Escolar Documentos

Profissional Documentos

Cultura Documentos

Pictures - 1554996824136-W4V22 - Pinch Methodology

Enviado por

Israel JosueDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pictures - 1554996824136-W4V22 - Pinch Methodology

Enviado por

Israel JosueDireitos autorais:

Formatos disponíveis

Week 4 – Session 22

Energy Efficiency

Pinch Methodology

Olivier BERNAERT

MOOC ENERGY TRANSITION

IFP SCHOOL

Introduction

In this section, we will take a look at the energy efficiency importance as a

key element to reach the COP 21 objectives. As you have seen several times

during this MOOC, in order to reach the objective of keeping global warning

below 2°C we have to reduce our CO2 emissions.

To go further, have a look at the following graph. The difference between the

two lines represents the gain of energy done thanks to energy efficiency

programs. From 2000 to 2016, we saved 16 terawatts.

This is really a huge quantity of energy!

it is equivalent to the energy needed to run

16 000 lights sabers from the Star wars movie.

Energy Efficiency – Pinch Methodology Page 1 on 7

Heat Exchanger

But more seriously, in industries the main equipment to recover energy is heat

exchanger.

What is a heat exchanger? A heat exchanger allows transferring heat from

one fluid to another one without mixing. It is used each time you want to heat

cold fluids or to cool down hot fluids.

For instance, one section– called tubes - is filled with the cold fluid and the

other section - called shell - with the hot fluid.

Let’s have a look inside a heat exchanger. The cold stream enters at a

temperature t1 and the hot stream enters at a temperature TA. The tube, here

in blue, is filled with the cold fluid. And the shell, in red, with the hot one.

During the circulation of both fluids into the exchanger, there is a transfer of

heat from the hot fluid to the cold one. At the outlet, the cold fluid is hotter

and the hot fluid is colder.

It is easy to calculate the quantity of heat exchanged between the 2 streams.

Let’s focus on the cold fluid. We have to know several parameters:

• The inlet and outlet temperatures

• The flowrate of the fluid, here designed by mc.

• And finally its heat capacity, Cp. The heat capacity is the amount of

heat in kcal needed to raise the temperature of 1°C for 1 kilogram of

fluid.

Energy Efficiency – Pinch Methodology Page 2 on 7

Finally, without vaporization, the quantity of heat exchanged is calculated

thanks to this formula: Q = M x Cp x Delta T

.

The quantity of heat released by the hot fluid is equal to the quantity received

by the cold one.

Heat Exchangers network

Here is an example of a real unit. The feed needs to be heated to enter into a

reactor. It goes through several exchangers (in red) and is heated by steam.

The steam is produced inside a boiler, where we burn fuel gas and thus

produce a certain amount of CO2.

At the reactor exit, the fluid finally needs to be cooled down through other

exchangers (in blue). Without heat integration, this process uses a lot of steam

to heat up the feed: it is a waste of energy and money and contributes to

CO2 emissions.

We can improve the situation by installing a feed / effluent exchanger to

recover energy and decrease CO2 emissions.

Energy Efficiency – Pinch Methodology Page 3 on 7

In this example, the energy needed to heat the feed is coming directly from

the outlet of the reactor by installing a feed / effluent exchanger.

Pinch Methodology

To improve energy efficiency, increase heat recovery and reduce CO2

emissions, we need to use a dedicated methodology called Pinch.

Let’s now explain this approach developed by Professor Linhoff in the 70’s.

Let’s work on the following example.

We have 4 streams: 2 cold ones and 2 hot ones. We must try to combine

these flows in order to recover as much energy as possible.

Energy Efficiency – Pinch Methodology Page 4 on 7

To do this, we first calculate each streams heat’s quantity using the previous

formula: Q = M CP Delta T. Then we can represent the 2 cold streams on the

following graph:

• A from 30 to 120 °C with a heat quantity of 162 kW

• B from 60 to 100°C.

Let’s start to draw what we call « the cold composite curve. » We start at the

lowest temperature, it is 30°C, until the next interval of temperature here 60°C.

Between these 2 points we have only one stream (A)! So it easy! We take the

heat quantity from A to start to draw the cold composite curve.

