Escolar Documentos

Profissional Documentos

Cultura Documentos

Chemical Vapor Deposition of Boron Nitride in The B-N-H-He-O System

Enviado por

thacalTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chemical Vapor Deposition of Boron Nitride in The B-N-H-He-O System

Enviado por

thacalDireitos autorais:

Formatos disponíveis

Inorganic Materials, Vol. 38, No. 7, 2002, pp. 677–682. Translated from Neorganicheskie Materialy, Vol. 38, No.

7, 2002, pp. 820–825.

Original Russian Text Copyright © 2002 by Golubenko, Kosinova, Titov, Kuznetsov.

Chemical Vapor Deposition of Boron Nitride

in the B–N–H–He–O System

A. N. Golubenko*, M. L. Kosinova**, V. A. Titov**, and F. A. Kuznetsov**

* Novosibirsk State University, ul. Pirogova 2, Novosibirsk, 630090 Russia

** Institute of Inorganic Chemistry, Siberian Division, Russian Academy of Sciences,

pr. Akademika Lavrent’eva 3, Novosibirsk, 630090 Russia

e-mail: marina@che.nsk.su

Received June 21, 2001

Abstract—Thermodynamic analysis of boron nitride (cubic, hexagonal, and wurtzite forms) chemical vapor

deposition in the B–N–H–He–O system was carried out for temperatures from 300 to 2100 K, a total pressure

of 1.33 Pa, residual pressures from 1.33 × 10–5 to 0.133 Pa, and a wide range of He : B3N3H6 ratios. The con-

ditions for the deposition of c-BN, h-BN, or mixtures of BN and B2O3 (solid or liquid) were established. Oxy-

gen impurities are shown to have a significant effect on the temperature stability limits of the condensed phases

involved.

INTRODUCTION shown that c-BN can be deposited at temperatures

below 1804 K. Above this temperature, CVD yields

The cubic and hexagonal forms of boron nitride find h-BN. Wurtzite BN was shown to be unstable over the

various applications in modern technology. One entire range of CVD conditions studied.

method widely employed to produce BN coatings is

chemical vapor deposition (CVD). Typical precursors At the same time, Sal’man et al. [20] and Kosinova

in BN CVD are mixtures of ammonia and volatile et al. [21] were able to produce h-BN films at low dep-

boron compounds, such as B2H6 [1], BF3 [2], BCl3 [3], osition temperatures in the B–N–H–He system. The

and B10H14 [4]. In recent years, a great deal of attention discrepancy between thermodynamic predictions and

experimental results was tentatively attributed to the

has been paid to precursors whose molecules contain influence of impurities, e.g., oxygen or water vapor,

both boron and nitrogen atoms, e.g., borazine (B3N3H6) which might be present in the starting reagents or intro-

[5, 6], its derivatives [7, 8], and alkylaminoboranes [9]. duced into the vapor phase in the course of deposition

A number of earlier works focused on thermody- [22]. Thermodynamic analysis of the B–N–H–Cl–He–O

namic analysis of BN CVD in the systems B–N–Cl–H system [22] indicates that minor amounts of solid or liq-

[2], B–N–F–H, B–N–H–F–Si–C–O [2, 10], B–N–O– uid (above 723 K) B2O3 may be codeposited with BN if

C–Cl–H [11], and B–N–Si–H–Cl [12] with the aim of the vapor phase contains more than 10–3 mol % O2 .

optimizing CVD conditions—deposition temperature, In this work, we use thermodynamic analysis of

total pressure, and vapor-phase composition. Note that boron nitride CVD in the B–N–H–He system

those studies were only concerned with graphite-like (B3N3H6 + He) in the presence of trace levels of oxygen

hexagonal boron nitride, h-BN, considered to be the

only thermodynamically stable condensed phase under to assess the effect of oxygen impurity on the stability

regions of the condensed phases involved.

