Escolar Documentos

Profissional Documentos

Cultura Documentos

Chapter - 1: Bicycle Operated Pedal Power Water Pump

Enviado por

SHAIK NISHARDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chapter - 1: Bicycle Operated Pedal Power Water Pump

Enviado por

SHAIK NISHARDireitos autorais:

Formatos disponíveis

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 1

ABSTRACT

A Water system includes a reciprocating pump operated by pedaling

power. The pump set and includes a housing in which a foot pedal and drive

shaft rotate an eccentric pin rotating with the drive shaft moves a connecting

rod which in turn causes push rod to move linearly. The pushrod extends into

a pressure tight chamber formed above the rising main. A pump rod

connected to the push-rod extends to the conventional plunger through

verified motion. Pumps are a common means of lifting water from a clean

ground water source to a useful point of access, but all pumps have moving

parts and are therefore destined to break proper selection of a pump will

reduce undesirable downtime and will empower the local community to

manage their water source. Here we use the foot pedal pump, powered by our

legs instead of arms to lift the water from a depth range of two ft.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 1

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 2

CHARACTERISTIC OF PROJECT

The following are the main characteristic of the Project:

1) OBJECTIVE: - A project should have specific objective to

Be filled

2) TIME PERIOD: - A project it has be complete participating in

It.

3) TERM WORK: - Term work includes all the aspects of the te

Term work.

4) FEATURE: - A project should have good feature i.e. :- Q

quality,prfomance,pharmaceutical.

5) SUCCESIVE: - More and more aspects of the project and k

know at each stage Of project work.

6) MADE TO ORDER: - A project should have servile of ingredients

in term of technology.

7) RISK: - Project has certain amount involved in it, its

Perfomanc depend upon construction, Qual

quality Mechanisms.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 2

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 3

PROJECT PLANNING

After the selection of project, planning is to be done.

The success of the project depends upon the keen, careful and efficient planning of

the activities involved.

In project planning we carried out…….

MARKET SURVEY

PROJECT CAPACITY

SELECTION CAPACITY

DESIGN CAPACITY

OPERATING PLANNING

METHOD AND TIME STUDY

MATERIAL HANDLING

BUILDING AND COSTING

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 3

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

MARKET SURVEY

Market survey is essential before planning the actual production. During

market survey knowing and considering other available products their futures

demand price and quality.

Market survey helps to know about location of market, scope scales,

availability of raw material, equipment, man power and other manufacturing facilities.

After considering above all facts mass production should be planned.

We can with stand in the market but we should hence two things is that the

projects we have chosen never face any problem reading material working

procedure. In our project we had consider all above factors are confirmed to get big

market.

On basis of concept of products the market survey and group discussion we

had, we find out our project material rest for hack-saw machine will be very useful

from scale fabrication to large engineering production units where, fabrication based

production is being performed.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 4

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 4

INTRODUCTION

There is a marked need for medium head, low volume pumps in

underdeveloped countries. Such pumps, however, must satisfy a number of

very stringent constraints due to the environment to which they are exposed.

The units must be extremely low cost, uitra-reliable and almost elegantly

simple. Poverty stricken cultures that possess virtually no technical skill

comprise the environment for these pumps. The pumps must be rugged

enough to withstand substantial physical abuse in addition to an abrasive

environment. They must be simple enough in construction that local people

can be dependably trained for the maintenance and operation of these units.

Cost and the need for fuel, lubrication and maintenance eliminate

commercially available gasoline powered pump units. Windmills are generally

too experience as commercial units. And they are usually too complex and

fragile when built as low cost units. A particular problem for low cost units is a

mechanism to accommodate high winds, their resultant speed and loads. This

leads to the simplest power source – human power. Various schemes have

been devised for producing and coupling muscle power. But, by far the most

applicable, is the bicycle and the drives derived from it. This is due to the

worldwide availability of low cost bicycles. It is also due to the almost

unparalleled physiological coupling efficiency of the bicycle mechanism.

Hence, introduction of small scale irrigation like pedal pumps can play

a vital role for increasing food grain production in Bangladesh. Capital

intensive technology like deep tubewells, shallow tubewells are beyond the

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 5

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

purchasing capacity of the poor farmers, while they can afford labour

intensive technologies such as pedal pump, hand pumps, rower pumps,

treadle pumps

etc. due to their lower cost. In the context of Bangladesh, where labours are

abundant and most of the farmers are poor, the pedal pump seems to be an

appropriate irrigation technology.

Such kind of irrigation technologies are operated and maintained by

farmers themselves from their own capital for producing crop in the small

fragmented lands. The average small farm sizes spreading over a number of

scattered plots are unsuitable to irrigate with a large size of stream. But, the

manually operated technology with a small stream size is suitable for small

and fragmented farm holding and involves less mechanical and maintenance

problems. In fact the poor farmers represent 70% of population in Bangladesh

and they own only 20% of total land (GOB, 1986). Due to their extreme

poverty, they are gradually joining the landless group. In this context,

manually operated pedal pump is helpful for poor farmers to reduce poverty.

