Escolar Documentos

Profissional Documentos

Cultura Documentos

Adsorbents and Carbon Technology For Air Sampling & Thermal Desorption

Enviado por

skTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Adsorbents and Carbon Technology For Air Sampling & Thermal Desorption

Enviado por

skDireitos autorais:

Formatos disponíveis

Adsorbents and Carbon Technology for

Air Sampling & Thermal Desorption

PEFTEC

November, 2015

Klaus Buckendahl,

Jamie Brown

sigma-aldrich.com/analytical

© 2013 Sigma-Aldrich Co. All rights reserved.

Agenda

• Introduction

• Type of Adsorbents

• Selection Tool

© 2013 Sigma-Aldrich Co. All rights reserved.

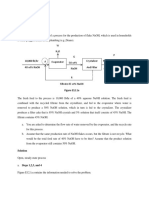

What is Thermal Desorption?

A Sample Preparation technique for Air & Gas Analysis and GC.

• The gas /air sample is collected onto an adsorbent packed glass or

stainless steel tube. The sample is concentrated on the adsorbents.

• The packed tube is heated (Thermal) and the compounds are released into

the carrier gas (Desorption) transfered onto GC column for Analysis

GC Detector

~300 °C ~300 °C

Carrier

Gas

Thermal Desorber

Transfer Line

Gas Chromatograph

© 2013 Sigma-Aldrich Co. All rights reserved.

Adsorbent Characteristics for Thermal Desorption

• Able to retain & release the compounds of interest

• Able to withstand high temperatures ~ 300°C

• Low background levels

• Low metal content

• Hydrophobic

Desirable

• Consistent mesh/particle size

• Consistent density

• Low shrinkage

• Low amount of fines

© 2013 Sigma-Aldrich Co. All rights reserved.

Terms Defined

Surface Area:

• provides a general idea of the adsorbent strength, but it doesn't provide the

whole picture.

• Other characteristics such as pore size, pore shape, and porosity can also

play a role in the adsorbent’s ability to retain and release different

compounds.

• General Rule:

– The higher the surface area value, the stronger the adsorbent.

– For surface area >800 m2/g, the size and shape of the pore becomes more

important.

© 2013 Sigma-Aldrich Co. All rights reserved.

Terms Defined (cont.)

Pore Size:

• Macropores: > 50 nm diameter

• Mesopores: 2 - 50 nm diameter

• Micropores: < 2 nm diameter

Molecules cannot access pores smaller than their size

© 2013 Sigma-Aldrich Co. All rights reserved.

Will the strongest adsorbent work for everything?

Desorption of 43-compounds from Carbosieve-SIII

Poor Desorption

Efficiency

Desorption of 43-compounds from a Carbotrap-300

Carbotrap-300 = Carbotrap-C, Carbotrap-B, and Carbosieve SIII

© 2013 Sigma-Aldrich Co. All rights reserved.

Thermal Desorption Tube

Adsorbent Beds

Single-Bed Tube

(e.g Tenax® TA)

Multi-Bed Tube

Carbotrap® 300

© 2013 Sigma-Aldrich Co. All rights reserved.

Adsorbent Types used in Thermal Desorption

© 2013 Sigma-Aldrich Co. All rights reserved.

Typical Adsorbents for Thermal Desorption

• Polymers

• Tenax® TA (2,6-diphenyl-p-phenylene oxide)

• Graphitized Carbon Blacks (GCB)

• Non porous

• Names: Carbopack™, Carbotrap™

• Various types available

Key Expertise

• Carbon Molecular Sieves (CMS) of Sigma-Aldrich / Supelco !!

• Porous

Materials used on the NASA missions

• Names: Carboxen™, Carbosieve™ Galileo (Jupiter) & Cassini-Huygens (Saturn-Titan)

• Various types available

• Glass beads

• Used to retain large molecular weight volatiles

© 2013 Sigma-Aldrich Co. All rights reserved.

