Escolar Documentos

Profissional Documentos

Cultura Documentos

Sizing of Pressure Relief Valve

Enviado por

Shammaz SaleemDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sizing of Pressure Relief Valve

Enviado por

Shammaz SaleemDireitos autorais:

Formatos disponíveis

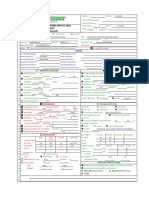

Customer Document No.

:

Project Rev. Date:

Plant Rev. No.:

DATASHEET FOR PLATE HEAT EXCHANGER

Area Tag No.: PHE-5001

Quantity

Ref P&ID

SERVICE CONDITIONS

HOT SIDE COLD SIDE HOT SIDE COLD SIDE

1 FLUID HANDLED RO WATER SOFT WATER REQUIRED CAPACITY (kcal/hr)

ACIDIC ACIDIC FLOW RATE (kg/hr) 72000 72000

ALKALINE ALKALINE 7 INLET TEMPERATURE (°C) 24 13

EROSIVE EROSIVE OUTLET TEMPERATURE (°C) 21 16

2 NATURE OF FLUID

√ NEUTRAL √ NEUTRAL INLET PRESSURE (bar g) 2 2.75

CORROSIVE CORROSIVE 8 PRESSURE DROP, ALLOWABLE (bar g) 0.5 0.5

EXPLOSIVE EXPLOSIVE 9 SOLIDS (% wt) NA NA

3 DENSITY (KG/M³) AT TEMPERATURE 1000 1000 10 LARGEST PARTICLE SIZE (µm) NA NA

4 VAPOR PRESSURE AT OP.TEMP. (bar a) 0.06 0.05 11 SPECIFIC HEAT(kcal/kg°C) 1 1

5 VISCOSITY(cP) AT TEMPERATURE 1 1 LATENT HEAT (kcal/kg) NA NA

12

6 NEWTONIAN / NON NEWTONIAN NEWTONIAN NEWTONIAN HEAT DUTY (kcal/hr) 216000

6 (A) FLOW CONSISTENCY INDEX(K) (cP) 13 DUTY MARGIN, % 10

6 (B) FLOW BEHAVIOR INDEX(n) 14

SITE DATA

15 AMBIENT TEMPERATURE (MIN / MAX) (°C) 17 LOCATION OF HEX (INSIDE / OUTSIDE) OUTDOOR

16 ATMOSPHERIC PRESSURE (bar a) 18 EXPLOSION AREA CLASSIFICATION NA

MATERIALS OF CONSTRUCTION

19 PLATE VENDOR TO SPECIFY 23 SURFACE FINISH OF WETTED PARTS VENDOR TO SPECIFY

20 TUBE SIDE VENDOR TO SPECIFY 24 END PLATE VENDOR TO SPECIFY

21 GASKETS VENDOR TO SPECIFY 25

22 NON WETTED PARTS VENDOR TO SPECIFY 26

DESIGN DATA

27 MAKE VENDOR TO SPECIFY NO SIZE (NB) SERVICE

28 MODEL VENDOR TO SPECIFY H1

29 TYPE VENDOR TO SPECIFY 37 SUCTION/DISCHARGE ORIENTATION-SIZE H2

30 RATED CAPACITY (kcal/hr) H3

31 DESIGN PRESSURE (bar g) H4

32 DESIGN TEMPERATURE (MIN / MAX) (°C) 38 HEAT TRANSFER AREA (m2)

33 DESIGN (SANITARY/NON-SANITARY) NON-SANITARY 39 EFFICIENCY VENDOR TO SPECIFY

34 NUMBER OF PLATES VENDOR TO SPECIFY 40 RELATIVE DIRECTION OF FLUID

35 EFFECTIVE PLATES VENDOR TO SPECIFY 41 EXTENSION CAPACITY VENDOR TO SPECIFY

36 42 PRESSURE VESSEL CODE ASME STANDARDS

OTHERS

LENGTH ( mm) VENDOR TO SPECIFY 48

45 OVERALL DIMENSION WIDTH (mm) VENDOR TO SPECIFY 49

HEIGHT ( mm) VENDOR TO SPECIFY 50

UNIT WEIGHT EMPTY (kg) VENDOR TO SPECIFY 51

46

(WITH SUPPORT) FULL (kg) VENDOR TO SPECIFY 52

47 LIQUID VOLUME (m³) 53

INSPECTION AND TEST

√ PERFORMANCE √ HYDROSTATIC TEST

SCOPE OF SUPPLY

√ HEAT EXCHANGER √ ANCHOR BOLTS

SUPPORTS SPECIAL TOOL

NOZZLE ARRANGEMENTS

H1 H2

H4 H3

NOTES

01. Construction should be as per ASME standards .

02. All inlet/outlet flanged end connections should follow ASME standard.

03. All Elastomers should be of ASME standards

04. Inlet pressure values based on tentative hydraulics calculations.

INSERT '√' WHEREVER REQUIRED √

1 of 1

Você também pode gostar

- Handbook of Heating, Ventilating and Air ConditioningNo EverandHandbook of Heating, Ventilating and Air ConditioningNota: 4 de 5 estrelas4/5 (6)

- Chiller Data SheetDocumento3 páginasChiller Data SheetMoriyasuNguyenAinda não há avaliações

- Transducer Handbook: User's Directory of Electrical TransducersNo EverandTransducer Handbook: User's Directory of Electrical TransducersAinda não há avaliações