The current success of manually operated pump can be explained in terms of

factors like appropriate design, low cost, effective marketing, and high cash

returns (Orr et al., 1991).

Some researchers had focused their endeavor on the development of

low lift labor-intensive devices and had succeeded to develop some devices

of such characters like treadle pump, rower pump, wheel pump, diaphragm

pump, blower pump, etc. Operation of the devices is very laborious and

operators often complain about their suffering from various health hazards.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 6

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 5

HISTORY OF PUMPS

The pumping of water is a basic and practical technique, for more

practical than scooping it up with one’s hands or lifting it in a hand bucket.

This is true whether the water is drawn from afresh source, moved to a

needed location, purified or used for irrigation, washing or sewage treatment

or for evacuating water from an undersirable location. Regardless of the

outcome, the energy required to pump water is an extremely demanding

component of water consumption. All other processes depend or benefit

either from water descending from a higher elevation or some pressurized

plumbing system.

The ancient concept of the aqueduct took simple and eloquent

advantage of maintaining elevation of water for as long and far a distance as

possible. Thus, as water moves over great distances, it retains a larger

component of its kinetic energy by spending small portion of this energy

flowing doen a slight gradation. Granted, a useful aqueduct system ultimately

depends on a fresh water source existing at a higher elevation than the

location where the water can be of use. Gravity does all the work. In all other

instances, pumps are necessary.

No date has been established as to when the first bicycle pump was

invented, but it is believed to have been in or around 1887.

The pumping of water is a basic and practical technique, far more

practical than scooping it up with one's hands or lifting it in a hand-held

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 7

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

bucket. This is true whether the water is drawn from afresh source, moved to

a needed location, purified, or used for irrigation, washing, or sewage

treatment, or for evacuating water from an undesirable location.

Regardless of the outcome, the energy required to pump water is an

extremely demanding component of water consumption. All other processes

depend or benefit either from water descending from a higher elevation or

some pressurized plumbing system. The ancient concept of the aqueduct took

simple and eloquent advantage of maintaining elevation of water for as long

and far a distance as possible.

Thus, as water moves over great distances, it retains a larger

component of its kinetic energy by spending small portions of this energy

flowing down a slight gradation. Granted, a useful aqueduct system ultimately

depends on a fresh water source existing at a higher elevation than the

location where the water can be of use. Gravity does all the work. In all other

instances, pumps are necessary.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 8

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 6

CLASSIFICATION OF PUMPS

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 9

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER – 7

WORKING OF RECIPROCATING PUMP

Our bicycle operated pumps working principle is based on

reciprocating pump’s working principle.

Working Principle :-

(FIG. Two cylinder (duplex) reciprocating pump)

Reciprocating pump is a positive displacement pump, which causes a

fluid to move by trapping a fixed amount of it then displacing that trapped

volume into the discharge pipe.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 10

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

The fluid enters a pumping chamber via an inlet valve and is pushed

out via a outlet valve by the action of the piston or diaphragm. They are either

single acting; independent suction and discharge strokes or double acting;

suction and discharge in both directions.

During the suction stroke the piston moves left thus creating vacuum in

the Cylinder. This vacuum causes the suction valve to open and water enters

the Cylinder. During the delivery stroke the piston moves towards right.

This increasing pressure in the cylinder causes the suction valve to

close and delivery to open and water is forced in the delivery pipe. The air

vessel is used to get uniform discharge.

(FIG. WORKING OF RECIPROCATING PUMP)

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 11

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

WORKING OF BICYCLE OPERATED WATER PUMP

First of all in our project which name is “bicycle operated pedal power water

pump”. We are used in this project one bicycle body, reciprocating pump, v-belt,

stand for bicycle and extra piping assembly. Our project is worked on pedal power,

so we adjust the bicycle on a stand and its back wheel is up. Then after we use only

ring of bicycle which called in mechanical driver pulley.

And then we used the reciprocating pump. Its pulley is become driver pulley.

Then after we match the horizontal center line of both pulley and fix the pump pulley

and the cycle ring. Then after we use the v – belt to connect the bicycle ring (driver

pulley) and pump pulley (driven pulley). But before we clamp the pump on stand and

fix them so during the process it not loose.

Then after we start the pedaling the bicycle. So the back side ring (Driver

pulley) was rotate and it rotate also pump pulley (Driven pulley) so that it made the

reciprocate effect in pump and this reciprocating effect the water is come out in

pump. And we get the water by reciprocating effect by the pedal power. This is a

ecofriendlly project.

