Escolar Documentos

Profissional Documentos

Cultura Documentos

Assignment PDF

Enviado por

Devansh Bhardwaj0 notas0% acharam este documento útil (0 voto)

77 visualizações2 páginasoptimisation of ammonia production overveiw

Título original

Assignment.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentooptimisation of ammonia production overveiw

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

77 visualizações2 páginasAssignment PDF

Enviado por

Devansh Bhardwajoptimisation of ammonia production overveiw

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 2

Devansh Bhardwaj PDP-II

ASSIGNMENT

2016A1PS0612P

CHE-F343

12/04/2019

Cost Analysis of Urea Production with ASPEN

Summary:

Urea is an organic compound with the chemical formula CO(NH2)2 consisting of

carbonyl and amide functional groups. Urea serves an important role in the

metabolism of nitrogen-containing compounds by animals and is the main

component of urine of mammals. It is an important component of nitrogen-based

fertilizers and also as a raw material for urea-formaldehyde resin which is an

industrially important polymer

(1) 2NH3 + CO2 => CARBAMATE

(2) CARBAMATE => UREA + H2O

The first reaction is carried out in a stoichiometric reactor, while the second reaction

which produces urea is carried out in a plug flow reactor where the conversion

increases along the length of the reactor.

Optimization analysis has been carried out across the plug flow reactor by varying

two parameters the length of the reactor as well as the operating pressure to obtain

maximum profit by increasing the flow rate of the urea stream

For stoichiometric reactor the pressure and the temperature has been varied, and

the profit has been similarly maximized

The length of the reactor has to be in the range of 25m- 30m.

The pressure is kept within 140 kg/sq. cm – 150 kg/sq. cm keeping in consideration

the space provisions and compressor capabilities.

In PFR It was found that as the pressure increases, we are able to increase the flow

rate of urea, which in turn increases the revenue by product sales from the process.

However, in order to increase the pressure, a greater compression cost is also

incurred. Clearly, this is a trade-off between compressor cost and product revenue

and the revenue is optimised by plotting a graph in excel by varying the pressure

from 140-150 kg/sq.-cm.

the length of the reactor has been varied which when increased, provides a greater

reactor volume that increases conversion and therefore, the final output of urea. But

increasing the length of the reactor incurs a higher equipment installation cost and

thus there is again a trade-off between urea production and equipment cost.

For stoichiometric reactor It was found that as the pressure increases, we are able to

increase the flow rate of urea, which in turn increases the revenue by product sales

from the process. However, in order to increase the pressure, a greater compression

cost is also incurred. Clearly, this is a trade-off between compressor cost and product

revenue and the revenue is optimised by plotting a graph in excel by varying the

pressure from 140-150 kg/sq.-cm.

For stoichiometric reactor’ the temperature of the reactor has been varied which

when increased, increases the conversion of the product, but also the coolant costs

and other heat exchanger costs.

After performing the sensitivity analysis of the Distillation Columns and plotting the

relevant curves, the following conclusions were arrived at.

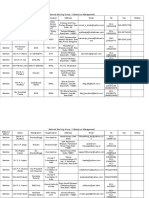

For PFR

For stoichiometric reactor

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Course Recorder (Paperless) MDR290Documento4 páginasCourse Recorder (Paperless) MDR290Jay SanchaniyaAinda não há avaliações

- Configuring and Tuning HP Servers For Low-Latency Applications-C01804533Documento29 páginasConfiguring and Tuning HP Servers For Low-Latency Applications-C01804533PhucAnhAinda não há avaliações

- Example Quality PlanDocumento11 páginasExample Quality PlanzafeerAinda não há avaliações

- Weilding TechnologyDocumento15 páginasWeilding TechnologyRAMALAKSHMI SUDALAIKANNANAinda não há avaliações

- High Impact Presentation SkillsDocumento5 páginasHigh Impact Presentation SkillsMohd AqminAinda não há avaliações

- Design Checklist-9 USACE AngineeringDocumento15 páginasDesign Checklist-9 USACE AngineeringSankar CdmAinda não há avaliações

