Escolar Documentos

Profissional Documentos

Cultura Documentos

BW24RH / BW27RH

Enviado por

Vlad SuteuDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

BW24RH / BW27RH

Enviado por

Vlad SuteuDireitos autorais:

Formatos disponíveis

Pneumatic Tired Rollers

BW24RH / BW27RH

KEY FEATURES PLUS

• Excellent jobsite visibility: the roller complies • Auto tire inflation for quick adjustment on the

with 1 m x 1 m visual range legislation run. No external air lines

• Efficient hydrostatic drive, sensitive and precise • Efficient compaction of thin layers on sensitive

handling mixes, avoids aggregate crushing, shoving or

crack formation

• Easy servicing with central drain points

(engine/hydraulic oil, coolant) • Dense, close knit surface finish

• Weight adjustment from 10 to 25 tons • High performance on thicker layers, e.g. higher

or 15 to 30 tons depending on model temperature at middle of layer and cool surface

• Easy water ballasting • Good wheel track overlap

BW24RH / BW27RH

Simple Operation FOPS/ROPS Std. (Optional Cabin Shown)

– Clear dashboard layout – Optimum visibility (1m x 1m)

– Automotive Style driving / – Swivel/sliding seat

braking controls

– Easy to operate

– Choice of 3 travel speeds

Corrosion Free Water Tank Powerful Drive

– Minimizes material pick-up – Fuel efficient Deutz water

on the tires cooled diesel engine

– Easy access

– Complies with EPA

requirements

Large Capacity Diesel Fuel Tank

– Easy to access

– Over 12 hrs operation

before refill

Access

– Easy and Hydrostatic Drive

safe – 2 Hydraulic motors

Steering Axle – Precise: smooth handling

– 2 steering pivots Emptying Ballast – 2 multi-disk brakes for

with axle and wheel – Large opening parking and dynamic

hub oscillation access on both service brake

– Uniform compaction Automatic Tire-Inflation System sides

across the working – Pressure adjustment on the run

width – Safety valves prevent total air

loss through leakage or puncture Drainage for Water

– Good conformity to

Ballast Cavity

uneven surfaces

– Easy to empty

■ The BW24RH / BW27RH have numerous key features to offer...

BW24RH and BW27RH Pneumatic ■ Applications:

Tired Rollers proven compaction

technology - with hydrostatic drive. BOMAG PTR’s are used for a

range of compaction applications.

Two (2) distinct models meeting two

(2) specific operating weight classes, These include:

25 and 30 Tons. A model to match • Base Compaction

virtually all application requirements. • Soil and Asphalt finishing

• Stabilized soils Shown with optional cabin.

• Chip and Seal used in

surface overlay

Two steering positions with a swivel/sliding seat makes the work

environment more comfortable and safe.

■ MODERN DRIVE DESIGN:

The BW 24 RH and BW 27 RH rubber converter and driveshaft, the rear axle is now

tired rollers provide traditional driven by two hydraulic motors. This design

compaction technology with modern is more efficient and reduces operating and

hydrostatic drives. In contrast to maintenance costs.

conventional designs using a torque

Pneumatic tired models All key machine functions at a glance: clear symbols – providing

safe, precise operation.

provide maximum versatility

■ KNEADING EFFECT: ■ AUTOMOTIVE CONTROLS:

Rubber tired rollers produce a unique BOMAG PTR’s (Pneumatic Tired Rollers)

compaction effect through the kneading are very easy to operate. The controls

action of the wheels. Highly uniform are automotive design with throttle pedal

compaction can be achieved by this and brake.

effect which also achieves a dense finish

at the surface. Also the hydrostatic drive provides precise

control in close area maneuvering. This is

The heavy weight of the rollers (up to particularly important for smooth

30 U.S. Tons) generates large vertical directional changes. The engine: Rear, transverse positioned for ease of access and

maintenance.

pressures to which are added horizontal

forces acting in all directions beneath the ■ SIMPLE TO OPERATE:

tires.

Roller operators will master the controls

in no time. As is typical with BOMAG, all

■ WEIGHT ADJUSTMENT: operating controls are within easy reach.