Carbon Adsorbents

History in Supelco

>20 year Experience in preparing Carbon Adsorbents

Carbosieves

• First Family of Carbon molecular sieves (S-I, S-II, S-III)

• Carbosieve S-III one of strongest adsorbens

• Microporus only

• First CMS in air monitoring

Carboxenes (Introduced 1987)

• Carboxene-1000 highly efficient adsorbent

• Not as strong as S-III but far better kinetics

• Materials on NASA Missions

– (e.g. Galileo, Cassini/Huygens to Titan)

16

© 2013 Sigma-Aldrich Co. All rights reserved.

Porous Polymers

Tenax®-TA

• The most popular adsorbent used in thermal desorption

• Maximum temperature: 350 °C

• Recommended desorption temp: 300 °C

• Recommended conditioning temp: 320 °C

• Methanol not retained (Good for spiking tubes with liquid calibration

standards)

Typical Characteristics

• Granular - Tan in color

• Surface area: 35 m2/g

• Hydrophobic

© 2013 Sigma-Aldrich Co. All rights reserved.

Porous Polymers (cont.)

PoraPak™-N, Chromosorb®-106, HayeSep®-D

• Relatively low maximum temperatures: 225-290 °C

• Recommended desorption temp: 200 °C

• Recommended conditioning temp: 210 °C

• Typically has higher background levels than other adsorbents

Typical Characteristics

• Spherical - Light Yellow in color

• Surface area: 500 to 800 m2/g

• Hydrophobic

© 2013 Sigma-Aldrich Co. All rights reserved.

Other Adsorbents

Glass Beads 5 m2/g ("good pre-filter")

Rarely used for Thermal Desorption

• Petroleum Charcoal

• Coconut Charcoal

• Silica Gel

• Molecular Sieves (Zeolites)

© 2013 Sigma-Aldrich Co. All rights reserved.

Graphitized Carbon Blacks

Carbotrap® and Carbopack™

• Maximum temperature: 400 °C

• Recommended desorption temp: 330 °C

• Recommended conditioning temp: 350 °C

• Methanol not retained by most of them Carbotrap = 20/40 mesh

Carbopack = 40/60, 60/80, 80/100,

and 100/120 mesh

Typical Characteristics

• Granular - Flat Grey/Black in color

• Surface area: 5 to 240 m2/g

• Designed to retain and release mid

to large molecular weight compounds

• Hydrophobic

• High Purity - Low Background

© 2013 Sigma-Aldrich Co. All rights reserved.

Water vapor retained by Carbopack(s) & Tenax-TA

© 2013 Sigma-Aldrich Co. All rights reserved.

Adsorptive Strength of Graphitized Carbon Blacks

Relative Adsorption

Strength

F

Carbopack X 5 m2m

240 /g2/g Strongest

Weakest

C

Carbopack Z 10 mm2/g

220 2/g

Y

Carbopack B 24 mm2/g

100 2/g

Carbopack Y

B 100mm 2/g

2/g

24

Carbopack C

Z 220mm 2/g

2/g

10

X

Carbopack F 5240 /g2/g

m2m Weakest

Strongest

© 2013 Sigma-Aldrich Co. All rights reserved.

Graphitized Carbon Blacks

© 2013 Sigma-Aldrich Co. All rights reserved.

Fence line Monitoring EPA325B (Draft)

On September 29, 2015, the U.S. EPA issued a final rule - requiring all

U.S. Petroleum Refineries to conduct passive air sampling along the

perimeter of their properties. (40 CFR Parts 60 and 63) Coming Method

will be EPA325A/B.

EPA Method 325 uses passive (diffusive) samplers to collect air samples

at specific intervals along the fence line of the petroleum refineries

property1. The target compound is Benzene.

These passive air samplers are comprised of a inert-coated* stainless

steel thermal desorption tube packed with a graphitized carbon

adsorbent. Carbopack™X is listed as primary adsorbent.

The Carbopack X is also validated by the EPA and listed in the Method.

*The I.D. of the stainless steel tube are coated with a protective layer (Supelcoat™), which masks

any active sites that could be present on the inside of the tube.

27

© 2013 Sigma-Aldrich Co. All rights reserved.