Then, for the next interval between 60 and 100 we have 2 streams (A+B), so

the MCP will be the sum of the 2 streams. In this example: the second interval

goes from 60 to 100 with a heat quantity of 5.8 multiply by 40 °C equals 232

kW.

And we continue like that until the end to obtain the cold composite curve.

Energy Efficiency – Pinch Methodology Page 5 on 7

We follow the same approach for the hot composite curve.

These 2 curves give us a lot of information. We can calculate the minimum

cold utility needed to run the process: here 6 kW.

We can calculate the (hot) minimum energy required to run the process: here

48 kW. It’s the quantity of hot utilities needed: like steam from a boiler, or heat

from a furnace.

Energy Efficiency – Pinch Methodology Page 6 on 7

In the center of the graph, you can read the maximum energy you can

recover by installing heat exchangers network (HEN). Here 274 kW of energy

could come directly from the process itself and reduce CO2 emissions by

saving hot utilities.

The minimum gap in temperature between both curves is called the pinch. It

is important to try to optimize this gap in order to minimize the energy required

to run the unit.

Conclusions

To sum up what we just said:

Heat exchangers are the key equipment to recover and save energy.

Pinch methodology gives us the potential savings of energy inside a unit. From

this method, we obtain the minimum cold and hot utilities required to run a

unit and the energy you can recover by installing a heat exchanger network.

To finish I would like to thank Agathe, Baptiste and César, IFP School

graduates, who help me preparing this lecture.

Energy Efficiency – Pinch Methodology Page 7 on 7

Você também pode gostar

- 9hp48TE Introduction PDFDocumento63 páginas9hp48TE Introduction PDFТетяна Ліч100% (6)

- Doosan Operation&MaintenanceManual SB2355E00 PDFDocumento350 páginasDoosan Operation&MaintenanceManual SB2355E00 PDFSami Enis Arıoğlu100% (2)

- Refrigeration and Air ConditioningDocumento263 páginasRefrigeration and Air ConditioningAjeet Verma92% (12)

- 0530b4f5ec562edc711a PDFDocumento100 páginas0530b4f5ec562edc711a PDFrahmatmemet80% (10)

- Motor Mitsubishi Eclipse 3.8 LTS PDFDocumento68 páginasMotor Mitsubishi Eclipse 3.8 LTS PDFRafael RamosAinda não há avaliações

- Pinch Analysis ToolDocumento23 páginasPinch Analysis ToolAntoni SaundersAinda não há avaliações

- Selection of Explosion Proof Electrical Equipment For Installation in Harzardous AreaDocumento7 páginasSelection of Explosion Proof Electrical Equipment For Installation in Harzardous AreaYeong Ju JeongAinda não há avaliações

- Engineering TechnologyDocumento66 páginasEngineering TechnologyMhmoud Al-TamimiAinda não há avaliações

- Steam ChartDocumento47 páginasSteam Chartamuronegadu100% (1)

- 2nd Law of Thermo DynamicsDocumento58 páginas2nd Law of Thermo DynamicsTalha WaqarAinda não há avaliações

- DLRO Guide V01 - LR PDFDocumento48 páginasDLRO Guide V01 - LR PDFIsrael Josue0% (1)

- Chapter 3 - Heat IntegrationDocumento25 páginasChapter 3 - Heat IntegrationAmeerRashidAinda não há avaliações

- GDTE en PDFDocumento80 páginasGDTE en PDFIsrael JosueAinda não há avaliações

- Simulation and Optimization of Distillation Processes For Separating A Close-Boiling Mixture of N-Butanol and IsobutanolDocumento6 páginasSimulation and Optimization of Distillation Processes For Separating A Close-Boiling Mixture of N-Butanol and IsobutanolZangAinda não há avaliações

- Pinch Technology AnalysisDocumento20 páginasPinch Technology AnalysisPiyush JainAinda não há avaliações

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesNo EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesAinda não há avaliações

- Manual For Experiment With Bomb CalorimeterDocumento12 páginasManual For Experiment With Bomb CalorimeterArunSutharAinda não há avaliações

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersNo EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersNota: 4 de 5 estrelas4/5 (13)

