Escolar Documentos

Profissional Documentos

Cultura Documentos

One-Step Preparation and Characterization of Zinc Phosphate Nanocrystals With Modified Surface

Enviado por

Dương Minh MẫnTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

One-Step Preparation and Characterization of Zinc Phosphate Nanocrystals With Modified Surface

Enviado por

Dương Minh MẫnDireitos autorais:

Formatos disponíveis

Soft Nanoscience Letters, 2011, 1, 81-85 81

doi:10.4236/snl.2011.13015 Published Online July 2011 (http://www.scirp.org/journal/snl)

One-Step Preparation and Characterization of

Zinc Phosphate Nanocrystals with Modified

Surface

Jian Dong Wang1, Da Li1, Jin Ku Liu1*, Xiao Hong Yang2*, Jia Luo He3, Yi Lu1

1

Department of Chemistry, East China University of Science and Technology, Shanghai, China; 2Department of Chemistry, Chizhou

University, Anhui, China; 3School of Materials and Engineering, Nanjing University of Technology, Nanjing, China.

Email: jkliu@ecust.edu.cn, yxh6110@yeah.net

Received February 14th, 2011; revised May 27th, 2011; accepted June 30th, 2011.

ABSTRACT

The surface-modified zinc phosphate (Zn3(PO4)2) nanocrystals were synthesized by a facile and efficient one-step ul-

trasonic-template-microwave (UTM) assisted route. The crystal structure, optical properties and morphologies of zinc

phosphate nanocrystals were characterized by X-ray diffraction, Fourier transform infrared spectroscopy, Raman

spectroscopy and transmission electron microscope. And the TEM image showed that the product had good dispersion

with a particle size of 30 - 35 nm. The anti-corrosion function of anti-corrosive paint using zinc phosphate nanocrystals

was researched and the experiment result showed that the salt atmosphere-resistant time was 158 h longer than that of

zinc phosphate bulk materials on market. The performance of zinc phosphate nanocrystals with modified surface syn-

thesized by one-step UTM assisted route was improved 63.2% compared with the bulk materials.

Keywords: Synthesis, Ultrasonic, Microwave, Zinc Phosphate, Nanocrystals, Anti-Corrosion

1. Introduction tribution [8,9]. And microwave-assisted synthesis was a

new way to produce inorganic compounds because mi-

Zinc phosphate, a non-toxic foundational material, has

crowave heating is an in situ mode of energy conversion

been widely applied in coating industry, medicine, elec-

[10]. In this paper, the ultrasonic, microwave and triton

trical fields, especially anti-corrosion due to its low solu-

bility in water/biological environment [1,2]. The crystal x-100 were applied together in the synthesis of zinc

size has a great effect on the function of anti-corrosion phosphate nanocrystals for the first time and this method

due to the un-smoothness of the surface of metal base- can be extended into the industry production for its low-

ment. Meanwhile, the common technology of zinc phos- cost and one-step reaction of preparations and surface

phate production was hard to manufacture nanoscaled modification. The product’s anti-corrosion function was

products. So, various techniques such as hydrothermal tested by the neutral salt spray (NSS) experiment and the

method [3-5], sol-gel method [6] and solid-state method result showed that the effective anti-corrosion time was

[7] have been investigated for synthesis of zinc phos- obviously longer than that of the zinc phosphate bulk

phate nanocrystals in the recent several years. However, materials on market. This good performance was mainly

these methods were difficult to be applied in the industry owing to the small size and good-dispersion in painter.

production because of the high cost and complicated And the dosage of zinc phosphate nanocrystals would be

technology. Especially, the dispersion of prepared zinc reduced which could make the cost lower. The using of

phosphate nanocrystals was very difficult in practical ultrasonic, microwave and triton x-100 in the synthesis

application. So, a method to prepare zinc phosphate na- process can decrease the crystal diameter and modify the

nocrystals with modified surface which is small enough surface. The triton x-100 shell covered on the surface of

with low-cost and simple way is the research object of product can prevent the agglomeration of the products

many chemists. from the excess drying temperature in the drying process

The ultrasonic technology has been adapted to fabri- and improve the product’ dispersion ability in the painter

cate inorganic nanocrystals to improve the products’ dis- because of the dispersant effect of surfactant.