EPA Method 325 (DRAFT) for Fenceline Monitoring (FLM)

Using Carbopack X in Specially Treated

Thermal Desorption Tube

• Inert TD Tube with diffusion cap

• Carbopack X bed

• retains wide range of analytes

– recovery of key analytes, 1,3-butadiene,

benzene, toluene, remain at 100% when

sampling large volumes

• is hydrophobic

– water will not be retained

Cat# 28686-U Stainless Steel w/SupelCoat Carbopack X (60/80)

shown with diffusive sampling cap

© 2013 Sigma-Aldrich Co. All rights reserved.

EPA325B (Draft)

Table 12.1:

Validated Sorbents and Uptake Rates (mL/min) for

Selected Clean Air Act Compounds

Carbopack X was validated for the broadest

compound portfolio due to its broad suitability,

not just Benzene (or BTEX).

a Reference 3, McClenny, J. Environ. Monit. 7:248-256. Based on 24-hour duration.

© 2013 Sigma-Aldrich Co. All rights reserved.

More Information

US EPA Method 325B Compliance

Flyer (RNW)

Passive Fenceline Sampling Solution for

Benzene and Other VOCs

sigma-aldrich.com/flm

© 2013 Sigma-Aldrich Co. All rights reserved.

Passive Sampling Options for Thermal Desorption

Using Carbopack X

diffusive surface adsorbing

(S) Surface (A)

Axial Sampler

Radial Sampler

(RAD141 for 1,3 Butadiene)

Radial Sampler (radiello®)

due to design

• Higher Sampling rates

• Higher sensitivity

© 2013 Sigma-Aldrich Co. All rights reserved.

Radiello (RAD141)

Sampler for 1,3-Butadiene

After sampling, the RAD141 adsorbent cartridge is placed in an empty

stainless steel thermal desorption tube for analysis.

© 2013 Sigma-Aldrich Co. All rights reserved.

Carbon Molecular Sieves

Carbosieve® and Carboxen®

• Maximum temperature: 400 °C

• Recommended desorption temp: 330 °C

• Recommended conditioning temp: 350 °C

• Methanol is retained

Typical Characteristics

• Spherical (Carbosieve-G is granular)

• Shiny/Dull Black in color

• High surface area 400 to 1500 m2/g

• Designed to retain and release

small molecular weight compounds

© 2013 Sigma-Aldrich Co. All rights reserved.

Adsorptive Strength of Carbon Molecular Sieves

Relative Adsorption

Strength

Carboxen-1016 (75 m2/g) Weakest

Carbosieve-G (1160 m2/g)

Carboxen-1012 (1500 m2/g)

Carboxen-564 (400 m2/g)

Carboxen-1000 (1200 m2/g)

Carboxen-1001 (500 m2/g)

Carboxen-569 (485 m2/g)

Carboxen-1003 (1000 m2/g)

Carboxen-1018 (675 m2/g)

Carbosieve-SIII (975 m2/g)

Carboxen-1021 (1160 m2/g) Strongest

© 2013 Sigma-Aldrich Co. All rights reserved.

Relative Hydrophobicity

Very Glass Beads

Hydrophobic

Graphitized Carbon Blacks

Porous Polymers

Retains

Less H2O Carboxen-1016

Carboxen-569,1001,1003

Carboxen-563 Carbon

Carboxen-564 Molecular Sieves

Carboxen-1000

Carboxen-1012

Carboxen-1018,1021, Carbosieve G & SIII

Retains

More H2O

Silica Gel, Mole Sieve 5x, 13x

© 2013 Sigma-Aldrich Co. All rights reserved.

Information on Carbon

Adsorbens

Wide Range of Properties

How to choose?

© 2013 Sigma-Aldrich Co. All rights reserved.

Adsorbent / Thermal Desorption Literature

"A Tool for Selecting an Adsorbent for Thermal Desorption"

www.sigmaaldrich.com/air-monitoring

© 2013 Sigma-Aldrich Co. All rights reserved.

Spiking the Tubes with the Gas Mix

Adsorbent Tube Injector System (ATIS)

used for spiking tubes

• 20 mL of gas mix

• 43 Compounds: 50 to 260 in molecular weight,

-30 to 215°C in boiling point.

