Escolar Documentos

Profissional Documentos

Cultura Documentos

03 March Pistons Engine Technology International

Enviado por

renatoeliegeTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

03 March Pistons Engine Technology International

Enviado por

renatoeliegeDireitos autorais:

Formatos disponíveis

PISTON EVOLUTION

Pistons have come a long

way in recent years. Here,

Federal-Mogul’s high-tech

EcoTough coating is being

applied to a gasoline piston

Pumped up Its function might be relatively straightforward, mechanically speaking,

but the humble piston is far from simple. And as engine sophistication

continues to increase, so too does the complexity of the modern piston

WORDS: MATT ROSS

34 // March 2015 // Engine Technology International.com

PISTON EVOLUTION

N

owadays, engines tend to be hotter, smaller

and boosted. So how do today’s modern

pistons compare with their older counterparts?

And perhaps more pressing, what does

tomorrow hold for this vital engine technology?

“In the past 20 years, engines have undergone big

changes – much greater than those seen in preceding

decades,” says James Allen, head of design at Cosworth.

“Earlier pistons were used primarily in normally

aspirated engines, and their design was based very much

on experience and previous designs. Modern engines are

more likely to be boosted, with higher specific power

output. This places much greater demands on the piston.”

And those demands need to be met on a multitude

of fronts. For piston developers, focusing on any one

single area of research – be it component design, material

selection, manufacturing processes or friction reduction

– simply won’t cut it. So tight is the link between these

factors – change one and you invariably affect another

– that research and development into new piston

technologies has thrown up a mass of challenges

and solutions.

Downward trend

Downsizing has rendered the operating conditions in

modern engines far more intense. “Piston design is a

greater challenge because of the increased performance,

and the increased peak fire pressure you now have in

the combustion system,” states Jens Wartha, diesel

powertrain engineer at GM. “Basically you have to design

the piston in a way that means it will survive.”

Hotter, higher-pressure boosted engines are a hostile

place for pistons, and component developers are striving

to stay ahead of that curve in terms of composition,

design and friction reduction. “Piston materials have

had to evolve, as has the design of the piston, to ensure

adequate fatigue performance due to increasing load

demands,” explains Sebastian Howell-Smith, technical

director of Capricorn Automotive.

“Changing lubricant rheology places

“Piston design is a greater increased demands on combating unwanted

frictional asperity interactions, requiring

challenge because of the greatly increased attention to tribological

increased performance” issues for the piston-cylinder system as

a whole.”

Jens Wartha, diesel powertrain engineer, GM Managing thermal performance is equally

vital, and requires the latest design and

inspection techniques to develop specialist cooling

geometries. “We have to manage the heat flow path from

the piston crown to the ring pack by methods such as

internal cooling galleries,” adds Federal-Mogul’s director

of technology, global pistons, Frank Dörnenburg.

“Thanks to our in-house developments in 2D ultrasonic

inspection, we can ensure robust series production even

with the gallery positioned high in the crown, where it is

most effective. This would not have been practical a few

years ago. We have also developed new materials to

withstand the increased temperatures, as well as strategic

techniques such as Durabowl, which re-melts the

material around the combustion bowl ring on a diesel

piston to increase the fatigue strength.”

Engine Technology International.com // March 2015 // 35

PISTON EVOLUTION

1. Capricorn Automotive’s

facilities in Basingstoke,

UK. The company offers

specialist piston design,

analysis and manufacture

Embracing efficiency The solutions are as varied – and also as

The race to produce engines that are increasingly efficient, interconnected – as the challenges. For

and capable of meeting stringent emissions targets, also Federal-Mogul, a multidisciplinary approach

has consequences for piston design. “For us, higher is clearly important: “Key milestones have

efficiency means lower mass pistons operating at higher been the introduction of new, high-

temperatures, higher ignition pressure and lower skirt performance aluminum alloys and coatings,

friction,” outlines Arnd Baberg, chief engineer, product 2 Durabowl, raised cooling galleries and

engineering at Federal-Mogul. “We operate the piston advanced non-destructive testing techniques,”

material closer to its temperature limits and improve the says Dörnenburg. “All of these have improved

thermal management by using a cooling gallery high in piston durability, despite the gradual increase

the piston, behind the ring pack, or an Alfin insert to in engine power output and combustion

carry the top ring. In gasoline applications, both methods pressures. Technologies such as cooling

mean greater robustness against knocking, so our OEM galleries and top ring land inserts have

2. A recently developed

customers can use higher compression ratios, or calibrate AVL piston. The supplier

migrated from diesel to gasoline applications

combustion across a wider crank angle range. These believes pistons will be a as the firing pressures in today’s high-output

technologies are applicable to both gasoline and diesel fundamental part of vehicle gasoline engines match those of the diesel

powertrain development

pistons because developments such as downsizing, for many years to come

engines we had 15 years ago.”