The working of the reciprocating pump is very simple and just like an I.C

engine. First of all the piston has the function of providing the suction force, so that

the liquid can be lift up or can be sucked in with great force. After that comes the

compression part which will impart the required pressure energy to the fluids. In this

part of the phase the piston have to do a great work so that the liquid can be

compressed properly and its pressure can increased to the desired level. The inlet

and the outlet valve open at a certain pressure which is set by the manufacturer.

If the piston is of single acting type which means it can suck from one side

and transmit to the same side only. But we can have the double reciprocating pump

too which have the function of the giving suction and discharge simultaneously in

each stroke. This pump can be used as the compressor also but for that we have to

have a good valve arrangement which can operate with good frequency.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 12

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

There are various uses of the reciprocating pump and they are as following:

1)The lubricating pump is a reciprocating pump and it supplies the lubrication oil to

the main engine.

2)Main bilge suction pump is also a reciprocating pump.

3)For ballast they are sometimes used.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 13

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 8

CONSTRUCTION OF BICYCLE OPERATED PUMP

MATERIALS AND METHODS

Material required :-

1) RECIPROCATING PUMP :-

A reciprocating pump is a class of positive-

displacement pumps which includes the piston pump, plunger

pump and diaphragm pump. It is often used where a relatively

small quantity of liquid is to be handled and where

delivery pressure is quite large. In reciprocating pumps, the

chamber in which the liquid is trapped, is a stationary cylinder

that contains the piston or plunger.

(FIG. RECIPROCATING PUMP)

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 14

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

2) FLAT BELT :-

A belt is a loop of flexible material used to mechanically

link two or more rotating shafts, most often parallel. Belt may be

used as a source of motion, to transmit power efficiency or to

track relative movement. In a two pulley system, the belt can

either drive the pulleys normally in one direction or the belt may

be crossed, so that the direction of the driven shaft is reversed.

As a source of motion, a conveyor belt is one application where

the belt is adapted to continuously carry a load between two

points.

( FIG. V-BELT)

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 15

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

3) BICYCLE :-

From the beginning and still today, bicycles have been

and are employed for many uses. In a utilitarian way, bicycles

were used for transportation, bicycle commuting, and utility

cycling. It could be used as a 'work horse', used by mail

carriers, paramedics, police,messengers, and general

delivery services.

The bicycle is also used for recreational purposes, such

as bicycle touring, mountain biking, physical fitness, and

play. Bicycle competitionincludes racing, BMX racing, track

racing, criterium, roller racing and time trial. Major multi-stage

events are the Tour of California, Giro d'Italia, the Tour de

France, the Vuelta a España, and the Volta a Portugal.

( FIG. BICYCLE)

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 16

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

4) COUPLER :-

A coupler is a device used to connect two shafts together at

their ends for the purpose of transmitting power. Couplings do not

normally allow disconnection of shafts during operation, however

there are torque limiting couplings which can slip or disconnect

when some torque limit is exceeded.

The primary purpose of couplings is to join two pieces of

rotating equipment while permitting some degree of misalignment or

end movement or both. By careful selection, installation and

maintenance of couplings, substantial savings can be made in

reduced maintenance costs and downtime.

(FIG. COUPLER)

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 17

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

DRAWING OF COUPLER

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 18

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

5) ELBOW:-

A durable elbow support is an accessory product used in the

commercial and residential HVAC industry to shape flexible ducts

into efficient 90-degree bends. It is also sometimes defined as a

"radius forming brace." [1] Where HVAC ducts need to bend or turn,

the elbow creates a sturdy 90-degree angle and keeps the duct

from kinking or folding, thereby increasing energy efficiency. This

can improve consistency of temperature in rooms that are heated

and air conditioned, lower the cost of utility bills, and reduce energy

consumption. Durable elbow supports can be installed on both new

and existing HVAC systems. Manufactured and marketed under

several brands, the durable elbow support is often specified by

mechanical engineers and widely recommended by environmental

agencies because it has been proven to improve energy efficiency.

(FIG. ELBOW)

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 19

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

DRAWING OF ELBOW

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 20

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

6) PULLEY :-

A pulley is a wheel on an axle or shaft that is designed to

support movement and change of direction of a cable or belt along

its circumference. Pulleys are used in a variety of ways to lift loads,

apply forces, and to transmit power. In nautical contexts, the

assembly of wheel, axle, and supporting shell is referred to as a

"block."

A pulley may also be called a sheave or drum and may have

a groove between two flanges around its circumference. The drive

element of a pulley system can be a rope, cable, belt, or chain that

runs over the pulley inside the groove.

