Escolar Documentos

Profissional Documentos

Cultura Documentos

Annex G 800-2007

Enviado por

sbarwal90 notas0% acharam este documento útil (0 voto)

4 visualizações3 páginasAnnex G 800-2007

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoAnnex G 800-2007

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

4 visualizações3 páginasAnnex G 800-2007

Enviado por

sbarwal9Annex G 800-2007

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 3

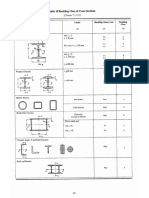

‘They shall be designed to resist tension due to uplift

forces and tension due to bending moments as

appropriate.

F-5.2.2 When calculating the tension forces due to

bending moments, the lever arm shall not be taken as

‘more than the distance between the centroid of the

1s 800 : 2007

F-5.2.4 If no special elements for resisting the shear

force are provided, such as block or bar shear

connectors, it shall be demonstrated that sufficient

resistance to transfer the shear force between the

column and the foundation is provided by one of the

following:

bearing area on the compression side and the centroid ) Frictional resistance of the joint between the

‘of the bolt group on the tension side, taking the base plate and the foundation.

tolerances on the positions of the holding down bolts bb) Shear resistance of the holding down bolts

into account. ©) Shear resistance of the surrounding part of

F-5.2.3 Holding down bolts shall either be anchored {he foundation.

into the foundation by a hook or by a washer plate or 4) Shear and bearing resistance ofthe shear key

by some other appropriate load distributing member plates welded tothe base plate and embedded

embedded in the concrete, in the pedestal/foundation.

ANNEX G

(Clause 17.16)

GENERAL RECOMMENDATIONS FOR STEELWORK TENDERS AND CONTRACTS,

G-1 GENERAL

G-1.1 The recommendations given in this Annex are

in line with those generally adopted for steelwork

construction and are meant for general information,

G-1.2 These recommendations do not form part ofthe

requirements ofthe standard and compliance with these

is not necessary forthe purpose of complying with this

standard

G-1.3 The recommendations are unsuitable for

inclusion asa block requirement in a contract, but in

drawing up a contact the points mentioned should be

given consideration,

G-2 EXCHANGE OF INFORMATION

Before the steelwork design is commenced, the

building designer should be satisfied that the planning

of the building, its dimensions and other principal

factors meet the requirements of the building owner

and comply with regulations of all authorities

concerned Collahoration af building designer and

steelwork designer should begin at the outset of the

project by joint consideration of the planning and of

such questions as the stanchion spacing, materials to

be used for the construction, and depth of basement.

G-3 INFORMATION REQUIRED BY THE

STEELWORK DESIGNER

G-3.1 General

a) Site plans showing in plan and elevation of

135

the proposed location and main dimensions

of the building or structure;

Ground levels, existing and proposed;

Pariculars of buildings or other constructions

‘which may have to remain on the actual site

of the new building or structure during the

erection of the steelwork;

Particulars of adjacent buildings affecting, or

affected by, the new work;

Stipulation regarding the erection sequence

‘or time schedule:

Conditions affecting the position or continuity

of members;

Limits of length and weight of steel members

in tansit and erection;

Drawings of the substructure, proposed or

existing, showing:

1) levels of stanchion foundations, if already

determined;

any dotaile affecting the stanchion bavee

‘or anchor bolts;

permissible bearing pressure on the

foundation; and

4) provisions for grouting,

[NOTE — In the case of new work, the substructure

‘should be designed in accordance with the eelevant

standards dealing with foundations and substructure.

»

°

4

°

FE)

)

2)

3)

i) The maximum wind velocity appropriate to

the site (see IS 875); and

1s 800:

%

a)

b)

°

8)

°

0

2)

2007

Environmental factors, such as proximity to

sea coast, and corrosive aumosphiere,

Reference to bye-laws and regulations

affecting the steelwork design and

construction.

Further Information Relating to Buildings

Plans of the floors and roof with principal

dimensions, elevations and cross-sections

showing heights between floor levels.

