Escolar Documentos

Profissional Documentos

Cultura Documentos

JEKSOTIN

Enviado por

Florencia MandaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

JEKSOTIN

Enviado por

Florencia MandaDireitos autorais:

Formatos disponíveis

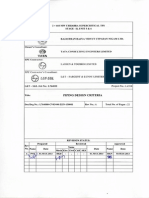

ACTION (QW – 405) PREHEAT (QW-406)

ACTION (5) OF GROOVE : PREHEAT TEMP. MIN :

3G : INTERPASS TEMP. MAX :

WELDING PROGRESS UD HILL : PREHEAT MAINTENANCE :

TEST HEST TREATMENT ( QW – 407 ) GAS (QW – 408)

TEMPERATURE RANGE : SHELDING GAS (ES)] :

TIME RANGE : PRECENT COMPOSITION :

SPEER RANGE : FLOW RATE :

GAS BACKING : GAS BACKING :

ELECTRICAL CHARACTERISTICS (QW – 409 )

CURRENT AC or DC DC POLARITY RP

SPACE ( RANGE) See Welding Parameter VOLT (RANGE) See Welding Parameter

TUNGSTEN ELECTRODE SIZE AND TYPE :

SPACE OF METAL TRANSFER FOR GMAW / GTAW :

ELECTRODE WIRE FEED SPEED RANGE (IPM) :

TECHNIQUE (QW – 410)

STRING OR WEAVE BEAD : String and Weaving

ORIFICE OR GAS CUP SIZE :-

INITIAL AND INTERPASS CLEANING : Grinding and Brushing

BRUSHING, GRINDING, ETC :-

METHODE OF BACK GAUGING : Grinding

MULTIPLE OR SINGLE ELECTRODE : Multiple

LEVEL SPEED : See Welding Parameter

PEENING : Yes

FILLELEMENTAL FILLER METAL :-

OTHER : Back Weld

WELDING PARAMETER

WELD PROCESS FILLER METAL CURRENT TRAVEL

CLASS Dia. mm TYPE POLAR AMPERE VOLT SPEED OTHER

RANGE RANGE RANGE

1. SMAW E 7016 3,2 DCRP 110 25 7,6 Cm / Menit -

2. SMAW E 7016 4,0 DCRP 150 25 9 Cm / Menit -

3. SMAW E 7016 4,0 DCRP 130 25 6,5 Cm / Menit -

4. SMAW E 7016 3,2 DCRP 110 25 6 Cm / Menit -

5. SMAW E 7016 3,2 DCRP 110 25 6 Cm / Menit -

NON DESTRUCTIVE TESTING

MHETODE : Findiography Test

RESULT : Good / Pass

DESTRUCTIVE TESTING

RESULT OF TENSILE TEST

SPECIMENT WIDTH THICKNESS AREA ULTIMATE TOTAL TENSILE CHARACTER

LOAD KG F

No mm mm STREGHT OF FAILURE

KG-F / mm2

T1 19 16 304 18000 59,21 BASE METAL

T2 19 16 304 16200 59,86 BASE METAL

RESULT OF BEND TEST

TYPE AND FIGURE RESULT

(QW 462, 3 a) Good ( No Defect)

(QW 462, 3 a) Good ( No Defect)

(QW 462, 3 a) Good ( No Defect)

(QW 462, 3 a) Good ( No Defect)

OTHER TEST

TYPE OF TEST :-

OPPOSITE ANALYSIS :-

OTHER :-

WELDER NAME : SIDIK CLOCK No: - STAMP No. W 12

TEST CONDUCTED By : BKI LABORATORY TEST No.3801195 L1LAB-A

WE CERTIFY THAT THE SATATEMENTS THIS RECORD AND THE TEST WELDS WERE

PREPARED, WELDED, AND TESTED IN ACCORDANCE WITH THE REQUIREMENT OF SECT.

IX ASME CODE.

PREPARED BY, WITHNESS BY, WITHNESS BY, APPROVED BY

I II DEPNAKER

Date: Date: Date: Date:

SURAT REKOMENDASI

Nomor : AST/001-X/2017

Hal : Surat Rekomendasi

Kepada Yth,

PT. Indah Kiat Pulp & Paper

Pengawas Project MB#26

Bapak Alfian

Di

Tempat

Dengan Hormat

Yang Bertanda tangan di bawah ini:

Nama : Alfian

SAP ID : 01106567

Unit / Line / Div : CWD

Memberikan rekomendasi kepada nama yang tercantum di bawah ini :

Nama : Setiaddy

KIM : 0801042800

Jabatan : Welder

Dengan ini merekomendasikan nama tersebut untuk mengikuti Welder Test. Demikina surat rekomendasi ini di

sampaikan atas segala bantuan dan kerjasamanya kami ucapkan terimakasih.