Copyright © 2011 SciRes. SNL

82 One-Step Preparation and Characterization of Zinc Phosphate Nanocrystals with Modified Surface

2. Experimental Section used in the depositing process and it could enhance the

vibration and shear between particles for its line-changed

2.1. Synthesis of Zinc Phosphate Nanocrystals

effect, which could promote the product separating better.

Into 0.1 mol/L Na3PO4·12H2O solution of 20 mL and of [12] Microwave technology was applied in the drying

0.1 mol/L Zn(NO3)2·6H2O solution of 30 mL in the clean process and it was also an effective way to avoiding ag-

beaker were added triton x-100 of 0.2 mL and 0.3 mL, glomeration. Due to strong thermal gradients induced by

respectively. The both reaction solutions were dropwise microwave heating, strong stirring occurs for liquids

added into the 100 mL deionized water, and then the leading to thermal uniformity of heated medium. [13,14]

reaction system was put in the ultrasonic machine with The triton x-100 was a surfactant in the precipitation

continuous stirring until complete precipitate. And the which can reduce agglomeration and decrease the di-

reaction was carried out as the follow equation: ameter of product. In the drying process, the triton x-100

2Na 3 PO 4 12H 2 O 3Zn NO3 2 6H 2 O

(1)

Zn 3 PO 4 2 4H 2 O 6NaNO3 38H 2 O

Then, the white deposition was filtrated out, washed 3

times by deionized water and dried completely for 2 h in

the microwave machine (The drying power was 400 W).

Finally, after the product was dried completely, the zinc

phosphate nanocrystals were obtained.

2.2. Characterization

The structures of the obtained products were character-

ized by X-ray powder diffraction (XRD, Shimadzu XD-

3A diffractometer), Raman spectra (Jobin-Yvon) and

Fourier transform infrared spectroscopy (IR, Nicolet

Nagna-IR 550). The microstructures and morphologies

were analyzed with transmission electron microscopy

(TEM, Hitachi-800).

2.3. Experiment of Anti-Corrosion

(a)

The anti-corrosion function of the anticorrosive paint

using zinc phosphate nanocrystals was tested by the neu-

tral salt spray (NSS) experiment. [11] The 5 wt% NaCl

aqueous solution was used as the corrodent and its pH

should be kept between 6.5 and 7.2. The temperature of

the test system was 35˚C and the sedimentation rate of

salt fog was 2 mL/h (the incept area is 80 cm2).

3. Results and Discussions

3.1. Morphologies and Structures

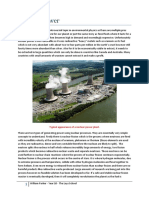

Figure 1(a) and (b) were the TEM images and selected

area electron diffraction (SAED) image of zinc phos-

phate nanocrystals. Figure 1(a) clearly showed that the

zinc phosphate nanocrystals had a uniform size with a

diameter about 40 - 45 nm, good-dispersion and modi-

fied surface. The partial enlarged image of single zinc

phosphate particle in Figure 1(a) expressed a core/shell

structure with a zinc phosphate core of 30 - 35 nm and

shell of about 5 nm. And the shell was the result of sur-

face modified by triton x-100. The SAED image (Figure (b)

1(b)) showed that the zinc phosphate nanocrystal was a Figure 1. TEM images and SAED image of zinc phosphate

polycrystal structure. In this study, the ultrasonic was nanocrystals.

Copyright © 2011 SciRes. SNL

One-Step Preparation and Characterization of Zinc Phosphate Nanocrystals with Modified Surface 83

3.2. Optical Properties

Figure 3(a) was the Raman spectrum for the zinc phos-

phate products. The absorption bands at 372 cm–1 and

870 cm–1 were attributed to P-O bending and stretching

vibration, respectively. The absorption band within 1500

- 1750 cm–1 was the O-H stretching broad. The IR spec-

trum of zinc phosphate products were shown in Figure

3(b). The O-H stretching broad band at 3378 cm–1 and

1640 cm–1 can be observed, implying the existence of

crystal water. The several sharp absorption bands from

900 to 1200 cm–1 were a complex of stretching of PO43–

group as reported [17]. The absorption band at 1010 and

1120 cm–1 were the anti-symmetric stretching and sym-

metric stretching of PO43–, respectively. The P-O bend-

ing vibration at 960 cm–1 was observed. The bending vi-

Figure 2. XRD pattern of zinc phosphate nanocrystals.

which can reduce agglomeration and decrease the dia-

meter of product. In the drying process, the triton x-100

can prevent the possible integrality of crystal from over

high temperature in the microwave heating machine.

