Escolar Documentos

Profissional Documentos

Cultura Documentos

Kaise Hain

Enviado por

forplancessDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Kaise Hain

Enviado por

forplancessDireitos autorais:

Formatos disponíveis

Hindi CONTENTS

Maintenance Manual for BG coaches of ICF design Painting

CHAPTER 12

PAINTING

1201 GENERAL 1202c After allowing adequate drying time for

primer, the entire coach should be

1201a After the coach body is fully repaired applied with the first coat of brushing

and the flooring work completed, it filler to IS 110-83 by spray/brush to a

should be swept and cleaned of all dust, DFT of 30 micron minimum.

shavings, etc., before the coach is placed 1202d (i) After hard drying of filler, apply the

in the Paint shop for painting and first coat of knifing stopper putty

polishing. to IS:5083-88 followed by spot

1201b The condition of the paint on the inside putty application and wet rubbing.

and outside surfaces should be examined (ii) After ensuring drying of water,

to decide whether the old paint should apply necessary putty to get a

be removed to the bare metal. Usually, uniform surface followed by wet

extensive corrosion repair work rubbing.

necessitates removal of old paint to bare (iii) After drying of water, apply

metal and complete repainting of the second coat of filler to IS:110-83

coach. to a DFT of 30 microns

minimum.

1201c If the condition of the paint so warrants

or at every 5th POH of a coach, the paint 1202e The dry surface should be wet rubbed

should be completely removed to the down with bone cuttle and silicon

bare metal and the coach repainted as carbide water proof paper grade 120

per paint schedule `A'. If the general and 220. It should then be allowed to

condition of the paint is good, follow dry.

paint schedule `C'. These paint 1202f After ensuring that there is no trace of

schedules cover the exterior painting of water on the surface, a coat of under-

coaches with synthetic enamel paint coating to IS 8662-93 should be

system. RDSO Sketch No :CSC - 1723 sprayed or applied by brush to a DFT of

gives the exterior colour scheme of the 25 microns minimum.

coaches (Sketch no. CSC - 1723 has 1202g The entire surface should again be

been made into two parts i.e. figure rubbed down smooth with silicon

12.1a & figure 12.1b and attached at carbide water proof paper grade 320

pages 2 and 3). and after drying, a coat of enamel

finishing to IS 8662-93 should be

1202 PAINT SCHEDULE `A' (Refer applied to a DFT of 20 microns

Annexure 12.1) minimum.

1202h After the first coat of finish enamel has

1202a The entire surface should be applied

dried completely, it should again be

with a suitable paint remover and the old

flattened with silicon carbide water

paint scraped off. Thereafter, the coach

proof paper grade 400 and apply a

surface shall be swabbed with petroleum

second coat of synthetic finish enamel to

hydrocarbon solvent to IS:1745 to

remove all traces of paint remover. IS 8662-93 to a DFT of 20 microns

minimum.

1202b After the surface dries up completely, it 1202i The door handles, if not chrome plated,

should be sand papered to make it should be painted with golden yellow to

slightly rough and a coat of red oxide IS 8662-93. The foot steps, roof, etc.,

zinc chromate primer to IS 2074 -92 to a should be painted as per prescribed

DFT of 25 microns minimum should colour scheme.

be applied by spray/brush immediately.

1202j Standard lettering, as sp ecified, should

Where facilities exist, the entire coach

be done with golden yellow to IS 8662-

body should be sand blasted and the

93. Similarly, all standard schedule

primer coat of red oxide zinc chromate

charts, signs, etc., should be

should be applied by spray/brush

stenciled/painted as prescribed.

immediately thereafter.

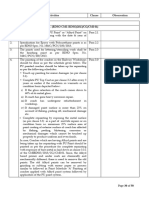

Chapter 12, Page 1 of 6

Hindi CONTENTS

Maintenance Manual for BG coaches of ICF design Painting

Maintenanc e Manual for BGICFc oaches

Cha pter 12, Page 2 of 6

GULF RED

Figure I : Vacuum Brake Trains

A. Side wall - Gulf Red shade No. 473

AIRCRAFT BLUE

5

7

SATIN BLUE

75

AIRCRAFT BLUE

Figure II : Air Brake Trains other than Rajdhani & Shatabdi Express

A. Side wall upto 75 mm below window and from 75 mm above window - Air Craft blue shade No. 108

B. Side wall window area 75 mm above and below windows - Satin blue shade No. 177

NOTE: 1. For special rakes, instructions as per Rly. Board's letter No. 76/M (C)/137 / 31 dated 5.6.1986 shall be followed.