( FIG. PULLEY)

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 21

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

BASIC DESIGN OF OUR PROJECT

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 22

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER – 9 : FLOW PROCESS CHARTS

FLOW PROCESS CHART

CHART NO OF SUMMARY

EQUIPMENT/MATERIAL/MEN SAVING

PRESENT PROPOSED

ACTIVITY/

MADE A BASE OF PROJECT OPERATION 2

TRANSPORT 3

DELAY -

METHOD:PRESENT/PAST

INSPECTION 2

STORAGE 2

LOCATION : WORKSHOP

OPERATION(S) CLOCK NO. COST DISTANCE

LABOUR TIME

MATERIAL DATE

TOTAL 9

SR DISCRIPTION QTY. DIST. TIME SYMBOL REMARKS

NO. (m) (min)

1 RAW MATERIAL IN

STORE

2 TRANSPORT TO

H.M/C

3 CUTTING

OPERATION

4 INSPECTION

5 TRANSPORT TO

WELDING M/C

6 WELDING

OPERATION

7 INSPECTION OF

WELD

8 READY TO TRANS

TO STORE

9 TO STORE

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 23

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

FLOW PROCESS CHART

CHART NO OF SUMMARY

EQUIPMENT/MATERIAL/MEN SAVING

PRESENT PROPOSED

ACTIVITY/

MADE A STAND FOR BICYCLE OPERATION 3

TRANSPORT 3

DELAY -

METHOD:PRESENT/PAST

INSPECTION 3

STORAGE 2

LOCATION : WORKSHOP

OPERATION(S) CLOCK NO. COST DISTANCE

LABOUR TIME

MATERIAL DATE

TOTAL 11

SR DISCRIPTION QTY. DIST TIME SYMBOL REMARKS

NO. . (min)

(m)

1 RAW MATERIAL IN

STORE

2 TRANSPORT TO

H.M/C

3 CUTTING OPERATION

4 INSPECTION

5 TRANSPORT TO

DRILLING M/C

6 DRILLING OPERATION

7 INSPECTION

8 OPERATION BY

HAMMERY CUTTER

9 INSPECTION

10 READY TO TRANS

11 TO STORE

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 24

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

FLOW PROCESS CHART

CHART NO OF SUMMARY

EQUIPMENT/MATERIAL/MEN SAVING

PRESENT PROPOSED

ACTIVITY/

ASSEMBLY OF ALL OF MATERIAL OPERATION 3

TRANSPORT 2

DELAY -

METHOD:PRESENT/PAST

INSPECTION -

STORAGE 2

LOCATION : WORKSHOP

OPERATION(S) CLOCK NO. COST DISTANCE

LABOUR TIME

MATERIAL DATE

TOTAL 7

SR DISCRIPTION QTY. DIST. TIME SYMBOL REMARKS

NO. (m) (min)

1 MATERIAL IN

STORE

2 TO TRANS

MATERIAL IN

ASSEMBLY

SECTION

3 ASSEMBLY BICYCLE

ON STAND

4 FIT THE PUMP

BEHIND OF

BICYCLE

5 FIT A BELT

BETWEEN BICYCLE

RING AND PUMP

PULLEY

6 READY TO TRANSP

TO STORE

7 IN STORE

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 25

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 10

COSTING

It is the determination of actual cost of article after adding different expenses

incurring in various department. It may also be defined as a system which

systematically records all the expenditure in various department to determine the

cost manufacturing.

AIM OF COSTING

1. To determine the cost of each article.

2. To determine the cost of each operation.

3. To help in deciding sale price.

4. To supply information for detecting of waste

5. It helps in reducing the total cost of manufacturing.

PROCEDURE OF COSTING :-

Costing is the technique & process of ascertaining cost. It is the classify,

recording & appropriate allocation Expenditure for determine of the production or

services.

The main elements of cost of any product areas under.

1. Material Cost

2. Labour Cost

3. Expenses

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 26

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

MATERIAL COST

DIRECT MATERIAL COST :-

Material which is directly used for manufacturing of a particular product and

which becomes the part of final product is called Direct Material. The cost of

this material is called Direct Material Cost.

INDIRECT MATERIAL COST :-

Material which is not directly used for manufacturing of a particular product

and which does not becomes the part of final product is called Indirect

Material.

LABOUR COST

DIRECT LABOUR COST :-

The labour which actually does not perform the manufacturing

processes of different material with the help of different machines is

called Direct Labour.

INDIRECT LABOUR COST :-

The labour which actually does not perform the manufacturing

processes different material directly is called Indirect Labour Cost.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 27

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

EXPENSES

DIRECT EXPENSES :-

The expenses which can be directly changed on the cost of a particular

product is called Direct Expenses.

INDIRECT EXPENSES :-

The expenses which can not be changed on the cost of a particular product is

called Indirect Expenses.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 28

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

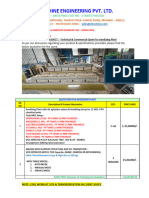

PART’S NAME AND PRICE

SR NO. PART NAME QTY. Rs.

