Escolar Documentos

Profissional Documentos

Cultura Documentos

Hazop

Enviado por

Syuhadah Noordin0 notas0% acharam este documento útil (0 voto)

28 visualizações1 páginaTítulo original

hazop.docx

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

28 visualizações1 páginaHazop

Enviado por

Syuhadah NoordinDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 1

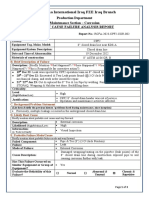

No.

What if analysis Consequences Recommendation

1 Valve in pipeline clogged Overpressure at stream Maintenance or

A consider replace the

valve

2 Pipeline A is leaking due to corrosion Composition in reactor Regular checked

changed. Coat the pipeline with

Leakage of pipeline suitable coating

causes hazardous material

chemicals to the

workspace

3 Air bubble present in pipeline Damage the pump Install air relieve valve

at the pipeline

4 Defective parts of the pump (Eg: motor Pump underspeed lead Regular maintenance

burned out) to underflow of

material A to reactor

5 Power cord of the pump damage Pump power failure Battery power backup

pump

6 Valve become fouled or corroded Damaging seals and Coating valve disc with

valve failure corrosion synthetic

material such as halar

7 Pressure changed in the pipeline Backflow in pipeline Install backflow

that will decrease preventer device

flowrate of material A

8 Piping support failed Breakage of pipeline Install rigid pipe

support

9 External factor (Eg: storm) Circuit is tripped Install lightning

causing pump conductor or power

generator

APPENDIXS

https://www.a2gov.org/departments/engineering/Documents/Sump%20Pump%20Common%2

0Causes%20of%20Failure.pdf

https://www.a2gov.org/departments/engineering/Documents/Sump%20Pump%20Common%2

0Causes%20of%20Failure.pdf

https://www.a2gov.org/departments/engineering/Documents/Sump%20Pump%20Common%2

0Causes%20of%20Failure.pdf

appendix D PHA and What-If Analysis Checklist

Você também pode gostar

- 47 Dosing Device Specification For Outer Circulating WaterDocumento8 páginas47 Dosing Device Specification For Outer Circulating WaterRiyal MorshadAinda não há avaliações

- Commonly Missed Overpressure Scenarios - SmithBurgess, Wahid WakilDocumento40 páginasCommonly Missed Overpressure Scenarios - SmithBurgess, Wahid WakilJacekAinda não há avaliações

- SECTION 15440 Plumbing Pumps General 1.1Documento6 páginasSECTION 15440 Plumbing Pumps General 1.1Munir RasheedAinda não há avaliações

- Pump HazopDocumento3 páginasPump HazopUzair AftabAinda não há avaliações

- Bushing Failures in Medium Voltage Switchgear - Coetzee Van HeerdenDocumento16 páginasBushing Failures in Medium Voltage Switchgear - Coetzee Van HeerdenJorge CáceresAinda não há avaliações

- COUPP - 60 Hydraulic Hose Failure AnalysisDocumento26 páginasCOUPP - 60 Hydraulic Hose Failure AnalysisRomulus Situ MorankAinda não há avaliações

- CSC IOM Manual BombaDocumento18 páginasCSC IOM Manual BombaLuis Sánchez RoblesAinda não há avaliações

- EN ManualDocumento32 páginasEN Manualantonio vukeAinda não há avaliações

- Differential Pressure Valve: Model 4143ADocumento7 páginasDifferential Pressure Valve: Model 4143Ashahrol effendy rodziAinda não há avaliações

- EM00136453 Kompact AMS ML Rev1.0Documento34 páginasEM00136453 Kompact AMS ML Rev1.0Emilio Jose EstevezAinda não há avaliações

- Avoiding Pressure Surge Damage in Pipeline Systems Presentation To IE AustDocumento30 páginasAvoiding Pressure Surge Damage in Pipeline Systems Presentation To IE AustMukeshAinda não há avaliações

- Hazop For CSTRDocumento3 páginasHazop For CSTRRomel Leo100% (1)

- Figure 1 Proposed Schematic Diagram of Lotion ProcessDocumento8 páginasFigure 1 Proposed Schematic Diagram of Lotion ProcessAltheaBAinda não há avaliações

