Escolar Documentos

Profissional Documentos

Cultura Documentos

Section 4: Specification Classification

Enviado por

Iam FroilanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Section 4: Specification Classification

Enviado por

Iam FroilanDireitos autorais:

Formatos disponíveis

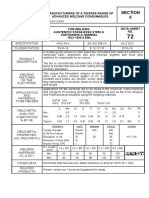

MANUFACTURERS OF A DIVERSE RANGE OF SECTION

ADVANCED WELDING CONSUMABLES 4

WI-0304 DS39 RD-100 Rev. 4, 01.07.2013

DATA SHEET

BASIC LOW HYDROGEN ELECTRODE NO.

RD-100 FOR WELDING STEELS WITH A MINIMUM UTS

OF 700 N/mm2 39

SPECIFICATION AWS A5.5 JIS Z 3212

CLASSIFICATION E10016-G D7016

The design emphasis of the chemically basic flux is engineered to ensure the

optimum weld metal properties demanded by the specification are fully met. The

PRODUCT basic flux containing the appropriate alloying elements but minimal iron powder,

DESCRIPTION is extruded onto a high purity ferritic core wire and bound with a blend of silicates

that ensure both coating strength and a coating resistant to subsequent moisture

absorption.

The chemical nature of the flux together with its controlled coating factor allows

WELDING the electrode to be used at relatively low amps. This factor together with the fairly

fluid but quick freezing slag facilitate vertical up welding including controlled

FEATURES

penetration root runs.

OF THE

ELECTRODE Overall the arc is very stable, slag detachability is good, fillet welds are slightly

convex and metal recovery is some 98% with respect to weight of the core wire.

Ferritic high strength low alloy (HSLA) steels, eg: quenched and tempered AISI

4130, 4140, BS970 709M40 (En19), and DIN 42CrMo4.

APPLICATIONS Fabrication of higher strength steels involving a requirement to meet a minimum

all-weld metal UTS of 700 N/mm2 (100 ksi) with butt welds in the stress relieved

AND

condition.

MATERIALS For offshore oil well-head process pipework and fittings, these nickel-free

TO BE WELDED electrodes satisfy NACE MR-0175 requirements intended to ensure resistance to

sulphide-induced stress corrosion cracking combined with good sub-zero notch

toughness.

C Mn Si S P Cr Ni Mo Fe

WELD METAL MIN 0.05 0.5 0.2 - - 0.1 - 0.2

ANALYSIS MAX. 0.15 2.0 0.8 0.02 0.03 0.4 1.8 0.4

COMPOSITION TYPICAL 0.10 1.5 0.4 0.01 0.01 0.2 1.6 0.3 Bal.

% BY Wt.

* Undiluted weld metal shall have the minimum of at least one of the element as specified on AWS A5.5-2006

PROPERTY UNITS MINIMUM TYPICAL OTHERS

2

Tensile strength N/mm 690 750

WELD METAL 0.2% Proof stress N/mm2 600 680

PROPERTIES

Elongation on 4d % 16 25

(ALL WELD METAL)

Reduction of Area (RA) % - 65

Impact energy -20 C o

J - 80

WELDING Ø (mm) 2.6 3.2 4.0 5.0

AMPERAGE MIN 50 70 130 180

AC or DC+ MAX 85 125 170 220

OTHER DATA Electrodes that have become damp should be re-dried at 150oC for 1 hour

RELATED

Please contact our Technical Department for detail

PRODUCTS

Você também pode gostar

- Section 4: Specification ClassificationDocumento1 páginaSection 4: Specification ClassificationIam FroilanAinda não há avaliações

- RD 360 1post File 2019 12 10 161048Documento1 páginaRD 360 1post File 2019 12 10 161048Adityo Bambang WAinda não há avaliações

- Section 4: Specification ClassificationDocumento1 páginaSection 4: Specification ClassificationTheo AnggaraAinda não há avaliações