standard conditions (298.15 K, 1.013 × 105 Pa). Other

forms of boron nitride—cubic, c-BN, and wurtzite-like,

w-BN—were thought to be stable only at high temper- THERMODYNAMIC CALCULATIONS

atures and pressures. Recent experimental data on the

thermodynamic properties of the cubic and wurtzite Our purpose was to find the compositions of the

phases [13–16] suggest, however, that c-BN is a stable vapor and condensed phases at equilibrium. In calcula-

phase at low temperatures and atmospheric pressure. In tions, we minimized the Gibbs energy of the system

earlier studies, we used the thermodynamic data for the using the procedure described elsewhere [17]. We

cubic, hexagonal, and wurtzite forms to analyze BN examined different B3N3H6 + He vapor mixtures with

CVD in the systems B–N–H–Cl–He [17] and B–N–H– oxygen impurities at temperatures in the range 300–

He [18, 19] for temperatures from 800 to 2300 K, total 2100 K. The conditions considered were typical of the

pressures from 1.33 to 1.013 × 105 Pa, and a wide range BN CVD process: total pressure in the system ptotal =

of vapor-phase compositions. In this way, we identified 1.33 Pa, residual pressure in the reactor pres = 0.133 Pa

CVD conditions for individual BN polymorphs. It was (0.79 mol % nitrogen and 0.21 mol % oxygen). The

0020-1685/02/3807-0677$27.00 © 2002 MAIK “Nauka /Interperiodica”

678 GOLUBENKO et al.

compositions of the starting vapor mixtures were sure, and, to a lesser extent, on R (at small R). Figure 2

expressed as the He : B3N3H6 molar ratio R. We took shows the partial pressures of vapor species as func-

into account 61 vapor species and 11 condensed tions of temperature for R = 0 and 1. Only those vapor

phases: h-BN, c-BN, w-BN, B(cr), B2O3(cr), B2O3(l), species were included whose partial pressure exceeded

HBO2(cr), HBO2(l), H3BO3(cr), H3BO3(l), and H2O(l). 10–7 Pa.

We supposed that the compositions of the condensed Under the conditions examined, the dominant vapor

phases were constant and that the vapor phase obeyed species are H2 , N2 , and He (Fig. 2b). Their partial pres-

the ideal-gas law. sures vary little with temperature. Throughout the tem-

As the input thermodynamic information, we used perature range studied, one of the major oxygen-con-

taining vapor species is H2O, both in the c-BN + B2O3

∆f H°(298 K), S°(298 K), and C °p (T) data for individual

and c-BN (T > 1250 K) fields. The concentrations of

substances. The set of self-consistent thermodynamic other oxygen-containing vapor species (HBO2 , HBO,

data and the software used were taken from the Elec- B2O3 , B2O2 , and BO) increase sharply with tempera-

tronic Materials Properties Database [23], which was

configured using, for the most part, data from [24]. ture, attaining the highest levels in the temperature

range of single-phase BN deposition. The vapor phase

also contains trace levels of NH3 (below 700 K) and BO

RESULTS AND DISCUSSION (above 1200 K).

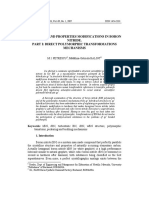

The results of thermodynamic analysis are dis- Our results demonstrate that the films deposited

played in Fig. 1 as a section of the B–N–H–He–O from the vapor phase containing oxygen impurities

(B3N3H6 + He + oxygen impurity) phase diagram in (from 0.38 at. % at R = 0 to 3.5 at. % at R = 100) consist

which composition–temperature stability fields are out- of BN and B2O3 at temperatures ranging up to 1250 K.

lined for ptotal = 1.33 Pa and pres = 0.133 Pa. As apparent For example, at R = 0, pres = 0.133 Pa, and an oxygen

from these data, the set of condensed phases in equilib- content of 0.38 at. %, the bulk composition of the

rium with the vapor phase depends strongly on deposi- deposit varies insignificantly with temperature (Table 1).

tion conditions, especially on the deposition tempera- Increasing the He : B3N3H6 ratio in the vapor phase

ture Td . Note that there is a very narrow stability field of increases the B2O3 content of the BN + B2O3 deposit

h-BN above 1718 K. Single-phase c-BN can be depos- (Table 2).

ited between 1250 and 1718 K. At lower temperatures, It follows from our results that the deposition condi-

BN is codeposited with liquid (724–1250 K) or solid tions and the purity of the starting reagents are critical

(below 724 K) B2O3 . The temperature stability limits of for the preparation of single-phase c-BN. Even small

the condensed phases are seen to depend little on R. amounts of oxygen in the starting vapor mixture lead to

As would be expected, the equilibrium composition codeposition of c-BN and B2O3 . It seems likely that the

of the vapor phase depends on temperature, total pres- presence of liquid or solid hexagonal B2O3 in the

deposit, on the one hand, impedes c-BN nucleation and,

on the other, favors the formation of h-BN.

