Escolar Documentos

Profissional Documentos

Cultura Documentos

AISC Properties Viewer

AISC Properties Viewer

Enviado por

miguel sotoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AISC Properties Viewer

AISC Properties Viewer

Enviado por

miguel sotoDireitos autorais:

Formatos disponíveis

10/4/2019 AISC_Properties_Viewer.

xls

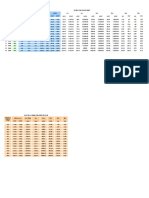

AISC 13th EDITION MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single Angles Double Angles Rectangular

Y Y Y Y Y Y

k1=1.0625

k tf=0.855 tf=0.436 b=6

bf=5.75 t=0.5

y(bar)=1.07 x(bar)=0.655

x(bar)=0.634 tf=0.36 d=3.5 t=0.375 X

d=14.3 T X d=10 X X d=6 h=16

d=5.09 X y(bar)=1.15

tw=0.51 tw=0.24 tw=0.24 b=2.5 y(bar)=1.67

(0, 3/8, or 3/4

bf=10.1 bf=2.6 gap) b=16

W14X82 C10X15.3 WT5X11 L3-1/2X2-1/2X3/8[2] 2L6X6X1/2 HSS16X16X5

A= 24 in.^2 A= 4.48 in.^2 A= 3.24 in.^2 A= 2.11 in.^2 A= 11.5 in.^2 A= 35

d= 14.3 in. d= 10 in. d= 5.090 in. d= 3.5 in. d= 6 in. h= 16

tw = 0.51 in. tw = 0.24 in. tw = 0.240 in. b= 2.5 in. b= 6 in. b= 16

bf = 10.1 in. bf = 2.6 in. bf = 5.750 in. t= 0.375 in. t= 0.5 in. t(des) = 0.581[3]

tf = 0.855 in. tf = 0.436 in. tf = 0.360 in. k= 0.7500 in. wt./ft. = 39.3 plf. wt./ft. = 127.00

k(des) = 1.45 in. k= 1 in. k(des) = 0.6600 in. wt./ft. = 7.20 plf. Ix = 39.7 in.^4 Ix = 1370

k(det) = 1.6875 in. T= 8 in. k(det) = 0.9375 in. eo = 0.30 in. Sx = 9.18 in.^3 Sx = 171

k1 = 1.0625 in. gage = 1.5 in. gage = 2.75 in. Ix = 2.56 in.^4 rx = 1.86 in. rx = 6.25

T= 10.875[4] in. rts = 0.869 in. wt./ft. 11.00 plf. Sx = 1.09 in.^3 y(bar) = 1.67 in. Zx = 200

gage = 5.5[5] in. ho = 9.56 in. bf/(2*tf) 7.990 rx = 1.100 in. Zx = 16.4 in.^3 Iy = 1370

wt./ft. = 82 plf. wt./ft. = 15.3 plf. d/tw 21.200 y(bar) = 1.150 in. yp = 0 in. Sy = 171

bf/(2*tf) 5.92 eo = 0.796 in. Ix = 6.88 in.^4 Zx = 1.960 in.^3 ry(0) = 2.5[6] in. ry = 6.25

h/tw = 22.4[7] Ix = 67.3 in.^4 Sx = 1.72 in.^3 yp = 0.668 in. ry(3/8) = 2.63[8] in. Zy = 200

Ix = 881 in.^4 Sx = 13.5 in.^3 rx = 1.46 in. Iy = 1.09 in.^4 ry(3/4) = 2.76[9] in. h(flat) = 13.1875

Sx = 123 in.^3 rx = 3.87 in. y(bar) = 1.070 in. Sy = 0.59 in.^3 Qs(0) = 3.42 b(flat) = 13.1875

rx = 6.05 in. Zx = 15.9 in.^3 Zx = 3.02 in.^3 ry = 0.716 in. Qs = 3.52 J= 2170

Zx = 139 in.^3 Iy = 2.27 in.^4 yp = 0.282 in. x(bar) = 0.655 in. ro(bar)(0) = 3.62 in. C= 276