- RD 360R3Documento1 páginaRD 360R3Rachmad Budi WAinda não há avaliações

- Section 4: Specification ClassificationDocumento1 páginaSection 4: Specification ClassificationTheo AnggaraAinda não há avaliações

- Section 6: Specification ClassificationDocumento1 páginaSection 6: Specification ClassificationDimas Wisnu WardanaAinda não há avaliações

- Section 3: Specification Classification Product DescriptionDocumento1 páginaSection 3: Specification Classification Product DescriptionFery FebryantoAinda não há avaliações

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocumento1 página3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarAinda não há avaliações

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocumento1 página3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarAinda não há avaliações

- Section 3: Specification Classification Product DescriptionDocumento1 páginaSection 3: Specification Classification Product DescriptiontamharAinda não há avaliações

- CIN2Documento1 páginaCIN2aditya wicaksonoAinda não há avaliações

- Section 4: Specification ClassificationDocumento1 páginaSection 4: Specification ClassificationTheo AnggaraAinda não há avaliações

- Ga-24 Aws E7024Documento1 páginaGa-24 Aws E7024Bang OchimAinda não há avaliações

- Cin 1 Post File 2019 12 17 100704Documento1 páginaCin 1 Post File 2019 12 17 100704Adrian SetyadharmaAinda não há avaliações

- Data Sheet AL-BRONZEDocumento1 páginaData Sheet AL-BRONZEAris WicaksonoAinda não há avaliações

- Ds134ns Eco 6r0Documento1 páginaDs134ns Eco 6r0yadi_baeAinda não há avaliações

- Spek Electoda Nikko CIN-1Documento1 páginaSpek Electoda Nikko CIN-1anon_962923083Ainda não há avaliações

- SS 316 (0.5 FN) : Stainless Steel ElectrodeDocumento1 páginaSS 316 (0.5 FN) : Stainless Steel Electrodeflasher_for_nokiaAinda não há avaliações

- Section 4: Specification ClassificationDocumento1 páginaSection 4: Specification ClassificationRudi SyamAinda não há avaliações

- DS125NSSUGARR2Documento1 páginaDS125NSSUGARR2Frandika PrimayogaAinda não há avaliações

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocumento1 páginaSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SAinda não há avaliações

- Betanox D Welding ElectrodeDocumento1 páginaBetanox D Welding ElectrodearavindpeetaAinda não há avaliações

- Section 2 - Nikko Welding ConsumablesDocumento9 páginasSection 2 - Nikko Welding Consumablesangga franugrahaAinda não há avaliações

- NDS-2209R: Section 13Documento1 páginaNDS-2209R: Section 13hilwan sultonAinda não há avaliações

- 1564 Fox Ev 85 ElettrodoDocumento1 página1564 Fox Ev 85 ElettrodoAminAinda não há avaliações

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Documento3 páginasAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouAinda não há avaliações

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocumento1 páginaL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55Ainda não há avaliações

- Electrode Booklet F Web 93Documento1 páginaElectrode Booklet F Web 93satnamAinda não há avaliações

- 1.smaw All PDFDocumento76 páginas1.smaw All PDFkaviatchennaiAinda não há avaliações

- 1.4462 PropertiesDocumento1 página1.4462 PropertiesutreshwarmiskinAinda não há avaliações

- 5 - Section 14 - Arc Welding ConsumablesDocumento11 páginas5 - Section 14 - Arc Welding Consumablesrizkialia12Ainda não há avaliações

- FOX CN 23-12 Mo-ADocumento1 páginaFOX CN 23-12 Mo-AVIRPOPAinda não há avaliações

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocumento1 páginaYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusAinda não há avaliações

- Electrode Booklet F Web 100Documento1 páginaElectrode Booklet F Web 100satnamAinda não há avaliações

- Cu ZN 05Documento2 páginasCu ZN 05wjjt6chgtmAinda não há avaliações

- Domex 420 MCDocumento2 páginasDomex 420 MCHugo RodriguezAinda não há avaliações