1 BICYCLE 1 400 Rs.

2 RECIPROCATING PUMP 1 10,000 Rs.

3 V-BELT 1 250 Rs.

4 BICYCLE STAND 1 250 Rs.

5 PUMP BASE 1 400 Rs.

6 REDUCER 1 30 Rs.

7 NIPPLE 2 40 Rs.

8 ELBOW 1 30 Rs.

9 CUPLER 2 40 Rs.

10 PAINT COLOUR 200 g. 60 Rs.

11 TAPLONE TAPE 1 m. 10 Rs.

12 PRESSURE GAUGE 1 300 Rs.

TOTAL 11,810 Rs.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 29

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CALCULATION OF COSTING

PRIME COST OF PRODUCT IS :

= MATERIAL COST + LABOUR COST

= 11,810 + 2000

= 13,810 Rs.

FACTORY OVERHEAD :-

= 15% OF PRIME COST

= 13,810 *15% prime cost

= 2071 Rs.

FACTORY COST :-

= PRIME COST + FACTORY OVERHEAD

= 13,810 + 2071

= 15,881 Rs.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 30

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

SELLING OVERHEAD :-

= 20% OF FACTORY COST

= 15,881 * 20% FACTORY COST

= 3176 Rs.

PRODUTION COST :-

= FACTORY COST + SELLING OVERHEAD

= 15,881 + 3176

= 19,057 Rs.

PROFIT :-

= 15% OF PRODUTION COST

= 19,057 * 15% PRODUCTION COST

= 3811 Rs.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 31

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 11

APPLICATION

1) It can be used at farms, where electricity is not reached.

2) It can also use at mountain areas and very High Mountain villages,

where electricity is not reached.

3) Mostly it application based on agricultural related.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 32

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 12

ADVANTAGES

1) Gives high pressure at outlet.

2) Gives high suction lift.

3) Priming is not required in this pump.

4) They are used for air also.

5) The pump is self-priming.

6) Reciprocating pumps will deliver fluid at high pressure.

7) The pump can working at wide pressure range.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 33

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER – 13

DIS-ADVANTAGES

1) Reciprocating pumps give a pulsating flow.

2) The suction stroke is difficult when pumping viscous liquids.

3) The cost of producing piston pumps is high. This is due to the very

accurate sizes of the cylinders and pistons. Also, the gearing needed to

convert the rotation of the drive motor into a reciprocating action involves

extra equipment and cost.

4) The close fitting moving parts cause maintenance problems, especially

when the pump is handling fluids containing suspended solids, as the

particles can get into the small clearances and cause severe wear. The piston

pump therefore, should not be used for slurries.

5) They give low volume rates of flow compared to other types of pump.

6) Early price is much more in this pump.

7) Low discharge capacity.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 34

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER – 14

CONCLUSION

By observing the dis-advantages of the existing human powered water

pump the proposed model has been designed and fabricated.

This model can with stand with abrasive environment, manufacturing cost

of the machine is also low, about three thousand rupees. This model can be

transported any where on the same bicycle where it is used to power the water pump

so it is portable and transportable. The potential market of the machine is quite good.

In india more than 50% population are agricultural labour force and there

are approximately one hundred million bicycles in India which are being used by

farmers, the ned for irrigation water is predicated to rise dramatically.

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 35

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER - 15

REFERENCE

We find our project on you tube video. And we discussed

about this project and think to made this project. We find the information about

this project under as:-

1) www.slideshare.com

2) www.binodpanday.wordpress.com

3) www.iosrjournals.org

4) 4mechtech.blogspot.com

5) articles.compressionjobs.com

6) www.indiastudychannel.com

7) www.pumpmanufacturerindia.in

8) www.preevolvetechnics.com

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 36

[BICYCLE OPERATED PEDAL POWER WATER PUMP April 15, 2015

CHAPTER – 16

LOG BOOK

NO. DATE REASON SIGN.

1 06/02/15 SELECTION OF BODY MATERIAL

2 13/02/15 OPERATION AT WELDING M/C FOR

BASE AND STAND FOR BICYCLE

3 20/02/15 ASSEMBLE BODY PARTS

4 27/02/15 INSPECTION OF BODY

5 06/03/15 ASSEMBLE OTHER PARTS

6 13/03/15 WRINGING WORK IN PROJECT

7 20/03/15 INSPECTION

8 10/04/15 WE MANAGED TO ASSEMBLE EVERY

PARTS PROPERLY

DALIA INSTITUTE OF DIPLOM STUDIES,KANERA. 37

Você também pode gostar

- Estimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemDocumento13 páginasEstimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemAnand M VAinda não há avaliações

- Pump Final Report Winter 2011 PDFDocumento72 páginasPump Final Report Winter 2011 PDFramarao6Ainda não há avaliações

- Latest Pneumatics and Hydraulics Based Projects PDFDocumento8 páginasLatest Pneumatics and Hydraulics Based Projects PDFMahe dude0% (1)

- Adigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Documento50 páginasAdigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Melese HaileAinda não há avaliações