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Documento3 páginasData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisAinda não há avaliações

- Data Sheet For Heat ExchangerDocumento2 páginasData Sheet For Heat ExchangerdgmprabhakarAinda não há avaliações

- Ejercicio 246 PSV438 RESUELTODocumento2 páginasEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaAinda não há avaliações

- Introduction to Flow Assurance and OLGA SoftwareDocumento10 páginasIntroduction to Flow Assurance and OLGA SoftwareG Vengat VinayagamAinda não há avaliações

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Documento7 páginasData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaAinda não há avaliações

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Documento14 páginasFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024Ainda não há avaliações

- 22-DS-R-001 Rev 1 API 617 GTCPsDocumento25 páginas22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Contract: API 610 Vertical Centrifugal Pump DataDocumento7 páginasContract: API 610 Vertical Centrifugal Pump DataNAHASALI11Ainda não há avaliações

- Process Data Sheet For Fired HeaterDocumento8 páginasProcess Data Sheet For Fired HeaterBangkiyak LanangAinda não há avaliações

- Water Supply NotesDocumento13 páginasWater Supply NotesVenkat RamanAinda não há avaliações

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocumento60 páginasMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHAinda não há avaliações

- Business PlanDocumento6 páginasBusiness PlanRosette Sabaco0% (2)

- API 675 Pump DatasheetDocumento2 páginasAPI 675 Pump DatasheetArun CPAinda não há avaliações

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Documento7 páginasData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaAinda não há avaliações

- Data Sheet Rectangular - BG22383Documento12 páginasData Sheet Rectangular - BG22383Fitroh MalikAinda não há avaliações

- Api 610 Datasheet PDF FreeDocumento7 páginasApi 610 Datasheet PDF FreeRisyda PutriAinda não há avaliações

- IPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpDocumento4 páginasIPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpsudjonoAinda não há avaliações

- Reciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneralDocumento10 páginasReciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneraltxagusAinda não há avaliações

- Centrifugal Pump Data SheetDocumento20 páginasCentrifugal Pump Data SheetMojtabaAinda não há avaliações

- vs1 DatasheetDocumento22 páginasvs1 DatasheetMojtabaAinda não há avaliações

- bb2 Pump-DatasheetDocumento14 páginasbb2 Pump-DatasheetMojtabaAinda não há avaliações

- Distillation Tower DesignDocumento65 páginasDistillation Tower DesignNicholaus ShawAinda não há avaliações

- Brown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsDocumento15 páginasBrown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsLipika GayenAinda não há avaliações

- 5 HCDPDocumento36 páginas5 HCDPAditya DubeyAinda não há avaliações

- Hoja de Datos de BombaDocumento5 páginasHoja de Datos de Bombaluis zambranoAinda não há avaliações

- NHT Heater API DatasheetDocumento9 páginasNHT Heater API DatasheetAravind AravindAinda não há avaliações

- 30001-Technical Specification Sheet (Datasheet)Documento6 páginas30001-Technical Specification Sheet (Datasheet)ali valatabar100% (1)

- Página: 1 De: 5Documento6 páginasPágina: 1 De: 5Rathawit SingpanjanateeAinda não há avaliações