2. Postal portion of partial postal vans shall be painted with postal red.

3. Existing procedures for roof and end wall painting, lettering and exterior markings continue unchanged.

4. All finishing paints should be to specification No. IS:8662-93 and coloures to specification No. IS:5-94

EXTERIOR COLOUR SCHEME FOR MAIN LINE COACHES

Painting

RDSO Sketch No. CSC-1723. Approved vide Railway Board's letter No. 97/M (C)/ 137 / 20 dated 23.6.98

FIGURE 12.1a

Chapter 12, Page 2 of 6

Hindi CONTENTS

Maintenance Manual for BG coaches of ICF design Painting

Maintenance Manua l for BG ICF coaches

Cha pter 12, Pa ge 3 of 6

SIGNALRED

60

OFFWHITE

SIGNAL RED BAND

7 88

60

O FFWHI TE

OFFWHITE

SIGNAL RED BAND

OFFWHITE

11 4

SIGNALRED

Figure III : Rajdhani Express

A. Side walls upto 234 mm below window and from 234 mm above window - Signal Red shade No. 537

B. Band of 60 mm above and below windows at a distance of 114 mm from window - Signal Red shade No. 537.

C. Side wall window area 234 mm above and below window - Off white ICI shade No. 28-1004

PALE CREAM

OXFORD BLUE BAND

PALE CREAM BAND

1 00

50

OXFORD BLUE

Figure IV : Shatabdi Express

A. Side walls upto lower window sill - Oxford Blue shade No. 105

B. Side wall above lower window sill - Pale cream shade No. 352

C. Band of 100 mm at a distance of 50 mm below lower window sill - Pale cream shade No. 352

EXTERIOR COLOUR SCHEME FOR MAIN LINE COACHES

Pa inting

RDSO Sketch No. CSC-1723. Approved vide Railway Board's letter No. 97/M (C)/ 137 / 20 dated 23.6.98

FIGURE 12.1b

Chapter 12, Page 3 of 6

Hindi CONTENTS

Maintenance Manual for BG coaches of ICF design Painting

1202k Finally, the window glasses, etc., should § Laminated panels should be polished

be cleaned well and all paint marks with silicon paste or similar suitable

removed. Any damage to the paint polish to restore luster and also to

should be touched up before the coach is provide a protective coating.

turned out after POH. § Coaches other than those fitted with

laminated plastic panels should be

1203 PAINT SCHEDULE `C' cleaned with soap solution or

suitable detergent and thereafter

§ The portions where paint has flaked cleaned thoroughly with wet cloth so

or is damaged, should be scraped off that all head stains, oily marks, etc.,

of all the loose and damaged paint. are completely removed. Then a

The coach should then be washed single coat or, if required, a double

thoroughly with soap and water and coat of synthetic enamel to IS:133 -

allowed to dry. Then a coat of red 93 should be applied by brush/spray.

oxide zinc chromate primer to IS

2074-92 should be applied by brush § In case where the old paint has

at the places where metal surface is become thick due to repeated

visible. painting or where the paint has

§ After the primer dries up completely, deteriorated or cracked, the wooden

it should be puttied and a coat of panel should be removed and

under -coating to IS 8662-93 should replaced or reused after completely

be applied at these portions. removing the old paint and

§ The complete coach shall thereafter repainting it.

be painted in the manner described

in paragraphs 1202g to 1202k above. 1205 PAINTING OF PARTS

1204 INTERIOR PAINTING § The laminated plastic seats or

moulded seats of synthetic materials

§ Newly built coaches with laminated require no painting. They should

plastic panels require painting only only be thoroughly cleaned with

on the steel mouldings. The soap solution or suitable detergent.