‘The occupancy of the floors and the positions

of any special loads should be given.

‘The building drawings, which should be fully

dimensioned, should preferably be tothe scale

of 1 to 100 and should show all stairs, fire-

escapes, lifts, ete, suspended ecilings, flues

and ducts for hesting and ventilating. Doors

and windows should be shown, as the

‘openings may be taken into account in the

computations of dead load.

Requirements should be given in respect of

any maximum depth of beams or minimum,

head room.

Large-scale details should be given of any

special features effecting the steelwork.

‘The inclusive weight per m? of walls, floors,

roofs, suspenced ceilings, stairs and

partitions, or particulars of their construction

and finish for the computation of dead load.

‘The plans should indicate the floors, which

are to be designed to carry partitions. Where

the layout of partitions is not known, or a

given layouts liable to alteration, these facts

should be specially noted so that allowance

say be made for pastitions in any position

(see IS 875).

The superimposed loads on the floors

appropriate to the occupancy, as given in

15875 or as otherwise required.

Details of special loads from cranes, runways,

tips, lifts, bunkers, tanks, plant and equipment.

‘The grade of fieresistance appropriate to the

‘occupancy as mzy be required.

G-4 INFORMATION REQUIRED BY TENDERER

(IF NOT ALSO DESIGNER )

G-4.1 General

a)

»

°

All information listed under G-3.1;

Climatic conditions at site-seasonal variations

of temperature, humidity, wind velocity and

direction;

Nature of soil, Results of the investigation of

sub-soil at site of building or structure;

136

a

°)

2

»)

d

»

m)

n)

»)

Accessibility of site and details of power

supply:

Whether the steelwork contractor will be

required to survey the site and set outor check

the building or structure lines, foundations and

levels;

Seting-out plan of foundations, stanchions

and levels of bases;

Cross-sections and elevations of the steel

structure, as necessary, with large-scale details

of special features:

Whether the connections are to be bolted,

riveted or welded, Particular attention should

bbe drawn to connections of a special nature,

such as tuned bolts, high strength friction grip

bolis, long rivets and overhead welds;

Quality of steel, and provisions for

identification;

Requirements in respect of protective

paiatings at works and on site, galvanizing or

cement wash;

Approximate dates for commencement and

completion of erection;

Details of any tests which have to be made

during the course of erection or upon

completion; and

Schedule of quantities. Where the tenderer is

required to take off quantities, a list should

be given of the principal items to be included

in the schedule

G-4.2 Additional Information Relating to Buildings

a)

»)

°

ed

°

Schedule of stanchions giving sizes, lengths

and typical details of brackets, joints, ete;

Plan of grillages showing sizes, lengths and

levels of grillage beams and particulars of any

stiffeners required;

Plans of floor beams showing sizes, lengths

and levels eccentricities and end moments.

‘The beam reactions and details of the type of

connection required should be shown on the

plans;

Plan of roof steelwork. Fora flat roof, the plan

shuld give particutars simtlar to those of a

floor plan. Where the roof is pitched, details

should be given of trusses, portals, purlins,

bracing, ete;

‘The steelwork drawings should preferably be

toa scale of 1 to 100 and should give

identification marks against all members; and

Particulars of holes required for services,

pipes, machinery fixings, etc. Such holes

should preferably he drilled at works

G-43 Information Relating to Execution of Building

Work

a)

»)

°

4

‘Supply of Materials;

Weight of Steelwork for Payment;

Wastage of Steel;

Insurance, Freight and Transport from Shop

to Site;

Site Facilities for Erection:

‘Tools and Plants;

Mode and Terms of Payment;

Schedules:

Forced Majeure (Sections and provisions for

liquidation and damages for delay in

completion); and

Escalation Sections.

e

0

2

h)

d

&

G-5 DETAILING

In addition to the number of copies of the approved

drawings or details required under the contract,

dimensioned shop drawings or detalls should be

submitted in duplicate to the engineer who should

retain one copy and return the other tothe steel supplier

or fabricators with his comments if any.