Td , K

Assuming that the residual gas in the CVD system is

2000 the major source of oxygen impurity, we analyzed the

B(cr) reported data on BN low-pressure CVD in different

h-BN + B

vapor systems with the aim of assessing the effect of residual

c-BN + B h-BN pressure on the composition of the deposit. Unfortu-

1500

nately, the residual pressure and the purity of the

c-BN reagents used are rarely specified even in recent publi-

cations (Table 3). As is evident from Table 3, there is no

way to predict unambiguously which polymorph, c-BN

or h-BN, will be deposited at a particular residual pres-

1000 c-BN + B2O3(l) B2O3(l) sure in the CVD reactor. At the same time, it can be

seen that deposition at pres ≥ 0.133 Pa and temperatures

of 500–923 K onto Si, Fe, SiO2 , or sapphire substrates

yields, for the most part, h-BN or h-BN + c-BN films.

500 c-BN + B2O3(cr) B2O3(cr) At low residual pressures (pres < 1.33 × 10–4 Pa), the

CVD process yields either c-BN or c-BN + h-BN films.

0 20 40 60 80 R Taking into account this information, we examined

BN CVD from borazine at temperatures in the range

Fig. 1. Stability fields of condensed phases in CVD from 300–2100 K, ptotal = 1.33 Pa, and pres from 1.33 × 10–5

B3N3H6 + He mixtures at ptotal = 1.33 Pa and pres = to 0.133 Pa. The results are displayed in Fig. 3. It can

0.133 Pa. be seen that the residual pressure has a significant effect

INORGANIC MATERIALS Vol. 38 No. 7 2002

Você também pode gostar

- Schedule of Rates 2012 PDFDocumento235 páginasSchedule of Rates 2012 PDFBaburao Kanapala78% (27)

- Process Simulation of Ammonia PlantDocumento9 páginasProcess Simulation of Ammonia Planthamidrezaee008Ainda não há avaliações

- Heat - Mass Balance at ULCOS PDFDocumento3 páginasHeat - Mass Balance at ULCOS PDFROWHEITAinda não há avaliações

- Mahan J.E.,-Physical Vapor Deposition of Thin FilmsDocumento323 páginasMahan J.E.,-Physical Vapor Deposition of Thin Filmsthacal100% (1)

- Fundamentals of Metal Forming - Wagoner ChenotDocumento401 páginasFundamentals of Metal Forming - Wagoner Chenotthacal67% (3)

- MOS of Thermoplastic PaintDocumento2 páginasMOS of Thermoplastic PaintL V Laxmipathi Rao100% (1)

- Separation Techniques WorksheetDocumento2 páginasSeparation Techniques Worksheetmarleigh75% (4)

- Hoigné, Bader, 1981 2Documento10 páginasHoigné, Bader, 1981 2Markus MeierAinda não há avaliações

- Rate Constants of Reactions of Ozone With Organic and Inorganic Compounds in WaterDocumento10 páginasRate Constants of Reactions of Ozone With Organic and Inorganic Compounds in WaterIngrid Rincón ValdiviesoAinda não há avaliações

- Mathematical Model of RH Blow Argon Mode Affectin - 2012 - Journal of Iron and SDocumento6 páginasMathematical Model of RH Blow Argon Mode Affectin - 2012 - Journal of Iron and SFra RebsAinda não há avaliações

- Thelmechanisms: of Reductive Carboxylation ReactionsDocumento8 páginasThelmechanisms: of Reductive Carboxylation ReactionsRaymond LaBoyAinda não há avaliações

- Vol 49 - 1 0002 PDFDocumento94 páginasVol 49 - 1 0002 PDFUdara Sampath PraAinda não há avaliações

- Kinetics of MethanationDocumento12 páginasKinetics of MethanationGabriela Campos DávilaAinda não há avaliações