- RCFA-2023-CPF2-COR-002-8'' CD Leak Near EDS-A (12-02-23)Documento3 páginasRCFA-2023-CPF2-COR-002-8'' CD Leak Near EDS-A (12-02-23)Vignesh PanchabakesanAinda não há avaliações

- Pipeline Defect Repair MethodsDocumento20 páginasPipeline Defect Repair MethodsAyon RoyAinda não há avaliações

- SECTION 15175 Swimming Pool Piping and Equipment General 1.1Documento14 páginasSECTION 15175 Swimming Pool Piping and Equipment General 1.1fatREVITAinda não há avaliações

- 46 Dosing Device Specification For Boiler Feed WaterDocumento10 páginas46 Dosing Device Specification For Boiler Feed WaterRiyal MorshadAinda não há avaliações

- Marine Engineering PracticeDocumento159 páginasMarine Engineering PracticeRemisius Corera100% (1)

- STATIM 1000 / 2000 / 2000S Service Manual Overview and Table of ContentsDocumento5 páginasSTATIM 1000 / 2000 / 2000S Service Manual Overview and Table of ContentsJJ Bioelectrored EsSalud TumbesAinda não há avaliações

- HPLC Troubleshooting - 6 - AprilDocumento27 páginasHPLC Troubleshooting - 6 - AprilYulis AdrianaAinda não há avaliações

- Safety and Hazard Analysis ProjectDocumento16 páginasSafety and Hazard Analysis ProjectGautham Krishna KbAinda não há avaliações

- High-Voltage Bushing Maintenance Techniques PDFDocumento20 páginasHigh-Voltage Bushing Maintenance Techniques PDFAdetunji TaiwoAinda não há avaliações

- SPD50100 Ins Serv ManDocumento12 páginasSPD50100 Ins Serv Manallen_worstAinda não há avaliações

- HAZOP WorksheetDocumento5 páginasHAZOP WorksheetchristyleneAinda não há avaliações

- Avoiding Pressure Surge Damage in Pipeline SystemsDocumento33 páginasAvoiding Pressure Surge Damage in Pipeline SystemsmdsaleemullaAinda não há avaliações

- Cavitron Jet Plus Part2Documento26 páginasCavitron Jet Plus Part2sotaquitoAinda não há avaliações

- Trouble Shooting Vacuum PumpsDocumento2 páginasTrouble Shooting Vacuum PumpsarunperthAinda não há avaliações

- Some Possible Causes and Probability of Leakages in LMFBR Steam Generators P.R. BoltDocumento3 páginasSome Possible Causes and Probability of Leakages in LMFBR Steam Generators P.R. Boltwaheed2286Ainda não há avaliações

- Final Maintenance PresentationDocumento19 páginasFinal Maintenance PresentationSamuel WozabAinda não há avaliações

- PoolDocumento2 páginasPoolskgreenduneAinda não há avaliações

- RCFA-2023-CPF1-COR-001 ( " Outlet Line From Reverse Demulsifier) (SK-11680) (25-2-23)Documento3 páginasRCFA-2023-CPF1-COR-001 ( " Outlet Line From Reverse Demulsifier) (SK-11680) (25-2-23)Vignesh PanchabakesanAinda não há avaliações

- Resource Center - DuPontDocumento1 páginaResource Center - DuPontAbdiel AlonsoAinda não há avaliações

- PD Pump Systems: Service ManualDocumento46 páginasPD Pump Systems: Service ManualJorge HuertaAinda não há avaliações

- ACS5000 Water-Cooled: Preventive Maintenance ScheduleDocumento3 páginasACS5000 Water-Cooled: Preventive Maintenance SchedulemlutfimaAinda não há avaliações

- Failure Mechanisms For Hoses PDFDocumento10 páginasFailure Mechanisms For Hoses PDFMahmoud Al HomranAinda não há avaliações

- Hydraulic System Troubleshooting GuideDocumento13 páginasHydraulic System Troubleshooting Guidesaiful100% (1)

- Failure of Circulating Water Pumps Discharge Header Cross Connect Valve - Optimum SolutionsDocumento3 páginasFailure of Circulating Water Pumps Discharge Header Cross Connect Valve - Optimum SolutionsFernando100% (1)

