Escolar Documentos

Profissional Documentos

Cultura Documentos

Sri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 6

Enviado por

Ʀoʛeʀ Ɩeo ƖɩbɩŋDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 6

Enviado por

Ʀoʛeʀ Ɩeo ƖɩbɩŋDireitos autorais:

Formatos disponíveis

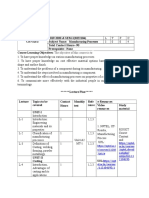

FT/GN/68/01/23.01.

16

SRI VENKATESWARA COLLEGE OF ENGINEERING

COURSE DELIVERY PLAN - THEORY Page 1 of 6

LP: ME16302

Department of MECHANICAL ENGINEERING

Rev. No: 00

B.E : Mechanical Engineering Regulation: R2016 Date: 18-06-2018

PG Specialisation : -NA-

Sub. Code / Sub. Name : ME16302 / Manufacturing Technology -I

Unit : I

Unit Syllabus: “METAL CASTING PROCESSES”

Sand Casting : Sand Mould – Type of patterns - Pattern Materials – Pattern allowances –Moulding sand

Properties and testing – Cores –Types and applications – Moulding machines– Types and applications; Melting

furnaces : Blast and Cupola Furnaces; Principle of special casting processes : Shell - investment – Ceramic

mould – Pressure die casting - Centrifugal Casting - CO2 process – Stir casting; Defects in Sand casting

Objective: ‘To familiarize the students the concepts of Metal Casting Process’

Session Teaching

Topics to be covered Ref

No * Aids

Sand casting – Sand moulds - Type of patterns

1 Ref.-1 (Chapter 1.1 pp. 1-3) PPT

Pattern materials, Pattern allowances Ref.-1 (Chapter 1.2 pp. 4-

2 PPT

12)

Types of Moulding sand Properties and Testing Ref.-1 (Chapter 1.3 pp. 15-

3 PPT

32)

Ref.-1 (Chapter 1.4 pp. 35-

4 Types and applications of core making PPT

45)

Moulding machines – Types of moulding machines, Melting Ref.-1 (Chapter 1.5 pp. 45-

5 Furnaces: Blast and Cupola Furnaces PPT

49)

Working principle of Special casting processes– Shell, TB-1 (Chapter 11 pp. 386 -

6 investment casting PPT

392)

7 Ceramic mould – Pressure die casting TB-1 (Chapter 11 pp. 385) PPT

Centrifugal casting , CO2 process, Stir Casting TB-1 (Chapter 11 pp. 386 -

8 PPT

392)

9 Defects in Sand casting TB-1 (Chapter 11 p. 419 PPT

Content beyond syllabus covered (if any):

* Session duration: 50 minutes

FT/GN/68/01/23.01.16

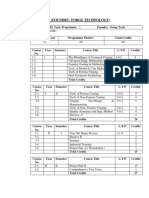

SRI VENKATESWARA COLLEGE OF ENGINEERING

COURSE DELIVERY PLAN - THEORY Page 2 of 6

Sub. Code / Sub. Name: ME16302 / Manufacturing Technology -I

Unit : II

Unit Syllabus: “JOINING PROCESSES”

Operating principle, basic equipment, merits and applications of : Fusion welding processes : Gas welding -

Types – Flame characteristics; Manual metal arc welding – Gas Tungsten arc welding - Gas metal arc welding –

Submerged arc welding – Electro slag welding; Operating principle and applications of : Resistance welding -

Plasma arc welding – Thermit welding – Electron beam welding – Friction welding and Friction Stir Welding;

Brazing and soldering; Weld defects: types, causes and cure.

Objective: ‘To familiarize the students the concepts of Joining Process’

Session Teaching

Topics to be covered Ref

No * Aids

Fusion welding processes – Types of Gas welding, Ref. - 1 (Chapter 2.3 pp. 161-

10 PPT

177)

Flame characteristics, Manual metal arc welding Ref. - 1 (Chapter 2.2 pp. 120-

11 PPT

141)

Gas Tungsten arc welding,Gas metal arc welding Ref. – 1 (Chapter 2.2 pp. 149-

12 PPT

154)

Ref. – 1 (Chapter 2.2 pp.