turbocharging and DI have become widespread in both.” The possibility of implementing steel pistons

Meanwhile Howell-Smith at Capricorn says that friction in passenger vehicles is one that has begun to

reduction is the key driver when it comes to reducing garner interest. A number of leading suppliers

piston-bore parasitic losses. “Increasing in-cylinder loads (and several OEMs) have been conducting

and evolving crown geometry place additional thermo- research into whether steel – which boasts a

mechanical loads on pistons – in local regions and overall. higher yield strength than aluminum, and

These require a matching progression in terms of design, can offer a potentially lower piston height but

materials, coatings and processes employed.” has lower thermal conductivity and requires

On the whole, it seems that there’s no one single greater cooling – is a viable material for

approach to developing new pistons for modern engines. pistons in diesel-powered passenger vehicles.

ELECTRIC DREAMS

By their nature, electric powertrains we get to 2020 and 2021, and of course

don’t use pistons. So is the EV movement both these electrified products still rely

giving piston developers sleepless nights? on the IC engine. The pure EV market

The simple answer is ‘no’. “If you share is still a very low percentage.”

look at the current market introduction, And even if an unexpectedly sudden

and the future market introduction, we demand for electric powertrains caused

currently see a very low percentage of consumers to flock to pure EVs in

vehicles without a combustion engine,” substantial numbers, the days of the

says Wolfgang Schöffmann, AVL’s head piston don’t appear to be numbered.

of design for passenger car powertrains. “In the medium term, we anticipate

“If we look toward 2025, we will see that any reduction in sales volume

the majority of vehicles still with piston due to the growing EV market share,

engines, coupled with electrification of or downsizing trends toward engines

some kind. I wouldn’t be concerned that with fewer cylinders, will be more than

we will have piston-less engines.” offset by the huge increase in demand

“We’ve got a long, long way to go on from emerging markets,” says Federal-

IC engines with pistons,” says Ford’s Joe Mogul’s Dörnenburg. “Our projections, to

Bakaj. “I think the market will move more at least 2020, are for continued growth

toward hybrids and plug-in hybrids as in piston manufacturing volumes.”

Engine Technology International.com // March 2015 // 37

PISTON EVOLUTION

“In the diesel field, the latest technology that everybody 1. Federal-Mogul 1

Monosteel diesel pistons

is working on, us included, is steel pistons,” reveals Joe are manufactured by

Bakaj, vice president of product development at Ford. “We friction-welding the crown

don’t produce our own pistons anymore; we work with to the skirt, creating a large

volume cooling gallery

the big piston suppliers. But we are also doing a lot of between the ring pack

in-house work to understand where the opportunities are, and the combustion bowl

and the potential benefits of competing technologies.”

Federal-Mogul’s Baberg agrees with his Ford counterpart:

“The prospects for steel pistons are exciting and they

could be of interest for smaller engines if exceptionally

high temperatures and loads are to be contained. Steel

pistons have started to penetrate the passenger car diesel

segment, and our OEM customers will determine

how far this trend progresses.”

It’s no coincidence, then, that in

January 2015, Mahle announced that

it would be manufacturing steel 2

Monotherm pistons for Renault’s

1.5- and 1.6-liter four-cylinder diesel increase knowledge about the ever- 2. EcoTough coating cuts

engines, the first instance of such changing boundary conditions within piston-to-bore friction

by up to 13% in diesel

pistons entering series production the cylinder system,” he says. “Higher applications and 10% in

for a diesel passenger car. accuracy boundary data is essential to gasoline over the best

formulate a current representative model coatings that were

previously available

Key analysis of the cylinder system, thereby allowing a

Advances in component design, cyclical, prioritized and measured approach 3. By using a cooling

materials and friction reduction are all to development.” gallery high in the piston,

Federal-Mogul pistons can

vital to the development of new pistons. Predictions for the future of the piston, from operate reliably at higher

But OEMs and suppliers alike are also industry developers at least, are largely evolutionary combustion temperatures

pursuing advances in the simulation based, all of which suggests that the piston of and under higher pressures

and analysis of new designs. “The 2020 will look pretty familiar. Though the 4. Mahle steel pistons for

improvement in modeling rise of alternative drivetrain technologies passenger car applications.

capability of the piston over is noteworthy, the majority of suppliers The company recently

announced that Renault’s

the past 10 years has been believe that pistons will continue to be in 1.5-liter and 1.6-liter

tremendous,” says Ford’s Bakaj. common use, with designs not radically four-cylinder diesel

“Capability under dynamic different from those of today. “The engines would be using

Monotherm steel pistons

conditions has always been the gasoline pistons of 2020 are more likely

issue with pistons, but that’s to make greater use of reinforced inserts

improved quite dramatically.” and cooling galleries,” predicts Dörnenburg.