- Fulton FB-L ManualDocumento39 páginasFulton FB-L ManualHilman (Melissa)Ainda não há avaliações

- ML 042960393Documento10 páginasML 042960393TXEMAAinda não há avaliações

- Submersible Sewage Ejector Pump: Pump Installation and Service ManualDocumento8 páginasSubmersible Sewage Ejector Pump: Pump Installation and Service Manualallen_worstAinda não há avaliações

- Piping Hydrostatic Testing (Overview) - QA - QC ConstructionDocumento11 páginasPiping Hydrostatic Testing (Overview) - QA - QC ConstructionSonNguyenAinda não há avaliações

- Troubleshooting Centrifugal Pumps-2Documento3 páginasTroubleshooting Centrifugal Pumps-2vignesh guru100% (1)

- Zero Transformer FailuresDocumento9 páginasZero Transformer FailuresprotectionAinda não há avaliações

- D1 HNR62 ZNK SDocumento17 páginasD1 HNR62 ZNK Sabderrahim ouladaliAinda não há avaliações

- Peristaltic Metering PumpDocumento50 páginasPeristaltic Metering PumpGlen C. ChadwickAinda não há avaliações

- Plant Water Booster PumpDocumento4 páginasPlant Water Booster PumpBanupriya BalasubramanianAinda não há avaliações

- Service Manual Trucks vn770Documento16 páginasService Manual Trucks vn770Neojai jaiyuAinda não há avaliações

- 10 Common Wastewater Pump Issues-20141014Documento77 páginas10 Common Wastewater Pump Issues-20141014Manoj NairAinda não há avaliações

- Sox Open Loop Scrubber Common Failures: Clip # 03 - 2021Documento4 páginasSox Open Loop Scrubber Common Failures: Clip # 03 - 2021Sanket PatilAinda não há avaliações

- Building Better Boiler Feedwater Pumps With Composites 1697382780Documento6 páginasBuilding Better Boiler Feedwater Pumps With Composites 1697382780avciayAinda não há avaliações

- Operator'S Manual Aquablast Pro Automatic WashoutDocumento19 páginasOperator'S Manual Aquablast Pro Automatic WashoutAsadAinda não há avaliações

- Alarm Trouble ShootingDocumento3 páginasAlarm Trouble ShootingShannia CelosoAinda não há avaliações

- 394M - Parr - 4540 High Pressure Reactor Inst PDFDocumento32 páginas394M - Parr - 4540 High Pressure Reactor Inst PDFlorenzoAinda não há avaliações

- Fig.5.1-5 Rehabilitation Equipment Feed Water Pumps: Current StatusDocumento5 páginasFig.5.1-5 Rehabilitation Equipment Feed Water Pumps: Current StatusMohamed HamdallahAinda não há avaliações

- Pump Power Failure Response: Bryan KarneyDocumento27 páginasPump Power Failure Response: Bryan KarneyshahqazwsxAinda não há avaliações

- 2020 Express Water - Reverse Osmosis System Installation ManualDocumento32 páginas2020 Express Water - Reverse Osmosis System Installation ManualBobAinda não há avaliações

- Rcause of Boiler Tube FailuresDocumento16 páginasRcause of Boiler Tube FailuresKR PAAinda não há avaliações

- Beacon EnglishDocumento1 páginaBeacon EnglishKiranAinda não há avaliações

- Troubleshooting Symptoms of Trouble, Causes, and Corrective MeasuresDocumento5 páginasTroubleshooting Symptoms of Trouble, Causes, and Corrective MeasuresAbdiel AlonsoAinda não há avaliações

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- HazopDocumento34 páginasHazopSyuhadah NoordinAinda não há avaliações

- Cel 2106 SCL Worksheet Week 3Documento1 páginaCel 2106 SCL Worksheet Week 3Syuhadah NoordinAinda não há avaliações

- Acetaldehyde Production by Ethanol DehydrogenationDocumento9 páginasAcetaldehyde Production by Ethanol DehydrogenationHugo Gerdulli AlbertinAinda não há avaliações