13 Submerged arc welding, Electro slag welding PPT

1146-148, 155-157)

Resistance welding, Plasma arc welding Ref. - 1 (Chapter 2.4, pp.181,

14 PPT

Chapter 2.6, pp.204,)

Ref. - 1 (Chapter 2.6, pp. 206,

15 Thermit welding – Electron beam welding PPT

219)

Friction welding and Friction Stir Welding

16 Ref. - 1 & 2 PPT

Brazing and soldering; Ref. - 1 (Chapter 2.5, pp.193-

17 PPT

199)

Weld defects: types, causes and cure. Ref. - 1 (Chapter 2.7, pp.222-

18 PPT

230)

Content beyond syllabus covered (if any):

* Session duration: 50 mins

FT/GN/68/01/23.01.16

SRI VENKATESWARA COLLEGE OF ENGINEERING

COURSE DELIVERY PLAN - THEORY Page 3 of 6

Sub. Code / Sub. Name: ME16302 / Manufacturing Technology -I

Unit : III

Unit Syllabus: “METAL FORMING PROCESSES”

Hot working and cold working of metals – Forging processes – Open, impression and closed die forging –

forging operations. Rolling of metals– Types of Rolling – Flat strip rolling – shape rolling operations – Defects

in rolled parts. Principle of rod and wire drawing – Tube drawing – Principles of Extrusion – Types – Hot and

Cold extrusion.

Objective: To introduce the students the concepts of metal working process

Session Teaching

Topics to be covered Ref

No * Aids

Hot working of metals

19 TB-1 (Chapter 7 pp. 153) PPT

Cold working of metals

20 TB-1 (Chapter 7 pp. 161) PPT

Forging processes – Open and closed die forging Ref.-1 (Chapter 3.2 pp. 244-

21 PPT

264)

Forging processes – Impression die forging

22 Ref.-1 (Chapter 3.2 pp. 244-264) PPT

Rolling of metals– Types of Rolling

23 Ref.-1 (Chapter 3.3 pp. 266-274) PPT

Flat strip rolling – Shape rolling operations, Defects in

24 rolled parts. Ref.-1 (Chapter 3.3 pp. 266-274) PPT

Principle of rod and wire drawing, Tube drawing

25 Ref.-1 (Chapter 3.5 pp. 286-291) PPT

26 Principles of Extrusion & Types Ref.-1 (Chapter 3.4 pp. 277-285) PPT

27 Hot and Cold extrusion process Ref.-1 (Chapter 3.4 pp. 277-285) PPT

Content beyond syllabus covered (if any):

FT/GN/68/01/23.01.16

SRI VENKATESWARA COLLEGE OF ENGINEERING

COURSE DELIVERY PLAN - THEORY Page 4 of 6

Sub. Code / Sub. Name: ME16302 / Manufacturing Technology -I

Unit : IV

Unit Syllabus: “SHEET METAL PROCESSES”

Sheet metal characteristics – shearing, bending and drawing operations – Stretch forming operations –

Formability of sheet metal – Test methods –special forming processes-Working principle and applications –

Hydro forming – Rubber pad forming – Metal spinning– Introduction of Explosive forming, magnetic pulse

forming, peen forming, Super plastic forming – Micro forming

Objective: To introduce the students the concepts of Sheet metal processes

Session Teaching

Topics to be covered Ref

No * Aids

28 Sheet metal characteristics, Shearing operations Ref.-1 (Chapter 4.1 pp. 295-301) PPT

Ref.-1 (Chapter 4.3, 4.4 pp. 318-

29 Bending and drawing operations PPT

337)

Ref.-1 (Chapter 4.6.2 pp. 347-

30 Stretch forming operations PPT

350)

31 Formability of sheet metal , Test Methods TB-2 (Chapter 16.4 pp. 424 ) PPT

32 Special forming processes- Ref.-1 (Chapter 4.6 pp. 345) PPT

33 Hydro forming, Rubber pad forming TB-2 (Chapter 16.10 pp. 443 ) PPT

Metal spinning, Explosive forming, Ref.-1 (Chapter 4.6.3, 4.5.1 pp.

34 PPT

351, 338 )

Ref.-1 (Chapter 4.6.4, 4.5.2 pp.