Models BW 24 RH and BW 27 RH can be

adjusted to provide the specified weight The dashboard is precisely arranged with

for the job. To achieve this a range of all functions clearly identified. The

ballasting choices are available. The operator’s platform has a swivel/sliding

rollers can be preballasted with seat with two steering positions.

individual weights (attached under the

This arrangement provides excellent

frame).

visibility to the operator for safe and

Standard pressurized waterspray produces even tire wetting –

This is necessary to give the maximum precise rolling along mat edges or for regardless of grades or water tank level.

weight of either 25 or 30 tons depending high speed transport between jobs. The

on the model. The PTR's large ballast best viewing position can always be

obtained. With these features and many more, it’s

space (approx. 124 ft3) is usually filled

with sand or steel scrap for flexible easy to see why this model maintains a

weight adjustment. With the water-tight high residual value while delivering lower

welded frame the rollers can also be lifetime operating costs.

ballasted with water.

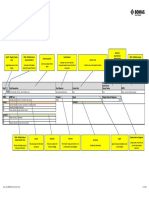

Technical Specifications

BW24RH / BW27RH

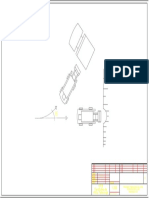

Shipping dimensions H2

in cubic feet (m3) without/with ROPS/FOPS H

BW24RH 879.9 (24.9) 1152.1 (32.6)

BW27RH 879.9 (24.9) 1152.1 (32.6)

H

A W

O1 O2

Standard Equipment L B

✓ Hour meter

DIMENSIONS IN INCHES (MM)

✓ Warning horn A B H H2 K L W

✓ Control panel for BW24RH 145.7 (3700) 83.4 (2118) 92.9 (2360) 121.7 (3090) 11.8 (300) 196.3 (4985) 80.4 (2042)

BW27RH 145.7 (3700) 83.4 (2118) 92.9 (2360) 121.7 (3090) 11.8 (300) 196.3 (4985) 80.4 (2042)

- Engine oil pressure

- Engine temperature TECHNICAL DATA BW24RH BW27RH

- Air filter vacuum

Weights

- Charge control Operating weight CECE with FOPS / ROPS . . . . . . . lbs (kg) 18570 (8423) 29262 (13273)

Operating weight CECE with ROPS-cabin. . . . . . . . . lbs (kg) 19070 (8650) 29762 (13500)

- Hydraulic oil filter Grossweight Max Ballast . . . . . . . . . . . . . . . . . . . . . . . lbs (kg) 52911 (24000) 59525 (27000)

Max. middle wheel load CECE. . . . . . . . . . . . . . . . . . lbs (kg) 6614 (3000) 7441 (3375)

- Coolant Level

✓ Pressure sprinkler system Dimensions

Track radius, inner . . . . . . . . . . . . . . . . . . . . . . . . . . . in (mm) 209.4 (5.320) 209.4 (5.320)

✓ Lockable anti vandal dashboard

Driving Characteristics

protection Speed (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . mph (km/h) 0 - 4.3 (0 - 7.0) 0 - 4.3 (0 - 7.0)

✓ Central tire inflating system Speed (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . mph (km/h) 0 - 6.8 (0 - 11.0) 0 - 6.8 (0 - 11.0)

Speed (3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . mph (km/h) 0 - 12.4 (0 - 20.0) 0 - 12.4 (0 - 20.0)

✓ Operator's platform with: Max. gradeability (depending on soil conditions) . . . . . . . . % 30 27

- two steering wheels Drive

✓ Seat belt Engine manufacturer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Deutz Deutz

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TCD 2012 L04 TCD 2012 L04

✓ Indicator and hazard lights Turbocharger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . standard standard

✓ Back-up alarm Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

water

4

water

4

✓ FOPS / ROPS Performance J1349 @ 2300. . . . . . . . . . . . . . . . . . . . hp (kW)

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

99 (74.9)

diesel

134 (100)

diesel

✓ Thermal aprons Electric equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V 12 12

✓ Additional weights (BW27RH) Drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driven axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

hydrost.

rear

hydrost.

rear

12 x 882 lbs = 10584 lbs

Tires

✓ Speedometer Tire size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.00-20 18PR 11.00-20 18PR

Wheel track overlap . . . . . . . . . . . . . . . . . . . . . . . . . . in (mm) 1.65 (42) 1.65 (42)

✓ Ballast can be applied with water

2M608TTTP

Brakes

Service brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pneum./hydr. pneum./hydr.