- Diamondspark 52 MC: Seamless Metal-Cored WireDocumento2 páginasDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesAinda não há avaliações

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDocumento3 páginasStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulAinda não há avaliações

- Bohler Fox S 308L-16Documento1 páginaBohler Fox S 308L-16HAKANAinda não há avaliações

- Duplex Stainless Steel WeldingDocumento25 páginasDuplex Stainless Steel WeldingcfcshakerAinda não há avaliações

- NSN 308post File 2019 12 11 145456.en - IdDocumento1 páginaNSN 308post File 2019 12 11 145456.en - Idabu yazidAinda não há avaliações

- 2594 TigDocumento1 página2594 TigAnonymous skBAwexAinda não há avaliações

- Welding Consumables For Hydro Power StationsDocumento16 páginasWelding Consumables For Hydro Power StationsMohamed FaragAinda não há avaliações

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocumento7 páginas22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeNguyen Anh TuanAinda não há avaliações

- D and H NewDocumento37 páginasD and H NewBharat AhirAinda não há avaliações

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocumento2 páginasDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangAinda não há avaliações

- Welding Electrodes CatalogueDocumento7 páginasWelding Electrodes CatalogueFiroj Al HasanAinda não há avaliações

- Cu ZN 20Documento2 páginasCu ZN 20wjjt6chgtmAinda não há avaliações

- Diamondspark Ni1 RC: Seamless Cored WireDocumento2 páginasDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyAinda não há avaliações

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Documento1 páginaSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaAinda não há avaliações

- NSB 316LR0 PDFDocumento1 páginaNSB 316LR0 PDFDika AnggaraAinda não há avaliações

- 9Cr - 1mo Modified With V, NB, and N.: OdificationDocumento1 página9Cr - 1mo Modified With V, NB, and N.: OdificationAshok RajAinda não há avaliações

- E7018 1 Eutherme lh1 PDFDocumento1 páginaE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hAinda não há avaliações

- 421 - Domex 700 MCDocumento2 páginas421 - Domex 700 MClalamed21Ainda não há avaliações

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocumento1 páginaOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanAinda não há avaliações

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonAinda não há avaliações

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantNo EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantNota: 3.5 de 5 estrelas3.5/5 (3)

- Eisenreich 2006Documento22 páginasEisenreich 2006Nicolas GIL ROMEROAinda não há avaliações

- Condensate PumpsDocumento69 páginasCondensate PumpsGABRIELAinda não há avaliações

- Opuscolo Pompeii Nov18 HiResDocumento5 páginasOpuscolo Pompeii Nov18 HiResnot a bookwormAinda não há avaliações

- Chapter ViDocumento4 páginasChapter ViBrielle Shai CruzAinda não há avaliações

- Module 4 Introduction To Electrical Conductors Wiring Techniques and Schematic Reading Part1Documento10 páginasModule 4 Introduction To Electrical Conductors Wiring Techniques and Schematic Reading Part1Jan Renn ArleAinda não há avaliações

- Pu-2013-Color-fixing Polyester and Preparatio1Documento4 páginasPu-2013-Color-fixing Polyester and Preparatio1Syed Tawab ShahAinda não há avaliações

- Applications of Synthetic Polymers in Clinical Medicine: M.F. MaitzDocumento3 páginasApplications of Synthetic Polymers in Clinical Medicine: M.F. MaitzNokhuthula MutemararoAinda não há avaliações

- Calculate Saturated-Gas Loads For Vacuum SystemsDocumento137 páginasCalculate Saturated-Gas Loads For Vacuum SystemsDHAVALESH AMAinda não há avaliações

- Solution For Assignment 2Documento3 páginasSolution For Assignment 2akshaythakkar_219925Ainda não há avaliações

