Escolar Documentos

Profissional Documentos

Cultura Documentos

Economics of Power Factor Correction

Enviado por

Syed FaheemTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Economics of Power Factor Correction

Enviado por

Syed FaheemDireitos autorais:

Formatos disponíveis

Economics of Power Factor Correction

© 2013 Eaton. All rights reserved.

Understanding Utility Bills

• Kilowatt hours (kWH) – kWH consumption is

measure of electrical energy that has been used

during the billing period. Consist of a unit rate

times accumulated kWH reading from the meter.

• Fuel charge adjustment – Monthly charge

based on the cost of fuel used to produce power

each month. Typically a unit charge times kWH.

• Kilowatt demand – Based on maximum recorded kW demand interval

for the month and represents how much a utility has to provide in terms

of transformers, wire and generation capability. Typically a unit charge

times max kW demand interval for the month.

• Power factor penalties – Charged by some utilities. Usually based on

falling below a minimum PF level. Penalties vary widely among utilities.

© 2013 Eaton. All rights reserved.

2

What is Power Factor?

Inductive loads (motors) require two kinds of

power

Real power(kW)

• Real Power (kW) – that actually performs 𝜃

the work

Reactive power(kvar)

• Reactive Power (kvar) – that maintains the

electromagnetic field Apparent power(kVA)

• Apparent Power (kVA) – total power,

vector sum of kW and kvar

Real power kW

Power Factor is a measure of efficiency = = cos 𝜃

Apparent power kVA

Expressed in a percentage or decimal number (95% or 0.95) and also

with an added “Lag” or “Lead” term.

© 2013 Eaton. All rights reserved.

4

PF Correction

kW =1000

kvar=150

kVA =1010

1000 kW kvar=750

load@

load @.99

.8 kVA =1250

lagging

PF PF

600 kvar

Add 600 kvar

capacitor

• Present load at 1000 kW and 80% lagging PF

• Adding capacitors improves PF by providing leading kvar.

• Capacitors cancel the effects of the lagging kvar required by

inductive loads. PF improved to 99%.

• Use capacitors to correct PF to desired value based on utility

penalties

© 2013 Eaton. All rights reserved.

5

Typical PF by Industry and by Operation

Industry Power Factor Operation Power Factor

Auto parts 75-80 Air compressor:

Brewery 76-80 External motors 75-80

Cement 80-85 Hermetic motors 50-80

Chemical 65-75 Metal working:

Coal mine 65-80 Arc welding 35-60

Clothing 35-60 Arc welding with 40-60

Electroplating 65-70 standard capacitors

Foundry 75-80 Resistance welding 40-60

Forge 70-80 Machining 40-65

Hospital 75-80 Melting:

Machine manufacturing 60-65 Arc furnace 75-90

Metalworking 65-70 Inductance furnace 100

Office building 80-90 60Hz

Oil-field pumping 40-60 Stamping:

Paint manufacturing 55-65 Standard speed 60-70

Plastic 75-80 High speed 45-60

Stamping 60-70 Spraying 60-65

Steelworks 65-80 Weaving:

Textile 65-75 Individual drive 60

Tool, die, jig 60-65 Multiple drive 70

Brind 70-75

© 2013 Eaton. All rights reserved.

6

HV and LV Recommendations

Low Voltage capacitors

• Applicable for secondary (LV) or primary (HV) metering

• located closest to inductive load for optimum loss reduction and

voltage boost

• Can be switched with the load

• Solutions for harmonic issues can be more complex

Medium Voltage capacitors

• Applicable for primary metering on HV side of the transformer

• Less expensive installed cost per kvar

• Simplifies solutions for harmonic issues

© 2013 Eaton. All rights reserved.