Optional Equipment Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SAHR SAHR

Cabin with heating Steering B479H-2240

Special painting Steering system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Point Oscillation 2 Point Oscillation

Steering method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydrost. hydrost.

Rotary beacon Steering angle +/- . . . . . . . . . . . . . . . . . . . . . . . degrees (grad) 30 (30) 30 (30)

Oscillation of tires, front . . . . . . . . . . . . . . . . . . degrees (grad) 4 (4) 4 (4)

DUNLOP 11.00-R20 - Tires (8) Level adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . in (mm) 3.94 (100) 3.94 (100)

Michelin 11.00-R20 - Tires (8)

Sprinkler System

Air condition Type of sprinkling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pressure pressure

Tool kit Capacities

Tachograph Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . gal (l) 66 (250) 66 (250)

Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . gal (l) 105.7 (400) 105.7 (400)

Radio Volume of ballast compartment . . . . . . . . . . . . . . . . . . ft3 (m3) 123.6 (3.5) 123.6 (3.5)

Technical modifications reserved. Machines may be shown with options.

BOMAG Americas, Inc.

2000 Kentville Rd. • Kewanee, IL 61443

www.bomag.com/usa Tel: 309 853-3571 • Fax: 309 852-0350

Você também pode gostar

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusNo EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusAinda não há avaliações

- BW24RH-BW27RH 4pgDocumento4 páginasBW24RH-BW27RH 4pgabdelrhmangbr86Ainda não há avaliações

- Roadtec Cold Planers BrochureDocumento24 páginasRoadtec Cold Planers BrochureKuntawee100% (1)

- BOMAG Finisher BF 800. The Heavy Weight ChampionDocumento20 páginasBOMAG Finisher BF 800. The Heavy Weight ChampionVany LunaAinda não há avaliações

- Vibratory Compactor With Hammtronic: C M Y CM MY Cy Cmy KDocumento2 páginasVibratory Compactor With Hammtronic: C M Y CM MY Cy Cmy KCopemaq CopemaqAinda não há avaliações

- BW 219 DH 5Documento2 páginasBW 219 DH 5Hữu Dũng Nguyễn0% (1)

- BW213DH-4 BVC PDFDocumento2 páginasBW213DH-4 BVC PDFVlad SuteuAinda não há avaliações

- 3705 Brochure Bf800 CDocumento4 páginas3705 Brochure Bf800 CAbdul Khaliq100% (1)

- Bomag bw219Documento2 páginasBomag bw219ZabdyRA YT0% (1)

- Kenr5125kenr5125-02 SisDocumento13 páginasKenr5125kenr5125-02 Sisygor valdezAinda não há avaliações

- SUPER 1603-3: Universal ClassDocumento22 páginasSUPER 1603-3: Universal ClassBurazBurazAinda não há avaliações

- Vision 5203-2 Us VogeleDocumento14 páginasVision 5203-2 Us VogeleRobinson Guaneme0% (1)

- Baldwin Fuel Dahl PDFDocumento27 páginasBaldwin Fuel Dahl PDFjack sliverAinda não há avaliações

- BF 800P Finally Schematic 03 - 08 - 12 - 1 - 8549Documento19 páginasBF 800P Finally Schematic 03 - 08 - 12 - 1 - 8549Hidayat100% (1)

- E-Teile Winter10 enDocumento12 páginasE-Teile Winter10 enVladimir Illich Pinzon BallenAinda não há avaliações

- Brochure Abg7820b Abg8820b t3 en 21 20000048 CDocumento12 páginasBrochure Abg7820b Abg8820b t3 en 21 20000048 CKurniawan100% (1)

- Brochure Variomatic Screed en 21 20000043 DDocumento12 páginasBrochure Variomatic Screed en 21 20000043 DHaris100% (1)

- DYNAPAC F 150 C 769130 - SpecificationDocumento254 páginasDYNAPAC F 150 C 769130 - Specificationhoan100% (2)