- Birla Institute of Technology and Science, Pilani: Mid-Semester TestDocumento4 páginasBirla Institute of Technology and Science, Pilani: Mid-Semester TestDevansh BhardwajAinda não há avaliações

- Mid-Semester Test: Birla Institute of Technology and Science, PilaniDocumento3 páginasMid-Semester Test: Birla Institute of Technology and Science, PilaniDevansh BhardwajAinda não há avaliações

- An Investigation On Thermo-Hydraulic Performance oDocumento15 páginasAn Investigation On Thermo-Hydraulic Performance oDevansh BhardwajAinda não há avaliações

- Birla Institute of Technology and Science, Pilani: Quiz - 3Documento1 páginaBirla Institute of Technology and Science, Pilani: Quiz - 3Devansh BhardwajAinda não há avaliações

- Selected Chemical Engineering Operations: Lecture - 23Documento50 páginasSelected Chemical Engineering Operations: Lecture - 23Devansh BhardwajAinda não há avaliações

- Committee Report PDFDocumento72 páginasCommittee Report PDFVivek BadkurAinda não há avaliações

- StatementDocumento3 páginasStatementSachinBMetre87 SachinBMetreAinda não há avaliações

- Monthly Ladder Inspection ChecklistDocumento4 páginasMonthly Ladder Inspection ChecklistPeter Sare WolloAinda não há avaliações

- Second Invitation OriginalDocumento4 páginasSecond Invitation Originalsudhakar80Ainda não há avaliações

- Lancaster LinksDocumento3 páginasLancaster LinksTiago FerreiraAinda não há avaliações

- Fuses & Circuit Breakers PDFDocumento13 páginasFuses & Circuit Breakers PDFCarlos Luis Santos SomcarAinda não há avaliações

- Luyện tâp Liên từ Online 1Documento5 páginasLuyện tâp Liên từ Online 1Sơn KhắcAinda não há avaliações

- Customers at SurveyDocumento10 páginasCustomers at Surveynaren000Ainda não há avaliações

- Cie Earth Tester.187133635Documento3 páginasCie Earth Tester.187133635velan84Ainda não há avaliações

- Bobcat 3 Phase: Quick SpecsDocumento4 páginasBobcat 3 Phase: Quick SpecsAnonymous SDeSP1Ainda não há avaliações

- Colebrook EquationDocumento3 páginasColebrook EquationMuhammad Ghufran KhanAinda não há avaliações

- Questions Supplychain RegalDocumento2 páginasQuestions Supplychain RegalArikuntoPadmadewaAinda não há avaliações

- Delta Tester 9424 Training ModuleDocumento35 páginasDelta Tester 9424 Training ModuleNini FarribasAinda não há avaliações

- Fandek Evaporative Cooling System: F F F F Fan An An An Andek Dek Dek Dek DekDocumento2 páginasFandek Evaporative Cooling System: F F F F Fan An An An Andek Dek Dek Dek DekCH1253Ainda não há avaliações

- Vibration Isolaton SelectionDocumento24 páginasVibration Isolaton SelectionvelmuruganAinda não há avaliações

- Contact List For All NWGDocumento22 páginasContact List For All NWGKarthickAinda não há avaliações

- BMC ProactiveNetDocumento202 páginasBMC ProactiveNetfranc_estorsAinda não há avaliações

- Stand-mount/Books Helf Louds Peaker System Product SummaryDocumento1 páginaStand-mount/Books Helf Louds Peaker System Product SummaryCatalin NacuAinda não há avaliações

- 2141908Documento22 páginas2141908krunal07786Ainda não há avaliações

- Trumpf TruSystem 7500 Service ManualDocumento424 páginasTrumpf TruSystem 7500 Service ManualVitor FilipeAinda não há avaliações

- CMMIDocumento23 páginasCMMIChaithanya KumarAinda não há avaliações

- Model 7691Documento1 páginaModel 7691Khiết trầnAinda não há avaliações

- DS5000 User's GuideDocumento120 páginasDS5000 User's Guidetinu_catarigAinda não há avaliações

- Project Reoprt On JSW SteelsDocumento30 páginasProject Reoprt On JSW SteelsSakthi Krishnan100% (1)