- Process Datasheet for On-Off ValvesDocumento1 páginaProcess Datasheet for On-Off ValvesChakravarthy BharathAinda não há avaliações

- Centrifugal Pumps Datasheet for Power Plant ProjectDocumento6 páginasCentrifugal Pumps Datasheet for Power Plant ProjectRodrigo CondorettyAinda não há avaliações

- Datasheet For Booster PumpDocumento1 páginaDatasheet For Booster PumpLe Anh DangAinda não há avaliações

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsDocumento4 páginasBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsLipika GayenAinda não há avaliações

- Air DryerDocumento12 páginasAir DryerAl AminAinda não há avaliações

- EXCHANGER SPECIFICATION SHEET Hoja EspecificacionesDocumento2 páginasEXCHANGER SPECIFICATION SHEET Hoja EspecificacionesDaniel SalasAinda não há avaliações

- TD HE S&T v2020.00Documento29 páginasTD HE S&T v2020.00Claudia BonocoreAinda não há avaliações

- D04-V-E809 Instrument Air ReceiverDocumento2 páginasD04-V-E809 Instrument Air Receiverpragnesh82011Ainda não há avaliações

- Chiller Sch.Documento1 páginaChiller Sch.MarzookAinda não há avaliações

- bb1 DatasheetDocumento14 páginasbb1 DatasheetMojtabaAinda não há avaliações

- DATA SHEET VCM Condenser No 2Documento1 páginaDATA SHEET VCM Condenser No 2nabila OktavianiAinda não há avaliações

- Solvent Recovery Bottoms Pumps (09P007A/B) : Data SheetDocumento6 páginasSolvent Recovery Bottoms Pumps (09P007A/B) : Data SheetAthiphap SrisupareerathAinda não há avaliações

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocumento5 páginasMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiAinda não há avaliações

- Data Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Documento2 páginasData Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Avinash ShuklaAinda não há avaliações

- Data Sheet For LBV ActuatorDocumento1 páginaData Sheet For LBV ActuatorSinaAinda não há avaliações

- Olukunle Afeni - Datasheet Plate Heat ExchangerDocumento2 páginasOlukunle Afeni - Datasheet Plate Heat ExchangerBolakale UthmanAinda não há avaliações

- 01-Apiflo Oh2 80-365-9-S-6-DS - RaDocumento4 páginas01-Apiflo Oh2 80-365-9-S-6-DS - RapaachangaAinda não há avaliações

- Api 674 Pump Data SheetDocumento5 páginasApi 674 Pump Data Sheetroronoa_zorro11Ainda não há avaliações

- BFP - Part 1Documento1 páginaBFP - Part 1nejatihosseinAinda não há avaliações

- Data Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary UnitsDocumento10 páginasData Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1Ainda não há avaliações

- Data Sheet - 007-SU-RCLM-001Documento1 páginaData Sheet - 007-SU-RCLM-001Luis Miguel Torres SayasAinda não há avaliações

- Hoja API Vs4 001Documento9 páginasHoja API Vs4 001brujula24Ainda não há avaliações

- NSDocumento1 páginaNSXemtintuc Xem TinAinda não há avaliações

- Checking critical and subcritical flow conditionsDocumento11 páginasChecking critical and subcritical flow conditionsDharmik PatelAinda não há avaliações

- Data SheetsDocumento5 páginasData Sheetshector cano moraAinda não há avaliações

- Cam 200-390-110kwDocumento4 páginasCam 200-390-110kwbocahjeblogAinda não há avaliações

- 141014.datasheet For PSV-1323Documento2 páginas141014.datasheet For PSV-1323ocanhthuAinda não há avaliações

- TXTL-De-F1!07!032 - A - Gas Electric Heater For Auxiliary Power UnitDocumento4 páginasTXTL-De-F1!07!032 - A - Gas Electric Heater For Auxiliary Power UnitMiguel Jiménez FloresAinda não há avaliações

- CVCalculation For Swage Sludge Tank 11-9-14Documento10 páginasCVCalculation For Swage Sludge Tank 11-9-14Henry VungtauAinda não há avaliações

- Ejercicios AliviosDocumento20 páginasEjercicios AliviosPaola ChavezAinda não há avaliações