- Datasheet BW161AD-50 BW202AD-50 BW206AD-50 PRE92118010 SA03Documento4 páginasDatasheet BW161AD-50 BW202AD-50 BW206AD-50 PRE92118010 SA03Eng-AhmedRashadAinda não há avaliações

- 6 Finisor de Asfalt Pe Senile Volvo Abg9820 47542Documento6 páginas6 Finisor de Asfalt Pe Senile Volvo Abg9820 47542Farkas Pal100% (1)

- Workshop Manual W3030EN1.pdf Workshop Manual W3030EN1 PDFDocumento43 páginasWorkshop Manual W3030EN1.pdf Workshop Manual W3030EN1 PDFAlexander LopezAinda não há avaliações

- Compactadores CB22-CB24-CB32Documento8 páginasCompactadores CB22-CB24-CB32juan apazaAinda não há avaliações

- Wacker LTC4L PDFDocumento54 páginasWacker LTC4L PDFSoyluhan ApoAinda não há avaliações

- ZX210W-3 Technical Manual (Troubleshooting)Documento632 páginasZX210W-3 Technical Manual (Troubleshooting)derekpalang1003100% (1)

- PM2000 SchematicsDocumento18 páginasPM2000 SchematicsThilina JayasingheAinda não há avaliações

- Double Drum Bomag BW 161 Ad 50Documento4 páginasDouble Drum Bomag BW 161 Ad 50Mohamed SaiedAinda não há avaliações

- Bitelli BB781Documento2 páginasBitelli BB781Dem Hasi100% (1)

- Fuel Consumption by EngineDocumento2 páginasFuel Consumption by EngineRie ReiAinda não há avaliações

- 7 Finisoare de Asfalt Pe Senile Volvo p7820c p8820c 47543Documento16 páginas7 Finisoare de Asfalt Pe Senile Volvo p7820c p8820c 47543Farkas PalAinda não há avaliações

- BOMAG - Datasheet - BF600C-3 - PRE89245010 - SA02Documento4 páginasBOMAG - Datasheet - BF600C-3 - PRE89245010 - SA02Jason TanAinda não há avaliações

- Service Manual BF600CDocumento782 páginasService Manual BF600CshaheenikhtiyaralikhanAinda não há avaliações

- BF600-2 P, BF800 P - Error Code List: Actuator / Input Device / Sensor Device BSPNDocumento228 páginasBF600-2 P, BF800 P - Error Code List: Actuator / Input Device / Sensor Device BSPNJuan PerezAinda não há avaliações

- Hamm GRW-18Documento2 páginasHamm GRW-18casigreAinda não há avaliações

- 35 - DF135 ManualDocumento222 páginas35 - DF135 Manualussama abdo100% (2)

- Strength at Work: Iveco Genuine PartsDocumento4 páginasStrength at Work: Iveco Genuine PartsEndang WahyudiAinda não há avaliações

- Entire Group Ref. Note Part No. Part Name 137-0266-PRODUCT Valve Gp-Pilot CartridgeDocumento2 páginasEntire Group Ref. Note Part No. Part Name 137-0266-PRODUCT Valve Gp-Pilot CartridgeLenin Gullapalli100% (1)

- W Brochure SP1200 0116 ENDocumento24 páginasW Brochure SP1200 0116 ENمحمد شبانةAinda não há avaliações

- Product Guide NEWDocumento236 páginasProduct Guide NEWalex72Ainda não há avaliações

- TG Series EngDocumento9 páginasTG Series EngAyman AlhalfawyAinda não há avaliações

- Vogelle S1600-3iDocumento22 páginasVogelle S1600-3ijhonycvzAinda não há avaliações

- Terex Finlay J-1160Documento4 páginasTerex Finlay J-1160eaglego00Ainda não há avaliações

- 386 - 200 Ultrasonic Sensor Auger 13962097 PDFDocumento1 página386 - 200 Ultrasonic Sensor Auger 13962097 PDFDmitryAinda não há avaliações

- PL2000LS Maintenance 900981071enDocumento120 páginasPL2000LS Maintenance 900981071enHussein SayedAinda não há avaliações

- Service Information Systems: Know How For Your Success.: Road and Mineral TechnologiesDocumento32 páginasService Information Systems: Know How For Your Success.: Road and Mineral TechnologiesFelipe HernandezAinda não há avaliações