8

Medium Voltage Solution Options

• Pole Mounted Rack

• Group fuse protection

• Fixed or switched, single or multi step

• Lowest cost solution

• Open Rack Design

• Individual fuse protection

• Unbalance protection scheme required

• Fixed or switched, single or multi step

• Fenced area required

• Moderate cost solution

• Metal Enclosed

• Current limiting fuses or fusesless designs

• Fixed or switched, single or multi step

• Reduced space requirements, indoor or outdoor

• Fully assembled and tested

• Most costly solution

© 2013 Eaton. All rights reserved.

9

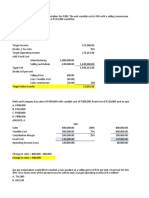

Savings Analysis

Multiplier 0.39523

kVAR charge $2.60

kVAR added 2000

Month Max kW Max kvar Base kvar1 Excess kvar2 Penalty3 New kvar

Mar-12 4020 1961 1589 372 $ 968 -39

Apr-12 3948 3296 1560 1736 $ 4,513 1296

May-12 4011 2391 1585 806 $ 2,095 391

Jun-12 4276 1869 1690 179 $ 465 -131

Jul-12 4426 3536 1749 1787 $ 4,645 1536

Aug-12 4383 3645 1732 1913 $ 4,973 1645

Sep-12 3632 3281 1435 1846 $ 4,798 1281

Oct-12 3937 3344 1556 1788 $ 4,649 1344

Nov-12 3883 2859 1535 1324 $ 3,443 859

Dec-12 3891 2394 1538 856 $ 2,226 394

Jan-13 3724 2891 1472 1419 $ 3,690 891

Feb-13 3616 1446 1429 17 $ 44 -554

Total $ 36,509

1

Base kvar = Max kW x Multiplier

2

Excess kvar = Max kvar - Base kvar

3

Penalty = Excess kvar x kvar Charge

• Power factor penalty = $2.60/kvar for all excess kvar

• Excess kvar = Max kvar - (Max kW for the Billing Period x .39523)

• Annual savings = $36,000

• Possible solution - 2000 kvar metal enclosed bank. Could range from

$30-90K depending on steps. Payback 1-3 years.

© 2013 Eaton. All rights reserved.

10

Harmonics

• Harmonic producing loads can lead to

Fundamental

• Capacitors fuse operations and failed capacitors

• Transformer heating Distorted Waveform 3rd Harmonic

• Motor heating 0

• VFD malfunction

5th Harmonic

• Increased neutral currents

• Common harmonic producing loads

• Power electronic equipment (drives, rectifiers, inverters, computers, etc.)

• Rotating machines (generators, motors)

• Iron saturating devices (transformers)

• Arcing devices (welders, arc furnaces, florescent lights, etc.)

• Harmonic Study should always be performed in conjunction with

power factor correction capacitors when there are significant sources

of harmonics in the system.

© 2013 Eaton. All rights reserved.

11

Engineering Service’s Harmonic Analysis

• Do field measurements

• This is a recommended but optional step to

benchmark system

• Develop system model

• Transformers, lines, loads, harmonic sources,

switches

• Power Flow analysis to determine

• Reactive power needs

• Location of capacitors

• Capacitor bank ratings (steps)

• Harmonic analysis:

• Impact of capacitors on harmonic performance

• Analyze alternatives to comply with harmonic

distortion requirements

© 2013 Eaton. All rights reserved.

12

Total Solutions Process

Pre Installation Installation Support Maintenance

• Utility bill analysis • Acceptance testing • Capacitor testing

• PF correction • Installation • Switch testing

• Harmonic studies • Verify protection • Control testing

• Filter design • Commissioning • Thermography

• Training • Service contracts

© 2013 Eaton. All rights reserved.

13

© 2013 Eaton. All rights reserved.