- Designing An Optimized Model of Water Lifting Device Without Conventional PracticesDocumento8 páginasDesigning An Optimized Model of Water Lifting Device Without Conventional PracticesKishore RaviAinda não há avaliações

- Design of 5-Megawatt Small-Hydroelectric Power PlantDocumento39 páginasDesign of 5-Megawatt Small-Hydroelectric Power PlantDeteu Cabadonga100% (1)

- Design and Fabrication of Rope Pump: Mohamed Abu Waseem RDocumento5 páginasDesign and Fabrication of Rope Pump: Mohamed Abu Waseem Rimma coverAinda não há avaliações

- Batch - 3 Project Report CorrectedDocumento40 páginasBatch - 3 Project Report CorrectedT2L KISHOREAinda não há avaliações

- MRN Project Proposal V2Documento4 páginasMRN Project Proposal V2samson kabasaAinda não há avaliações

- MRN Project Proposal V2Documento4 páginasMRN Project Proposal V2samson kabasaAinda não há avaliações

- Bicycle Water Purifier Project ReportDocumento34 páginasBicycle Water Purifier Project ReportPawan mehta70% (10)

- Hagos and Alemu ProjectDocumento33 páginasHagos and Alemu Projectmengstuhagos1223Ainda não há avaliações

- Automatic Dish Washing MachineDocumento4 páginasAutomatic Dish Washing MachineMohammed AwolAinda não há avaliações

- HydramDocumento70 páginasHydramMburu NjorogeAinda não há avaliações

- Design & Fabrication of Agricultural SprayerDocumento9 páginasDesign & Fabrication of Agricultural SprayerPiyush Pathak60% (5)

- Simplified Design and Fabrication of Water Sprinkler System: A Survey Based AnalysisDocumento6 páginasSimplified Design and Fabrication of Water Sprinkler System: A Survey Based AnalysisangelicaAinda não há avaliações

- Development of A Solar-Powered Slider-Crank Mechanism For Hand Pump in Rural AreasDocumento9 páginasDevelopment of A Solar-Powered Slider-Crank Mechanism For Hand Pump in Rural AreasPoonam KilaniyaAinda não há avaliações

- Summer Vocational Training: Gujarat Refinery, Indian Oil Corporation Ltd. Duration:15/05/2022-14/06/2022Documento76 páginasSummer Vocational Training: Gujarat Refinery, Indian Oil Corporation Ltd. Duration:15/05/2022-14/06/2022Akash YadavAinda não há avaliações

- Portable Water FiltersDocumento10 páginasPortable Water Filters124swadeshiAinda não há avaliações

- Pedal Operated Multi-Operational Machine 1Documento9 páginasPedal Operated Multi-Operational Machine 1John P0% (1)

- 1 About AHEC Presentation B Tech - 03.08.2021Documento31 páginas1 About AHEC Presentation B Tech - 03.08.2021Naruto UzumakiAinda não há avaliações

- Research Project Proposal: Optimal Design of A Smaller Diameter Airlift PumpDocumento3 páginasResearch Project Proposal: Optimal Design of A Smaller Diameter Airlift Pumpsamson kabasaAinda não há avaliações

- Improvement On OverhaulDocumento52 páginasImprovement On OverhaulyezqcpAinda não há avaliações

- Planning and Evaluation of Irrigation Projects: Methods and ImplementationNo EverandPlanning and Evaluation of Irrigation Projects: Methods and ImplementationNota: 4.5 de 5 estrelas4.5/5 (3)

- Design, Construction and Performance Test of A Foot Pump SprayerDocumento6 páginasDesign, Construction and Performance Test of A Foot Pump SprayerneivenAinda não há avaliações

- I RJ Mets 40300097618Documento10 páginasI RJ Mets 40300097618design gipfelAinda não há avaliações

- Detailed Design ReportDocumento34 páginasDetailed Design Reportktm5118Ainda não há avaliações

- Case StudyDocumento13 páginasCase StudypapapAinda não há avaliações

- Dissertation On Artificial LiftDocumento7 páginasDissertation On Artificial LiftPaperWriterServicesWashington100% (1)

- Solar Water PumpingDocumento10 páginasSolar Water PumpingderejeAinda não há avaliações

- Design Fabrication of Engine Operated Weed CutterDocumento54 páginasDesign Fabrication of Engine Operated Weed CutterVinayaga Projectinstitute100% (2)

- Boreholes and TubewellsDocumento3 páginasBoreholes and TubewellsAbebe GoshuAinda não há avaliações

- Dira Dawa University Dira Dawa Institute of Technology: Proposal For Final Project (Thesis)Documento12 páginasDira Dawa University Dira Dawa Institute of Technology: Proposal For Final Project (Thesis)andom niguseAinda não há avaliações

- Burns Noah Project Proposal Presentation 2023Documento13 páginasBurns Noah Project Proposal Presentation 2023noah burnsAinda não há avaliações