3

Federal-Mogul’s Baberg further “Diesel pistons are more likely to use a

explains where the industry is at: “Today’s premium aluminum alloy material, or steel,

pistons are more highly optimized because and to be a little smaller in diameter than today.”

the analysis of temperature, deflection, stress Cosworth’s Allen also agrees that it’s far more a case

and fatigue life is more accurate now, and also quicker to of evolution than revolution: “We have explored radical

execute. This has helped in achieving lower piston weights. piston concepts, such as metal matrix composites, in

“Analysis is the tool that enables better piston design racing applications and others that can justify the cost.

through greater understanding. New materials, treatments A big reduction in the cost of one of these technologies

and process developments then allow the hardware to be could affect piston design considerably, but we don’t

delivered robustly in series production.” believe that we are yet at the limit of more conventional

Capricorn’s Howell-Smith fully agrees with Baberg’s techniques. The piston of 2020 will most probably be an

outlook: “A notable addition is multiscale testing to evolution of current designs.”

38 // March 2015 // Engine Technology International.com

Você também pode gostar

- 06-Eb+cranktrain-2024 01 03Documento350 páginas06-Eb+cranktrain-2024 01 03renatoeliege100% (1)

- Materion Engine Technology International June 2018 PerforMet Piston RingsDocumento5 páginasMaterion Engine Technology International June 2018 PerforMet Piston RingsrenatoeliegeAinda não há avaliações

- Addendum To Teikin Catalog Vol - 22 Dated September 30, 2022Documento7 páginasAddendum To Teikin Catalog Vol - 22 Dated September 30, 2022renatoeliegeAinda não há avaliações

- Model # 4Th3S+Ssv3-1626Thb, Selfeeder™ CNC Turret Head 4Th3S Drilling UnitsDocumento2 páginasModel # 4Th3S+Ssv3-1626Thb, Selfeeder™ CNC Turret Head 4Th3S Drilling UnitsrenatoeliegeAinda não há avaliações

- ToyobDocumento339 páginasToyobrenatoeliegeAinda não há avaliações

- PERSAN - CatalogoCompleto 16-17Documento168 páginasPERSAN - CatalogoCompleto 16-17renatoeliegeAinda não há avaliações

- Hasting - Hyundai, Kia, DaewooDocumento9 páginasHasting - Hyundai, Kia, DaewoorenatoeliegeAinda não há avaliações

- e727d5073efad641af12a41150dec01bDocumento6 páginase727d5073efad641af12a41150dec01brenatoeliegeAinda não há avaliações

- FP Diesel Case EnginesDocumento124 páginasFP Diesel Case EnginesFabian Bolivar100% (2)

- Máquinas Pra DLCDocumento43 páginasMáquinas Pra DLCrenatoeliegeAinda não há avaliações

- Japan KoreaDocumento299 páginasJapan KorearenatoeliegeAinda não há avaliações

- NPRDocumento158 páginasNPRrenatoeliege100% (1)

- Takisawa Japan TPS Series Machine Catalogue - February 2016Documento11 páginasTakisawa Japan TPS Series Machine Catalogue - February 2016renatoeliege100% (2)

- Ring PistonsDocumento33 páginasRing PistonsrenatoeliegeAinda não há avaliações

- 12 Piatkowski Chosen Aspects 4 2015 PDFDocumento4 páginas12 Piatkowski Chosen Aspects 4 2015 PDFrenatoeliegeAinda não há avaliações

- Centrinel Centrifugal PDFDocumento110 páginasCentrinel Centrifugal PDFrenatoeliegeAinda não há avaliações

- AnelDocumento5 páginasAnelrenatoeliegeAinda não há avaliações

- Análise Termal Pistão DieselDocumento92 páginasAnálise Termal Pistão DieselrenatoeliegeAinda não há avaliações

- Precision Machining of An Aluminum Alloy Piston Reinforced With A Cast Iron InsertDocumento8 páginasPrecision Machining of An Aluminum Alloy Piston Reinforced With A Cast Iron InsertrenatoeliegeAinda não há avaliações

- 1106C-70TA Industrial Engine PN1970 PDFDocumento2 páginas1106C-70TA Industrial Engine PN1970 PDFrenatoeliegeAinda não há avaliações

- Wellfar PDFDocumento2 páginasWellfar PDFrenatoeliegeAinda não há avaliações

- 3054Documento2 páginas3054Juan Diego SarangoAinda não há avaliações

- Catgt1501 PDFDocumento432 páginasCatgt1501 PDFrenatoeliegeAinda não há avaliações

- Dieselmax - 444 - I t3 Tcae 97 PDFDocumento4 páginasDieselmax - 444 - I t3 Tcae 97 PDFrenatoeliege100% (1)