35 Magnetic pulse forming, peen forming PPT

354, 342 )

36 Super plastic forming – Micro forming Ref.-1 (Chapter 4.6.5 pp. 354) PPT

Content beyond syllabus covered (if any):

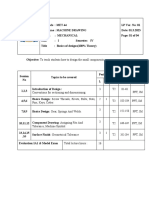

FT/GN/68/01/23.01.16

SRI VENKATESWARA COLLEGE OF ENGINEERING

COURSE DELIVERY PLAN - THEORY Page 5 of 6

Sub. Code / Sub. Name: ME16302 / Manufacturing Technology -I

Unit : V

Unit Syllabus: “MANUFACTURE OF PLASTIC COMPONENTS”

Types and characteristics of plastics – Moulding of thermoplastics – working principles and typical applications

– injection moulding – Plunger and screw machines – Compression moulding, Transfer Moulding – Typical

industrial applications – introduction to blow moulding –Rotational moulding – Film blowing – Extrusion –

Thermoforming – Bonding of Thermoplastics.

Objective: To familiarize the students the concepts of Plastic Moulding Processes

Session Teaching

Topics to be covered Ref

No * Aids

37 Types and characteristics of plastics Ref.-1 (Chapter 5.1 pp. 359-364) PPT

38 Moulding of thermoplastics, injection moulding Ref.-1 (Chapter 5.2.2 pp. 366) PPT

39 Plunger and screw machine Ref.-1 (Chapter 5.2.3 pp. 365) PPT

40 Compression moulding Ref.-1 (Chapter 5.3.1 pp. 376) PPT

41 Transfer Moulding – Typical industrial applications Ref.-1 (Chapter 5.3.2 pp. 378) PPT

42 Introduction to blow moulding Ref.-1 (Chapter 5.2.3 pp. 368) PPT

Ref.-1 (Chapter 5.2.4, 5.2.6 pp.

43 Rotational moulding, Film blowing PPT

370, 372)

44 Extrusion – Thermoforming Ref.-1 (Chapter 5.2.7 pp. 373) PPT

45 Bonding of thermoplastics. Ref.-1 (Chapter 5.4 pp. 382-389) PPT

Content beyond syllabus covered (if any):

FT/GN/68/01/23.01.16

SRI VENKATESWARA COLLEGE OF ENGINEERING

COURSE DELIVERY PLAN - THEORY Page 6 of 6

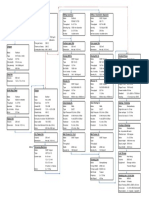

Você também pode gostar

- The Objective of This Course Is To: Manufacturing ProcessesDocumento5 páginasThe Objective of This Course Is To: Manufacturing ProcessesKARAMTOTHU GANESH NAIK (N160423)Ainda não há avaliações

- Course ObjectivesDocumento4 páginasCourse ObjectivesHOD TD GITAinda não há avaliações

- MPR-1 2Documento7 páginasMPR-1 2pradipd4271Ainda não há avaliações

- Machine DrawingDocumento4 páginasMachine DrawingsithananthansithuAinda não há avaliações

- Hindusthan College of Engineering and Technology: AircraftDocumento12 páginasHindusthan College of Engineering and Technology: AircraftKathirvel KAinda não há avaliações

- Course File - Introduction To Composite MaterialsDocumento9 páginasCourse File - Introduction To Composite MaterialsAmarAinda não há avaliações

- M.Tech (Foundry-Forge Technology)Documento8 páginasM.Tech (Foundry-Forge Technology)JagdishAinda não há avaliações

- Crystal PhysicsDocumento15 páginasCrystal PhysicsManiyarasu OppilamaniAinda não há avaliações

- ME2201 Manufacturing Technology-IDocumento9 páginasME2201 Manufacturing Technology-IHiru Purushothaman HirudayanathanAinda não há avaliações

- Dhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Documento8 páginasDhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Kalai ArasanAinda não há avaliações

- Production Syllabus 2017-18-1Documento71 páginasProduction Syllabus 2017-18-1Akankshya MishraAinda não há avaliações

- Machine DrawingDocumento4 páginasMachine DrawingsithananthansithuAinda não há avaliações

- BMP - Electric Arc WeldingDocumento91 páginasBMP - Electric Arc Weldingsujay nayakAinda não há avaliações

- R PT Instruction PlanDocumento6 páginasR PT Instruction PlanVipin KumarAinda não há avaliações

- Experimental Investigation and Analysis of Drilling Parameters of Metal Matrix (Ti/Tib) CompositesDocumento12 páginasExperimental Investigation and Analysis of Drilling Parameters of Metal Matrix (Ti/Tib) CompositesvinothksAinda não há avaliações

- BMP - ExtrusionDocumento24 páginasBMP - Extrusionmantra2010Ainda não há avaliações