- Intern Problem 1Documento3 páginasIntern Problem 1Anuj PalAinda não há avaliações

- Ranvir Singh Project B.techDocumento15 páginasRanvir Singh Project B.techANUJ MalhotraAinda não há avaliações

- Spiarl Tube Water Wheel Pump: A Proposed ModelDocumento4 páginasSpiarl Tube Water Wheel Pump: A Proposed ModelJAERC IQQOAinda não há avaliações

- Research ProjectDocumento4 páginasResearch Project2K20-A1-27 Celonio Elias JoaoAinda não há avaliações

- Course On: Wastewater Pumping Stations DesignDocumento10 páginasCourse On: Wastewater Pumping Stations DesignAQ UAAinda não há avaliações

- Automatic Watering Machine.: 1. Brief Introduction Digital TechniqueDocumento11 páginasAutomatic Watering Machine.: 1. Brief Introduction Digital TechniqueSiddhant GunjalAinda não há avaliações

- Sai FoundationDocumento49 páginasSai FoundationyugalmehtaAinda não há avaliações

- Low Cost TechnologiesDocumento11 páginasLow Cost Technologiessudheer chekkaAinda não há avaliações

- Synopsis Miniproject11Documento7 páginasSynopsis Miniproject11Suraj VishwakarmaAinda não há avaliações

- Automated Irrigation SystemDocumento73 páginasAutomated Irrigation SystemNaeem GulAinda não há avaliações

- Marketing ReportDocumento45 páginasMarketing ReportSharanya HaladyAinda não há avaliações

- Barrogo Arron S.Documento4 páginasBarrogo Arron S.markadizon17Ainda não há avaliações

- Hydropower Plant Report 4 PDFDocumento17 páginasHydropower Plant Report 4 PDFadigkpupAinda não há avaliações

- Rope Pump Final Vs4Documento98 páginasRope Pump Final Vs4aquaprivyAinda não há avaliações

- HHHHBBDocumento4 páginasHHHHBBThinesh Rau KrishnamurtyAinda não há avaliações

- Report On Reciprocating PumpDocumento22 páginasReport On Reciprocating PumpAshokAinda não há avaliações

- Capstone FinalDocumento12 páginasCapstone Finalmathynil41Ainda não há avaliações

- Solar Water Pump - Project ReportDocumento32 páginasSolar Water Pump - Project ReportTanvi33% (3)

- Design and Fabrication of Mini Industrial Vacuum Cleaner PDFDocumento5 páginasDesign and Fabrication of Mini Industrial Vacuum Cleaner PDFPtomsa KemuelAinda não há avaliações

- Water Hand PumpsDocumento8 páginasWater Hand PumpsJonathan IlosoAinda não há avaliações

- Boat Based Solar IrrigtionDocumento23 páginasBoat Based Solar Irrigtionशशी कुमारAinda não há avaliações

- Effective Performance and Infleuence of Automated Inbuilt Hydraulic Jack in A Four Wheeler VehicleDocumento5 páginasEffective Performance and Infleuence of Automated Inbuilt Hydraulic Jack in A Four Wheeler VehiclePaul deshmukhAinda não há avaliações

- Pedal Operated Multipurpose Bicycle With Sprayer and Water Lifting PumpDocumento9 páginasPedal Operated Multipurpose Bicycle With Sprayer and Water Lifting PumpNoil SonAinda não há avaliações

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowNo EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowNota: 2 de 5 estrelas2/5 (1)

- Supplier Management in ETO Companies: An Analysis of Practices and ContingenciesDocumento4 páginasSupplier Management in ETO Companies: An Analysis of Practices and ContingenciesSHAIK NISHARAinda não há avaliações

- Engineer-To-Order (ETO) Production Planning and Control: An Empirical Framework For Machinery-Building CompaniesDocumento48 páginasEngineer-To-Order (ETO) Production Planning and Control: An Empirical Framework For Machinery-Building CompaniesSHAIK NISHARAinda não há avaliações

- Pharmaceutics 1st STERILIZATION Unit 4Documento32 páginasPharmaceutics 1st STERILIZATION Unit 4SHAIK NISHARAinda não há avaliações

- Ethylene Oxide Gas Sterilization of Medical Devices: ReviewDocumento16 páginasEthylene Oxide Gas Sterilization of Medical Devices: ReviewSHAIK NISHARAinda não há avaliações

- Finite Element Analysis FormulasDocumento19 páginasFinite Element Analysis FormulasSHAIK NISHARAinda não há avaliações

- Diploma in Mechanical Engineering: Pedal Powered Water PumpDocumento31 páginasDiploma in Mechanical Engineering: Pedal Powered Water PumpSHAIK NISHARAinda não há avaliações

- Washing Machine: Service ManualDocumento41 páginasWashing Machine: Service Manualimagex5Ainda não há avaliações

