Escolar Documentos

Profissional Documentos

Cultura Documentos

Quality Formats

Enviado por

Sheena BansalTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Quality Formats

Enviado por

Sheena BansalDireitos autorais:

Formatos disponíveis

ASSIGNMENT ON QUALITY

Quality Inspection Formats for Different Departments

SUBMITTED BY

Group 6

AMIT

ANJALI

ASHISH HOODA

KUSHAGRA PRAKASH

SAKSHAM ARUN

MFTECH Apparel Production

Semester 2

Fabric Quality Inspection

Lot No…………………… Fabric Type………………..

Sr. No. Parameters

1 Fabric roll length

2 Fabric Width

3 GSM

4 Defects

Holes

Patta

Missing Pick

Broken Pick

Oil Stain

Contamination

Double Pick

Broken End

Barre/Skew

5 Points/100yards

6 Shade Variation

Center to Selvedge

Selvedge to selvedge

Comments:

Inspected By: Signature:

Marker Quality inspection Form

Style No……………….. Date……………..

Sr. No. Check Point

1 Marker Length

2 Marker Width

3 Marker Efficiency(%)

4 Correct Pattern Pcs Count Yes No

5 Correct labelling acc to size Yes No

6 Spacing Between Pattern Pcs

7 Correct Allignment of Pattern Pcs

As Per Grain Yes No

As per Nap Yes No

8 Marker Visibility on paper Clear Poor

9 Correct Marking Of splicing Zones Yes No

10 Correct placement as per check/stripes Yes No

11 Marking notches and drill points Yes No

12 Repositioning of pieces as Yes No

per shade variation (If Any)

Inspected By: Signature:

Spreading Quality inspection Form

Style No……………….. Date……………..

Sr. No. Check Point

1 Correct Length of spread Yes No

According to Marker Lgth (Short)

(Long)

2 Spreading According to Maker Mode Yes No

3 Spreading acc to nap Yes No

4 Ply allignment

Solid Dyed (At selvedge) Yes Yes

Checks/Stripes (At Center)

5 Correct Ply Tension Yes No

(Slack)

(Tight)

6 Tight Selvedge Yes No

7 Provision for Interply slippage Yes No

8 Correct number of plies Yes No

9 Segregation for Lot change Yes No

Inspected By: Signature:

Cutting Room Quality Inspection

Lay No……………. Date…………….

Sr. No Parameter

1 Frayed Edges Yes No

2 Fuzzy ,ragged or serrated edges Yes No

2 Fusion Or Scorched Edges

Ply to ply Yes No

Single edge fusion Yes No

3 Rips or pulled yarns Yes No

4 Pattern Precision Over-cut Under-Cut

Top

Middle

Center

5 Notches and Drills

Correct Not Correct

Size

Placement

Inspected by: Signature:

INLINE INSPECTION

Style No……………….. Line No…………..

Date………………

Sr. No. Point of Measurement Deviation

1

2

3

4

5

6

7

8

9

10

12

13

Puckering Yes No

Staggered Stitches Yes No

Open seam Yes No

Broken Stitches Yes No

Correct & even Stitch density Yes No

Cockling and pleating Yes No

Skip Stitches Yes No

Pannel and component Matching Yes No

(According To Ticket)

Check matching Yes No

Inspected By: Signature:

Final Inspection Sheet

Style No…………… Buyer…………………

Sr. No. Check point Frequency

1 Broken Button/ Snap

2 Broken Stitch

3 Skip Stitches

4 Dropped Stitches

5 Embroidery marks

6 Exposed Raw edges

7 Fabric Defect

8 Holes

9 Loose/Hanging Sewing Threads

10 Needle Cuts

11 Open Seam

12 Pulled or loose yarn

13 Stains

14 Unfinishes button Holes

15 Missing/Loose Buttons

16 Shrinkage in fabric

17 Shrinkage in Lining

18 Wrinkles

19 Water spot and oil stains

20 Iron/Pressing Marks

21 Correct Care Label

22 Correct Size Label

23 Shade difference in panels

24 Inoperative Zipper

Comments On Fit of Garment:-

Inspected By: Signature:

Signature:

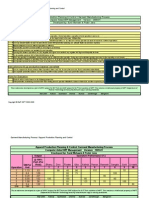

ANNUAL INLINE QUALITY SUMMARY

Previous Yearly

Year Target Jan Feb March April May June July Augst Sept Oct Nov Dec Avg.