• Concentration : 1ppm of each compound

• Injected into a stream of N2

• N2 carried the compounds to the tube

• Challenges volumes tested

sigma-aldrich.com/atis

50

© 2013 Sigma-Aldrich Co. All rights reserved.

ATIS - Principle

Thermometer

Adsorbent Tube

Glass Cuvett

Inert

Gas Inlet

Heater Block

© 2013 Sigma-Aldrich Co. All rights reserved.

How to use the performance charts

Information about the adsorbent

The 6 volumes studied

Green = Recommend for use

Recoveries are greater then 80%

Yellow = Use caution

(Watch the trend)

Recoveries are 21 to 79%

Too

strongly Red = Not recommend

adsorbed Recoveries are below 20%

59

© 2013 Sigma-Aldrich Co. All rights reserved.

The outcome of this research …

60

© 2013 Sigma-Aldrich Co. All rights reserved.

“Inlet” First adsorbent bed

Breaks through

Retained

Back-up adsorbent bed

Retained

Carryover was observed (Too Strongly Adsorbed)

Most likely irreversibly adsorbed

64

© 2013 Sigma-Aldrich Co. All rights reserved.

Test different Carbon Adsobents?

(MQR)

Custom Tubes possible! 69

Sampler Kits

© 2013 Sigma-Aldrich Co. All rights reserved.

Conclusion

• Thermal desorption covers a wide range of analytes

• Available Adsorbents offer enables broad sampling scope

• Single bed tubes are often have limits for a wider analyte portfolio

• Multibed tubes provide a wider range

• Synthetic carbon adorbents (Carbopack, Carboxen) are most suitable

due to stability, reproducibility & purity

• Sigma-Aldrich / Supelco has long year experience and wide selection

• Adsorbent selection can be done

• by literature research (official methods, journal articles, vendor information)

• using „A Tool for Selecting an Adsorbent for Thermal Desorption”

• Custom selected adsorbents for a multibed tube allow to achieve

optimal retention & release characteristics for desired application

© 2013 Sigma-Aldrich Co. All rights reserved.

Acknowledgments

Jamie Brown – Principal R&D Scientist

William Betz - Associate Fellow R&D Scientist

Olga Shimelis - Principal R&D Scientist

Kristen Schultz - Air Monitoring Product Manager

Bellefonte, Pennsylvania USA

Trademarks:

Carbotrap®, Carbopack™, Carboxen®, Carbosieve® – Sigma Aldrich, USA

Chromosorb® - Imerys Minerals California, Inc. USA

HayeSep® - Hayes Separations, USA

PoraPak™ - Waters Associates, USA

Tenax® - Buchem B.V., Netherlands

© 2013 Sigma-Aldrich Co. All rights reserved.

Thank you!

(RKA) (KQV)

See the complete portfolio of Air Monitoring products,

find product literature, and more at:

sigma-aldrich.com/air-monitoring

© 2013 Sigma-Aldrich Co. All rights reserved.

Você também pode gostar

- HimmelblauDocumento17 páginasHimmelblauadilla nitaaAinda não há avaliações

- Appendix B Koretsky SteamDocumento13 páginasAppendix B Koretsky SteamPortia ShilengeAinda não há avaliações

- Kelompok 4 TRK 2Documento5 páginasKelompok 4 TRK 2Katharina AjengAinda não há avaliações

- Tutorial PolymathDocumento10 páginasTutorial PolymathRizky RAinda não há avaliações

- Lant in PT. Petrokimia Gresik: Flow Diagram of The Process To Making Sulfuric AcidDocumento3 páginasLant in PT. Petrokimia Gresik: Flow Diagram of The Process To Making Sulfuric AcidAnisa SudarmajiAinda não há avaliações

- Hexamine 1Documento66 páginasHexamine 1Pradhita Ramdani HAinda não há avaliações

- Modul Pemat 2018 v2 Suksma, Agam, SatrioDocumento46 páginasModul Pemat 2018 v2 Suksma, Agam, SatrioSuksma Sotya PAinda não há avaliações

- Eat of Solution Data For Aqueous SolutionsDocumento2 páginasEat of Solution Data For Aqueous SolutionsJúlio Gabriel Queiroz dos SantosAinda não há avaliações