Perawang, 17 Oktober 2017

Disetujui Oleh, Di Ketahui,

Alfian ( Octavianus B.O Lubis)

Manager Project

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- LUDV Control Block of Mono and Sandwich Plate Design Type M7-22Documento16 páginasLUDV Control Block of Mono and Sandwich Plate Design Type M7-22W Morales100% (2)

- Whirlpool Duet Washer Component TestingDocumento6 páginasWhirlpool Duet Washer Component TestingSamurai Appliance Repair Man50% (2)

- Arc Welding Process PDFDocumento12 páginasArc Welding Process PDFBiswanath RoulAinda não há avaliações

- MD Lecture 3 4 PDFDocumento35 páginasMD Lecture 3 4 PDFDeekshaomarAinda não há avaliações

- Pre-Board Hydraulics Geothecnical EngineeringDocumento14 páginasPre-Board Hydraulics Geothecnical EngineeringPhreetzi ÜnseenAinda não há avaliações

- Blind Flange DesignDocumento1 páginaBlind Flange DesignSachin5586Ainda não há avaliações

- Kruger Tunnel Ventilation Products BrochureDocumento12 páginasKruger Tunnel Ventilation Products BrochureMarino AyalaAinda não há avaliações

- CRDI Seminar ReportDocumento19 páginasCRDI Seminar ReportBharadwaj PradhanAinda não há avaliações

- Manufacturing EngineeringDocumento72 páginasManufacturing EngineeringAnirban PalAinda não há avaliações

- Piping Design CriteriaDocumento20 páginasPiping Design Criteriasuman_ghosh6798Ainda não há avaliações

- Lecture 7. HumidificationDocumento29 páginasLecture 7. HumidificationNOBLEMAN100% (1)

- AMI Organics LTD Unit II 100 TRDocumento18 páginasAMI Organics LTD Unit II 100 TRVatsal VermaAinda não há avaliações

- Öhlins Ka049 Zxr750r 91-94Documento2 páginasÖhlins Ka049 Zxr750r 91-94sasaAinda não há avaliações

- SP Concare Pvt. LTD.: Repair & RetrofittingDocumento15 páginasSP Concare Pvt. LTD.: Repair & RetrofittingAnkita Baban GavadeAinda não há avaliações

- Impulse and Momentum Problem Set October 21, 2014Documento2 páginasImpulse and Momentum Problem Set October 21, 2014Nikko Angelo V MolinaAinda não há avaliações

- 9A03302 ThermodynamicsDocumento4 páginas9A03302 ThermodynamicssivabharathamurthyAinda não há avaliações

- IMI CCI Product DRAG-Control-Valves AW LRESDocumento4 páginasIMI CCI Product DRAG-Control-Valves AW LRESOscarGomezMecanicoAinda não há avaliações

- Pennbarry SX Catalogue TS v9bDocumento34 páginasPennbarry SX Catalogue TS v9bjacaAinda não há avaliações

- Outline Design Specification of Phase IV (March 2019) 01042019 PDFDocumento164 páginasOutline Design Specification of Phase IV (March 2019) 01042019 PDFBilal A BarbhuiyaAinda não há avaliações

- 77 3001 TypeDDocumento8 páginas77 3001 TypeDSasan AbbasiAinda não há avaliações

- Iso 2768 Tolerancias GeneralesDocumento2 páginasIso 2768 Tolerancias GeneralesjavierAinda não há avaliações

- Nouvelle Brochure BTTDocumento28 páginasNouvelle Brochure BTTskirubananthAinda não há avaliações

- Hangers and Supports For Hvac Piping and EquipmentDocumento10 páginasHangers and Supports For Hvac Piping and EquipmentAmeen Mohamed Ali SanadAinda não há avaliações

- Experiment No: Name of The Experiment: Pressure Process Rig Objective of The ExperimentDocumento4 páginasExperiment No: Name of The Experiment: Pressure Process Rig Objective of The ExperimentBhaswati MedhiAinda não há avaliações

- SWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Documento2 páginasSWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Paulo MoreiraAinda não há avaliações

- Bombas en El Libro de Re Metallica 1556Documento4 páginasBombas en El Libro de Re Metallica 1556Carlos DelgadoAinda não há avaliações

- ValveTypesSelection - ControlsWikiDocumento42 páginasValveTypesSelection - ControlsWikiMayur PatelAinda não há avaliações

- Valtra T Series HiTech Models T144 H, T154 H, T174e H, T194 H, T214Documento414 páginasValtra T Series HiTech Models T144 H, T154 H, T174e H, T194 H, T214Zsombor Gyergyai100% (1)

- H. K. Moffatt and Tadashi Tokieda - Celt Reversals: A Prototype of Chiral DynamicsDocumento8 páginasH. K. Moffatt and Tadashi Tokieda - Celt Reversals: A Prototype of Chiral DynamicsVortices3443Ainda não há avaliações