mouldings should be cleaned in

§ In case of seats made of wooden

every POH and repainted with one

battens, the battens which have been

coat of synthetic enamel to IS:133-

replaced should be sand papered

93 of appropriate colour. Sketch

smooth and a coat of filler should be

90068 gives the interior colour

applied. Then, entire surface

scheme of coaches.

including old painted surface should

§ If the condition of the paint on the be sand papered smooth and the

mouldings has deteriorated or seats should be repainted with a coat

become thick, the complete paint of enamel finishing of the prescribed

should be removed by the paint colour to IS 133-93.

remover. The moulding should then

be washed thoroughly, allowed to 1206 MARKING OF COACHES

dry and repainted with one coat Red- TOGETHER WITH EXTERIOR

oxide zinc chromate primer to

IS:2074 -92 followed by synthetic All lettering on coaches should be

enamel to IS 133 -93 of appropriate according to the sizes prescribed in the

colour. marking diagrams for the type of coach to

which they pertain (refer RDSO drawing

§ Aluminum window frames should

number CSC-970). Anti telescopic coach

not be painted, but should be

end walls should be marked with yellow

thoroughly cleaned of all stains in

stripes as sketch no. 77356. Each should

position. If they are very dirty, they

be marked with following details:

should be removed and cleaned with

oxalic acid. FRP windows should be

i) Coach No., Owning Railway,

painted with polyurethane paints to

and Mechanical code if any.

RDSO specification No. M&C/

PCN/100/ 96 (Chapter IV). ii) Name of base station for primary

maintenance

Chapter 12, Page 4 of 6

Hindi CONTENTS

Maintenance Manual for BG coaches of ICF design Painting

iii) No. of compartments and seating § Specific gravity (at full

capacity as prescribed for the charge)

type of coach § Corrected to temperature

iv) Notices for use of alarm signal, § Cell watered on

safety precautions etc. if separate § Cell examined on

notice plates for these are not

placed. 1207 TOOLS AND PLANTS FOR

v) Transportation code applicable to PAINTING

the type of coach as per appendix

‘B’ of IRCA Conference Rule 1207a Types of brushes

part IV.

vi) Carrying capacity of OCV’s to i) Round brushes nos. 1/0, 2/0, 3/0 &

the nearest tonnes up to one 4/0.

decimal place above actual

capacity. ii) Flat brushes nos. 25 mm, 38 mm,

vii) Tare weights as recorded at the 50 mm, 63 mm, 75 mm, 100 mm

time of initial building or iii) Lettering brushes:

subsequent major modifications.

§ Flat brushes nos. 1 to 12

viii) A woman’s fi gure head painted

on illuminated panel of § Round brushes nos. 1 to 12

compartments permanently

iv) Stencil brushes

reserved for ladies.

ix) Return date showing the month v) Cleaning brushes for LP sheets with

and year in which the coach is soda ash

required to be returned to the

owning railway workshop for 1207b Putty knife

POH.

x) A block as shown below to be i) Pallet knife

stenciled on the left side of end

panel ii) Falling knife

iii) Haking knife

Table 12.1

Schedules Station Date 1207c Scrapers

code

Disinfected

Alarm chain periodical i) Shave tukes

examination done ii) Triangular

Dash pot oil checked

iii) Semi circular

Side bearer oil level

checked iv) Diagonal

Over head tank flushed

Intermediate lifting 1207d Abrasive papers

DA valve examined

i) Silicon carbide water proof paper

Note: Size of letters should be grade nos. 120, 220, 320 & 400.

10 mm and the block

350x250mm. 1207e Safety apparels

xi) The capacity of the dynamo and

light/fan loads to be stenciled on i) Goggles

the end panels.

xii) The following legends should be ii) Helmet

stenciled on battery box covers to iii) Gum boots

enable stenciling of necessary

particulars against each. 1207f Painting spray gun with air compressor

§ Make plant for painting.

§ Type

Chapter 12, Page 5 of 6

Hindi CONTENTS

Maintenance Manual for BG coaches of ICF design Painting

Annexure 12.1

A SCHEDULE (NINE DAYS)

1st Day : Remove old paint

2nd Day : One coat of Red Oxide Zinc chromate primer.

3rd Day : One coat of brush filler followed by spot putty to fill up holes/dents where required.