- Log (Dim: Vapor-Liquid Equilibria For The System Water + Tert.-Pentanol at 4 TemperaturesDocumento23 páginasLog (Dim: Vapor-Liquid Equilibria For The System Water + Tert.-Pentanol at 4 TemperaturesHarry Vara MarceloAinda não há avaliações

- Ideal Gas Non Ideal LiquidDocumento21 páginasIdeal Gas Non Ideal Liquidt_ntiAinda não há avaliações

- Heat Capacity of Liquids - Critical Review and Recommended ValuesDocumento404 páginasHeat Capacity of Liquids - Critical Review and Recommended ValuesDoris AngAinda não há avaliações

- S16 CPSDDocumento4 páginasS16 CPSDGohit BhatAinda não há avaliações

- Destilasi MultikomponenDocumento22 páginasDestilasi MultikomponenAgudaAinda não há avaliações

- Ocw Chapter 4Documento48 páginasOcw Chapter 4Agam HanasichulaAinda não há avaliações

- CHE656 2010 Homework2 SolutionsDocumento20 páginasCHE656 2010 Homework2 Solutionsdinesh1989novemberAinda não há avaliações

- Absorber Design (Methanol Vopur Into Water)Documento10 páginasAbsorber Design (Methanol Vopur Into Water)Kah AikAinda não há avaliações

- Yulianti Sampora, Yenni Apriliany Devy, Dewi Sondari, Dan Athanasia Amanda Septevani. 2020. Simultaneous Pretreatment ProceDocumento9 páginasYulianti Sampora, Yenni Apriliany Devy, Dewi Sondari, Dan Athanasia Amanda Septevani. 2020. Simultaneous Pretreatment ProceAdhan AkbarAinda não há avaliações

- Bairstow Method PDFDocumento22 páginasBairstow Method PDFjadadAinda não há avaliações

- Silica Plastic BlockDocumento5 páginasSilica Plastic Blockdharshini deivasigamaniAinda não há avaliações

- Butadiene SulfoneDocumento58 páginasButadiene SulfoneChunchu AnilAinda não há avaliações

- Presentasi TRK Topik 3 - Kelompok 8Documento19 páginasPresentasi TRK Topik 3 - Kelompok 8Martha IvanaAinda não há avaliações

- MEBERC PhyChemDocumento122 páginasMEBERC PhyChemJames Ivan Palanas RotorAinda não há avaliações

- Transport Phenomenon NotesDocumento7 páginasTransport Phenomenon Notesvishakha goelAinda não há avaliações

- Something Related To Catalysts.Documento2 páginasSomething Related To Catalysts.Deepro BhattacharyaAinda não há avaliações

- Elements of Chemical Reaction Engineering H. Scott Fogler Prentice Hall ParcialDocumento1 páginaElements of Chemical Reaction Engineering H. Scott Fogler Prentice Hall ParcialJWAN RA YA3QOBAinda não há avaliações

- MSDS Vanadium PentoxideDocumento5 páginasMSDS Vanadium PentoxideRezer AxelAinda não há avaliações

- TorefaksiDocumento4 páginasTorefaksirifkasyaputriAinda não há avaliações

- GasLiquid Reactions - First Order - Hatta NumberDocumento4 páginasGasLiquid Reactions - First Order - Hatta NumberShivahari GopalakrishnanAinda não há avaliações

- Makalah 4.19 EditedDocumento22 páginasMakalah 4.19 EditedRana Rezeki Najeges100% (1)

- Pressure DropDocumento42 páginasPressure DropSói Con100% (1)

- Tugas PP Lanjut Shinta Leonita 0906635772Documento5 páginasTugas PP Lanjut Shinta Leonita 0906635772HarryAinda não há avaliações

- Optimalisasi Kompresor SentrifugalDocumento27 páginasOptimalisasi Kompresor SentrifugalDea Amelia100% (1)

- Lampiran Lampiran PDFDocumento486 páginasLampiran Lampiran PDFDian KemalaAinda não há avaliações