When the product was added into the resin to form the

anti-corrosion painter, the zinc phosphate nanocrystals

can disperse better than the ones without surface-modi-

fication because of the rule of similarity. From the Fig-

ure 1(a) and (b), we can see that the UTM route can de-

crease the zinc phosphate’s diameter and reduce the ag-

glomeration effectively. Furthermore, the using of triton

x-100 can improve the dispersion of zinc phosphate,

prevent the agglomeration and modify the surface.

The XRD pattern of the zinc phosphate nanocrystals

was shown in Figure 2. The fifteen strong peaks at 2- (a)

theta values of 9.65˚, 16.68˚, 17.79˚, 18.26˚, 19.38˚,

22.17˚, 25.67˚, 31.31˚, 35.67˚, 39.88˚, 46.78˚, 47.54˚,

49.94˚, 56.41˚ and 61.07˚ were thought to be originated

from (020), (200), (210), (011), (040), (230), (221), (241),

(002), (171), (371), (521), (402), (123) and (303) of

crystal face of zinc phosphate (Zn3(PO4)2·4H2O) which

are matched with the standard XRD data of JC-PDS file

(Numbers: 33-1474) [15].

According to Debye-Scherrer formula [16] estimates:

d 0.89 / Bcos (2)

The zinc phosphate particle size (core of modified

products) of the products was about 34 nm which is con-

sistent with the data in TEM images. When the ultrasonic,

triton x-100 and microwave were used in the preparation,

in the range of 2 = 5˚ - 70˚, no other peaks could be

observed which also confirmed that the product was ex- (b)

clusively Zn3(PO4)2·4H2O. In this research, the zinc Figure 3. Raman (a) and IR spectrum (b) for zinc phos-

phosphate nanocrystals without impurities can be pre- phate prepared by different ways: 1) nanocrystals; 2) bulk

pared successfully by the UTM route. materials.

Copyright © 2011 SciRes. SNL

84 One-Step Preparation and Characterization of Zinc Phosphate Nanocrystals with Modified Surface

Figure 4. The anti-corrosion mechanism drawing of zinc phosphate.

bration at 960 cm–1 was observed. The bending vibration existence of the crystal water in the structure. Then, the

at 810 and 1375 cm–1 was the characteristic absorption H3PO4 and Zn(OH)2 would react with the metal base-

peak of 1, 4-substituted phenyl and C-H symmetry ment to form an undissolved complex of phosphate

bending vibration of methyl in triton x-100, respectively. (MZn2(PO4)2).When the zinc phosphate product had a

These results showed that the zinc phosphate crystal was touch with the metal basement, an undissolved complex

present, some crystal water existed in the product and the of phosphate were produced to form a compact protec-

triton x-100 can be observed in the product synthesized tive layer on the surface of the metal which can separate

by UTM route. the metal basement from the corrosion. But in fact, the

surface of metal basement was not smooth and intact,

3.3. Anti-Corrosion Effect

there were many indentations which can’t be seen by

The neutral salt spray experiment was going on to test eyes on it. According to the anti-corrosion mechanism

the anti-corrosion function and salt spray was carried out drawing (Figure 4), it was hard for the zinc phosphate

for 1000 h and the sedimentation rate of salt fog was 2 bulk material to touch inside the indentations and the

mL/h (the incept area is 80 cm2). The prohesion test was metal was still corroded. In the other hand, the zinc

performed using 1150 cycles with 1 h spraying of 5 wt% phosphate nanosrystals can enter into the indentation and

NaCl aqueous solution at 35℃ and its pH should be kept form a protective layer. Just because of this, the undis-

between 6.5 and 7.2, followed by drying for 1 h. A paint solved complex of phosphate formed by the zinc phos-

horizontal scribe was used on the laboratory test speci- phate nanocrystals synthesized by the UTM route can

mens according to ISO/DIS standard 12944-6 [18]. For avoid not only the electrochemical corrosion but also the

electrochemical measurements, two irony cells of 2.5 cm chemical corrosion effectively.

diameter and 3 cm high were used.