- Mook Et Al - Earth and Planetary Science Letters-1974Documento8 páginasMook Et Al - Earth and Planetary Science Letters-1974SalvaAinda não há avaliações

- Nsec 2022Documento13 páginasNsec 2022Ayushmaan DhanaiAinda não há avaliações

- Kinetic Model of Biomass GasificationDocumento7 páginasKinetic Model of Biomass GasificationjuaanxpoonceAinda não há avaliações

- Oxidation of C1-C10 Hydrocarbons in Stoichiometric and Lean Mixtures With Air and Oxygen Under The Action of Nanosecond DischargeDocumento6 páginasOxidation of C1-C10 Hydrocarbons in Stoichiometric and Lean Mixtures With Air and Oxygen Under The Action of Nanosecond DischargeNasser ArishiAinda não há avaliações

- Chemistry SQPDocumento4 páginasChemistry SQPstressAinda não há avaliações

- 114 AnnesiniDocumento6 páginas114 AnnesiniRizky KusumastutiAinda não há avaliações

- Vol 47 - 2 0008 PDFDocumento37 páginasVol 47 - 2 0008 PDFSahil DaradeAinda não há avaliações

- Ceat 270140409Documento5 páginasCeat 270140409mehtab ul hassanAinda não há avaliações

- 1 s2.0 S0040603120301040 MainDocumento9 páginas1 s2.0 S0040603120301040 MainArunAinda não há avaliações

- Gasification of Selected Woody PlantsDocumento8 páginasGasification of Selected Woody PlantsCitra Adelina SitorusAinda não há avaliações

- Prediction of NOx Emissions in Recovery Boilers PDFDocumento14 páginasPrediction of NOx Emissions in Recovery Boilers PDFNilesh KhadeAinda não há avaliações

- Molecular orbital calculations reveal hydrogen storage potential of carbon and boron nitride clustersDocumento4 páginasMolecular orbital calculations reveal hydrogen storage potential of carbon and boron nitride clustersAdityaAinda não há avaliações

- Processes For Methanol ProductionDocumento4 páginasProcesses For Methanol ProductionShoaib AliAinda não há avaliações

- Hydrate Phase Equilibria of The Guest Mixtures Containing CO2, N2 and Tetrahydrofuran - SP KangDocumento9 páginasHydrate Phase Equilibria of The Guest Mixtures Containing CO2, N2 and Tetrahydrofuran - SP KangAarya PatelAinda não há avaliações

- Chemosphere: Patricio I. Cano, Fernando Almenglo, Martín Ramírez, Domingo CanteroDocumento10 páginasChemosphere: Patricio I. Cano, Fernando Almenglo, Martín Ramírez, Domingo CanteroKentner Chavez CorreaAinda não há avaliações

- 1961 - Dynamics of Nox Gas AbsorptionDocumento9 páginas1961 - Dynamics of Nox Gas AbsorptionfalconeyerAinda não há avaliações

- Experimental Thermal and Fluid Science: Minghui Ge, Shixue Wang, Jun Zhao, Yulong Zhao, Liansheng LiuDocumento9 páginasExperimental Thermal and Fluid Science: Minghui Ge, Shixue Wang, Jun Zhao, Yulong Zhao, Liansheng Liuait hssainAinda não há avaliações

- 86.7.1 Boron Trihalides 195Documento21 páginas86.7.1 Boron Trihalides 195laythAinda não há avaliações

- Simulation of Natural Gas Production in Hydrate ReservoirsDocumento5 páginasSimulation of Natural Gas Production in Hydrate ReservoirsGAURAV KUMARAinda não há avaliações

- 11R PDFDocumento7 páginas11R PDFMary Grace VelitarioAinda não há avaliações

- The Ammonia-Carbon Dioxide-Water Equilibrium in Boiler Feedwater ConditioningDocumento8 páginasThe Ammonia-Carbon Dioxide-Water Equilibrium in Boiler Feedwater ConditioningFelipe GuilaynAinda não há avaliações

- Adsorption and Decomposition of Formaldehyde On The B N Nanostructure: A Density Functional Theory StudyDocumento5 páginasAdsorption and Decomposition of Formaldehyde On The B N Nanostructure: A Density Functional Theory StudyEsra KeskinAinda não há avaliações