- Chemical Reactors: FoglerDocumento34 páginasChemical Reactors: FoglerMike PoulinAinda não há avaliações

- Afifa Nur Alya - Matrikulasi (1-27) PDFDocumento46 páginasAfifa Nur Alya - Matrikulasi (1-27) PDFtsabbita husna100% (1)

- Kinetics and Mechanism of Urea FormaldehydeDocumento5 páginasKinetics and Mechanism of Urea FormaldehydeDessy A. SariAinda não há avaliações

- PR 01 - Kelompok 06Documento5 páginasPR 01 - Kelompok 06Jenny AzzahraAinda não há avaliações

- Ayırma İşlemleri SorularDocumento9 páginasAyırma İşlemleri SorularElif Yaren Öztürk0% (1)

- Drying Operation: Meika Syahbana RusliDocumento69 páginasDrying Operation: Meika Syahbana RusliFrida GinaAinda não há avaliações

- EtbeDocumento11 páginasEtbeSebastian Pala100% (1)

- CN2116 HW11 Solution (XJP - 2012) FinalDocumento9 páginasCN2116 HW11 Solution (XJP - 2012) FinalPrimus OngAinda não há avaliações

- Parameter Menghitung Temperatur Kalorik (Caloric Temperatur, TDocumento4 páginasParameter Menghitung Temperatur Kalorik (Caloric Temperatur, TRiski Maulana100% (1)

- CHE S402 Chapter9 Deactivation Part2Documento9 páginasCHE S402 Chapter9 Deactivation Part2Sonu SinghAinda não há avaliações

- Soal Heat BalanceDocumento5 páginasSoal Heat BalanceRfc KusyadiAinda não há avaliações

- Tugas Simulasi OptimasiDocumento3 páginasTugas Simulasi Optimasidimas wAinda não há avaliações

- Tugas Bab 2Documento6 páginasTugas Bab 2Wibowo Unggul0% (1)

- Frequency Domain Analysis of Dynamic Systems: Jos E C. GeromelDocumento43 páginasFrequency Domain Analysis of Dynamic Systems: Jos E C. Geromelblister_xbladeAinda não há avaliações

- Drying of Process MaterialDocumento30 páginasDrying of Process MaterialsehagendutAinda não há avaliações

- Makalah Termodinamika IIIDocumento33 páginasMakalah Termodinamika IIIdata laptop asusAinda não há avaliações

- Zhang Yie Zien. High-Rate Mesophilic Anaerobic Digestion of Palm Oil Mill Effluent (POME) PDFDocumento6 páginasZhang Yie Zien. High-Rate Mesophilic Anaerobic Digestion of Palm Oil Mill Effluent (POME) PDFZainul Fikri TampengAinda não há avaliações

- SCR - Calculation of Accentric Fator by Various MethodsDocumento9 páginasSCR - Calculation of Accentric Fator by Various MethodsscranderiAinda não há avaliações

- Operasi Teknik Kimia 2 Diberikan 1Documento28 páginasOperasi Teknik Kimia 2 Diberikan 1Dewala KutaAinda não há avaliações

- Tugas Operasi Teknik Kimia 1 TranslateDocumento12 páginasTugas Operasi Teknik Kimia 1 Translategira daraAinda não há avaliações

- Introduction To Mass TransferDocumento44 páginasIntroduction To Mass TransferGhazanferAliAinda não há avaliações

- Lampiran PerhitunganDocumento15 páginasLampiran PerhitunganAchmadJa'farShodiqShahabAinda não há avaliações

- P11 2aDocumento7 páginasP11 2aFachri MunadiAinda não há avaliações

- Data Bps Asam AkrilatDocumento8 páginasData Bps Asam AkrilatAdePuspitaSariAinda não há avaliações

- Methods For The Determination of HumidityDocumento2 páginasMethods For The Determination of HumidityMuhammad SalmanAinda não há avaliações

- Humidity ChartDocumento5 páginasHumidity ChartAde SonyaAinda não há avaliações

- X Global Lorentzian Geometry BeemDocumento331 páginasX Global Lorentzian Geometry BeemzahorskiAinda não há avaliações