The result showed that effective anti-corrosion time 4. Conclusions

was 408 h which was 158 h longer than zinc phosphate In this paper, the surface-modified zinc phosphate nano-

bulk materials on market. Because of the existence of crystal was synthesized by UTM method in one step re-

crystal water inside the zinc phosphate crystal, a thin action and its dispersion were better than the ones which

liquid layer formed in the surface of the product com- synthesized by the method reported before. The micro-

posed with Zn2+, PO43– and water. In the follow reaction wave and ultrasonic can not only prevent products reun-

equation, the M meant the composition of the metal ion, but also improve the dispersion of product; the sur-

basement. face-modifying of triton x-100 can not only reduce the

Zn 3 PO 4 2 6H 2 O 2H 3 PO 4 3Zn OH 2 (3) agglomeration of zinc phosphate nanocrystals in the re-

action system and prevent the enlargement of the prod-

M 2H 3 PO 4 2Zn OH 2 uct’s size from the excess drying temperature in the dry-

(4)

MZn 2 PO 4 2 4H 2 O H 2 ing process, but also promote the dispersion of zinc

phosphate in the painting. The NSS experiment was car-

As the reaction (3) and (4) showed, the Zn3(PO4)2 ried out and the result showed that the effective anti-

would hydrolyze into H3PO4 and Zn(OH)2 due to the corrosion time was 408 h which was obviously superior

Copyright © 2011 SciRes. SNL

One-Step Preparation and Characterization of Zinc Phosphate Nanocrystals with Modified Surface 85

to the 250 h of zinc phosphate bulk material on market; [8] J. K. Liu, C. X. Luo, X. H. Yang and X. Y. Zhang, “Ul-

smaller size and better dispersion can enhance the anti- trasonic—Template Method Synthesis of CdS Hollow

Nanoparticle Chains,” Materials Letters, Vol. 63, No. 1,

corrosion function of zinc phosphate nanocrystals and

2009, pp. 124-126.

decrease the dosage of products. This method is eligible doi:10.1016/j.matlet.2008.09.029

for the industry production because of its low cost and

[9] J. K. Liu, X. H. Yang and X. G. Tian, “Preparation of

one-step reaction of preparation and surface modifica- Silver/Hydroxyapatite Nanocomposite Spheres,” Powder

tion. Technology, Vol. 184, No. 1, 2008, pp. 21-24.

doi:10.1016/j.powtec.2007.07.034

5. Acknowledgements

[10] A. L. Jose and J. B. Kenneth, “Microwave Synthesis of

This work was supported by the State Key Laboratory of NTHU-4 and Related Materials,” Microporous and

Pollution Control, Resource Reuse Foundation (NO. Mesoporous Materials, Vol. 113, No. 1, 2008, pp. 325-

PCRRF09005) and National Natural Science Foundation 332.

of China (21071024). [11] A. Amirudin and D. Thierry, “Corrosion Mechanisms of

Phosphated Zinc Layers on Steel as Substrates for Auto-

motive Coatings,” Progress in Organic Coatings, Vol. 28,

REFERENCES No. 1, 1996, pp. 59-76.

[1] B. D. A. R. Romagnoli, V. F. Vetere and L. S. Hernandez, doi:10.1016/0300-9440(95)00554-4

“Study of the Anticorrosive Properties of Zinc Phosphate [12] F. L. Yuan, C. H. Chen, E. M. Kelder and J. Schoonman,

in Vinyl Paints,” Progress in Organic Coatings, Vol. 33, “Preparation of Zirconia and Yttria-Stabilized Zirconia

No. 1, 1998, pp. 28-35. (YSZ) Fine Powders by Flame-Assisted Ultrasonic Spray

doi:10.1016/S0300-9440(97)00124-0 Pyrolysis (FAUSP),” Solid State Ionics, Vol. 109, No. 1-2,

[2] B. Czarnecka and J. W. Nicholson, “Ionrelease, Dissolu- 1998, pp. 119-123. doi:10.1016/S0167-2738(98)00108-8

tion and Buffering by Zinc Phosphate Dental Coments,” [13] J. D. Wang, C. X. Luo, J. K. Liu and Y. Lu, “Synthesis of