% Defective

% Rework

% Spoilage

Você também pode gostar

- Stack & Cut Hexagon Quilts: Mix & Match 38 Kaleidoscope Blocks & 12 Quilt Settings • New Serendipity PatternsNo EverandStack & Cut Hexagon Quilts: Mix & Match 38 Kaleidoscope Blocks & 12 Quilt Settings • New Serendipity PatternsNota: 5 de 5 estrelas5/5 (1)

- Grey FanricDocumento73 páginasGrey FanricSaiful IslamAinda não há avaliações

- Inline Inspection ReportDocumento7 páginasInline Inspection ReportM A. Mannan BiswasAinda não há avaliações

- Heena Enterprises Final Pass SS24ITSLHE6613Documento4 páginasHeena Enterprises Final Pass SS24ITSLHE6613SandipRathodAinda não há avaliações

- Mold Name: Vendor Name:: Part Name S. NO Check DateDocumento1 páginaMold Name: Vendor Name:: Part Name S. NO Check DateAbdul BasitAinda não há avaliações

- Quality ManualDocumento100 páginasQuality ManualPuneethSrinivas50% (2)

- Fabric InspectionsDocumento53 páginasFabric InspectionsMukes Rajak100% (2)

- ComparisonDocumento1 páginaComparisonMuhammadAliAinda não há avaliações

- Assignment 2: Understanding of Apparel QualityDocumento11 páginasAssignment 2: Understanding of Apparel Qualitykashorina AgarwalAinda não há avaliações

- Job Card: Slab Size Total Ok Slabs Remarks Qty Area From To Qty Area No of Blades Running Hrs Ok Slabs Sl. NoDocumento4 páginasJob Card: Slab Size Total Ok Slabs Remarks Qty Area From To Qty Area No of Blades Running Hrs Ok Slabs Sl. Norameshyear20020% (1)

- Stages of Inspection in The Apparel IndustryDocumento10 páginasStages of Inspection in The Apparel IndustrygvncdfAinda não há avaliações

- Garment Defect CodesDocumento22 páginasGarment Defect CodesSteve ShamAinda não há avaliações

- Sueter Con Capucha 3 Meses A 6 AñosDocumento16 páginasSueter Con Capucha 3 Meses A 6 AñosguadalupeAinda não há avaliações

- Karthika M Dev: Soft (Nift, Pune)Documento57 páginasKarthika M Dev: Soft (Nift, Pune)textile028Ainda não há avaliações

- Rubrics MTWDocumento2 páginasRubrics MTWapi-601240077Ainda não há avaliações

- PAD Jury - Testing (Krishna & Nanditha)Documento44 páginasPAD Jury - Testing (Krishna & Nanditha)nanditha sivanAinda não há avaliações

- Garment Defect AnalysisDocumento21 páginasGarment Defect AnalysisIndranil Saha100% (10)

- Apparel InternshipDocumento11 páginasApparel InternshipES MaxternAinda não há avaliações

- Features Dream Stitch Allure Wonder StitchDocumento3 páginasFeatures Dream Stitch Allure Wonder StitchBalasubramanianAinda não há avaliações

- Formwork Check ListDocumento1 páginaFormwork Check ListnadunAinda não há avaliações

- Asg 2 Inspection - My DressDocumento7 páginasAsg 2 Inspection - My DressC V M JAHNAVIAinda não há avaliações

- Gas Engine Diagnostic SheetDocumento1 páginaGas Engine Diagnostic SheetAlejo SanabriaAinda não há avaliações

- Welding Project RubricDocumento1 páginaWelding Project RubricAnonymous dh6DITAinda não há avaliações

- P GROUPDocumento9 páginasP GROUPrummanbsc8923Ainda não há avaliações

- Extremitas Radiography Interpretation: Faculty of Veterinary Medicine, IPB University Telp: +62 8111191333 (Abby Pratama)Documento2 páginasExtremitas Radiography Interpretation: Faculty of Veterinary Medicine, IPB University Telp: +62 8111191333 (Abby Pratama)Intan PradikaAinda não há avaliações

- Karlova LaEmpanada A4Documento4 páginasKarlova LaEmpanada A4Leo TomaszAinda não há avaliações

- Sketch For Pile Group NoDocumento4 páginasSketch For Pile Group NojitendraAinda não há avaliações