- SCL 7Documento3 páginasSCL 7Syuhadah NoordinAinda não há avaliações

- Hydration of Acetylene To Acetaldehyde Using K (Run' (EDTA-II) C11211a0Documento7 páginasHydration of Acetylene To Acetaldehyde Using K (Run' (EDTA-II) C11211a0Syuhadah NoordinAinda não há avaliações

- Recommended Operating Procedures For Cwc-Related Analysis: Nur Syuhadah Binti NoordinDocumento6 páginasRecommended Operating Procedures For Cwc-Related Analysis: Nur Syuhadah Binti NoordinSyuhadah NoordinAinda não há avaliações

- Chapter 9aDocumento16 páginasChapter 9aSyuhadah NoordinAinda não há avaliações

- Hydration of Acetylene To Acetaldehyde Using K (Run' (EDTA-II) C11211a0Documento7 páginasHydration of Acetylene To Acetaldehyde Using K (Run' (EDTA-II) C11211a0Syuhadah NoordinAinda não há avaliações

- Result and CalculationDocumento4 páginasResult and CalculationSyuhadah NoordinAinda não há avaliações

- Result Exp 7Documento3 páginasResult Exp 7Syuhadah NoordinAinda não há avaliações

- Liquid Level: 9.1.1 Instrumentation Signals & Data Networks 9.1.2 Sensors Main Types of Measurement in Process ControlDocumento1 páginaLiquid Level: 9.1.1 Instrumentation Signals & Data Networks 9.1.2 Sensors Main Types of Measurement in Process ControlSyuhadah NoordinAinda não há avaliações

- Lab Manual ECH 3905Documento17 páginasLab Manual ECH 3905Syuhadah NoordinAinda não há avaliações

- IntroductionDocumento1 páginaIntroductionSyuhadah NoordinAinda não há avaliações

- Chapter8&9 Enzyme KineticsDocumento68 páginasChapter8&9 Enzyme KineticsSyuhadah NoordinAinda não há avaliações

- Probability Density Function Cumulative Distribution FunctionDocumento2 páginasProbability Density Function Cumulative Distribution FunctionSyuhadah NoordinAinda não há avaliações

- IntroductionDocumento1 páginaIntroductionSyuhadah NoordinAinda não há avaliações

- Evaporation: Physical Separation Processes ECH3118 Faizah MD YasinDocumento49 páginasEvaporation: Physical Separation Processes ECH3118 Faizah MD YasinSyuhadah Noordin100% (1)

- Introduction To Process ControlDocumento28 páginasIntroduction To Process ControlSyuhadah NoordinAinda não há avaliações

- Chapter 04 Orthographic WritingDocumento46 páginasChapter 04 Orthographic WritingSyuhadah NoordinAinda não há avaliações

- The Transfer FunctionDocumento16 páginasThe Transfer FunctionSyuhadah NoordinAinda não há avaliações

- Evaporation: Physical Separation Processes ECH3118 Faizah MD YasinDocumento49 páginasEvaporation: Physical Separation Processes ECH3118 Faizah MD YasinSyuhadah Noordin100% (1)

- Intro To Numerical Methods and Source of Errors: Dr. Mus'ab Abdul RazakDocumento19 páginasIntro To Numerical Methods and Source of Errors: Dr. Mus'ab Abdul RazakSyuhadah NoordinAinda não há avaliações

- Us6210562 PDFDocumento8 páginasUs6210562 PDFSyuhadah NoordinAinda não há avaliações

- 9 - Mechanical Behavior (POGIL) - Part2Documento82 páginas9 - Mechanical Behavior (POGIL) - Part2Syuhadah NoordinAinda não há avaliações

- Chapter 5 Elimination Reaction - 2016Documento19 páginasChapter 5 Elimination Reaction - 2016Syuhadah NoordinAinda não há avaliações

- B G Standard Mechanical EngeneeringDocumento19 páginasB G Standard Mechanical EngeneeringhamdiiiiiiiiiiiiiiiiAinda não há avaliações

- ICorr CED CT01 InspectionAndTestingOfCoatings Issue1-2Documento13 páginasICorr CED CT01 InspectionAndTestingOfCoatings Issue1-2AlineMeirelesAinda não há avaliações