4th Day : Filler second coat (including spot putty where necessary)

5th Day : Rub down with silicon carbide water proof paper Gr. 120 & 220

6thDay : One coat of under coat

7th Day : Flat with silicon Carbide water proof Paper Gr. 320. One coat of enamel finishing.

8th Day : Flat with silicon Carbide water proof Paper Gr. 400 and apply a second coat of

synthetic enamel finishing.

9th Day : Lettering with Golden yellow and miscellaneous work (cleaning window glasses

etc.)

Annexure 12.2

POH PAINTING PROCEDURE "C" SCHEDULE

1st Day : Cleaning with soap solution or any other cleaning solution and wash thoroughly with

water touch up damaged portion with primer recommended under A sch edule .

2nd Day : Spot putty if necessary and one coat of under coat.

3rd Day : Flat with silicon carbide water proof paper Gr. 120 & 220, and apply one coat of

finishing enamel.

4th Day : Flat with silicon carbide water proof Gr. 400 and apply a second coat of synthetic

enamel finishing.

5th Day : Lettering with golden yellow and miscellaneous work.

*****

Chapter 12, Page 6 of 6

Você também pode gostar

- Installation Manual: 17 PaintingDocumento10 páginasInstallation Manual: 17 PaintingMiguelAinda não há avaliações

- Qa LHB PaintingDocumento5 páginasQa LHB PaintingSriram SubramanianAinda não há avaliações

- Repair of Damages in Zinc LayersDocumento4 páginasRepair of Damages in Zinc LayersBobAinda não há avaliações

- IS2395 (Part1) :1994Documento14 páginasIS2395 (Part1) :1994giriAinda não há avaliações

- Draft Handbook On Procedure For Painting of ICF CoachesDocumento32 páginasDraft Handbook On Procedure For Painting of ICF CoachessaraAinda não há avaliações

- Sheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportDocumento2 páginasSheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportTejas MohanAinda não há avaliações

- Site Paint Repair Procedure IntumescentDocumento4 páginasSite Paint Repair Procedure Intumescentrimshadtp100% (3)

- Sheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportDocumento2 páginasSheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportTejas MohanAinda não há avaliações

- 03 - Paint Spec - Added - FDC 25KDocumento15 páginas03 - Paint Spec - Added - FDC 25KJIM CAMPBELLAinda não há avaliações

- 15 UkDocumento4 páginas15 UkAhmed IbrahimAinda não há avaliações

- FIAT March23Documento9 páginasFIAT March23P.K.BALAAinda não há avaliações

- PAINTDocumento7 páginasPAINTIsyfi QulubanaAinda não há avaliações

- TSI 136 Adani - R1 PDFDocumento6 páginasTSI 136 Adani - R1 PDFKRISHNA ENGINEERING CO. BHOPALAinda não há avaliações

- Technical Specification FOR Flooring Treatment: System RecommendationDocumento69 páginasTechnical Specification FOR Flooring Treatment: System RecommendationLaxmana PrasadAinda não há avaliações

- Painting Procedure: Doc. No.: PLP-PAINT-P001Documento9 páginasPainting Procedure: Doc. No.: PLP-PAINT-P001คุณพ่อน้อง บิ๊กบอสAinda não há avaliações

- UHDE-Specs Section-9 PaintingDocumento12 páginasUHDE-Specs Section-9 PaintingDivyansh TripathiAinda não há avaliações

- UHDE Specs Section 9 PaintingDocumento12 páginasUHDE Specs Section 9 Paintingprabhash kumarAinda não há avaliações

- Ai Hempadur 17630 EnglishDocumento5 páginasAi Hempadur 17630 EnglishLukman ZakariyahAinda não há avaliações

- Sign TSDocumento16 páginasSign TSAjay SinghAinda não há avaliações

- Working Procedure For Coating Repair C4Documento7 páginasWorking Procedure For Coating Repair C4tuyen nguyenAinda não há avaliações

- Quotation-Tirupati GardenDocumento12 páginasQuotation-Tirupati GardenAnonymous fLgaidVBhzAinda não há avaliações

- Sheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportDocumento2 páginasSheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportTejas MohanAinda não há avaliações