- BMP - Powder MetallurgyDocumento71 páginasBMP - Powder Metallurgymantra2010Ainda não há avaliações

- MT (MEL - 3206) Course Handout Sem IVDocumento3 páginasMT (MEL - 3206) Course Handout Sem IVVikasAinda não há avaliações

- Course Handout (BMP)Documento4 páginasCourse Handout (BMP)058-Somyajit RayAinda não há avaliações

- Examination of Welds in Furnace Process CoilsDocumento2 páginasExamination of Welds in Furnace Process CoilsswatkoolAinda não há avaliações

- Syllabus With ReportDocumento44 páginasSyllabus With ReportrajeshAinda não há avaliações

- Sri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 6Documento6 páginasSri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 6anuAinda não há avaliações

- Gujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyDocumento3 páginasGujarat Technological University: Semester - V Subject Name: Manufacturing TechnologystarboyAinda não há avaliações

- Gujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyDocumento3 páginasGujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyPratik VishwakarmaAinda não há avaliações

- St. Michael College of Engineering & Technology: Course Plan (Theory)Documento5 páginasSt. Michael College of Engineering & Technology: Course Plan (Theory)MECHANICAL SMCETAinda não há avaliações

- Materials Joining TechnologyDocumento4 páginasMaterials Joining Technologykanna nrAinda não há avaliações

- BMP - Other Welding ProcessesDocumento76 páginasBMP - Other Welding Processessujay nayakAinda não há avaliações

- Sri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 7Documento7 páginasSri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 7Sanaka LogesAinda não há avaliações

- GMT Question21.12.2018Documento1 páginaGMT Question21.12.2018SAKTHIVELAinda não há avaliações

- ME F219 - Course Handout - 2022-23Documento3 páginasME F219 - Course Handout - 2022-23YERRAMILLI SRIVATSAVAinda não há avaliações

- PBL Proposal and Assessment: Product/Process: Arduino Pro Mini Customer: Kelompok 1 SMT Scope of Work: PcbaDocumento5 páginasPBL Proposal and Assessment: Product/Process: Arduino Pro Mini Customer: Kelompok 1 SMT Scope of Work: Pcbayogi arohmanAinda não há avaliações

- Lesson Plan PPEDocumento6 páginasLesson Plan PPEGajendran A MECH KIOTAinda não há avaliações

- RTM Nagpur University Syllabus (Theory)Documento5 páginasRTM Nagpur University Syllabus (Theory)Milind KshirsagarAinda não há avaliações

- BMP - CastingDocumento217 páginasBMP - Castingmantra2010Ainda não há avaliações

- Me 8392 - Manufacturing Technology: 14. Course OutcomesDocumento6 páginasMe 8392 - Manufacturing Technology: 14. Course OutcomesERKATHIRAinda não há avaliações

- Hard Rock Tunnel Boring Vol. 7 - The Boring Process: October 2000Documento91 páginasHard Rock Tunnel Boring Vol. 7 - The Boring Process: October 2000Annisa WisdayatiAinda não há avaliações

- TO Compare The Properties of Ferrous and Nonferrous AlloyDocumento13 páginasTO Compare The Properties of Ferrous and Nonferrous AlloyMann OjhaAinda não há avaliações

- BMP - DrawingDocumento22 páginasBMP - Drawingmantra2010Ainda não há avaliações

- BMP PDFDocumento17 páginasBMP PDFmantra2010Ainda não há avaliações

- BMP - Metal WorkingDocumento17 páginasBMP - Metal Workingmantra2010Ainda não há avaliações

- BMP - ForgingDocumento31 páginasBMP - Forgingmantra2010Ainda não há avaliações

- Fabrication Method For HSM 2 ProjectDocumento14 páginasFabrication Method For HSM 2 ProjectMikiRoniWijayaAinda não há avaliações

- ME-220 Manufacturing Processes I Lab Workbook October 2022Documento64 páginasME-220 Manufacturing Processes I Lab Workbook October 2022Aayan Ahmed KhanAinda não há avaliações

- Reduction Behaviour of Iron Ore Pellets: Bachelor of Technology in Metallurgical and Materials EngineeringDocumento38 páginasReduction Behaviour of Iron Ore Pellets: Bachelor of Technology in Metallurgical and Materials EngineeringDibya NayakAinda não há avaliações

- Manufacturing Engineering - IDocumento2 páginasManufacturing Engineering - Ivp02091988Ainda não há avaliações

