Escolar Documentos

Profissional Documentos

Cultura Documentos

Mech 3 4 II Sem Main 14

Enviado por

Anjaiah Madarapu0 notas0% acharam este documento útil (0 voto)

15 visualizações8 páginasq

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoq

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

15 visualizações8 páginasMech 3 4 II Sem Main 14

Enviado por

Anjaiah Madarapuq

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 8

34 Mech

Bsem April may 2esy

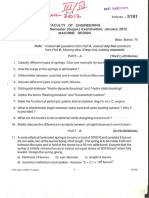

FACULTY OF ENGINEERING

B.E. 3/4 (MIP) Il-Semester (Main) Examination, April / May 2014

Code No, 6343

Subject: Machine Design

Time: 3 Hours Max. Marks: 75

Beet HSGaEn

é

4

12

13,

14

15

Note: Answer any all questions from Part-A & any Five question from Part-B.

PART ~ A (25 Marks)

Why Wah''s factor is to be considered in the design of helical compression or tension springs?

Explain in detail stresses induced in helical compression and tension springs?

Sketch the helical gear and show the forces acting in the gear and write equation for dynamic tooth load

Sketch the bevel gear and show the forces acting on the gear and write the tangential tooth load

Differentiate between hydrodynamic and hydrostatic lubrication

Sketch the pressure distribution in a journal bearing with thick film lubrication in axial and radial directions.

Sketch the crank shaft and show the forces acting in the crank shaft.

Describe the whipping stresses in the connecting rod,

Write the relationship between moment and curvature for trapezoidal section

Explain the design criteria for C clamps.

PART —B (50 Marks)

The spring of a small truck is to hold a maximum load of 4000 N each and to have a defection rate

50 Nimm. The engine develops a maximum torsional moment of 300 Nm. Where the rear axle ratio

is 3:1 and the 4-ply tyres are sized 170x760 mm. The coefficient of friction between the tyre and

ground is 0.6. The span length of the spring may be taken as 1.5 times the tyre diameter. Design the

leaf spring and make a neat sketch showing all necessary dimensions, Tabulate a satisfactory

‘combination of

(a) Thickness of leaf and width (b) Number of leaves

(c) Camber in free position (d) Radius of curvature

(e) Material used and heat treatment —_(f)_ Length of each leaf, and Deflection

A pair of spur gears consists of a 20 teath pinion meshing with 2 100 teeth gear. The pinion rotates

at 720 rpm. The normal pressure angle is 20°. The face width is 40 mm, and the module is 4 mm,

The pinion as well as gear is made of steel having ultimate strength of 600 MPa, and heat treated to

a surface hardness of 300 BHN. Taking factor of safety as 2.5, and assuming that the velocity factor

accounts for the dynamic load, calculate the power transmitting capacity of the gears.

Design a worm gear drive for an input power of 1 kW, with a transmission ratio of 25. The worm

speed is 1600 rpm. The worm is made of hardened steel, and gear of phosphor bronze, for which

the material combination factor is 0.7 Nimm*, The static strength of phosphor bronze is 56 MPa. The

worm is of double start type, and the center distance of the drive is 120mm. The tooth from is 20°

involute. Check the design for strength, wear and heat dissipation

shafi is mounted on two roller bearings, which are 350 mm apart. The shaft carries a bevel gear at

the middle. At a shaft speed of 900 rpm; the gear forces are radial load = 10 kN, and thrust load=3.5

kN. Determine the rated dynamic capacity of the bearing, for a desired life of 10,000 hours. The

service factors are 1.5, thrust factor is 3.7, and radial load factor is 0.67.

Design a cast iron piston for a four stoke I.C. engine, for the following specifications:

Cylinder bore=120 mm

Stroke length = 150 mm

Maximum gas pressure = 5 MPa

Brake mean effective pressure = 0.7 MPa

Fuel consumption = 0.25 kg / kWihr

Code No. 6344 /M

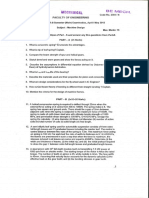

FACULTY OF ENGINEERING

B.E. 3/4 (Mech. ) II - Semester (Main) Examination, June 2014

Subject: Metal Cutting and Machine Tool Engineering

Time: 3 Hours Max. Marks

BO@Vausens

1

12

13

14

15

16

7

Note: Answer any all questions from Part-A & any Five question from Part-B

PART — A (25 Marks)

What are the various types of chips?