- BAL XXSB 2150516 01 00 00 enDocumento119 páginasBAL XXSB 2150516 01 00 00 enSAMİ ENİS ARIOĞLUAinda não há avaliações

- AP-1000b Vs Blow Knox Pf-3200 (Qexq9702)Documento27 páginasAP-1000b Vs Blow Knox Pf-3200 (Qexq9702)firman manaluAinda não há avaliações

- Wirtgen America v. RoadtecDocumento4 páginasWirtgen America v. RoadtecPriorSmartAinda não há avaliações

- Brochure BOMAG TELEMATIC EnglishDocumento8 páginasBrochure BOMAG TELEMATIC Englishseba6487Ainda não há avaliações

- Hydraulic Schematic BF 800 C Release 11 - 12Documento18 páginasHydraulic Schematic BF 800 C Release 11 - 12ikhtiyar ali khan100% (2)

- Bobcat 853 Operator ManualDocumento20 páginasBobcat 853 Operator ManualAbdul KhaliqAinda não há avaliações

- Dynapac PaverDocumento27 páginasDynapac Paverirfan ammar100% (3)

- Bomag PDFDocumento12 páginasBomag PDFm arif pAinda não há avaliações

- VF500 VF600 VR600Documento24 páginasVF500 VF600 VR600Mehdi FarrokhiAinda não há avaliações

- AP 240 enDocumento6 páginasAP 240 enJoão GuardadoAinda não há avaliações

- CS54 Cs533e en PDFDocumento16 páginasCS54 Cs533e en PDFXavier Millan100% (1)

- Binding Agent Spreader: High-Precision, Highly Efficient Binder DischargeDocumento12 páginasBinding Agent Spreader: High-Precision, Highly Efficient Binder DischargeRodrigo EncisoAinda não há avaliações

- BW27RHDocumento4 páginasBW27RHMando HamadAinda não há avaliações

- Bw9as 11asDocumento4 páginasBw9as 11asVlad SuteuAinda não há avaliações

- BW9AS 11AS 4pg PDFDocumento4 páginasBW9AS 11AS 4pg PDFshamen amarasekaraAinda não há avaliações

- Single Drum Vibratory Rollers: BW211D-50, BW211PD-50Documento4 páginasSingle Drum Vibratory Rollers: BW211D-50, BW211PD-50EndraAinda não há avaliações

- Dozers Dozers: DKA9501050J Page 1Documento20 páginasDozers Dozers: DKA9501050J Page 1Vlad SuteuAinda não há avaliações

- Crawler Tractor PR 724: Engine Output: 120 KW / 163 HP Operating Weight: 16,792 - 20,252 KG 37,020 - 44,648 LbsDocumento8 páginasCrawler Tractor PR 724: Engine Output: 120 KW / 163 HP Operating Weight: 16,792 - 20,252 KG 37,020 - 44,648 LbsVlad SuteuAinda não há avaliações

- D37expx 22 PDFDocumento20 páginasD37expx 22 PDFVlad SuteuAinda não há avaliações

- C H, C H: Pneumatic Tired CompactorDocumento2 páginasC H, C H: Pneumatic Tired CompactorVlad SuteuAinda não há avaliações

- C 530Documento4 páginasC 530Vlad SuteuAinda não há avaliações

- BW213DH-4 BVC PDFDocumento2 páginasBW213DH-4 BVC PDFVlad SuteuAinda não há avaliações

- Soil Compactor: BC772EB-2Documento4 páginasSoil Compactor: BC772EB-2Vlad SuteuAinda não há avaliações

- Bw9as 11asDocumento4 páginasBw9as 11asVlad SuteuAinda não há avaliações

- Wheel DozerDocumento20 páginasWheel DozerVlad SuteuAinda não há avaliações

- A 904 C Wheeled ExcavatorDocumento24 páginasA 904 C Wheeled ExcavatorVlad SuteuAinda não há avaliações

- 2.2 Calculul de PredimensionareDocumento3 páginas2.2 Calculul de PredimensionareVlad SuteuAinda não há avaliações

- Steel Wheel Roller: Bw9AswDocumento2 páginasSteel Wheel Roller: Bw9AswVlad SuteuAinda não há avaliações