- Technical Specifications - Painting of SteelDocumento1 páginaTechnical Specifications - Painting of SteeldineshAinda não há avaliações

- Painting Procedure For CondenceDocumento26 páginasPainting Procedure For CondenceNamta GeorgeAinda não há avaliações

- Pa 10Documento10 páginasPa 10sheikmoin0% (1)

- Customer Al Khaleej Sugar Refinery Company, Jebel Ali, DubaiDocumento6 páginasCustomer Al Khaleej Sugar Refinery Company, Jebel Ali, DubaiRoshan aravinthAinda não há avaliações

- Pamphlet On Painting of Rails & WeldsDocumento4 páginasPamphlet On Painting of Rails & WeldsAnonymous 5uPEDI6Ainda não há avaliações

- Interline 961 Eng A4 20081030Documento4 páginasInterline 961 Eng A4 20081030Linnie McleodAinda não há avaliações

- A2 - Painting Procedure PDFDocumento2 páginasA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- A2 - Painting Procedure PDFDocumento2 páginasA2 - Painting Procedure PDFJuan Carlos Sua SuaAinda não há avaliações

- Interior & Exterior PaintingDocumento11 páginasInterior & Exterior PaintingGabriel Gabe50% (2)

- Painting MSDocumento11 páginasPainting MSGabriel GabeAinda não há avaliações

- OA 9550 Road Marking Paint Yellow Product Data: (Exterior/InteriorDocumento1 páginaOA 9550 Road Marking Paint Yellow Product Data: (Exterior/Interior7981Ainda não há avaliações

- Painting Procedure - PolyurethaneDocumento2 páginasPainting Procedure - PolyurethanesanjeetkarAinda não há avaliações

- Pickling Passivation Procedure by JSDocumento2 páginasPickling Passivation Procedure by JSAkhilesh Kumar67% (3)

- 2 Methods Statement For Concrete Repair On Concrete StructureDocumento8 páginas2 Methods Statement For Concrete Repair On Concrete StructurePo RaksmeyAinda não há avaliações

- Renderoc HB40 NewDocumento5 páginasRenderoc HB40 NewJayvee G. DignosAinda não há avaliações

- RENDEROC-S - Merged SDSDocumento11 páginasRENDEROC-S - Merged SDSKannan Sasidharan PillaiAinda não há avaliações

- SSPC-SP 18-2020Documento7 páginasSSPC-SP 18-2020Yusuf Luqman HakimAinda não há avaliações

- Masterprotect 1825 TdsDocumento3 páginasMasterprotect 1825 TdsYudhaAinda não há avaliações

- Painting of BridgesDocumento4 páginasPainting of Bridgesradhakrishnang100% (1)

- Teknomastic 80 Primer 8803-00 Tds enDocumento6 páginasTeknomastic 80 Primer 8803-00 Tds en8q5tgtfn7tAinda não há avaliações

- Nitobond ArDocumento46 páginasNitobond ArGavriel NgAinda não há avaliações

- Gs 09Documento19 páginasGs 09mahendraAinda não há avaliações

- Dulux Firepro Epoxy Intumescent Application GuideDocumento10 páginasDulux Firepro Epoxy Intumescent Application GuideAlpha DekoAinda não há avaliações

- AI Hempadur Quattro XO 17870 EnglishDocumento4 páginasAI Hempadur Quattro XO 17870 EnglishLuka BornaAinda não há avaliações

- Korodur Copetti Floor PDFDocumento1 páginaKorodur Copetti Floor PDFIbrahim SahinAinda não há avaliações

- Renderoc S: Constructive SolutionsDocumento2 páginasRenderoc S: Constructive SolutionsMuhammad.FaisalAinda não há avaliações

- Carboguard 636 XT PDSDocumento4 páginasCarboguard 636 XT PDSCarlos Rojas HandalAinda não há avaliações

- Bgas PA10Documento23 páginasBgas PA10Ajith PayyanurAinda não há avaliações

- tk06 Cover PageDocumento3 páginastk06 Cover Pagespray1949Ainda não há avaliações

- Painting Procedures: Cleaning & Painting Aluminum Propellers & Gear HousingsDocumento1 páginaPainting Procedures: Cleaning & Painting Aluminum Propellers & Gear Housingsbetabet GeorgeAinda não há avaliações