Iy = 148 in.^4 Sy = 1.15 in.^3 Iy = 5.71 in.^4 Zy = 1.070 in.^3 H(0) = 0.827 A(surf) = 5.17

Sy = 29.3 in.^3 ry = 0.711 in. Sy = 1.99 in.^3 xp = 0.303 in. ro(bar)(3/8) = 0.836 in.

ry = 2.48 in. x(bar) = 0.634 in. ry = 1.33 in. Iz = 0.61 in.^4 H(3/8) = 0.846 Round HSS &

Zy = 44.8 in.^3 Zy = 2.34 in.^3 Zy = 3.05 in.^3 Sz = 0.33 in.^3 ro(3/4) = 1 in. Y

rts = 2.85 in. xp = 0.224 in. Qs(50) = 0.837 rz = 0.535 in. H(3/4) = 1

ho = 13.5 in. J= 0.209 in.^4 J= 0.12 in.^4 TAN(a) = 0.495

J= 5.07 in.^4 Cw = 45.5 in.^6 Cw = 0.107 in.^6 Qs(36) = 1.000

Cw = 6710 in.^6 a= 23.74[10] in. a= 1.53[11] in. J= 0.103 in.^4 Plates O.D.=8.625

a= 58.54[12] in. ro(bar) = 4.19 in. ro(bar) = 2.16 in. Cw = 0.0714 in.^6 Y

Wno = 33.9 in.^2 H= 0.884 H= 0.830 a= 1.34[13] in. t=0.375

Sw = 73.3 in.^4 ro(bar) = 1.69 in. X

Qf = 27.6 in.^3 H= 0.000 b=12 Pipe8STD

Qw = 68.2 in.^3 A= 7.85

t= 0.375 in. O.D. = 8.625

b= 12 in. I.D. = 7.981

wt./ft. = 15.31 plf. t(nom) = 0.322

A= 4.500[14] in.^2 t(des) = 0.3

Ix = 0.053[15] in.^4 wt./ft. = 28.60

Sx = 0.281[16] in.^3 Ix = Iy = 68.1

rx = 0.108[17] in. Sx = Sy = 15.8

Iy = 54.000[18] in.^4 rx = ry = 2.95

Sy = 9.000[19] in.^3 Zx = Zy = 20.8

ry = 3.464[20] in. J= 136

J= 54.053[21] in.^4 C= ---

NOMENCLATURE FOR AISC VERSION 13.0 MEMBER PROPERTIES AND DIMENSIONS:

A =Cross-sectional area of member (in.^2)

d =Depth of member, parallel to Y-axis (in.)

h =Depth of member, parallel to Y-axis (in.)

tw =Thickness of web of member (in.)

bf =Width of flange of member, parallel to X-axis (in.)

b =Width of member, parallel to X-axis (in.)

tf =Thickness of flange of member (in.)

k =Distance from outer face of flange to web toe of fillet (in.)

k1 =Distance from web centerline to flange toe of fillet (in.)

T =Distance between fillets for wide-flange or channel shape = d(nom)-2*k(det) (in.)

gage =Standard gage (bolt spacing) for member (in.) (Note: gages for angles are available by viewing comment box at cell K18.)