- Types of Stainless SteelDocumento5 páginasTypes of Stainless SteelAnonymous 6ZWS6IG2J9Ainda não há avaliações

- Manual Sigma Centrifuge 2-6 EngDocumento71 páginasManual Sigma Centrifuge 2-6 EngDavid Huamán GastelúAinda não há avaliações

- Cat Machinery Equipment enDocumento16 páginasCat Machinery Equipment enYeremiaAinda não há avaliações

- Primeroyal Series: API 675 Metering PumpDocumento6 páginasPrimeroyal Series: API 675 Metering PumpDavid GarciaAinda não há avaliações

- Technical Reference Guide Fastenal K Factor and MoreDocumento62 páginasTechnical Reference Guide Fastenal K Factor and Moredlight0Ainda não há avaliações

- Nandpur: Gas Field, OgdclDocumento5 páginasNandpur: Gas Field, OgdclAsad Ul HaqAinda não há avaliações

- Questions For Paint InspectorDocumento20 páginasQuestions For Paint InspectorHosam Ahmed100% (3)

- Tech CaatDocumento36 páginasTech CaatValeria Serrano VidalAinda não há avaliações

- Pipeclad Product Brochure Sherwin Williams EnglishDocumento12 páginasPipeclad Product Brochure Sherwin Williams EnglishCésarAinda não há avaliações

- Effect of Alloying ElementsDocumento86 páginasEffect of Alloying ElementsNavdeep JainAinda não há avaliações

- Troubleshooting VTP Vertical Turbine PumpDocumento20 páginasTroubleshooting VTP Vertical Turbine PumpKrrish100% (1)

- Regarding The Syllabus of The Written Test For PHD Admission (In The Department of Metallurgical and Materials Engineering)Documento2 páginasRegarding The Syllabus of The Written Test For PHD Admission (In The Department of Metallurgical and Materials Engineering)chauhan100% (1)

- View - File Value EngineeringDocumento24 páginasView - File Value EngineeringmagdyamdbAinda não há avaliações

- XXI Paper 046Documento10 páginasXXI Paper 046kkannan732153Ainda não há avaliações

- Stainleess Steel SpecificationDocumento11 páginasStainleess Steel SpecificationcysautsAinda não há avaliações

- Norsok GuidelineDocumento34 páginasNorsok GuidelineDuongthithuydung100% (2)

- Corrosion Inhibition by Naturally Occurring SubstancesDocumento5 páginasCorrosion Inhibition by Naturally Occurring SubstancesJefree BallesterosAinda não há avaliações

- Chapter 5-Metal AlloysDocumento74 páginasChapter 5-Metal AlloysMohd AziziAinda não há avaliações

- Innovation by Experience: Lo Hacemos SencilloDocumento36 páginasInnovation by Experience: Lo Hacemos SencilloDejan DosljakAinda não há avaliações

- Manual HS3400VSDDocumento121 páginasManual HS3400VSDwatt_hr100% (1)

- SF 0011 0 Quality ZnAl WiresDocumento4 páginasSF 0011 0 Quality ZnAl WiresanandelectricalsAinda não há avaliações

- CHANG CHANG DONG HAI - DISCH LIST - InicialDocumento21 páginasCHANG CHANG DONG HAI - DISCH LIST - InicialjulianoAinda não há avaliações

- Internal Corrosion - A Case Study: Sample 1Documento1 páginaInternal Corrosion - A Case Study: Sample 1Arun DeepanAinda não há avaliações

- Supreme PVC & PPR BrochuresDocumento28 páginasSupreme PVC & PPR BrochuresWeeBooh Wit-aAinda não há avaliações

- Cathodic Protection TrainingDocumento118 páginasCathodic Protection TrainingLâm ThanhAinda não há avaliações

- Classification of Metallic Engineering MaterialsDocumento24 páginasClassification of Metallic Engineering MaterialsidontlikeebooksAinda não há avaliações

- Wind Turbine Foundation SystemsDocumento8 páginasWind Turbine Foundation SystemsPrakashAinda não há avaliações

- Chemical Cleaning ProcedureDocumento4 páginasChemical Cleaning ProcedureAnuj Gupta100% (3)