- OA 9010 Road Marking Paint White Product Data: (Exterior/InteriorDocumento1 páginaOA 9010 Road Marking Paint White Product Data: (Exterior/Interior7981Ainda não há avaliações

- Coating SpecsDocumento3 páginasCoating SpecsAhmed WagihAinda não há avaliações

- Quattro XODocumento5 páginasQuattro XOnnuekAinda não há avaliações

- Technical Specification For Paints, Thinner and PrimerDocumento3 páginasTechnical Specification For Paints, Thinner and PrimerRadhakrishnan SreerekhaAinda não há avaliações

- 3.3 Secondary and Localized Surface Preparation: 3.3.1 General DescriptionDocumento8 páginas3.3 Secondary and Localized Surface Preparation: 3.3.1 General DescriptionAlex KuvoricAinda não há avaliações

- Junior EngineerDocumento9 páginasJunior EngineerDileep KodatiAinda não há avaliações

- Renderoc HS PDFDocumento2 páginasRenderoc HS PDFMuhammed KunnappillyAinda não há avaliações

- MillingDocumento1 páginaMillingforplancessAinda não há avaliações

- How To Get Placef in Top Tech CompaniesDocumento1 páginaHow To Get Placef in Top Tech CompaniesforplancessAinda não há avaliações

- Abraham LincolnDocumento4 páginasAbraham LincolnforplancessAinda não há avaliações

- Solutions by Graph and Simplex MethodDocumento1 páginaSolutions by Graph and Simplex MethodforplancessAinda não há avaliações

- Dil DiyaanDocumento1 páginaDil DiyaanforplancessAinda não há avaliações

- Public Class Solution PDFDocumento2 páginasPublic Class Solution PDFforplancessAinda não há avaliações

- 11 TheoryOfEquationsDocumento3 páginas11 TheoryOfEquationsRaju SharmaAinda não há avaliações

- SimpleDocumento1 páginaSimpleforplancessAinda não há avaliações

- TryDocumento1 páginaTryforplancessAinda não há avaliações

- Exam Calender English 2016 PDFDocumento1 páginaExam Calender English 2016 PDF123456789cisco123456789Ainda não há avaliações

- Dil DiyaanDocumento1 páginaDil DiyaanforplancessAinda não há avaliações

- Jee Main 2014 Question Paper With Solution PDFDocumento27 páginasJee Main 2014 Question Paper With Solution PDFFirdosh Khan92% (13)

- ArrayDocumento1 páginaArrayforplancessAinda não há avaliações

- Antifertility DrugsDocumento12 páginasAntifertility DrugsforplancessAinda não há avaliações

- RMO 2013 Paper 1Documento1 páginaRMO 2013 Paper 1Himansu MookherjeeAinda não há avaliações

- M M 022kiniknnikesss0225nxudncisudncoudisn26 Jnvj296kigktimb2wdcxwdc2820551Documento1 páginaM M 022kiniknnikesss0225nxudncisudncoudisn26 Jnvj296kigktimb2wdcxwdc2820551forplancessAinda não há avaliações

- HTTP 215 SDocumento1 páginaHTTP 215 SforplancessAinda não há avaliações

- YcycDocumento1 páginaYcycforplancessAinda não há avaliações

- Ycy 55 KKNCDocumento1 páginaYcy 55 KKNCforplancessAinda não há avaliações

- YcycDocumento1 páginaYcycforplancessAinda não há avaliações

- 07 - Rotational MotionDocumento15 páginas07 - Rotational Motionpoorv1235570Ainda não há avaliações

- Kinematics Type 1Documento11 páginasKinematics Type 1vishalbhardawaj07Ainda não há avaliações

- Work Energy PowerDocumento5 páginasWork Energy PowerforplancessAinda não há avaliações

- RMO 2013 Paper 4Documento1 páginaRMO 2013 Paper 4Himansu MookherjeeAinda não há avaliações

- 24 Excellent Esl: Conversation Questions For AdultsDocumento3 páginas24 Excellent Esl: Conversation Questions For AdultsSusana BárriosAinda não há avaliações