Journal of Materials Science: Materials in Medicine, Vol. Yttria-Stabilized Cubic Zirconia Nanocrystals by Ultra-

14, No. 7, 2003, pp. 601-604. sonic-Microwave Route,” NANO, Vol. 5, No.5, 2010, pp.

doi:10.1023/A:1024018923186 271-277. doi:10.1142/S1793292010002177

[3] B. Yan and X. Z. Xiao, “Hydrothermal Synthesis, Con- [14] L. Combemale, G. Caboche, D. Stuerga and D. Chau-

trolled Microstructure, and Photoluminescence of hy- mont, “Microwave Synthesis of Yttria Stabilized Zirco-

drated Zn3 (PO4)2: Eu3+ Nanorods and Nanoparticles,” nia,” Materials Research Bulletin, Vol. 40, No. 3, pp.

Journal of Nanoparticle Research, Vol. 11, No. 8, 2009, 529-536. doi:10.1016/j.materresbull.2004.10.024

pp. 2125-2135. doi:10.1007/s11051-008-9578-6

[15] S. P. Yan, W. He and C. Y. Sun, “The Biomimetic Syn-

[4] B. Boonchom, R. Baitahe, S. Kongtaweelert and N. Vit- thesis of Zinc Phosphate Nanoparticles,” Dyes and Pig-

tayakorn, “Kinetics and Thermodynamics of Zinc Phos- ments, Vol. 80, No. 2, 2009, pp. 254-258.

phate Hydrate Synthesized by a Simple Route in Aqueous doi:10.1016/j.dyepig.2008.06.010

and Acetone Media,” Industrial & Engineering Chemis-

try Research, Vol. 49, No. 8, 2010, pp. 3571-3576. [16] J. C. Ray, R. K. Pati and P. Pramanik, “Chemical Synthe-

doi:10.1021/ie901626z sis and Structural Characterization of Nanocrystalline

Powders of Pure Zirconia and Yttria Stabilized Zirconia,”

[5] O. Pawlig and R. Trettin, “Synthesis and Characterization Journal European Ceramic Society, Vol. 20, No. 9, 2000,

of -hopeite Zn3(PO4)2·4H2O,” Materials Research pp. 1289-1295. doi:10.1016/S0955-2219(99)00293-9

Bulletin, Vol. 34, No. 12, 1999, pp. 1959-1966.

[17] M. Zhang, J. K. Liu, R. Miao, G. M. Li and Y. J. Du,

doi:10.1016/S0025-5408(99)00206-8

“Preparation and Characterization of Fluorescence Probe

[6] B. I. Lee, W. D. Samuels, L. Q. Wang and G. J. Exarhos, from Assembly Hydroxyapatite Nanocomposite,” Nano-

“Sol-gel Synthesis of Phosphate Ceramic Composites,” scale Research Letters, Vol. 5, 2010, pp. 675-679.

Journal of Materials Research, Vol. 13, No. 6, 1996, pp. doi:10.1007/s11671-010-9530-4

134-143. doi:10.1016/S0025-5408(99)00206-8

[18] ISO/DIS 12944: Paint and Varnishes—Corrosion Protec-

[7] Q. A. Yuan, S. Liao, Z. F. Tong, J. Wu and Z. Y. Huang, tion of Steel Structures by Protective Paint Systems. Part

“Synthesis of Nanoparticle Zinc Phosphate Dihydrate by 6—Laboratory Performance Test Methods, ISO, Geneva,

Solid State Reaction at Room Temperature and Its Ther- 1998.

mochemical Study,” Materials Letters, Vol. 60, No. 17-

18, 2006, pp. 2110-2114.