- Simple Chemical Method For The Determination of Carbon Dioxide in AirDocumento8 páginasSimple Chemical Method For The Determination of Carbon Dioxide in AirEva HasanahAinda não há avaliações

- Simple Chemical Method For The Determination of Carbon Dioxide in AirDocumento2 páginasSimple Chemical Method For The Determination of Carbon Dioxide in AirSikander AliAinda não há avaliações

- Absorption of NOx in Packed ColumnDocumento6 páginasAbsorption of NOx in Packed ColumnPauloValdiviesoAinda não há avaliações

- Mieza 2011Documento10 páginasMieza 2011SantiagoAinda não há avaliações

- Kinetic of Iron Ore Reduction Using H2-CODocumento14 páginasKinetic of Iron Ore Reduction Using H2-COZaldi GeaAinda não há avaliações

- SMK Bandar Bintulu Chemistry 962 Semester 1 2016: Answer All Questions in This SectionDocumento9 páginasSMK Bandar Bintulu Chemistry 962 Semester 1 2016: Answer All Questions in This Sectiontang ka ongAinda não há avaliações

- 1967 - EQUILIBRIA BETWEEN BORATE and Poliol PDFDocumento9 páginas1967 - EQUILIBRIA BETWEEN BORATE and Poliol PDFLaura PerdomoAinda não há avaliações

- 2002-ENEA-Preliminary Studies On PbO Reduction in Liquid Pb-Bi Eutectic by Flowing HydrogenDocumento4 páginas2002-ENEA-Preliminary Studies On PbO Reduction in Liquid Pb-Bi Eutectic by Flowing Hydrogencqc2318273994Ainda não há avaliações

- Gasification of CoalDocumento28 páginasGasification of CoalAris Raymond GirsangAinda não há avaliações

- Gasification of Coal: A Guide to the Chemical Reactions and MechanismsDocumento67 páginasGasification of Coal: A Guide to the Chemical Reactions and MechanismsAris Raymond GirsangAinda não há avaliações

- An Extended Huckel Theory. III. Compounds of Boron and NitrogenDocumento8 páginasAn Extended Huckel Theory. III. Compounds of Boron and NitrogenPradipta GhoshAinda não há avaliações

- Direct Conversion of H-BN Into C-BN and Formation of Epitaxial c-BN/diamond HeterostructuresDocumento9 páginasDirect Conversion of H-BN Into C-BN and Formation of Epitaxial c-BN/diamond Heterostructuresanon_737096321Ainda não há avaliações

- Gas Hydrate Equilibria For CO 2 - N 2 and CO 2 - CH 4 Gas Mixtures-Experimental Studies and Thermodynamic ModellingDocumento20 páginasGas Hydrate Equilibria For CO 2 - N 2 and CO 2 - CH 4 Gas Mixtures-Experimental Studies and Thermodynamic ModellingAarya PatelAinda não há avaliações

- Abraham1990 SMD3 PDFDocumento4 páginasAbraham1990 SMD3 PDFSRS 2016Ainda não há avaliações

- Dependence of Earth's Thermal Radiation On Five Most Abundant Greenhouse GasesDocumento38 páginasDependence of Earth's Thermal Radiation On Five Most Abundant Greenhouse GasesMaycon Rogers Ribeiro AlvesAinda não há avaliações

- The Thermodynamic Stability of Refractory BoridesDocumento8 páginasThe Thermodynamic Stability of Refractory BoridesFatma SöğütAinda não há avaliações

- Chemistry Form 6 Sem 1 06Documento51 páginasChemistry Form 6 Sem 1 06Ng Swee Loong Steven100% (2)

- Chapter 1 BasicsDocumento35 páginasChapter 1 BasicsMohammed BahramAinda não há avaliações

- Formation of HNCO, HCN, and NH3 From The Pyrolysis of Bark and Nitrogen-Containing Model CompoundsDocumento13 páginasFormation of HNCO, HCN, and NH3 From The Pyrolysis of Bark and Nitrogen-Containing Model CompoundsAsmita AtreAinda não há avaliações

- Applied Surface Science: Susana Pinto, Lindora D'Ornelas, Paulino BetancourtDocumento4 páginasApplied Surface Science: Susana Pinto, Lindora D'Ornelas, Paulino BetancourtClaudia UngureanuAinda não há avaliações