- Why Literature MattersDocumento9 páginasWhy Literature MattersAndrew YanAinda não há avaliações

- Emmett SlidesManiaDocumento24 páginasEmmett SlidesManiaPhung Ngoc MaiAinda não há avaliações

- Pentatonic SuperimpositionDocumento2 páginasPentatonic SuperimpositionLucLaMotAinda não há avaliações

- (Doing... Series) Mark Donnelly, Claire Norton - Doing History-Routledge (2011) PDFDocumento251 páginas(Doing... Series) Mark Donnelly, Claire Norton - Doing History-Routledge (2011) PDFJessica Maximo100% (3)

- Abraham Father of FaithDocumento4 páginasAbraham Father of FaithEdem Kofi BoniAinda não há avaliações

- Moby Dick Chapters 102-114 PDFDocumento5 páginasMoby Dick Chapters 102-114 PDFRomesor ApolAinda não há avaliações

- 21 Meet Cute PDFDocumento120 páginas21 Meet Cute PDFMichel Lichand100% (1)

- The Relationship Between Characterization and Story Information Essay FinalDocumento9 páginasThe Relationship Between Characterization and Story Information Essay Finalrachel williamsAinda não há avaliações

- GAMABADocumento9 páginasGAMABAJhoe Anne B. LimAinda não há avaliações

- Estarn Book Linkers 2017Documento41 páginasEstarn Book Linkers 2017sunder27Ainda não há avaliações

- Aos Warscroll Blood Knights enDocumento1 páginaAos Warscroll Blood Knights enAdam KatzAinda não há avaliações

- Present Simple 2Documento2 páginasPresent Simple 2Andreea CretuAinda não há avaliações

- Online User's Guide: P-Touch PT-P750WDocumento59 páginasOnline User's Guide: P-Touch PT-P750WThura AungAinda não há avaliações

- Biology of The Cell Assignment - Answer KeyDocumento2 páginasBiology of The Cell Assignment - Answer KeyBen-ZionWeltschAinda não há avaliações

- Ea300 ReferencesDocumento9 páginasEa300 ReferencesSeanna DunseithAinda não há avaliações

- ENGLISH UB 2 Yr 3Documento5 páginasENGLISH UB 2 Yr 3Nadarajah SubramaniamAinda não há avaliações

- Types of Lathe MachineDocumento5 páginasTypes of Lathe MachineMD Mahmudul Hasan MasudAinda não há avaliações

- Portfolio GT PDFDocumento27 páginasPortfolio GT PDFPlatino Mulya BudimanAinda não há avaliações

- Grade 2 CorrelationsDocumento25 páginasGrade 2 CorrelationsGerardo SaucedaAinda não há avaliações

- Proof of Heaven 1 PDFDocumento8 páginasProof of Heaven 1 PDFIvana ParadinaAinda não há avaliações

- Utopian Visions (Time-Life Mysteries of The Unknown) PDFDocumento168 páginasUtopian Visions (Time-Life Mysteries of The Unknown) PDFVictor Chibici100% (1)

- Vdoe Essential Knowledge Grade 6 SolDocumento5 páginasVdoe Essential Knowledge Grade 6 Solapi-294145359Ainda não há avaliações

- 2012-06-16 Oley Led Projector Quotation-Promoting 2Documento3 páginas2012-06-16 Oley Led Projector Quotation-Promoting 2api-149208964Ainda não há avaliações

- Literary Devices Test: Section One - Matching The MeaningDocumento5 páginasLiterary Devices Test: Section One - Matching The MeaningKarin DenehyAinda não há avaliações

- Communication Skills 10 Lectures - LNKDocumento183 páginasCommunication Skills 10 Lectures - LNKCHAUDHARY NAQASH BASHIRAinda não há avaliações

- 18 Audition Monologues: For Men & WomenDocumento40 páginas18 Audition Monologues: For Men & WomentatarasiAinda não há avaliações

- Module Mounting StructureDocumento1 páginaModule Mounting StructureVasanth KumarAinda não há avaliações

- Dining Room OperationsDocumento35 páginasDining Room Operationsmarysue_baylongoAinda não há avaliações

- Ratatouille ScriptDocumento118 páginasRatatouille Scriptapi-3729580100% (7)