Copyright © 2011 SciRes. SNL

Você também pode gostar

- Wastewater Treatment Concepts and PracticesDocumento212 páginasWastewater Treatment Concepts and Practicesfajar waskito100% (5)

- Tinanium Anodising Space PDFDocumento7 páginasTinanium Anodising Space PDFgramuiitmAinda não há avaliações

- Plant NanotechnologyDocumento387 páginasPlant NanotechnologyKrishnendu Pramanik100% (2)

- Zinc PhosphateDocumento10 páginasZinc PhosphateShrishma PaikAinda não há avaliações

- BK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Documento45 páginasBK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Kev TraAinda não há avaliações

- ANSYS Fluent Teory Guide 21R1Documento1.072 páginasANSYS Fluent Teory Guide 21R1John Stone0% (3)

- The Chemistry of Heterocycles Structure, Reactions, Syntheses, and ApplicationsDocumento571 páginasThe Chemistry of Heterocycles Structure, Reactions, Syntheses, and Applications17.Hồ Nguyên Khang100% (1)

- Investigation The Calcite HydrophobisationDocumento10 páginasInvestigation The Calcite HydrophobisationDaniel L. FrandsenAinda não há avaliações

- 9fcfd50bc537b87b10 PDFDocumento7 páginas9fcfd50bc537b87b10 PDFAnonymous cgKtuWzAinda não há avaliações

- Soares 2014Documento6 páginasSoares 2014kionnysAinda não há avaliações

- Gupta 2011Documento6 páginasGupta 2011Rega DesramadhaniAinda não há avaliações

- Vacuum: Rapid CommunicationDocumento3 páginasVacuum: Rapid CommunicationLakshmi NarayananAinda não há avaliações

- Powder Technology: Issa M. El-Nahhal, Jamil K. Salem, Sylvia Kuhn, Talaat Hammad, Rolf Hempelmann, Sara Al BhaisiDocumento8 páginasPowder Technology: Issa M. El-Nahhal, Jamil K. Salem, Sylvia Kuhn, Talaat Hammad, Rolf Hempelmann, Sara Al BhaisiardhiAinda não há avaliações

- Synthesis of Sno Nano Rods and Their Photocatalytic PropertiesDocumento5 páginasSynthesis of Sno Nano Rods and Their Photocatalytic PropertiesLai van CuongAinda não há avaliações

- Green synthesis of ZnO nanoparticles via plant extractDocumento4 páginasGreen synthesis of ZnO nanoparticles via plant extractClaudia UngureanuAinda não há avaliações

- Cathodic phosphate coating with nano zinc improves adhesion on magnesium alloysDocumento4 páginasCathodic phosphate coating with nano zinc improves adhesion on magnesium alloysNurul Nadzirah IsmailAinda não há avaliações

- Effect of Chemical Composition of Zinc Phosphating Solution On Phosphate Coating PropertiesDocumento12 páginasEffect of Chemical Composition of Zinc Phosphating Solution On Phosphate Coating PropertiesJhon QsacAinda não há avaliações

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDocumento6 páginasSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosHaneen WaleedAinda não há avaliações

- Material & Energy Balancing in Process IndustryDocumento10 páginasMaterial & Energy Balancing in Process IndustryGeorge Michael Alvarado LopezAinda não há avaliações

- XRF analysis of ferromanganese slag differences between pulverized and fused samplesDocumento7 páginasXRF analysis of ferromanganese slag differences between pulverized and fused samplesomar rahmounAinda não há avaliações

- Surface & Coatings Technology: Kuang-Che Lee, Su-Jien Lin, Chih-Hong Lin, Chih-Song Tsai, Yu-Jen LuDocumento4 páginasSurface & Coatings Technology: Kuang-Che Lee, Su-Jien Lin, Chih-Hong Lin, Chih-Song Tsai, Yu-Jen LuAme OscarfelAinda não há avaliações

- Ban 2015Documento11 páginasBan 2015Septian Perwira YudhaAinda não há avaliações

- 182 189Documento8 páginas182 189QA LAB ISMAinda não há avaliações

- Green Synthesis ZN ODocumento4 páginasGreen Synthesis ZN OOsma Muñoz GarciaAinda não há avaliações

- 2 67 1588404633 20ijmperdjun202020Documento8 páginas2 67 1588404633 20ijmperdjun202020TJPRC PublicationsAinda não há avaliações

- 18 - Shen2008, Photocatalytic Degradation For Methylene Blue Using Zinc Oxide PreparedDocumento4 páginas18 - Shen2008, Photocatalytic Degradation For Methylene Blue Using Zinc Oxide Preparedhellna284Ainda não há avaliações

- Na SitratDocumento7 páginasNa SitratJohan LampungChelsea FcAinda não há avaliações