G-6 TIME SCHEDULE

As the dates on which subsequent trades can

‘commence, depend on the progress of erection of the

steel framing, the time schedule for the latter should

be carefully drawn up and agreed to by the parties

concemed at a joint meeting.

G-7 PROCEDURE ON SITE.

‘The steelwork contractor should be responsible for the

Positioning and levelling of all steelwork. Any checking

‘or approval of the setting out by the general contractor

or the engineer should not relieve the steelwork

contractor of his responsibilities in this respect.

G-8 INSPECTION

References may be made to IS 7215 for general

guidance,

137

1S 800 : 2007

G-8.1 Access to Contractor's Works

‘The contractor should offer facilites for the inspection

of the work at all stages.

G-8.2 Inspection of Fabrication

Unless otherwise, agreed, the inspection should be

carried out at the place of fabrication. The contractor

should be responsible for the accuracy of the work

and for any error, which may be subsequently

discovered.

G-8.3 Inspection on Site

‘To facilitate inspection, the contractor should during,

all working hours, have a foreman or properly

accredited charge hand available on the site, together

with a complete set of contract drawings and any

further drawings and instructions which may have been

issued from time to time,

G-9 MAINTENANCE

0.1 Coneral

Where steelwork is to be encased in solid concrete,

brickwork or masonry, the question of maintenance

should not arise, but where steelwork is to be housed

in hollow fire protection or is to be unprotected,

particularly where the steelwork is exposed to a

corroding agent, the question of painting or protective

treatment of the steelwork should be given careful

consideration at the construction stage, having regard

to the special circumstances of the case,

G-9.2 Connections

Where connections are exposed to a corroding agent,

they should be periodically inspected, and any corroded

part should be thoroughly cleaned and painted.

G-9.2.1 Where bolted connections are not solidly

encased and are subject to vibratory effects of

machinery or plant, they should be periodically

inspected and all bolt tightened.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Resistance To Overturning of Single Short Pile PDFDocumento26 páginasResistance To Overturning of Single Short Pile PDFsbarwal9Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Table 19 IS 800 2007 PDFDocumento1 páginaTable 19 IS 800 2007 PDFsbarwal9Ainda não há avaliações

- Table 20 IS 800 2007Documento1 páginaTable 20 IS 800 2007sbarwal9Ainda não há avaliações

- Table 17 IS 800 2007Documento1 páginaTable 17 IS 800 2007sbarwal9Ainda não há avaliações

- Table 14 IS 800 2007Documento1 páginaTable 14 IS 800 2007sbarwal9Ainda não há avaliações

- Table 15 IS 800 2007Documento1 páginaTable 15 IS 800 2007sbarwal9Ainda não há avaliações

- 2015 ICAS Exams Year 4-6 StudentsDocumento1 página2015 ICAS Exams Year 4-6 Studentssbarwal90% (1)

- Table 13a IS 800 2007Documento1 páginaTable 13a IS 800 2007sbarwal9Ainda não há avaliações

- Table 9C IS 800 2007Documento1 páginaTable 9C IS 800 2007sbarwal9Ainda não há avaliações

- Table 11 IS 800 2007Documento1 páginaTable 11 IS 800 2007sbarwal9Ainda não há avaliações

- Table 9B IS 800 2007Documento1 páginaTable 9B IS 800 2007sbarwal9Ainda não há avaliações

- Table 10 IS 800 2007Documento1 páginaTable 10 IS 800 2007sbarwal9Ainda não há avaliações

- Table 9A IS 800 2007Documento1 páginaTable 9A IS 800 2007sbarwal9Ainda não há avaliações

- Table 11 IS 800 1980Documento1 páginaTable 11 IS 800 1980sbarwal9Ainda não há avaliações

- FLR PlateDocumento1 páginaFLR Platesbarwal9Ainda não há avaliações

- Annex H 800-2007Documento3 páginasAnnex H 800-2007sbarwal9Ainda não há avaliações

- Reduction Factor NZS 3404Documento1 páginaReduction Factor NZS 3404sbarwal9Ainda não há avaliações