Explain the difference between positive rake and negative rake angles in cutting tools.

How do you measure chip-tool interface temperature by thermo-couple method?

What do you understand by tool life? How do you measure it?

Sketch a drill and indicate various parts on it

How do you specify a lathe?

Expiain Bumishing,

Explain gear grinding

Distinguish between Jig and Fixture

Expiain the working principle of ECM.

PART — B (50 Marks)

(@) Derive an equation developed by Lee and Shafer and indicate the assumptions

made.

(b) Name various cutting tools and high light the composition, their importance and

applications.

(a) Explain the Taylors tool life equation, what are the variables affecting tool life?

(b) Name the important properties that cutting fluid should posses and slate various

cutting fluids.

(a) Explain with the help of sketches various operations can be performed on a drilling

machine.

(b) Differentiate between shaper and planner.

(a) Name various indexing methods and explain clearly a method to generator 63

teeth spar gear on a given blank.

(b) Explain with schematic diagram the working of Jig boring machine. Mention its

advantages and limitations,

Explain the working of a gear hobbing process

How do you select a grinding wheel? Explain each factor.

Explain with neat sketch the working principle of USM. Discuss advantages and

disadvantages.

(b) Describe with neat sketches the working mechanism of box Jig and indexing Jig

Write short notes on

(a) Bonds in grinding wheel _(b)_ Economics of machining

(c) Influence of rake angle on Tool life and surface finish

SES

(

75

(2)

(3)

(3)

(3)

(2)

(2)

(2)

(2)

(3)

PROBUSTION

Code No. 6345 /M.

FACULTY OF ENGINEERING

B.E. 3/4 (M/AE) I - Semester (Main) Examination, June 2014

Subject: CAD/ CAM

Time: 3 Hours Max.Marks: 75

Note: Answer all questions from Part A. Answer any five questions from Part B

PART ~ A (25 Marks)

What are properties of splines?

Explain any four wire-frame entities

What are the advantages of parametric representation of entities?

What is finite element modelling?

Write transformation matrices for rotation and scaling.

Explain IGES and STEP formats.

What is the advantage of canned cycle?

What are the advantages of rapid prototyping?

Mention the applications of reverse engineering

0 What is meant by Turnkey CAD/CAM system?

AO@WRGRYENA=

PART ~ B (50 Marks)

14 (a) Whatare the characteristics of Bezier curves? Explain with sketches. 5

(b) Give applications of NURBS curves. 5

12. Differentiate wire-frame, surface and solid modelling 10

13 (a) Explain various CAD databases. 5

(b) What are G codes and M codes? 5

14 Write the part programming for the following component shown in Figure 1. 10

\&

TW

15 (a) Differentiate CNC and DNC.

(b) Explain programming methods for robotic systems.

16 (a) Write in brief about opitz type of GT.

(b) Whats variant and generative process planning?

17 Write short note on following 1

a) Mass property calculations b)_ Robot Anatomy

©) Computer Aided Inspection

Saaaa

Você também pode gostar

- ECE 4 4 II Sem Mak Up 14Documento5 páginasECE 4 4 II Sem Mak Up 14Anjaiah MadarapuAinda não há avaliações

- Mech 3 4 II Sem Supp 12Documento16 páginasMech 3 4 II Sem Supp 12Anjaiah MadarapuAinda não há avaliações

- Mech 3 4 II Sem Main 13Documento8 páginasMech 3 4 II Sem Main 13Anjaiah MadarapuAinda não há avaliações

- Mech 3 4 II Sem Supp 13Documento6 páginasMech 3 4 II Sem Supp 13Anjaiah MadarapuAinda não há avaliações