- Fabrication and Properties of Zinc Oxide Thin FilmDocumento6 páginasFabrication and Properties of Zinc Oxide Thin FilmLalu SuhaimiAinda não há avaliações

- Effect of Phosphating Time and Temperature On Microstructure and Corrosion Behavior of Magnesium Phosphate CoatingDocumento12 páginasEffect of Phosphating Time and Temperature On Microstructure and Corrosion Behavior of Magnesium Phosphate CoatingM MUSTAFAAinda não há avaliações

- Huang 2014Documento6 páginasHuang 2014Eslam EzzatneshanAinda não há avaliações

- Preparation of Resin/nano Fillers Mixture For Composites: A Case StudyDocumento11 páginasPreparation of Resin/nano Fillers Mixture For Composites: A Case StudyNiranjan HugarAinda não há avaliações

- A1 - Crystalline Silicon Solar Cells With Micro:nano TextureDocumento4 páginasA1 - Crystalline Silicon Solar Cells With Micro:nano Texturesiraramesh2023Ainda não há avaliações

- Crystal Phase Transition and Properties of Titanium Oxide Nanotube Arrays Prepared by AnodizationDocumento4 páginasCrystal Phase Transition and Properties of Titanium Oxide Nanotube Arrays Prepared by AnodizationEduardo BadelAinda não há avaliações

- Structural, Magnetic and Electrochemical Properties of Coxzn1-X Fe2O4 Nanoparticles Synthesized by Co-Precipitat..Documento10 páginasStructural, Magnetic and Electrochemical Properties of Coxzn1-X Fe2O4 Nanoparticles Synthesized by Co-Precipitat..vijayamathubalan pandyAinda não há avaliações

- Paper 2Documento7 páginasPaper 2ibrahim mustapha AlibeAinda não há avaliações

- Characterization of A Clay-Polymer Composite Using The Infrared SpectrosDocumento3 páginasCharacterization of A Clay-Polymer Composite Using The Infrared SpectrosAnonymous 9XI54PvKPAinda não há avaliações

- Thesis On Nickel OxideDocumento7 páginasThesis On Nickel OxideWriteMyEnglishPaperForMeCanada100% (2)

- Nirmalya, 2016mesoporous ZnO Nanoclusters As An Ultra-Active PhotocatalystDocumento8 páginasNirmalya, 2016mesoporous ZnO Nanoclusters As An Ultra-Active Photocatalysthellna284Ainda não há avaliações

- Preparation and Characterization of Amorphous Silica NanowiresDocumento6 páginasPreparation and Characterization of Amorphous Silica NanowiresLaode Jonas TugoAinda não há avaliações

- Crystal Growth During Ball-Milling ExplainedDocumento6 páginasCrystal Growth During Ball-Milling ExplainedWahidAinda não há avaliações

- Tin OxidationDocumento7 páginasTin Oxidationsunny kumarAinda não há avaliações

- Sol-gel synthesis of ZnO/rGO thin film for enhanced photoelectrochemical water splittingDocumento18 páginasSol-gel synthesis of ZnO/rGO thin film for enhanced photoelectrochemical water splittingchtououAinda não há avaliações

- 2023 3099 OnlinePDFDocumento9 páginas2023 3099 OnlinePDFBibhu Prasad SwainAinda não há avaliações

- Raman Scattering Study On Anatase Tio2 Nanocrystals: Home Search Collections Journals About Contact Us My IopscienceDocumento6 páginasRaman Scattering Study On Anatase Tio2 Nanocrystals: Home Search Collections Journals About Contact Us My IopsciencejeffreylopezAinda não há avaliações

- Iron Oxide Nanoparticles for Mercury RemovalDocumento5 páginasIron Oxide Nanoparticles for Mercury RemovalYsabelle JimeneaAinda não há avaliações

- 7-2016 - Surfactant Assisted Sonochemical Synthesis of Hollow Structured Zinc Phosphate Nanoparticles and Their Application As NanocarrierDocumento5 páginas7-2016 - Surfactant Assisted Sonochemical Synthesis of Hollow Structured Zinc Phosphate Nanoparticles and Their Application As NanocarrierIITRANANDJADHAVAinda não há avaliações

- Fabrication of PolyacrylonitrileDocumento21 páginasFabrication of PolyacrylonitrileFadhilatul AdhaAinda não há avaliações