- Eurocode 3 PDF FreeDocumento2 páginasEurocode 3 PDF FreeBret0% (1)

- Check List For Piping LayoutsDocumento3 páginasCheck List For Piping LayoutskarunaAinda não há avaliações

- Autonomous Maintenance Standards & ChecklistDocumento7 páginasAutonomous Maintenance Standards & ChecklistPanch BAinda não há avaliações

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocumento10 páginasEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyAinda não há avaliações

- Heat Design ExchangerDocumento3 páginasHeat Design ExchangerDavid Bello0% (1)

- ABB ABB Solar Photovoltaic Power Plant Design PDFDocumento112 páginasABB ABB Solar Photovoltaic Power Plant Design PDFbacuoc.nguyen356100% (1)

- UG40 GovernorDocumento5 páginasUG40 GovernorSaasi100% (2)

- N173 Iso CD 5149 1 2006Documento47 páginasN173 Iso CD 5149 1 2006heronguyen87100% (1)

- H00413783LAB4Documento8 páginasH00413783LAB4Huda AlkhouriAinda não há avaliações

- Lecture 3 - Coal Power PlantsaDocumento48 páginasLecture 3 - Coal Power PlantsaGomolemo BaarxxAinda não há avaliações

- Energy II - EnergyEfficiency and HeatRecoveryDocumento27 páginasEnergy II - EnergyEfficiency and HeatRecoverymluisa.boteroAinda não há avaliações

- ME 575: Heat Pump For Pasteurizing Milk: Optimization ProblemDocumento4 páginasME 575: Heat Pump For Pasteurizing Milk: Optimization ProblemAndyAinda não há avaliações

- LAB Assignment-1Documento12 páginasLAB Assignment-1haris shahAinda não há avaliações

- Pinch TechnologyDocumento7 páginasPinch TechnologyAakanksha MahajanAinda não há avaliações

- Utility Optimization in A Brewery Process Based On EnergyDocumento8 páginasUtility Optimization in A Brewery Process Based On EnergyArley NovaAinda não há avaliações

- Energy Policy: Robert LoweDocumento7 páginasEnergy Policy: Robert LowedrinkscoffeelikecrazAinda não há avaliações

- M.O Heat PumpDocumento11 páginasM.O Heat PumpLawand RaufAinda não há avaliações

- Pinch Point - Heat TransferDocumento2 páginasPinch Point - Heat TransferRavi KasaudhanAinda não há avaliações

- Entropy 19 00394 With CoverDocumento9 páginasEntropy 19 00394 With Coverarun rajaramAinda não há avaliações

- Organic Rankine CycleDocumento14 páginasOrganic Rankine Cycleoverlord5555Ainda não há avaliações

- Pinch AnalysisDocumento31 páginasPinch Analysisshafeeque79Ainda não há avaliações

- 7bab 6 HK IIDocumento52 páginas7bab 6 HK IILuAinda não há avaliações

- Thermodynamics 1Documento20 páginasThermodynamics 1ALFRED AKPOAinda não há avaliações

- Basics of Heat Exchanger Network March 2016Documento84 páginasBasics of Heat Exchanger Network March 2016Diksha SurekaAinda não há avaliações

- Electrical Compression Cooling Versus Absorption Cooling - A ComparisonDocumento3 páginasElectrical Compression Cooling Versus Absorption Cooling - A Comparisonquynhanh2603Ainda não há avaliações

- Abet So2Documento9 páginasAbet So2anasofig02Ainda não há avaliações

- Coefficient of Performance: From Wikipedia, The Free EncyclopediaDocumento4 páginasCoefficient of Performance: From Wikipedia, The Free EncyclopediaimtaftigosdAinda não há avaliações

- Pinch AnalysisDocumento6 páginasPinch Analysisshakil ahmadAinda não há avaliações

- Tafila Technical UniversityDocumento11 páginasTafila Technical UniversitySalam AlbaradieAinda não há avaliações

- MM321 Lab 1Documento5 páginasMM321 Lab 1Roshiv SharmaAinda não há avaliações

- Accepted Manuscript: Applied Thermal EngineeringDocumento24 páginasAccepted Manuscript: Applied Thermal EngineeringAnkit LonareAinda não há avaliações