Ix =Moment of inertia of member taken about X-axis (in.^4)

Sx =Elastic section modulus of member taken about X-axis (in.^3)

rx =Radius of gyration of member taken about X-axis (in.) = SQRT(Ix/A)

Iy =Moment of inertia of member taken about Y-axis (in.^4)

Sy =Elastic section modulus of member taken about Y-axis (in.^3)

ry =Radius of gyration of member taken about Y-axis (in.) = SQRT(Iy/A)

Zx =Plastic section modulus of member taken about X-axis (in.^3)

Zy =Plastic section modulus of member taken about Y-axis (in.^3)

rts =SQRT(SQRT(Iy*Cw)/Sx) (in.)

https://www.dropbox.com/sh/7blb9vy69hsjotr/AAAP8nZH1wJ3u21J56-Lxz95a/Ayudas y tablas/AISC_Properties_Viewer.xls?dl=0 1/6

10/4/2019 AISC_Properties_Viewer.xls

xp =horizontal distance from designated member edge to plastic neutral axis (in.)

yp =vertical distance from designated member edge to plastic neutral axis (in.)

ho =Distance between centroid of flanges, d-tf (in.)

J =Torsional moment of inertia of member (in.^4)

Cw =Warping constant (in.^6)

C =Torsional constant for HSS shapes (in.^3)

a =Torsional property, a = SQRT(E*Cw/G*J) (in.)

E =Modulus of elasticity of steel = 29,000 ksi

G =Shear modulus of elasticity of steel = 11,200 ksi

Wno =Normalized warping function at a point at the flange edge (in.^2)

Sw =Warping statical moment at a point on the cross section (in.^4)

Qf =Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Qw =Statical moment at the mid-depth of the section (in.^3)

x(bar) =Distance from outside face of web of channel shape or outside face of angle leg to Y-axis (in.)

y(bar) =Distance from outside face of outside face of flange of WT or angle leg to Y-axis (in.)

eo = Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) tf*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

xo =x-coordinate of shear center with respect to the centroid of the section (in.)

yo =y-coordinate of shear center with respect to the centroid of the section (in.)

ro(bar) =Polar radius of gyration about the shear center = SQRT(xo^2+yo^2+(Ix+Iy)/A) (in.)

H =Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

LLBB =Long legs back-to-back for double angles

SLBB =Short legs back-to-back for double angles

h(flat) =The workable flat (straight) dimension along the height, h (in.)

b(flat) =The workable flat (straight) dimension along the width, b (in.)

A(surf) =The total surface area of a rectangular or square HSS section (ft.^2/ft.)

STD =Standard weight (Schedule 40) pipe section

XS =Extra strong (Schedule 80) pipe section

XXS =Double-extra strong pipe section

https://www.dropbox.com/sh/7blb9vy69hsjotr/AAAP8nZH1wJ3u21J56-Lxz95a/Ayudas y tablas/AISC_Properties_Viewer.xls?dl=0 2/6

10/4/2019 AISC_Properties_Viewer.xls

https://www.dropbox.com/sh/7blb9vy69hsjotr/AAAP8nZH1wJ3u21J56-Lxz95a/Ayudas y tablas/AISC_Properties_Viewer.xls?dl=0 3/6

10/4/2019 AISC_Properties_Viewer.xls

https://www.dropbox.com/sh/7blb9vy69hsjotr/AAAP8nZH1wJ3u21J56-Lxz95a/Ayudas y tablas/AISC_Properties_Viewer.xls?dl=0 4/6

10/4/2019 AISC_Properties_Viewer.xls

[1]

"AISC 13.0 Properties Viewer.xls"

written by:Alex Tomanovich, P.E.

[2]

WORKABLE GAGES IN ANGLE LEGS (inches)

Leg876543-1/232-1/221-3/41-1/21-3/81-1/41

g4-1/243-1/232-1/221-3/41-3/81-1/817/87/83/45/8

g132-1/22-1/42

g2332-1/21-3/4

For an angle, the gage "g" shown is the distance from the back of the member to the bolt in the angle leg, when only one row of bolts is present.For angle legs >= 5", the potential for two rows of bolts exists.Thus, the gage "g1" is analog

Note:Other gages are permitted to suit specific requirements subject to clearances and edge distance

limitations.

[3]

The wall thickness, 't(des)', is the actual (design) value, not the nominal wall thickness.

[4]

The 'T' distance shown is the nominal "detailing" value, and not the "design" value.