- Single Drum Vibratory Rollers: BW124-40 SeriesDocumento4 páginasSingle Drum Vibratory Rollers: BW124-40 SeriesVlad SuteuAinda não há avaliações

- Desen DrumDocumento4 páginasDesen DrumVlad SuteuAinda não há avaliações

- A 900 C Wheeled ExcavatorDocumento32 páginasA 900 C Wheeled ExcavatorVlad SuteuAinda não há avaliações

- ChemestryDocumento1 páginaChemestryVlad SuteuAinda não há avaliações

- Procedee Tehnologice de Lucru Cu Incarcatorul L506 Procedeul in VDocumento1 páginaProcedee Tehnologice de Lucru Cu Incarcatorul L506 Procedeul in VVlad SuteuAinda não há avaliações

- Dymax Work Tools: Tie HandlersDocumento1 páginaDymax Work Tools: Tie HandlersVlad SuteuAinda não há avaliações

- Rototilt: Technical SpecificationsDocumento2 páginasRototilt: Technical SpecificationsVlad SuteuAinda não há avaliações

- Nota: Raze de Racordare R 5 MM Muchiile Se Tesesc La 1 X 45Documento1 páginaNota: Raze de Racordare R 5 MM Muchiile Se Tesesc La 1 X 45Vlad SuteuAinda não há avaliações

- SerialeDocumento1 páginaSerialeVlad SuteuAinda não há avaliações

- Wire Rope SlingsDocumento27 páginasWire Rope Slingsnasirfahim100% (1)

- 45e Pas 174Documento18 páginas45e Pas 174jads301179Ainda não há avaliações

- Microsoft Word - PIC16F877A Micro Controller Project TutorialDocumento19 páginasMicrosoft Word - PIC16F877A Micro Controller Project TutoriallocthanhAinda não há avaliações

- GSM900 Dual-Band Selective Repeater 200mw SGR-R310 User ManualDocumento15 páginasGSM900 Dual-Band Selective Repeater 200mw SGR-R310 User ManualIan MauhayAinda não há avaliações

- Manual Mbe 4000 TallerDocumento631 páginasManual Mbe 4000 TallerCristian Muñoz100% (19)

- DC Current Sensor Cyct04-Xnms20A: Product CharacteristicsDocumento3 páginasDC Current Sensor Cyct04-Xnms20A: Product CharacteristicsSenthilkumaran VenkatasamyAinda não há avaliações

- 11 - Installation Section - 1Documento40 páginas11 - Installation Section - 1mkctAinda não há avaliações

- Etisalat Design GuildlineDocumento4 páginasEtisalat Design GuildlinerjshnairAinda não há avaliações

- TMTransmissionTE27 32FF.01enDocumento96 páginasTMTransmissionTE27 32FF.01ensandeep palAinda não há avaliações

- Engine Cdi PDFDocumento78 páginasEngine Cdi PDFSergio Sanchez Rocha94% (16)

- Seminar Report 3C2Documento41 páginasSeminar Report 3C2Pritish KumarAinda não há avaliações

- Sailor Minimar Bicompact Rev03-12Documento38 páginasSailor Minimar Bicompact Rev03-12Leyla YılmazAinda não há avaliações

- B777 FuelDocumento0 páginaB777 Fuelandrinjo100% (3)

- AVK DONKIN Gas Handbook 2019 DownloadDocumento107 páginasAVK DONKIN Gas Handbook 2019 DownloadAhmed RedaAinda não há avaliações

- Audi A4 B8 VCDS Codings PDFDocumento10 páginasAudi A4 B8 VCDS Codings PDFcosteniuc100% (3)

- Wiring Instructions For Replacement of 2301A Load Sharing and Speed Controls With 2301D Load Sharing and Speed ControlsDocumento12 páginasWiring Instructions For Replacement of 2301A Load Sharing and Speed Controls With 2301D Load Sharing and Speed ControlsHammim HamzhahhAinda não há avaliações

- Diode Semiconductor Korea: Plastic Silicon RectifiersDocumento2 páginasDiode Semiconductor Korea: Plastic Silicon RectifiersJerry EscalonaAinda não há avaliações