- Kashimali Aluminium - Karnataka - Anodizing Plant - 18.11.2023Documento7 páginasKashimali Aluminium - Karnataka - Anodizing Plant - 18.11.2023Manjunath NemagoudarAinda não há avaliações

- Inplan - Ingenieurtechnik - Eng Thermal Oil BoilerDocumento6 páginasInplan - Ingenieurtechnik - Eng Thermal Oil BoilerMeilvy Rahmadani Pane0% (1)

- Fi̇z 137-CH 1-Measurement PDFDocumento27 páginasFi̇z 137-CH 1-Measurement PDFkaskoskasAinda não há avaliações

- Rimula FamilyDocumento1 páginaRimula FamilyChemist Ahmed FoudaAinda não há avaliações

- Hydrogen BombDocumento3 páginasHydrogen BombirfuuAinda não há avaliações

- Alpha, Beta and Gamma RadiationDocumento8 páginasAlpha, Beta and Gamma RadiationFarhan SadiqueAinda não há avaliações

- EEM328 Electronics Laboratory - Report2 - Diode CharacteristicsDocumento9 páginasEEM328 Electronics Laboratory - Report2 - Diode Characteristicsdonatello8480% (5)

- 4 - AppendicesDocumento27 páginas4 - AppendicesDin Flores MacawiliAinda não há avaliações

- Design and Fabrication of Stair Climber TrolleyDocumento21 páginasDesign and Fabrication of Stair Climber TrolleyAnonymous 1mMOyt9zAinda não há avaliações

- T-MEET324LA Experiment No.12 Shell Tube Heat Exchanger MEE31Documento15 páginasT-MEET324LA Experiment No.12 Shell Tube Heat Exchanger MEE31Paul Ryan GeneralAinda não há avaliações

- Led LightDocumento32 páginasLed LightHugo Hernandez GustherAinda não há avaliações

- TYH - TYA-Inverter Ducted PAC - CatalogueDocumento4 páginasTYH - TYA-Inverter Ducted PAC - CatalogueNguyễn Thành ChungAinda não há avaliações

- Electro Hydro Forming: Indian Institute of Technology, BhuDocumento10 páginasElectro Hydro Forming: Indian Institute of Technology, BhuSourabh KumarAinda não há avaliações

- Chapter 1Documento7 páginasChapter 1Ram Darcy PeñalosaAinda não há avaliações

- Fire Issue: BNBC 2006 and BNBC 2017 (Upcoming) PDFDocumento3 páginasFire Issue: BNBC 2006 and BNBC 2017 (Upcoming) PDFSayemAbusadat100% (1)

- France en Dec. 2022 v3Documento37 páginasFrance en Dec. 2022 v3Tarek OsmanAinda não há avaliações

- Chapter 1 Exercises PDFDocumento8 páginasChapter 1 Exercises PDFGeorges SalloumAinda não há avaliações

- 0-2103471 Introduction To Engine DesignDocumento85 páginas0-2103471 Introduction To Engine DesignJulian DavidAinda não há avaliações

- Development of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldDocumento14 páginasDevelopment of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldTaiwo Adenike BashorunAinda não há avaliações

- MRV 5 T3 Service Manual 202203Documento253 páginasMRV 5 T3 Service Manual 202203asadadAinda não há avaliações

- Department of Chemical Engineering: National Institute of Technology RourkelaDocumento53 páginasDepartment of Chemical Engineering: National Institute of Technology RourkelaDeep KaneriyaAinda não há avaliações

- Locomotive BoilerDocumento32 páginasLocomotive BoilerDr. BIBIN CHIDAMBARANATHANAinda não há avaliações

- Diagnostic Study For Cement Mill OptimizationDocumento9 páginasDiagnostic Study For Cement Mill OptimizationHilmy MuhammadAinda não há avaliações

- Norshore Drill Ship Presentation 1113Documento34 páginasNorshore Drill Ship Presentation 1113Grand PappyAinda não há avaliações

- TOEFL Writing 24+ Guide, Everything You Need To Know To Write A Perfect EssayDocumento34 páginasTOEFL Writing 24+ Guide, Everything You Need To Know To Write A Perfect EssayMeriska100% (3)

- Carbon Adsorption VaporDocumento12 páginasCarbon Adsorption VaporMehdi Hajd KacemAinda não há avaliações

- Tech Spec of PTR 33 11 KVDocumento34 páginasTech Spec of PTR 33 11 KVAnonymous sAmJfcVAinda não há avaliações

- CBC-DH For Wheisman-2022.11-DH2209-05Documento1 páginaCBC-DH For Wheisman-2022.11-DH2209-05Martín OsorioAinda não há avaliações

- Batch Processing Safely: Jim Bickerton Jbsafety ConsultancyDocumento4 páginasBatch Processing Safely: Jim Bickerton Jbsafety Consultancykirandevi1981Ainda não há avaliações