- (Robert Mailloux) Electronically Scanned ArraysDocumento92 páginas(Robert Mailloux) Electronically Scanned ArraysManikanta LalkotaAinda não há avaliações

- SRP FolioDocumento10 páginasSRP FolioYookie22Ainda não há avaliações

- PHY 2 - Problem Solution of CH 1Documento10 páginasPHY 2 - Problem Solution of CH 1Mohamed El-GoharyAinda não há avaliações

- The Atom SongDocumento1 páginaThe Atom SongSheena BelmonteAinda não há avaliações

- RPT Add Math Form 5Documento9 páginasRPT Add Math Form 5Suziana MohamadAinda não há avaliações

- Mechanochemical SynthesisDocumento46 páginasMechanochemical SynthesisYuppie RajAinda não há avaliações

- Oiml G 14 Guide To Density MeasurementDocumento29 páginasOiml G 14 Guide To Density Measurementhakim70Ainda não há avaliações

- Validation of Process Gas SystemsDocumento6 páginasValidation of Process Gas SystemsJuan Manuel Valdez Von FürthAinda não há avaliações

- Encyclopedia of Physical Science and Technology - Plasma Physics 2001Documento83 páginasEncyclopedia of Physical Science and Technology - Plasma Physics 2001edward floresAinda não há avaliações

- Addition of ForcesDocumento1 páginaAddition of ForcesMargam Kiran KumarAinda não há avaliações

- Nist Air Density FormulaDocumento4 páginasNist Air Density FormulaMichael FanAinda não há avaliações

- MPS500 Manual Robot Assembly CNC105 Siemens A002Documento63 páginasMPS500 Manual Robot Assembly CNC105 Siemens A002yossefAinda não há avaliações

- An Overview Heat Transfer Phenomena PDFDocumento536 páginasAn Overview Heat Transfer Phenomena PDFAteequeAinda não há avaliações

- CH 10Documento38 páginasCH 10furkanAinda não há avaliações

- Thermo1 Chapter 04Documento110 páginasThermo1 Chapter 04Yasser Hijji80% (15)

- Modelling The Consequence of Hazardous Multi-Component Two-Phase Releases To The AtmosphereDocumento16 páginasModelling The Consequence of Hazardous Multi-Component Two-Phase Releases To The AtmosphereparsmessengerAinda não há avaliações

- Dynamic Seismic Analysis of Multi Storey Buildings in Seismic Zone VDocumento10 páginasDynamic Seismic Analysis of Multi Storey Buildings in Seismic Zone VIJRASETPublicationsAinda não há avaliações

- Revised Affinity LawsDocumento13 páginasRevised Affinity Lawsscribdhas2006Ainda não há avaliações

- Structural Behavior of Weirs With One Bottom Circular OpeningDocumento13 páginasStructural Behavior of Weirs With One Bottom Circular Openingayman_awadallahAinda não há avaliações

- Anchor Bolts For Use in Concrete - UK GuidanceDocumento5 páginasAnchor Bolts For Use in Concrete - UK GuidanceMike StevensAinda não há avaliações

- Gas Laws Part 4 Gay Lussacs LawDocumento4 páginasGas Laws Part 4 Gay Lussacs LawBuzz manzhjanaAinda não há avaliações

- Satellite Image ClassificationDocumento13 páginasSatellite Image ClassificationTejaswi KatragaddaAinda não há avaliações

- Hybrid Structural System (#97445) - 83516 PDFDocumento15 páginasHybrid Structural System (#97445) - 83516 PDFakshaya bAinda não há avaliações

- Technical Note: Rockfall Impact Analysis On Fo Cable ISS.3Documento7 páginasTechnical Note: Rockfall Impact Analysis On Fo Cable ISS.3SRARAinda não há avaliações

- FEM Solved ExampleDocumento4 páginasFEM Solved ExampleZakria ToorAinda não há avaliações

- Pi Acryleze Ent Coat StabDocumento2 páginasPi Acryleze Ent Coat StabFlorin PătrulescuAinda não há avaliações

- 12 Shippropulsion PDFDocumento86 páginas12 Shippropulsion PDFdeepak16051988Ainda não há avaliações