- As 2358-1990 Adhesives - For Fixing Ceramic TilesDocumento8 páginasAs 2358-1990 Adhesives - For Fixing Ceramic TilesSAI Global - APAC100% (1)

- Semester 2 Lesson 11 Extra Pratice For Naming Covalent CompoundsDocumento2 páginasSemester 2 Lesson 11 Extra Pratice For Naming Covalent CompoundsKelvin RequenaAinda não há avaliações

- Budget Savello 2021Documento32 páginasBudget Savello 2021marketing kinaryaAinda não há avaliações

- Nut and Bolt Feeder Consumable Tooling PartsDocumento7 páginasNut and Bolt Feeder Consumable Tooling PartsirfanAinda não há avaliações

- ASTM D 3359-23 Rating Adhesion by Tape Test (X-Cut)Documento5 páginasASTM D 3359-23 Rating Adhesion by Tape Test (X-Cut)z6ytg7mcrjAinda não há avaliações

- Denso PVC Self-Adhesive Tape 200: Composition ApplicationDocumento1 páginaDenso PVC Self-Adhesive Tape 200: Composition ApplicationAloka KarunarathneAinda não há avaliações

- Chicken LonganisaDocumento3 páginasChicken LonganisaLemuel Jr MitchaoAinda não há avaliações

- Heatseal & Acf Heatseal & Acf Technology Technology Technology TechnologyDocumento25 páginasHeatseal & Acf Heatseal & Acf Technology Technology Technology TechnologyTuanAinda não há avaliações

- Pyrolysis of WoodDocumento42 páginasPyrolysis of WoodCléo VieiraAinda não há avaliações

- Anode Baking Furnaces WEb PDFDocumento3 páginasAnode Baking Furnaces WEb PDFuvsarathiAinda não há avaliações

- Dubai Universal Design Code - Part-HDocumento1 páginaDubai Universal Design Code - Part-Helectrowat engineeringAinda não há avaliações

- WP AssignmentDocumento10 páginasWP AssignmentMuhammad Bin TahirAinda não há avaliações

- Ceiling Cassette Split Type Air Conditioner (A Series) : Model: IM-CKA-0501-ACSONDocumento22 páginasCeiling Cassette Split Type Air Conditioner (A Series) : Model: IM-CKA-0501-ACSONslipargolokAinda não há avaliações

- Chapter 8Documento11 páginasChapter 8Tandra SinhaAinda não há avaliações

- Natraj Plastic: Agricultural ProductsDocumento10 páginasNatraj Plastic: Agricultural ProductsNatraj PlasticAinda não há avaliações

- Experiment No. 1 Difference Between Organic and Inorganic Compounds and Tests For Element Found in Organic CompoundsDocumento3 páginasExperiment No. 1 Difference Between Organic and Inorganic Compounds and Tests For Element Found in Organic CompoundsShechienahCatindoy100% (1)

- Qa-Qc Inspection / Observation Report: Municipal Market Complex, Bada Danda PuriDocumento1 páginaQa-Qc Inspection / Observation Report: Municipal Market Complex, Bada Danda PuriSandip PaulAinda não há avaliações

- This Study Resource Was: MEEN 360 Quiz: Chapter 16Documento1 páginaThis Study Resource Was: MEEN 360 Quiz: Chapter 16daniel valderramaAinda não há avaliações

- DPLV 2.1 Epoxy Primer: DP48LV (White) DP50LV (Gray) DP90LV (Black)Documento4 páginasDPLV 2.1 Epoxy Primer: DP48LV (White) DP50LV (Gray) DP90LV (Black)michaelguzziAinda não há avaliações

- Ufh Installation Guide PDFDocumento84 páginasUfh Installation Guide PDFMiroslav LuladžićAinda não há avaliações

- 1) Explain The Diffusion of Bromine Particles Throughout The Two Gas JarDocumento16 páginas1) Explain The Diffusion of Bromine Particles Throughout The Two Gas JarLee Li JieAinda não há avaliações