- 4th BTECH New SyllabusDocumento17 páginas4th BTECH New SyllabusnshsinghrajputAinda não há avaliações

- 3rd Sem Mechanical EnggDocumento22 páginas3rd Sem Mechanical EnggTabish SamarAinda não há avaliações

- BTU-B520-QMP-PR-025 Coating & Repair Coating For Welding Area (Outside) of Steel Box GirderDocumento15 páginasBTU-B520-QMP-PR-025 Coating & Repair Coating For Welding Area (Outside) of Steel Box GirderramdhaniAinda não há avaliações

- BMP - RollingDocumento46 páginasBMP - Rollingmantra2010Ainda não há avaliações

- MEF 112 Course HandoutDocumento4 páginasMEF 112 Course HandoutAR7 StudioAinda não há avaliações

- Surf. Engg-6Documento60 páginasSurf. Engg-6Barath SundarAinda não há avaliações

- Course Registration FormDocumento1 páginaCourse Registration Formabdulghaniyu obaroAinda não há avaliações

- 1B 98engDocumento58 páginas1B 98engDavide AgnellaAinda não há avaliações

- Manufacturing Tech SyllDocumento4 páginasManufacturing Tech SyllJagjit SinghAinda não há avaliações

- 00 Agenda 2019 Print PDFDocumento79 páginas00 Agenda 2019 Print PDFAlok KumarAinda não há avaliações

- 2018 - Evaluating The Wear of Polycrystalline Diamond Compact Drill Bits Using Indentation and Scratch TestsDocumento10 páginas2018 - Evaluating The Wear of Polycrystalline Diamond Compact Drill Bits Using Indentation and Scratch Testscse crteAinda não há avaliações

- MT II Exercise 2Documento17 páginasMT II Exercise 2Derry RahmaAinda não há avaliações

- Weld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingNo EverandWeld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingAinda não há avaliações

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingNo EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydAinda não há avaliações

- Score Booster For All Prelims Exam Day 2Documento31 páginasScore Booster For All Prelims Exam Day 2Ʀoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Watch Live Current Affairs at You Tube - SSC Adda (Mon - Sat at 6 Am)Documento5 páginasWatch Live Current Affairs at You Tube - SSC Adda (Mon - Sat at 6 Am)Ʀoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Score Booster For All Prelims Exam Day 1Documento26 páginasScore Booster For All Prelims Exam Day 1Ʀoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- RRB Group D Previous Question Paper PDF 08 12 2013.pdf 37 PDFDocumento9 páginasRRB Group D Previous Question Paper PDF 08 12 2013.pdf 37 PDFƦoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- List of Famous Temples in India-77Documento3 páginasList of Famous Temples in India-77Ʀoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Nba Ptam Ia Iii RTDocumento1 páginaNba Ptam Ia Iii RTƦoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Bethlahem Institute of Engineering Karungal-629 157: Question Set: 01 Roll Number: Register NumberDocumento1 páginaBethlahem Institute of Engineering Karungal-629 157: Question Set: 01 Roll Number: Register NumberƦoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Write Down The Shape Functions For A 4 Noded Quadrilateral ElementDocumento3 páginasWrite Down The Shape Functions For A 4 Noded Quadrilateral ElementƦoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Bethlahem Institute of Engineering Karungal-629 157Documento2 páginasBethlahem Institute of Engineering Karungal-629 157Ʀoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Nba Ptam Ia I RTDocumento1 páginaNba Ptam Ia I RTƦoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Fea Week 3Documento1 páginaFea Week 3Ʀoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Me8451 Rejinpaul Iq April May 2019Documento2 páginasMe8451 Rejinpaul Iq April May 2019Ʀoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Feaunit1to5qb 170719162712Documento26 páginasFeaunit1to5qb 170719162712Ʀoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- AT6002 - Unit 1 New FullDocumento36 páginasAT6002 - Unit 1 New FullƦoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Koren - CH 02 PDFDocumento19 páginasKoren - CH 02 PDFƦoʛeʀ Ɩeo ƖɩbɩŋAinda não há avaliações

- Super 00Cr Stainless Steel Sucker Rod IntroductionDocumento15 páginasSuper 00Cr Stainless Steel Sucker Rod IntroductionKevin XuAinda não há avaliações

- F - 8480 - Operation Manual New 2015 - 1Documento57 páginasF - 8480 - Operation Manual New 2015 - 1Robin PAinda não há avaliações