- Data Man Pro Plus SpecificationDocumento2 páginasData Man Pro Plus SpecificationAfolabi OlaniyiAinda não há avaliações

- 42CV 2012Documento10 páginas42CV 2012Mhd Garry LuthfiAinda não há avaliações

- CZ PLUS - EngDocumento8 páginasCZ PLUS - EngHungAinda não há avaliações

- User Guide: Issue 1.1 January 2006Documento17 páginasUser Guide: Issue 1.1 January 2006Allegra AmiciAinda não há avaliações

- Special Purpose Vehicles: Padhiyar Raj H Automobile Department Saffrony Institute of TechnologyDocumento34 páginasSpecial Purpose Vehicles: Padhiyar Raj H Automobile Department Saffrony Institute of TechnologyBirjesh YaduvanshiAinda não há avaliações

- Ericsson W-Cdma Bbu/rru SystemDocumento2 páginasEricsson W-Cdma Bbu/rru SystemAbdeladhim Stich67% (3)

- BinMaster SensorsDocumento10 páginasBinMaster SensorsdarkpilotAinda não há avaliações

- VRV IV S Didvs2001 PDFDocumento14 páginasVRV IV S Didvs2001 PDFmas zak danielAinda não há avaliações

- Siemens Power Engineering Guide 7E 327Documento1 páginaSiemens Power Engineering Guide 7E 327mydearteacherAinda não há avaliações

- Optical Smoke Detector IQ8Quad With IsolatorDocumento1 páginaOptical Smoke Detector IQ8Quad With IsolatorA2AAinda não há avaliações

- XBee Arduino Compatible Coding PlatformDocumento1 páginaXBee Arduino Compatible Coding Platformgece25Ainda não há avaliações

- Service Code in Electrical System (Abnormality in F Pump Pressure Sensor) E224Documento4 páginasService Code in Electrical System (Abnormality in F Pump Pressure Sensor) E224ariy yuli styawan100% (1)

- DEMO LESSON PLAN - Electric Motor&GeneratorDocumento9 páginasDEMO LESSON PLAN - Electric Motor&Generatormary graceAinda não há avaliações

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyNo EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyNota: 5 de 5 estrelas5/5 (1)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsNo EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsNota: 5 de 5 estrelas5/5 (4)

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionNo EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionAinda não há avaliações

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerNo EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerNota: 4.5 de 5 estrelas4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNo EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNota: 4 de 5 estrelas4/5 (28)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsAinda não há avaliações

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingNo EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingNota: 4.5 de 5 estrelas4.5/5 (9)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionNo EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionNota: 5 de 5 estrelas5/5 (2)

- Common Rail Fuel Injection Technology in Diesel EnginesNo EverandCommon Rail Fuel Injection Technology in Diesel EnginesAinda não há avaliações

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsNo EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsNota: 4.5 de 5 estrelas4.5/5 (17)

- Classic Car Museum Guide: Motor Cars, Motorcycles & MachineryNo EverandClassic Car Museum Guide: Motor Cars, Motorcycles & MachineryAinda não há avaliações

- How to Drive: Real World Instruction and Advice from Hollywood's Top DriverNo EverandHow to Drive: Real World Instruction and Advice from Hollywood's Top DriverNota: 4 de 5 estrelas4/5 (17)

- High-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionNo EverandHigh-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionAinda não há avaliações

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.No EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Nota: 3 de 5 estrelas3/5 (4)

- Trucking Business Startup: Build a Long-Term, Highly Profitable Trucking Company From Scratch in Just 30 Days Using Up-to-Date Expert Business Success SecretsNo EverandTrucking Business Startup: Build a Long-Term, Highly Profitable Trucking Company From Scratch in Just 30 Days Using Up-to-Date Expert Business Success SecretsNota: 5 de 5 estrelas5/5 (2)

- Why We Drive: Toward a Philosophy of the Open RoadNo EverandWhy We Drive: Toward a Philosophy of the Open RoadNota: 4.5 de 5 estrelas4.5/5 (21)

- The Longest Line on the Map: The United States, the Pan-American Highway, and the Quest to Link the AmericasNo EverandThe Longest Line on the Map: The United States, the Pan-American Highway, and the Quest to Link the AmericasNota: 4 de 5 estrelas4/5 (4)