14

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Master StationDocumento138 páginasMaster StationWilmer Quishpe AndradeAinda não há avaliações

- Intermediate Accounting Testbank 2Documento419 páginasIntermediate Accounting Testbank 2SOPHIA97% (30)

- Telangana Budget 2014-2015 Full TextDocumento28 páginasTelangana Budget 2014-2015 Full TextRavi Krishna MettaAinda não há avaliações

- The Power of Flexibility: - B&P Pusher CentrifugesDocumento9 páginasThe Power of Flexibility: - B&P Pusher CentrifugesberkayAinda não há avaliações

- Storage Reservior and Balancing ReservoirDocumento19 páginasStorage Reservior and Balancing ReservoirNeel Kurrey0% (1)

- CLC Customer Info Update Form v3Documento1 páginaCLC Customer Info Update Form v3John Philip Repol LoberianoAinda não há avaliações

- JWCh06 PDFDocumento23 páginasJWCh06 PDF007featherAinda não há avaliações

- Lesson 3 - Materials That Undergo DecayDocumento14 páginasLesson 3 - Materials That Undergo DecayFUMIKO SOPHIA67% (6)

- Hindustan Coca ColaDocumento63 páginasHindustan Coca ColaAksMastAinda não há avaliações

- MMPX 403 Parametr ListDocumento30 páginasMMPX 403 Parametr ListOğuz Kağan ÖkdemAinda não há avaliações

- CVP Solution (Quiz)Documento9 páginasCVP Solution (Quiz)Angela Miles DizonAinda não há avaliações

- Examination: Subject CT5 - Contingencies Core TechnicalDocumento7 páginasExamination: Subject CT5 - Contingencies Core TechnicalMadonnaAinda não há avaliações

- Air Cycle Refrigeration:-Bell - Coleman CycleDocumento21 páginasAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- Troubleshooting Edge Quality: Mild SteelDocumento14 páginasTroubleshooting Edge Quality: Mild SteelAnonymous U6yVe8YYCAinda não há avaliações

- Request For AffidavitDocumento2 páginasRequest For AffidavitGhee MoralesAinda não há avaliações

- Sound Wave Interference and DiffractionDocumento79 páginasSound Wave Interference and DiffractionMuhammad QawiemAinda não há avaliações

- VSP-12Way - Is Rev.03Documento55 páginasVSP-12Way - Is Rev.03Marcelo AlmeidaAinda não há avaliações

- Anomaly Sell Out Remap December 2019 S SUMATRA & JAMBIDocumento143 páginasAnomaly Sell Out Remap December 2019 S SUMATRA & JAMBITeteh Nha' DwieAinda não há avaliações

- Managing operations service problemsDocumento2 páginasManaging operations service problemsJoel Christian Mascariña0% (1)

- Lirik and Chord LaguDocumento5 páginasLirik and Chord LaguRyan D'Stranger UchihaAinda não há avaliações

- Duty Entitlement Pass BookDocumento3 páginasDuty Entitlement Pass BookSunail HussainAinda não há avaliações

- James Ashmore - Curriculum VitaeDocumento2 páginasJames Ashmore - Curriculum VitaeJames AshmoreAinda não há avaliações

- Proprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie AutovehiculDocumento3 páginasProprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie Autovehicultranspol2023Ainda não há avaliações

- PB Engine Kappa EngDocumento20 páginasPB Engine Kappa EngOscar AraqueAinda não há avaliações

- BIU and EU functions in 8086 microprocessorDocumento12 páginasBIU and EU functions in 8086 microprocessorDaksh ShahAinda não há avaliações

- DAP FullTextIntroductionByStuartLichtman PDFDocumento21 páginasDAP FullTextIntroductionByStuartLichtman PDFAlejandro CordobaAinda não há avaliações

- A K A G .: RUN Umar Shok UptaDocumento2 páginasA K A G .: RUN Umar Shok UptaArun GuptaAinda não há avaliações

- PHASE 2 - Chapter 6 Object ModellingDocumento28 páginasPHASE 2 - Chapter 6 Object Modellingscm39Ainda não há avaliações

- Fall Protection ANSIDocumento5 páginasFall Protection ANSIsejudavisAinda não há avaliações

- ITIL - Release and Deployment Roles and Resps PDFDocumento3 páginasITIL - Release and Deployment Roles and Resps PDFAju N G100% (1)