T = d(nom)-2*k(det).

[5]

The "gage" shown is the spacing between the bolts in the flange. The "halve-gage" is taken each side of the member centerline.

When a gage is displayed as a set ofthree numbers such as:(3) 7.5 (3)it refers to 4 rows of bolts with 3 "gages" or spacings

= 3", 7.5", and 3" in this case.

[6]

The radius of gyration for the minor (Y) axis, 'ry', with a 0" gap between back-to-back of angle legs.

[7]

The 'h/tw' ratio shown is calculated as follows:

h/tw = (d-2*k(des))/tw = T(des)/tw

[8]

The radius of gyration for the minor (Y) axis, 'ry', with a 3/8" gap between back-to-back of angle legs.

[9]

The radius of gyration for the minor (Y) axis, 'ry', with a 3/4" gap between back-to-back of angle legs.

[10]

Torsional property, 'a', is determined as follows:

a = SQRT(E*Cw/G*J)

where:E = 29,000 ksi (Elastic Modulus)

G = 11,200 ksi (Shear Modulus)

[11]

Torsional property, 'a', is determined as follows:

a = SQRT(E*Cw/G*J)

where:E = 29,000 ksi (Elastic Modulus)

https://www.dropbox.com/sh/7blb9vy69hsjotr/AAAP8nZH1wJ3u21J56-Lxz95a/Ayudas y tablas/AISC_Properties_Viewer.xls?dl=0 5/6

10/4/2019 AISC_Properties_Viewer.xls

G = 11,200 ksi (Shear Modulus)

[12]

Torsional property, 'a', is determined as follows:

a = SQRT(E*Cw/G*J)

where:E = 29,000 ksi (Elastic Modulus)

G = 11,200 ksi (Shear Modulus)

[13]

Torsional property, 'a', is determined as follows:

a = SQRT(E*Cw/G*J)

where:E = 29,000 ksi (Elastic Modulus)

G = 11,200 ksi (Shear Modulus)

[14]

Cross-sectional area, 'A', is determined as follows:

A = b*t

[15]

X-axis moment of inertia, 'Ix', is determined as follows:

Ix = b*t^3/12

[16]

X-axis section modulus, 'Sx', is determined as follows:

Sx = b*t^2/6

[17]

X-axis radius of gyration, 'rx', is determined as follows:

rx = t/SQRT(12)

[18]

Y-axis moment of inertia, 'Iy', is determined as follows:

Iy = t*b^3/12

[19]

Y-axis section modulus, 'Sy', is determined as follows:

Sy = t*b^2/6

[20]

Y-axis radius of gyration, 'ry', is determined as follows:

ry = b/SQRT(12)

[21]

Torsional constant, 'J', is determined as follows:

J = Ix + Iy

https://www.dropbox.com/sh/7blb9vy69hsjotr/AAAP8nZH1wJ3u21J56-Lxz95a/Ayudas y tablas/AISC_Properties_Viewer.xls?dl=0 6/6

Você também pode gostar

- AISC Properties ViewerDocumento81 páginasAISC Properties ViewerHomero Silva100% (22)

- Frame Design GuidelinesDocumento30 páginasFrame Design GuidelinesAnbazhagan Deenadhayalan91% (23)

- Steel Tubes PropertiesDocumento49 páginasSteel Tubes Propertieskarunamoorthi_p2209Ainda não há avaliações

- Steel Section PropertiesDocumento2 páginasSteel Section Propertiesman.drakeAinda não há avaliações

- Is 1893 2016Documento48 páginasIs 1893 2016navanit patel100% (2)

- ECCS - n45Documento13 páginasECCS - n45David MartinsAinda não há avaliações

- Ac133 2014Documento10 páginasAc133 2014Eddie ChanAinda não há avaliações

- Design of Vertical Beam (Gate) Loading CalculationDocumento7 páginasDesign of Vertical Beam (Gate) Loading CalculationSivaArabiAinda não há avaliações