- Berroco PommeryDocumento4 páginasBerroco Pommeryr86qpwfvn8Ainda não há avaliações

- 23 Fabric Defects To Look Out For During Fabric InspectionDocumento5 páginas23 Fabric Defects To Look Out For During Fabric Inspectionudi969100% (1)

- Shipment Sample Control ReportDocumento1 páginaShipment Sample Control Reportabusayed.textileAinda não há avaliações

- MIS Excel Test (SPE) - TemplateDocumento28 páginasMIS Excel Test (SPE) - Templateramesh thalariAinda não há avaliações

- PPM TemplateDocumento3 páginasPPM TemplateBaharul Islam Bahar100% (1)

- Free Pattern - Standard v2 DownloadDocumento75 páginasFree Pattern - Standard v2 DownloadWestwickateAinda não há avaliações

- Welding RubricDocumento2 páginasWelding Rubricapi-525855204Ainda não há avaliações

- Free Pattern - Long v2 DownloadDocumento83 páginasFree Pattern - Long v2 DownloadWestwickateAinda não há avaliações

- Garment Inspection Criteria CodesDocumento9 páginasGarment Inspection Criteria CodesKarthick Jayaram Karthick JayaramAinda não há avaliações

- TrainingDocumento29 páginasTrainingNavodita Singh100% (1)

- AQL Blank FormDocumento2 páginasAQL Blank FormkrishnaAinda não há avaliações

- Post Concrete InspectionDocumento1 páginaPost Concrete InspectionjitendraAinda não há avaliações

- Timing Male Female Total: 07.00 AM To 08.00 AMDocumento10 páginasTiming Male Female Total: 07.00 AM To 08.00 AMpwd2007Ainda não há avaliações

- Equipment Inspection ChecklistDocumento13 páginasEquipment Inspection ChecklistFebrian TamaraAinda não há avaliações

- ChecklistDocumento1 páginaChecklistManoj bfplAinda não há avaliações

- Fabric Inspection Criteria 10 Point SystemDocumento1 páginaFabric Inspection Criteria 10 Point Systemraghib2111100% (2)

- M4 - T1 - V13andV14 Sample Case StudyDocumento6 páginasM4 - T1 - V13andV14 Sample Case StudyDevanshu rajputAinda não há avaliações

- Rubric FashionDocumento4 páginasRubric FashionJun BelloAinda não há avaliações

- Fabric Quality ControlDocumento4 páginasFabric Quality ControlShazzad HossaInAinda não há avaliações

- 465 Запах розDocumento22 páginas465 Запах розapi-3713431Ainda não há avaliações

- Alter Defects PDFDocumento4 páginasAlter Defects PDFMd.Firoz faisalAinda não há avaliações

- Mold Inspection SpecificationDocumento6 páginasMold Inspection SpecificationNaukowyDrpAinda não há avaliações

- Printing Estimate Request R8 PDFDocumento1 páginaPrinting Estimate Request R8 PDFaradiel.andre.4Ainda não há avaliações

- nn05mm Cenact 5-10 AlDocumento2 páginasnn05mm Cenact 5-10 Alapi-293753588Ainda não há avaliações

- GK 663 (1) .Grand Mothers DoorwayDocumento51 páginasGK 663 (1) .Grand Mothers Doorwayapi-3775424Ainda não há avaliações

- PP Meeting Recap Sty# NS101DNDocumento21 páginasPP Meeting Recap Sty# NS101DNlodestar ieAinda não há avaliações

- (Att#03) Appendix III - Defect Classification - 20200814Documento10 páginas(Att#03) Appendix III - Defect Classification - 20200814yeuyeu555Ainda não há avaliações

- Comparison of Old New Currency or CoinsDocumento42 páginasComparison of Old New Currency or CoinsAvexx TeeAinda não há avaliações

- Final Inspection ReportDocumento6 páginasFinal Inspection Reportjayanti ThapaAinda não há avaliações

- Checklist For Equipment Inspection Chain Pulley BlockDocumento1 páginaChecklist For Equipment Inspection Chain Pulley BlockIdada EzekielAinda não há avaliações

- Baby Hats to Crochet: 10 Fun Designs for Newborn to 12 MonthsNo EverandBaby Hats to Crochet: 10 Fun Designs for Newborn to 12 MonthsNota: 5 de 5 estrelas5/5 (1)