- 1997 Chemical Erosion of Amorphous Hydrogenated Boron FilmsDocumento4 páginas1997 Chemical Erosion of Amorphous Hydrogenated Boron FilmsyouamareAinda não há avaliações

- Absorption of Carbonyl Sulphide in Aqueous PiperazineDocumento9 páginasAbsorption of Carbonyl Sulphide in Aqueous PiperazineBlack PearlAinda não há avaliações

- The Problem Set of The Four Rounds: ProblemsDocumento29 páginasThe Problem Set of The Four Rounds: ProblemsabcdefAinda não há avaliações

- MIN 106: ENGINEERING THERMODYNAMICS Tutorial Sheet 3 Properties of Pure SubstancesDocumento2 páginasMIN 106: ENGINEERING THERMODYNAMICS Tutorial Sheet 3 Properties of Pure Substancestanisha guptaAinda não há avaliações

- Example 3 Relating Downhole Rate With The Rate at Standard ConditionsDocumento8 páginasExample 3 Relating Downhole Rate With The Rate at Standard ConditionsMaisam AbbasAinda não há avaliações

- The Ionization Constant of Carbonic Acid in Water and The Solubility of Carbon Dioxide in Water and Aqueous Salt Solutions ToDocumento8 páginasThe Ionization Constant of Carbonic Acid in Water and The Solubility of Carbon Dioxide in Water and Aqueous Salt Solutions TozibaAinda não há avaliações

- Investigations On The Defect Chemistry and The Sintering of Barium Titanate Ceramics by Oxygen CoulometryDocumento7 páginasInvestigations On The Defect Chemistry and The Sintering of Barium Titanate Ceramics by Oxygen Coulometrykholid ristantoAinda não há avaliações

- Triazole Salts For Propellents Prep.202000187Documento10 páginasTriazole Salts For Propellents Prep.202000187منى غانم ضاحي الحديديAinda não há avaliações

- Recommended Reference Materials for Realization of Physicochemical Properties: Pressure–Volume–Temperature RelationshipsNo EverandRecommended Reference Materials for Realization of Physicochemical Properties: Pressure–Volume–Temperature RelationshipsE. F. G. HeringtonAinda não há avaliações

- Fricional Characteristics of Atomically Thin SheetsDocumento7 páginasFricional Characteristics of Atomically Thin SheetsthacalAinda não há avaliações

- Chapter3 PDFDocumento9 páginasChapter3 PDFthacalAinda não há avaliações

- Springer - U.S. Dixit, D.K. Sarma, J. Paulo Davim Environmentally Friendly Machining 2012 PDFDocumento97 páginasSpringer - U.S. Dixit, D.K. Sarma, J. Paulo Davim Environmentally Friendly Machining 2012 PDFthacalAinda não há avaliações

- KalistografikDocumento8 páginasKalistografikthacalAinda não há avaliações

- 06chapter5 PDFDocumento59 páginas06chapter5 PDFthacalAinda não há avaliações

- CBN Coating On Cutting Tools by Eckhart UlhmannDocumento0 páginaCBN Coating On Cutting Tools by Eckhart UlhmannpptmnltAinda não há avaliações

- Ultrasonic Machining ProcessDocumento44 páginasUltrasonic Machining ProcessSaravanan KumarAinda não há avaliações

- Chapter 2 SolutionDocumento11 páginasChapter 2 SolutionthacalAinda não há avaliações

- Chapter 1 SolutionDocumento9 páginasChapter 1 SolutionthacalAinda não há avaliações

- Impression Die Forging Process ParametersDocumento35 páginasImpression Die Forging Process ParametersthacalAinda não há avaliações

- Triaxial Stress State: (+ve Sense Shown)Documento18 páginasTriaxial Stress State: (+ve Sense Shown)Janjanam ChiranjeeviAinda não há avaliações

- Gypsum Partition & Dry Wall: AlpineDocumento10 páginasGypsum Partition & Dry Wall: Alpinekushagra agrawalAinda não há avaliações

- CHAPTER 2 Classification of NanomaterialsDocumento45 páginasCHAPTER 2 Classification of NanomaterialsFarah Hanani ZulkifliAinda não há avaliações