- Indian Steel Weight Calculator FreeDocumento1 páginaIndian Steel Weight Calculator Freeparth shahAinda não há avaliações

- For Maximum Load (Normal Case) : From Staad From STAAD With ImpactDocumento4 páginasFor Maximum Load (Normal Case) : From Staad From STAAD With ImpactVasu Deva Rao ChilukuriAinda não há avaliações

- Costing Calculations:: Date: 31-Mar-2016 Revision: 0 Costing Preet Vihar MezzanineDocumento5 páginasCosting Calculations:: Date: 31-Mar-2016 Revision: 0 Costing Preet Vihar MezzanineRakesh SharmaAinda não há avaliações

- Welding 12Documento21 páginasWelding 12AhmedAinda não há avaliações

- Client Comment Response - DG FoundationDocumento7 páginasClient Comment Response - DG FoundationAnnelzAinda não há avaliações

- Simple 4: 'file:///conversion/tmp/scratch/359433723.xls'#$BEAM DESIGN Last Updated: 2007Documento1 páginaSimple 4: 'file:///conversion/tmp/scratch/359433723.xls'#$BEAM DESIGN Last Updated: 2007امين الزريقيAinda não há avaliações

- Base Plate & BoltsDocumento3 páginasBase Plate & BoltsarvnndAinda não há avaliações

- Demo Weld Cost Calc XLDocumento10 páginasDemo Weld Cost Calc XLKhalid Ahmod ShibleeAinda não há avaliações

- Space 2001Documento43 páginasSpace 2001Nguyen Duc CuongAinda não há avaliações

- Design Wind Pressure: Aseana Bpo BuildingDocumento5 páginasDesign Wind Pressure: Aseana Bpo BuildingRyan De Vera PagalAinda não há avaliações

- Design of Non Composite Beams With Large OpeningsDocumento73 páginasDesign of Non Composite Beams With Large OpeningsbalaAinda não há avaliações

- Plate & RectangularDocumento7 páginasPlate & RectangularibicengAinda não há avaliações

- Jindal SectionsDocumento2 páginasJindal SectionsVivek GosaviAinda não há avaliações

- Flange Sizing ProgramDocumento15 páginasFlange Sizing Program심판자0% (1)

- Anchor BoltDocumento4 páginasAnchor BoltAhmed Shaban0% (1)

- Beam Design With Deflection CheckDocumento4 páginasBeam Design With Deflection Checkdinesh choudharyAinda não há avaliações

- Steel Table SectionsDocumento24 páginasSteel Table Sectionsshshank gupta100% (1)

- MOMENT CONNECTION-AISC-extended-r5Documento24 páginasMOMENT CONNECTION-AISC-extended-r5raghav abudhabi0% (1)

- Welded PipeDocumento2 páginasWelded PipeНемања КараклајићAinda não há avaliações

- Wind Load CalculationDocumento98 páginasWind Load CalculationAnonymous HJ7hmihhAinda não há avaliações

- Round To SQDocumento2 páginasRound To SQalexnomitaAinda não há avaliações

- Steel Column DesignDocumento4 páginasSteel Column DesignEly Jane DimaculanganAinda não há avaliações

- For Battened Columns For Strength Cal 10% Increase in The KL/RDocumento4 páginasFor Battened Columns For Strength Cal 10% Increase in The KL/RvineetukAinda não há avaliações

- Jindal SectionsDocumento2 páginasJindal Sectionsanon_107812982Ainda não há avaliações

- BOQ of Factory Building - Civil, CostingDocumento17 páginasBOQ of Factory Building - Civil, Costingengineermak2023Ainda não há avaliações

- Seismic Calculation IS 1893 - RSMDocumento3 páginasSeismic Calculation IS 1893 - RSMshazanAinda não há avaliações

- SP by CantileverDocumento18 páginasSP by CantileverPaldexAinda não há avaliações