- Self-Heat Recuperation: Theory and Applications: Yasuki Kansha, Akira Kishimoto, Muhammad Aziz and Atsushi TsutsumiDocumento19 páginasSelf-Heat Recuperation: Theory and Applications: Yasuki Kansha, Akira Kishimoto, Muhammad Aziz and Atsushi TsutsumiJeff Anderson CollinsAinda não há avaliações

- RevisionDocumento19 páginasRevisionmenemAinda não há avaliações

- Al 3419231934Documento12 páginasAl 3419231934IJMERAinda não há avaliações

- The Future Role of Heat Pumps in The Domestic Sector: KeywordsDocumento11 páginasThe Future Role of Heat Pumps in The Domestic Sector: KeywordsvisvanthAinda não há avaliações

- CH 06Documento15 páginasCH 06hirenpatel_universalAinda não há avaliações

- IntroductionDocumento4 páginasIntroductionHazel AdoAinda não há avaliações

- ! 19 Organic Rankine CycleDocumento14 páginas! 19 Organic Rankine Cyclesapcuta16smenAinda não há avaliações

- User Manual SPP MUETDocumento18 páginasUser Manual SPP MUETAlyan YousafAinda não há avaliações

- Cracker Oven Reducing Gas CostsDocumento12 páginasCracker Oven Reducing Gas Costsandresfel47100% (1)

- Dovan Angio S. Canama BSME 4ADocumento8 páginasDovan Angio S. Canama BSME 4A3rdjesse24321562Ainda não há avaliações

- Pinch TechnologyDocumento16 páginasPinch TechnologyAbubaker Faisal100% (1)

- Heat Chap13 068Documento17 páginasHeat Chap13 068Kerem GönceAinda não há avaliações

- Zhang 2020 J. Phys. Conf. Ser. 1449 012001Documento6 páginasZhang 2020 J. Phys. Conf. Ser. 1449 012001Minh TâmAinda não há avaliações

- Adiabatic Flame TemperatureDocumento5 páginasAdiabatic Flame TemperatureRaghav SharmaAinda não há avaliações

- Second Law of Thermodynamics: A Process Must Satisfy Both The First and Second Laws of Thermodynamics To ProceedDocumento57 páginasSecond Law of Thermodynamics: A Process Must Satisfy Both The First and Second Laws of Thermodynamics To ProceedMudit GoyalAinda não há avaliações

- Dougs Thermo 2a Complete Course Work Report FinalDocumento23 páginasDougs Thermo 2a Complete Course Work Report Finaldoug2710Ainda não há avaliações

- Energy Conversion and Rural Electrification: by Abrha FDocumento26 páginasEnergy Conversion and Rural Electrification: by Abrha FAbrha FtsumAinda não há avaliações

- Electrical To Thermal 1 ManualDocumento6 páginasElectrical To Thermal 1 ManualJake SmithAinda não há avaliações

- Che325 Tutorial KitDocumento10 páginasChe325 Tutorial KitCharles BaileyAinda não há avaliações

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsNo EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsAinda não há avaliações

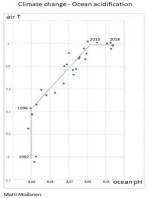

- Climate change - ocean acidity: Matemaattinen analyysiNo EverandClimate change - ocean acidity: Matemaattinen analyysiAinda não há avaliações

- Fluarc: Frame For Circuit - BreakerDocumento18 páginasFluarc: Frame For Circuit - BreakerIsrael JosueAinda não há avaliações

- Quotation NoDocumento8 páginasQuotation NoIsrael JosueAinda não há avaliações

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorDocumento20 páginasOperator'S Manual Manuel de L'Utilisateur Manual Del OperadorIsrael JosueAinda não há avaliações

- FRAX101-1 WP en V01 PDFDocumento5 páginasFRAX101-1 WP en V01 PDFIsrael JosueAinda não há avaliações