- Lcy 6733Documento1 páginaLcy 6733quangga10091986Ainda não há avaliações

- PLEXUS Product-CatalogDocumento44 páginasPLEXUS Product-CatalogsasidharkanthetiAinda não há avaliações

- Quality Improvement of Corn Husk As Raw Material For Textile ProductsDocumento5 páginasQuality Improvement of Corn Husk As Raw Material For Textile ProductsSophie BaromanAinda não há avaliações

- For Rolling Element Bearings - Aircraft Engine, Engine Gearbox, and Accessory Applications - Surface Temper EtchDocumento13 páginasFor Rolling Element Bearings - Aircraft Engine, Engine Gearbox, and Accessory Applications - Surface Temper Etchmohamed senoussiAinda não há avaliações

- Chs - Chem - ch3 - Mass - Ratios - and - Law - of - Multiple - Proportions Mod4Documento22 páginasChs - Chem - ch3 - Mass - Ratios - and - Law - of - Multiple - Proportions Mod4Marvel Felicity Rosell ArmestoAinda não há avaliações

- Separating Coloured Inks by Paper ChromatographyDocumento36 páginasSeparating Coloured Inks by Paper ChromatographyMANSI CHAUDHARYAinda não há avaliações

- Determination of Ammonia in The Atmosphere (Indophenol Method)Documento4 páginasDetermination of Ammonia in The Atmosphere (Indophenol Method)ECRD83% (6)

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDocumento1 páginaAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghAinda não há avaliações

- Basic Civil - Module 3 - RoofDocumento19 páginasBasic Civil - Module 3 - RoofSEKHAR JAinda não há avaliações

- 4014 03Documento7 páginas4014 03Carlos Romero Muñoz100% (2)

- Hardness Conversion Table - Brinell, Rockwell, Vickers, Tensile StrengthDocumento2 páginasHardness Conversion Table - Brinell, Rockwell, Vickers, Tensile StrengthSendi LuciverAinda não há avaliações

- US Small Business Administration Table of Small Business Size StandardsDocumento44 páginasUS Small Business Administration Table of Small Business Size StandardsMilton RechtAinda não há avaliações

- Alkalno Silikatna ReakcijaDocumento24 páginasAlkalno Silikatna Reakcijajozica majdaAinda não há avaliações

- HDPE Pipe InformationDocumento24 páginasHDPE Pipe InformationTylerAinda não há avaliações

- Esc Structural IfcDocumento9 páginasEsc Structural Ifcmohamed mohsenAinda não há avaliações

- Reversable Reactions QuestionsDocumento2 páginasReversable Reactions QuestionsMARK DEFREITASAinda não há avaliações

- Power Transmission Belt: V-Belt - Wedge - Banded - V-Ribbed - Timing - Automotive - SpecialtyDocumento8 páginasPower Transmission Belt: V-Belt - Wedge - Banded - V-Ribbed - Timing - Automotive - SpecialtyJUANPANIAGUAAinda não há avaliações

- Bejs Bridge Expansion Joint System Tech Data Sheet EmsealDocumento3 páginasBejs Bridge Expansion Joint System Tech Data Sheet EmsealrenandAinda não há avaliações

- Gate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimDocumento1 páginaGate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimGiovanni PetrizzoAinda não há avaliações

- Battery Thermal Management EbookDocumento13 páginasBattery Thermal Management Ebooktarun100% (2)

- Calculation For CO2 Released During CalcinationDocumento4 páginasCalculation For CO2 Released During CalcinationD N SHARMAAinda não há avaliações

- Hyjoist Install Guide 16pp Oct12 PDFDocumento16 páginasHyjoist Install Guide 16pp Oct12 PDFjames100% (1)

- Hydrothermal MethodDocumento16 páginasHydrothermal Methodavni vatsAinda não há avaliações

- Ratio - 3: Mixtures and Alligation QA QuestionsDocumento8 páginasRatio - 3: Mixtures and Alligation QA QuestionsAjeet Singh IMS JaipurAinda não há avaliações

- A New Scheme For Ammonia and Fertilizer GenerationDocumento14 páginasA New Scheme For Ammonia and Fertilizer GenerationChiaoAinda não há avaliações