- Modern Art Quilts: Design, Fuse & Quilt-As-You-GoNo EverandModern Art Quilts: Design, Fuse & Quilt-As-You-GoNota: 3 de 5 estrelas3/5 (1)

- Organization StructureDocumento3 páginasOrganization StructureSheena BansalAinda não há avaliações

- Front Body Placket Body Body Body Body BodyDocumento1 páginaFront Body Placket Body Body Body Body BodySheena BansalAinda não há avaliações

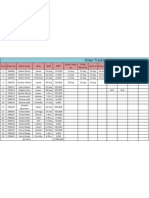

- Order Book-5Documento11 páginasOrder Book-5Sheena BansalAinda não há avaliações

- Floor Plan For Sewing DepartmentDocumento1 páginaFloor Plan For Sewing DepartmentSheena BansalAinda não há avaliações

- Sewing Floor Machine LayoutDocumento1 páginaSewing Floor Machine LayoutSheena BansalAinda não há avaliações

- Order Book-5Documento11 páginasOrder Book-5Sheena BansalAinda não há avaliações

- Bill OF Material: KG Collar & Cuff Tape 17"x4" & 30"X1"Documento1 páginaBill OF Material: KG Collar & Cuff Tape 17"x4" & 30"X1"Sheena BansalAinda não há avaliações

- Operation SequenceDocumento3 páginasOperation SequenceSheena BansalAinda não há avaliações

- Revised Guidelines For Training ModulesDocumento2 páginasRevised Guidelines For Training ModulesSheena BansalAinda não há avaliações

- Training Manual ContentsDocumento23 páginasTraining Manual ContentsSheena Bansal100% (4)

- GATE 2012 Answer Key Paper: TF: Paper Question No. Key Paper Question No. KeyDocumento1 páginaGATE 2012 Answer Key Paper: TF: Paper Question No. Key Paper Question No. KeykamalkantmbbsAinda não há avaliações

- 5-Footwear Pattern MakingDocumento16 páginas5-Footwear Pattern MakingTungleAinda não há avaliações

- Building Plan License Registration: Punjab Labor DepartmentDocumento13 páginasBuilding Plan License Registration: Punjab Labor DepartmentSheena BansalAinda não há avaliações

- Indian Factory Act 1948Documento89 páginasIndian Factory Act 1948Madhurya BaruahAinda não há avaliações

- Disha Kapil (11) Stanley SayoniDocumento12 páginasDisha Kapil (11) Stanley Sayonisahu_dishaAinda não há avaliações

- SMO Training ManualDocumento11 páginasSMO Training ManualSheena BansalAinda não há avaliações

- 2012 Gate PaperDocumento11 páginas2012 Gate PaperSheena BansalAinda não há avaliações

- CalculationDocumento26 páginasCalculationSheena BansalAinda não há avaliações

- CAD SoftwaresDocumento2 páginasCAD SoftwaresSheena BansalAinda não há avaliações

- Denim Basics Doc 7Documento6 páginasDenim Basics Doc 7Sheena BansalAinda não há avaliações

- Jeans Best FitDocumento6 páginasJeans Best FitSheena BansalAinda não há avaliações

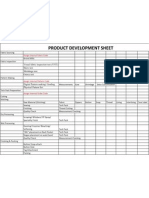

- Product Development SheetDocumento6 páginasProduct Development SheetSheena BansalAinda não há avaliações

- For Orders TrackingDocumento9 páginasFor Orders TrackingSheena BansalAinda não há avaliações

- Question A Ire For ConsumerDocumento6 páginasQuestion A Ire For ConsumerSheena BansalAinda não há avaliações

- Jeans ImperialDocumento7 páginasJeans ImperialSheena BansalAinda não há avaliações

- Question A Ire For Retailer or Store ManagerDocumento5 páginasQuestion A Ire For Retailer or Store ManagerSheena BansalAinda não há avaliações

- Garment Printing Machine Technology Index:: How To Use The Worksheets To Develop Technology Index?Documento8 páginasGarment Printing Machine Technology Index:: How To Use The Worksheets To Develop Technology Index?Sheena BansalAinda não há avaliações

- Steps of LayoutDocumento2 páginasSteps of LayoutSheena BansalAinda não há avaliações

- Pub 157 Preventing Bio Fouling With Copper NickelDocumento4 páginasPub 157 Preventing Bio Fouling With Copper NickelBiyong SantocildesAinda não há avaliações