- Beam DesignDocumento2 páginasBeam DesignvineetukAinda não há avaliações

- Section Properties of Cold Formed SteelDocumento8 páginasSection Properties of Cold Formed SteelDharaneshskumarAinda não há avaliações

- Calculator - U Tubes - HSA & QtyDocumento4 páginasCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Duct Support CalculationDocumento4 páginasDuct Support CalculationSuresh DAinda não há avaliações

- Beam Simply SupportedDocumento16 páginasBeam Simply SupportedVengatesh HariAinda não há avaliações

- Jim CK Load - Calc 052611Documento19 páginasJim CK Load - Calc 052611SudathipTangwongchaiAinda não há avaliações

- EqualAngle PDFDocumento2 páginasEqualAngle PDFGalih PutraAinda não há avaliações

- Table-1 Properties of Rolled Steel SectionsDocumento40 páginasTable-1 Properties of Rolled Steel Sectionsramanathan appu0% (1)

- ChimneyDocumento20 páginasChimneyA.K.M Shafiq MondolAinda não há avaliações

- Built Up Welding Calculation BeamDocumento1 páginaBuilt Up Welding Calculation Beamabou92Ainda não há avaliações

- Calculation of Safety Factor Guarding Against Joint OpeningDocumento12 páginasCalculation of Safety Factor Guarding Against Joint OpeningPandiyarajan RajuAinda não há avaliações

- Chimney Calculation SheetDocumento14 páginasChimney Calculation SheetSrinivasa Rao VenkumahanthiAinda não há avaliações

- Steel Beam Marked B6Documento27 páginasSteel Beam Marked B6Babu SundararamanAinda não há avaliações

- Thk. S.F. K.R.: Dish - Dish 2100Documento3 páginasThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarAinda não há avaliações

- Dimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mDocumento77 páginasDimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mPablo Cesar PanessoAinda não há avaliações

- Cost Estimate of WarehouseDocumento16 páginasCost Estimate of WarehouseAnil SuryawanshiAinda não há avaliações

- WL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Documento3 páginasWL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Tanwir AhmadAinda não há avaliações

- Header Pipe Design 27.01.2017Documento1 páginaHeader Pipe Design 27.01.2017maheshbandhamAinda não há avaliações

- UniversalBeam1 PDFDocumento1 páginaUniversalBeam1 PDFNarayanan MoorthyAinda não há avaliações

- CASTELLATED BEAM PropertiesDocumento2 páginasCASTELLATED BEAM PropertiesHemant SonawadekarAinda não há avaliações

- 8224 Grating No HeaderDocumento69 páginas8224 Grating No HeadervishalnalwarAinda não há avaliações

- Sheet Metal Thickness Schedule As Per Smacna: Thinckness in Inches Weight Thickness in MillimetersDocumento1 páginaSheet Metal Thickness Schedule As Per Smacna: Thinckness in Inches Weight Thickness in MillimetersMuhammedShafiAinda não há avaliações

- Thrust Block CalcsDocumento8 páginasThrust Block CalcsMUTHUKKUMARAMAinda não há avaliações

- Anchor Bolt Design As Per American CodeDocumento1 páginaAnchor Bolt Design As Per American CodeS A K ClostreAinda não há avaliações

- Isolated Footing (ACI)Documento4 páginasIsolated Footing (ACI)engyana engyyyAinda não há avaliações

- Design of Shear Connector For Composite Bending ActionDocumento2 páginasDesign of Shear Connector For Composite Bending ActionankitAinda não há avaliações

- Diseño de Elementos en Tracción - LRFDDocumento263 páginasDiseño de Elementos en Tracción - LRFDAlejandro CardenasAinda não há avaliações

- Aisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosDocumento3 páginasAisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosJharri E HuertoAinda não há avaliações

- AISC Properties ViewerDocumento4 páginasAISC Properties ViewerGANESHAinda não há avaliações

