Ball Dynaseal 310JonathanAinda não há avaliações

- Grapa Linea Viva - RichardsDocumento1 páginaGrapa Linea Viva - RichardsDIEGO GUTIERREZAinda não há avaliações

- With External Clamping Ring: PropertiesDocumento1 páginaWith External Clamping Ring: Propertiesmiguel.cruzAinda não há avaliações

- Presentación 21kDocumento36 páginasPresentación 21kCamilo MendozaAinda não há avaliações

- BBQ Chicken M-01Documento1 páginaBBQ Chicken M-01agflamesengineering.salesAinda não há avaliações

- PW SeriesDocumento8 páginasPW SeriesMt GrAinda não há avaliações

- GLT Gate ValveDocumento6 páginasGLT Gate Valveputra keluarga cipta bangunAinda não há avaliações

- CouplingDocumento1 páginaCouplingdavih007Ainda não há avaliações

- Demco Butterfly Valves BrochureDocumento44 páginasDemco Butterfly Valves BrochureSai PrasathAinda não há avaliações

- Pompes de ProcessDocumento20 páginasPompes de ProcessMohamed Islam HEDROUGAinda não há avaliações

- Acople 5R10Documento1 páginaAcople 5R10Jose Emilio Carrero AngaritaAinda não há avaliações

- Casing End SealsDocumento2 páginasCasing End SealsSebastián LagosAinda não há avaliações

- Standing Seam Awning Product SheetDocumento1 páginaStanding Seam Awning Product SheetMoezart JsAinda não há avaliações

- Ms Blind Bolts: Alloy Steel and A-286 StainlessDocumento19 páginasMs Blind Bolts: Alloy Steel and A-286 StainlessJuan Fernando Quintero BalcazarAinda não há avaliações

- Flow Solutions Division: Durametallic SealsDocumento2 páginasFlow Solutions Division: Durametallic SealshukAinda não há avaliações

- AF C-Clamp Beam Clamp AF JR Top Beam Clamp AF Wide Mouth Top Beam ClampDocumento4 páginasAF C-Clamp Beam Clamp AF JR Top Beam Clamp AF Wide Mouth Top Beam ClampWaqas NasirAinda não há avaliações

- 501 453 Universal ColdFlowDocumento2 páginas501 453 Universal ColdFlowRavi VarmaAinda não há avaliações

- 3TH Series Section GrayDocumento24 páginas3TH Series Section Graymarcos luqueAinda não há avaliações

- Castable - Ancbor 5Documento1 páginaCastable - Ancbor 5chenghongwei2008Ainda não há avaliações

- Section Index of Gate Valves: SPL SPL SPLDocumento18 páginasSection Index of Gate Valves: SPL SPL SPLAngela Viviana ChiquizaAinda não há avaliações

- Mez Standard System 40Documento1 páginaMez Standard System 40Antonio Carlos AtaideAinda não há avaliações

- Dezurik Extended Service Life Cast Stainless Steel Knife Gate Valves KGC Es Sales 35-00-1cDocumento8 páginasDezurik Extended Service Life Cast Stainless Steel Knife Gate Valves KGC Es Sales 35-00-1cTodd MolloyAinda não há avaliações

- D. Cosmic PUF PanelsDocumento4 páginasD. Cosmic PUF PanelsShubhrajeet TiwariAinda não há avaliações

- Round VolumeDocumento4 páginasRound Volumesamikhoury83Ainda não há avaliações

- SCP Series Technical DataDocumento8 páginasSCP Series Technical DataJaldhij PatelAinda não há avaliações

- RCD - Beams (Part 3) - Continuous BeamsDocumento21 páginasRCD - Beams (Part 3) - Continuous BeamsAl JameelAinda não há avaliações

- RCD - Two-Way Solid Slabs (Part 2) - Simply Supported - Worked ExampleDocumento14 páginasRCD - Two-Way Solid Slabs (Part 2) - Simply Supported - Worked ExampleAl JameelAinda não há avaliações

- RCD - Solid Slabs (Part 2) - Simply Supported One-Way Slab - Worked ExampleDocumento13 páginasRCD - Solid Slabs (Part 2) - Simply Supported One-Way Slab - Worked ExampleAl JameelAinda não há avaliações

- RCD - Solid Slabs (Part 3) - Continuous One-Way Slab - Worked ExampleDocumento13 páginasRCD - Solid Slabs (Part 3) - Continuous One-Way Slab - Worked ExampleAl JameelAinda não há avaliações

- RCD - Solid Slabs (Part 1) - One Way Solid SlabDocumento24 páginasRCD - Solid Slabs (Part 1) - One Way Solid SlabAl JameelAinda não há avaliações

- RCD - Two-Way Solid Slabs (Part 1)Documento22 páginasRCD - Two-Way Solid Slabs (Part 1)Al JameelAinda não há avaliações

- DN STR 03005 02 PDFDocumento32 páginasDN STR 03005 02 PDFsuprayitnoAinda não há avaliações

- Column Design As Per BS 8110-1:1997Documento16 páginasColumn Design As Per BS 8110-1:1997Al JameelAinda não há avaliações

- RCD - Beams (Part 2) - Design ExampleDocumento17 páginasRCD - Beams (Part 2) - Design ExampleAl JameelAinda não há avaliações

- A Car Free TownDocumento55 páginasA Car Free TownAl JameelAinda não há avaliações