- CTK CatalogueDocumento28 páginasCTK CatalogueAlexx SorokinAinda não há avaliações

- 02-14 QCS 2014Documento172 páginas02-14 QCS 2014Raja Ahmed Hassan100% (1)

- Acc CementDocumento1 páginaAcc CementAbhinav BharatAinda não há avaliações

- Form D.F.R. (P.W.) - 25 Running Account of ContractorDocumento7 páginasForm D.F.R. (P.W.) - 25 Running Account of Contractormuhammad iqbalAinda não há avaliações

- Mechanism of DBTO CatalystDocumento8 páginasMechanism of DBTO Catalystsahajahan shaikhAinda não há avaliações

- Design of Prestressed Concrete Tank A ReviewDocumento3 páginasDesign of Prestressed Concrete Tank A ReviewNada AL-Sabah AlsabahAinda não há avaliações

- Bien Phap Thi Cong Bang Tieng AnhDocumento24 páginasBien Phap Thi Cong Bang Tieng AnhGroup EnglishAinda não há avaliações

- Exxon IP 5-3-1 Pressure Testing of Unfired Pressure VesselsDocumento2 páginasExxon IP 5-3-1 Pressure Testing of Unfired Pressure Vesselshcsharma1967Ainda não há avaliações

- ARM Design Guide Introduction To Rotational MoldingDocumento29 páginasARM Design Guide Introduction To Rotational MoldingGabriel Lopez BarajasAinda não há avaliações

- Iso 10684Documento26 páginasIso 10684Jay GaneshAinda não há avaliações

- Segmentation PDFDocumento24 páginasSegmentation PDFRiya SachanAinda não há avaliações

- A Guide To BS en 998 - 1 and BS en 998 - 2Documento6 páginasA Guide To BS en 998 - 1 and BS en 998 - 2Emmanuel MzenaAinda não há avaliações

- Cambridge IGCSE: Chemistry 0620/23Documento16 páginasCambridge IGCSE: Chemistry 0620/23SasukeAinda não há avaliações

- Composites and Non MetallicsDocumento112 páginasComposites and Non MetallicssreeramAinda não há avaliações

- 1 - Paper - Planta Piloto Absorcion H2S PDFDocumento7 páginas1 - Paper - Planta Piloto Absorcion H2S PDFSilas Calderon LuloAinda não há avaliações

- Bce - H2so4 Filter Guide - Mist Eliminator TroubleshootingDocumento5 páginasBce - H2so4 Filter Guide - Mist Eliminator TroubleshootingDũng LêAinda não há avaliações

- DBL 8451 2015-06enDocumento16 páginasDBL 8451 2015-06enEmir AkçayAinda não há avaliações

- Chapter 16 - Acid-Base EquilibraDocumento28 páginasChapter 16 - Acid-Base EquilibraUzair IsmailAinda não há avaliações

- Steel Plate Comparision PDFDocumento2 páginasSteel Plate Comparision PDFchandakweAinda não há avaliações

- BiodieselDocumento2 páginasBiodieseligorsilva13123Ainda não há avaliações

- Jotatherm TB550Documento5 páginasJotatherm TB550Biju_PottayilAinda não há avaliações

- Info Az p4620Documento27 páginasInfo Az p4620Mudassar MeerAinda não há avaliações

- Anotha OneDocumento22 páginasAnotha OneMarc LaranjoAinda não há avaliações

- May 2018 Technical Data Sheet: Octyl/Decyl Trimellitate TMC - CDocumento1 páginaMay 2018 Technical Data Sheet: Octyl/Decyl Trimellitate TMC - CLim Chee SiangAinda não há avaliações

- Aws A5.1 (1991) PDFDocumento57 páginasAws A5.1 (1991) PDFRenier KoenAinda não há avaliações

- Raposa Gueicha-1Documento13 páginasRaposa Gueicha-1Andressa Lobeiro100% (2)

- Enviro-Solv B6 TDSDocumento1 páginaEnviro-Solv B6 TDSmehoAinda não há avaliações

- Nehad Paper-1Documento16 páginasNehad Paper-1Nguyễn Chính TrườngAinda não há avaliações

- Steel Grade AnaloguesDocumento8 páginasSteel Grade AnaloguesandreahankAinda não há avaliações