- Hatz Diesel Engine 2M41 BrochureDocumento6 páginasHatz Diesel Engine 2M41 BrochureWarren TarrAinda não há avaliações

- Manual Takisawa Tps 3000Documento248 páginasManual Takisawa Tps 3000renatoeliegeAinda não há avaliações

- Federal MogulDocumento35 páginasFederal Mogulrenatoeliege0% (1)

- Vitual PistonDocumento31 páginasVitual PistonrenatoeliegeAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Technical Specifications For ValvesDocumento32 páginasTechnical Specifications For ValvesEr Hussain GhadialiAinda não há avaliações

- Seleccion de RejillaDocumento4 páginasSeleccion de RejillaCarlos Eduardo Arista FloresAinda não há avaliações

- Nissan 370Z: 3.7 PETROL Periodic MaintenanceDocumento3 páginasNissan 370Z: 3.7 PETROL Periodic MaintenanceMichael KaneAinda não há avaliações

- Ujwal Steel Introduction LetterDocumento4 páginasUjwal Steel Introduction LettersamAinda não há avaliações

- Mecanica MotoareDocumento45 páginasMecanica MotoareAutogrederAinda não há avaliações

- Quasiturbine EngineDocumento16 páginasQuasiturbine Engineapi-238832008100% (1)

- 2.0 MZR-CD Engine Lubrication SystemDocumento20 páginas2.0 MZR-CD Engine Lubrication SystemPablo De Miguel GonzálezAinda não há avaliações

- D77003 enDocumento57 páginasD77003 enzliangAinda não há avaliações

- Assignment-1 (2020011108)Documento28 páginasAssignment-1 (2020011108)Atul KumarAinda não há avaliações

- Chapter 2 Stress and Strain: Fig. 2.1 External and Internal Forces in A Structural MemberDocumento14 páginasChapter 2 Stress and Strain: Fig. 2.1 External and Internal Forces in A Structural MemberMatthew LinAinda não há avaliações

- Sesion 7Documento40 páginasSesion 7Martin Y. KouAinda não há avaliações

- Constitutive Equation and Normalized Carpet Plots of Symmetrical Fiber Reinforced LaminatesDocumento90 páginasConstitutive Equation and Normalized Carpet Plots of Symmetrical Fiber Reinforced LaminatesjoereisAinda não há avaliações

- RCCDocumento101 páginasRCCJay PatelAinda não há avaliações

- Shear Strenght ExampleDocumento11 páginasShear Strenght ExamplealvinAinda não há avaliações

- Superhero ExampleDocumento8 páginasSuperhero Exampleapi-343241309Ainda não há avaliações

- Valves. Valves and Fittings Pressure Drop CoefficientsDocumento270 páginasValves. Valves and Fittings Pressure Drop CoefficientsJMV100% (1)

- Little Helper. Igantic Effect!: 150 VarioDocumento12 páginasLittle Helper. Igantic Effect!: 150 Variokgv_mailsAinda não há avaliações

- Problem 709 - Propped Beam With Spring Support: Stone Crusher Price ListDocumento2 páginasProblem 709 - Propped Beam With Spring Support: Stone Crusher Price Listmeda012Ainda não há avaliações

- Inertia and MassDocumento4 páginasInertia and MassTanAinda não há avaliações

- WascatorDocumento87 páginasWascatorRobinson SmithAinda não há avaliações

- Syllabus Mechanical Qaqc Course Sdlinc 9600162099Documento3 páginasSyllabus Mechanical Qaqc Course Sdlinc 9600162099Sridurgha Lakshmi Inc SDLINC NDT QA QC INSTITUTE100% (3)

- Eeguc Unit IDocumento28 páginasEeguc Unit IParventhan KannanAinda não há avaliações

- CollisionsDocumento28 páginasCollisionsIndushika SubasingheAinda não há avaliações

- Fluids and LubricantsDocumento2 páginasFluids and LubricantsRUN GOAinda não há avaliações

- Tut-371 No.2Documento8 páginasTut-371 No.2fletusdiabloiAinda não há avaliações

- IES Conventional Mechanical Engineering 1987Documento7 páginasIES Conventional Mechanical Engineering 1987eklavya koshtaAinda não há avaliações

- Revised Cleaning and Painting Piece Rate Data 02-07-2021Documento5 páginasRevised Cleaning and Painting Piece Rate Data 02-07-2021Corrosion FactoryAinda não há avaliações

- Flange TableDocumento0 páginaFlange TablemkstngrAinda não há avaliações

- Ipc 9521Documento4 páginasIpc 9521ashu0470Ainda não há avaliações

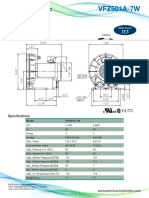

- Fuji Electric VFZ501A 7W DatasheetDocumento2 páginasFuji Electric VFZ501A 7W Datasheetghmp123Ainda não há avaliações