- Wind Turbine Test Leads For Low Resistance Ohmmeter: Megger Is A Registered Trademark Megger Is A Registered TrademarkDocumento4 páginasWind Turbine Test Leads For Low Resistance Ohmmeter: Megger Is A Registered Trademark Megger Is A Registered TrademarkIsrael JosueAinda não há avaliações

- ClampOnGuide V01 LowRes PDFDocumento30 páginasClampOnGuide V01 LowRes PDFIsrael JosueAinda não há avaliações

- Diagnostic Insulation Testing Digest 5 and 10 KV PDFDocumento2 páginasDiagnostic Insulation Testing Digest 5 and 10 KV PDFIsrael JosueAinda não há avaliações

- Earth Leakage Clamp Applications Application NoteDocumento2 páginasEarth Leakage Clamp Applications Application NoteIsrael JosueAinda não há avaliações

- DCM305E Earth Leakage Clamp - AN55 PDFDocumento2 páginasDCM305E Earth Leakage Clamp - AN55 PDFIsrael JosueAinda não há avaliações

- Dangerous Voltage - Staying Safe Using High Voltage Test Equipment PDFDocumento3 páginasDangerous Voltage - Staying Safe Using High Voltage Test Equipment PDFIsrael JosueAinda não há avaliações

- Guide To Cable TV Premise Wire TestingDocumento34 páginasGuide To Cable TV Premise Wire TestingIsrael JosueAinda não há avaliações

- CalFunctionality AG en V01 PDFDocumento2 páginasCalFunctionality AG en V01 PDFIsrael JosueAinda não há avaliações

- Testing For Ground Faults On Storage Batteries: Megger Is A Registered TrademarkDocumento5 páginasTesting For Ground Faults On Storage Batteries: Megger Is A Registered TrademarkIsrael JosueAinda não há avaliações

- Tire and Wheel PDFDocumento21 páginasTire and Wheel PDFwanawAinda não há avaliações

- Data CollectionDocumento15 páginasData CollectionIrene Elizabeth MathewAinda não há avaliações

- TS Nit N0 578Documento328 páginasTS Nit N0 578naveen prasadAinda não há avaliações

- Generation of High Voltage DC Using Diodes & Capacitors in Ladder NetworkDocumento6 páginasGeneration of High Voltage DC Using Diodes & Capacitors in Ladder NetworkEditor IJRITCCAinda não há avaliações

- GR00000300-90 EvoDocumento392 páginasGR00000300-90 Evodwi20100% (2)

- 2 Phase Stepper Motor PDFDocumento2 páginas2 Phase Stepper Motor PDFArif FaturohmanAinda não há avaliações

- Omega 85Documento1 páginaOmega 85Kelly RobertsAinda não há avaliações

- 641 Spec Omni F4147IDocumento6 páginas641 Spec Omni F4147Idoody.dpujaAinda não há avaliações

- Web Guide DO2000 PDFDocumento34 páginasWeb Guide DO2000 PDFdeviprasadAinda não há avaliações

- Vehicle Fire Protection: An Owner's Manual For Ansul Fire Suppression/Detection SystemsDocumento16 páginasVehicle Fire Protection: An Owner's Manual For Ansul Fire Suppression/Detection SystemsdeliaabreguAinda não há avaliações

- S 7079 37Documento1 páginaS 7079 37Jose RattiaAinda não há avaliações

- MechanicalDocumento2 páginasMechanicaljvc_84Ainda não há avaliações

- ReportDocumento62 páginasReportakankshajn8950% (4)

- Android Based Fire Fight RobotDocumento5 páginasAndroid Based Fire Fight RobotSkive FabsysAinda não há avaliações

- NDT Ultrasonic TestingDocumento3 páginasNDT Ultrasonic TestingSpace UnionAinda não há avaliações

- NV 175Documento2 páginasNV 175Amir ZozoAinda não há avaliações

- 31 Non Directional Over Current RelaysDocumento3 páginas31 Non Directional Over Current RelaysSrikrishna JanaAinda não há avaliações

- IDM International Diploma in ICT COMPUTING Combined Assesment: Computer Platforms (2014)Documento135 páginasIDM International Diploma in ICT COMPUTING Combined Assesment: Computer Platforms (2014)Hashan Thilakarathna0% (1)