- Unit 3Documento10 páginasUnit 3JOSE GOMEZAinda não há avaliações

- Hydraulic Press - Diagram, Working, Types & Application (PDF)Documento16 páginasHydraulic Press - Diagram, Working, Types & Application (PDF)Qamar JamilAinda não há avaliações

- OverdentureDocumento3 páginasOverdentureManjeevAinda não há avaliações

- Ac650 Mandrinadora Vertical P Cilindros y Bloques PDFDocumento8 páginasAc650 Mandrinadora Vertical P Cilindros y Bloques PDFJoseDavidSanchezYepesAinda não há avaliações

- 13 MembranesDocumento49 páginas13 Membraneswatersoul.nAinda não há avaliações

- JCQusa Alloy 825 PDFDocumento6 páginasJCQusa Alloy 825 PDFharan2000Ainda não há avaliações

- Skill Matrix TR 05-Aug-2021Documento14 páginasSkill Matrix TR 05-Aug-2021Fernando GomezAinda não há avaliações

- PB Canang Mechine SpecsDocumento1 páginaPB Canang Mechine SpecsRely TokAinda não há avaliações

- (201207) (TDS) Ig4848Documento2 páginas(201207) (TDS) Ig4848Abdelrahman AwadallahAinda não há avaliações

- The Anodic Collection 2022 Global Version FlipbookDocumento4 páginasThe Anodic Collection 2022 Global Version FlipbookAnthony_I2CAinda não há avaliações

- Presented By:-: Akshay Ts DTDM 6 SEM Roll No - 04Documento23 páginasPresented By:-: Akshay Ts DTDM 6 SEM Roll No - 04Deepak RameshAinda não há avaliações

- PSL1 PSL2 PDFDocumento1 páginaPSL1 PSL2 PDFArmandoZacariasAcostaAinda não há avaliações

- Hot Work PESB 01 PDFDocumento4 páginasHot Work PESB 01 PDFShureendran Muniandy RajanAinda não há avaliações

- Assembly Drawings With Dimensions and Details For Mounting: 2.38 2" Pipe SupportDocumento1 páginaAssembly Drawings With Dimensions and Details For Mounting: 2.38 2" Pipe Supporttatiana araujoAinda não há avaliações

- Leaching Reviewer: CpmonterolaDocumento23 páginasLeaching Reviewer: CpmonterolaAlyssa ApolinarioAinda não há avaliações

- Hyundai Welding Co., LTD.: Low Alloy, Cellulosic Smaw For PipeDocumento6 páginasHyundai Welding Co., LTD.: Low Alloy, Cellulosic Smaw For PipeKali AbdennourAinda não há avaliações

- PX MicDocumento6 páginasPX MicSoraire LucasAinda não há avaliações

- ASSET Summer SaleDocumento8 páginasASSET Summer SaleAssetPlantAinda não há avaliações

- WWJ 1995 #6 PDFDocumento84 páginasWWJ 1995 #6 PDFJennifer davisAinda não há avaliações

- Powder MetallurgyDocumento8 páginasPowder MetallurgyPritamAinda não há avaliações

- ASSAB 8407 Supreme-D20140715Documento12 páginasASSAB 8407 Supreme-D20140715yanuarAinda não há avaliações

- Belt Specifications - R19-Fabcon - 2rc - 5 - tr24 - 00-00 - Fa-Kc2tr2401Documento2 páginasBelt Specifications - R19-Fabcon - 2rc - 5 - tr24 - 00-00 - Fa-Kc2tr2401eng.mark.iskanderAinda não há avaliações

- Hardness Test Procedure For Spherical TankDocumento7 páginasHardness Test Procedure For Spherical TankHamid MansouriAinda não há avaliações

- Australian Wood Review June 2020Documento84 páginasAustralian Wood Review June 2020Jimmytron Gallegos100% (1)

- SM012807093970 - en - PDF Piston HoningDocumento24 páginasSM012807093970 - en - PDF Piston Honingibrahim salemAinda não há avaliações

- Sikagrout - 214 inDocumento4 páginasSikagrout - 214 invk SAinda não há avaliações

- DS Tna MineralityDocumento1 páginaDS Tna Mineralityabdulazeem703Ainda não há avaliações

- Challenge: Key AchievementsDocumento1 páginaChallenge: Key AchievementsAvishek PrasadAinda não há avaliações