- CONTROL VALVE DATA SHEETDocumento2 páginasCONTROL VALVE DATA SHEETMateus EliasAinda não há avaliações

- Sulphuric Acid Dosing Pump Motor ManualDocumento28 páginasSulphuric Acid Dosing Pump Motor ManualmohammedsfAinda não há avaliações

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Documento5 páginas18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaAinda não há avaliações

- Profoks Sea & Waste Water 15 06 - 2019Documento11 páginasProfoks Sea & Waste Water 15 06 - 2019Bora CanbolatAinda não há avaliações

- Venturi Test Efficiency Hole SizeDocumento4 páginasVenturi Test Efficiency Hole SizeCarlos CavalcanteAinda não há avaliações

- 195103-MS Simulation and Performance of Immiscible WAG Pilots in Mauddud Reservoir Using Three Phase Relative Permeability With HysteresisDocumento22 páginas195103-MS Simulation and Performance of Immiscible WAG Pilots in Mauddud Reservoir Using Three Phase Relative Permeability With HysteresisHadi Ali ALMeftahAinda não há avaliações

- Solved Problems Ref SystemDocumento5 páginasSolved Problems Ref SystemArchie Gil DelamidaAinda não há avaliações

- Tutorial 1Documento5 páginasTutorial 1anisAinda não há avaliações

- Lecture I - Classification of Fluid Machines - MCE 506 - Fluid Machinery by Professor WaheedDocumento22 páginasLecture I - Classification of Fluid Machines - MCE 506 - Fluid Machinery by Professor WaheedTemidayo DavidAinda não há avaliações

- Pressure in FluidsDocumento23 páginasPressure in FluidsANDREW BMGOAinda não há avaliações

- Gas Lift Pittman - para Revisar PDFDocumento8 páginasGas Lift Pittman - para Revisar PDFedi agurto carrascoAinda não há avaliações

- Gas Law WorksheetDocumento2 páginasGas Law WorksheetMJ VergaraAinda não há avaliações

- 5 Types of Flow MetersDocumento2 páginas5 Types of Flow Metersabdulkidwai20090% (1)

- Energy Equation - Flow MeasurementDocumento11 páginasEnergy Equation - Flow MeasurementAsa Ka50% (2)

- Well DesignDocumento17 páginasWell DesignabdulazizAinda não há avaliações

- Learn About Oil and Gas SeparatorsDocumento2 páginasLearn About Oil and Gas SeparatorsOlivier Whettem0% (1)

- Topic 4 - Fuels & Earth Sciences TestDocumento9 páginasTopic 4 - Fuels & Earth Sciences TestAaqib UlHaqAinda não há avaliações

- MF5400 Manual 12-EnDocumento36 páginasMF5400 Manual 12-EnJānis GrabisAinda não há avaliações

- APES Unit Test Weather Climate and PollutionDocumento5 páginasAPES Unit Test Weather Climate and PollutionudiAinda não há avaliações

- Fundamental of Exploration and ProductionDocumento34 páginasFundamental of Exploration and ProductionVelya Galyani Pasila Galla100% (1)

- Water Cycle Informational TextDocumento3 páginasWater Cycle Informational Textapi-233611431100% (2)

- Rosemount Inc. ASME Venturi Tube Calculation Data SheetDocumento1 páginaRosemount Inc. ASME Venturi Tube Calculation Data SheethaisamsarwarAinda não há avaliações

- CE 311 - Fluid MechanicsDocumento5 páginasCE 311 - Fluid MechanicsBrian SamendeAinda não há avaliações

- Bab 2 Pure SubstancesDocumento24 páginasBab 2 Pure SubstancesDaneal FikriAinda não há avaliações

- 109 Easa Meteorology DemoDocumento6 páginas109 Easa Meteorology DemoRUDRA PRATAP SINGH CHAUHANAinda não há avaliações

- Water Cycle Lesson 3Documento5 páginasWater Cycle Lesson 3api-247794398Ainda não há avaliações

- Review of Changes to Rational Method Computation in MSMA EditionsDocumento9 páginasReview of Changes to Rational Method Computation in MSMA EditionsGan Chin PhangAinda não há avaliações

- Ramthal Drip Irrigation Project, Ramthal, KarnatakaDocumento2 páginasRamthal Drip Irrigation Project, Ramthal, Karnatakakuhelika ghoshAinda não há avaliações