- Mathcad Leaf SpringDocumento3 páginasMathcad Leaf SpringsharanietAinda não há avaliações

- Homework 1Documento3 páginasHomework 1hassaniqbal84Ainda não há avaliações

- Pavement Fatigue CrackingDocumento43 páginasPavement Fatigue CrackingJorge Mauricio de SouzaAinda não há avaliações

- 2009 ACIStructJ LubellBentzCollins SpacingDocumento10 páginas2009 ACIStructJ LubellBentzCollins SpacingrohitAinda não há avaliações

- ThesisDocumento499 páginasThesisSevrinAinda não há avaliações

- Materials and Design: Mostafa Alizadeh, Morteza Mirzaei-AliabadiDocumento6 páginasMaterials and Design: Mostafa Alizadeh, Morteza Mirzaei-Aliabadiyahya nefawyAinda não há avaliações

- Z PurlinDocumento25 páginasZ Purlinharishram123456100% (1)

- 1 PhET-Unit 7-ELASTICITY-01 PDFDocumento10 páginas1 PhET-Unit 7-ELASTICITY-01 PDFChristian Nathaniel Ramon PalmaAinda não há avaliações

- Pipe Bend RadiusDocumento8 páginasPipe Bend RadiusAdagharaAinda não há avaliações

- Ejma 8TDocumento3 páginasEjma 8TpiziyuAinda não há avaliações

- CE4044 - Assign No.2 - Saromines, RDocumento3 páginasCE4044 - Assign No.2 - Saromines, RRichard SarominesAinda não há avaliações

- Bruhn + Supplement PDFDocumento1.128 páginasBruhn + Supplement PDFCraig Swenson100% (4)

- Course in Machine Design: Fatigue IDocumento58 páginasCourse in Machine Design: Fatigue IavenashaAinda não há avaliações

- Single Span Composite Precast Beam and Deck Bridge Design ManualDocumento26 páginasSingle Span Composite Precast Beam and Deck Bridge Design Manualani4576100% (1)

- Seismic Zone Factor (2305843009213704243)Documento3 páginasSeismic Zone Factor (2305843009213704243)Zwe Banyar MyatAinda não há avaliações

- Strength of Materials 2022 by S K Mondal 8 MB-edited PDFDocumento338 páginasStrength of Materials 2022 by S K Mondal 8 MB-edited PDFRajesh sahaAinda não há avaliações

- Materials Classification, Properties and ApplicationsDocumento76 páginasMaterials Classification, Properties and ApplicationsgatproAinda não há avaliações

- Plate End Debonding in FRP-plated RC Beams-I: Experiments: J. Yao, J.G. TengDocumento15 páginasPlate End Debonding in FRP-plated RC Beams-I: Experiments: J. Yao, J.G. TengHùngAinda não há avaliações

- Wa0019.Documento38 páginasWa0019.asraful.adalderAinda não há avaliações

- Tsunami!: What Happened & WhyDocumento27 páginasTsunami!: What Happened & WhyabiramihrAinda não há avaliações

- Analysis of Driven Pile Setup With Abaqus/Standard 2006Documento1 páginaAnalysis of Driven Pile Setup With Abaqus/Standard 2006SIMULIACorpAinda não há avaliações

- Ellipsoidal Ends en 13445-3 - 8.8.3Documento2 páginasEllipsoidal Ends en 13445-3 - 8.8.3met-calcAinda não há avaliações

- Practice ExcelDocumento117 páginasPractice ExcelNathanniel GonzalesAinda não há avaliações

- Base IsolationDocumento15 páginasBase Isolationcigogeorge100% (2)

- 9-4 Method of Virtual Work: Trusses 9-4 Method of Virtual Work: TrussesDocumento9 páginas9-4 Method of Virtual Work: Trusses 9-4 Method of Virtual Work: TrussesSheane GutomanAinda não há avaliações

- GuideDocumento42 páginasGuideGibral Maulana100% (2)