- Watershed Analysis: Autocad Civil 3D 2010 Education Curriculum Unit 4: Environmental DesignDocumento7 páginasWatershed Analysis: Autocad Civil 3D 2010 Education Curriculum Unit 4: Environmental DesignAl JameelAinda não há avaliações

- Alpha FCDocumento10 páginasAlpha FCAl JameelAinda não há avaliações

- Dua CoronavirusDocumento11 páginasDua CoronavirusOmer MubbasherAinda não há avaliações

- DP 1st FLR LayoutDocumento1 páginaDP 1st FLR LayoutAl JameelAinda não há avaliações

- Nieuwen Huijsen and Khreis 2016 Car-Free CitiesDocumento13 páginasNieuwen Huijsen and Khreis 2016 Car-Free CitiesAl JameelAinda não há avaliações

- Strategies For A Car-Free Oslo - Action Plan For Increased City LifeDocumento5 páginasStrategies For A Car-Free Oslo - Action Plan For Increased City LifeAl JameelAinda não há avaliações

- Citizens Guide LEED-NDDocumento44 páginasCitizens Guide LEED-NDDavid Moya ArancibiaAinda não há avaliações

- Project SampleDocumento1 páginaProject SampleAl JameelAinda não há avaliações

- DP Column-Beam-SlabDocumento1 páginaDP Column-Beam-SlabAl JameelAinda não há avaliações

- The Car Free City Model UT11013FU1Documento12 páginasThe Car Free City Model UT11013FU1Al JameelAinda não há avaliações

- FC 400Documento1 páginaFC 400Al JameelAinda não há avaliações

- Fca 501Documento3 páginasFca 501Al JameelAinda não há avaliações

- Style Cl1: Normal Range .40" W/ Removable LugsDocumento1 páginaStyle Cl1: Normal Range .40" W/ Removable LugsAl JameelAinda não há avaliações

- Style Cl2: Wider Range .80" W/ Removable LugsDocumento1 páginaStyle Cl2: Wider Range .80" W/ Removable LugsAl JameelAinda não há avaliações

- Style Sl1: Normal Range .40" W/ Removable BoltsDocumento1 páginaStyle Sl1: Normal Range .40" W/ Removable BoltsAl JameelAinda não há avaliações

- Structural Drawng For General NotesDocumento1 páginaStructural Drawng For General NotesMuhammad Wazim AkramAinda não há avaliações

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocumento4 páginasWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashAinda não há avaliações

- Tds of Takelac W Series 1 3Documento2 páginasTds of Takelac W Series 1 3Wang WJAinda não há avaliações

- Natural-Fiber - Glass-Fiber Hybrid Bio-Composite Building MaterialsDocumento14 páginasNatural-Fiber - Glass-Fiber Hybrid Bio-Composite Building MaterialskinfeAinda não há avaliações

- Vci-Anticorrosion Paper: Characteristics Ferrogard/Multiguard TypesDocumento2 páginasVci-Anticorrosion Paper: Characteristics Ferrogard/Multiguard TypesJaya RidwantoAinda não há avaliações

- Normas AlumínioDocumento45 páginasNormas AlumíniovanessaAinda não há avaliações

- BOQ For Lot6 RoadDocumento4 páginasBOQ For Lot6 RoadZelalem MengistuAinda não há avaliações

- ModernlongDocumento11 páginasModernlongAttila EngiAinda não há avaliações

- KomGuide E PDFDocumento260 páginasKomGuide E PDFAmândio PintoAinda não há avaliações

- TDS-US-ParaWeb M, Nov15Documento1 páginaTDS-US-ParaWeb M, Nov15Ammarah AzmatAinda não há avaliações

- Acoustic Insulation Under FloorDocumento11 páginasAcoustic Insulation Under FloorMiteshaAinda não há avaliações

- Purchase Spec. For Tubes-Nonferrous (SB111 H55 C70600)Documento5 páginasPurchase Spec. For Tubes-Nonferrous (SB111 H55 C70600)Daison PaulAinda não há avaliações

- Introduction To Masonry StructuresDocumento33 páginasIntroduction To Masonry StructuresNiraj JhaAinda não há avaliações

- Eaton Breather and Drains (Use This One) PDFDocumento3 páginasEaton Breather and Drains (Use This One) PDFmajesusAinda não há avaliações

- A319Documento2 páginasA319malika_000% (1)

- View W Section E-F: 41000 Bearing Housing CompressorDocumento3 páginasView W Section E-F: 41000 Bearing Housing CompressorMarco Avendaño PitmanAinda não há avaliações

- Norma Astm Ataque E407-99.28400Documento21 páginasNorma Astm Ataque E407-99.28400sureshkumar silvernitzAinda não há avaliações

- BFP By-Pass Tie-A/B/C: Description Quantity Capacity 1 Item NoDocumento4 páginasBFP By-Pass Tie-A/B/C: Description Quantity Capacity 1 Item NoLouie Raymond Abbas FernandezAinda não há avaliações

- ECS 3-12-4 Flanged Ductile Iron Gate Valves: Page 1 of 6Documento6 páginasECS 3-12-4 Flanged Ductile Iron Gate Valves: Page 1 of 6Florin Daniel AnghelAinda não há avaliações

- The Objective of The Experiment: Cupellation (Fire Assay)Documento8 páginasThe Objective of The Experiment: Cupellation (Fire Assay)Ibrahim MücahitAinda não há avaliações

- Sanitary Wares-NRB WESTDocumento4 páginasSanitary Wares-NRB WESTkimonirAinda não há avaliações