- Accepted ManuscriptDocumento18 páginasAccepted Manuscripthellna284Ainda não há avaliações

- Influence of Sodium Oxide On Properties of Fresh and Hardened Paste of Alkali Activation Blast Furnace SlagDocumento11 páginasInfluence of Sodium Oxide On Properties of Fresh and Hardened Paste of Alkali Activation Blast Furnace SlagAbd El-nour RamdAinda não há avaliações

- Covalent Attaching Protein To Graphene Oxide Via Diimide-Activated AmidationDocumento4 páginasCovalent Attaching Protein To Graphene Oxide Via Diimide-Activated AmidationClaramaria RodriguezAinda não há avaliações

- Microwave-Assisted Synthesis and Characterization of Cao NanoparticlesDocumento7 páginasMicrowave-Assisted Synthesis and Characterization of Cao NanoparticlesBeth JiménezAinda não há avaliações

- Materials 13 00641Documento16 páginasMaterials 13 00641sergio ataydeAinda não há avaliações

- Au-Ag Core-Shell Nanoparticles for SERSDocumento4 páginasAu-Ag Core-Shell Nanoparticles for SERSHEET MAHENDRA GALAAinda não há avaliações

- Elements Volume 2 Issue 6 2006 (Doi 10.2113/gselements.2.6.365) Lumpkin, G. R. - Ceramic Waste Forms For ActinidesDocumento8 páginasElements Volume 2 Issue 6 2006 (Doi 10.2113/gselements.2.6.365) Lumpkin, G. R. - Ceramic Waste Forms For ActinidesRaluca RainAinda não há avaliações

- SYNTHESIS OF ZnO NANOPARTICLES FOR ORGANIC POLLUTANT DEGRADATION PDFDocumento9 páginasSYNTHESIS OF ZnO NANOPARTICLES FOR ORGANIC POLLUTANT DEGRADATION PDFumar raza khanAinda não há avaliações

- Achieving High-Purity Colloidal Gold Nanoprisms and Their Application As Biosensing PlatformsDocumento8 páginasAchieving High-Purity Colloidal Gold Nanoprisms and Their Application As Biosensing PlatformsPhat HuynhAinda não há avaliações

- 2774 1 3783 1 10 20121113Documento6 páginas2774 1 3783 1 10 20121113Sepransiska WAinda não há avaliações

- Physical and Optical Properties of Sprayed Cu Znsns (CZTS) Thin Film: Effect of Cu ConcentrationDocumento9 páginasPhysical and Optical Properties of Sprayed Cu Znsns (CZTS) Thin Film: Effect of Cu ConcentrationSihem MansouriAinda não há avaliações

- Suresh 2014Documento12 páginasSuresh 2014Pranav PrajapatiAinda não há avaliações

- ZnO SynthesisDocumento4 páginasZnO Synthesissoumendra ghoraiAinda não há avaliações

- Quantification of CaCO3CaSO405H2OCaSO42H2ODocumento4 páginasQuantification of CaCO3CaSO405H2OCaSO42H2OaocpgsAinda não há avaliações

- Froth Flotation of Mixed Feldspar: Chairoj Rattanakawin and Benjapol ThacomDocumento5 páginasFroth Flotation of Mixed Feldspar: Chairoj Rattanakawin and Benjapol ThacomMarco Antonio Ojeda PradoAinda não há avaliações

- Colloids and Surfaces A: Physicochemical and Engineering AspectsDocumento7 páginasColloids and Surfaces A: Physicochemical and Engineering AspectsEduardo Marquez CastroAinda não há avaliações

- Top-Down Tuning of Nanosized Zeolites by Bead-Milling and RecrystallizationDocumento8 páginasTop-Down Tuning of Nanosized Zeolites by Bead-Milling and RecrystallizationKesya SaragihAinda não há avaliações

- Surface Plasmon Enhanced, Coupled and Controlled FluorescenceNo EverandSurface Plasmon Enhanced, Coupled and Controlled FluorescenceAinda não há avaliações

- 2018 - Prakash Et AlDocumento5 páginas2018 - Prakash Et AlDương Minh MẫnAinda não há avaliações

- Wu 2011Documento10 páginasWu 2011Dương Minh MẫnAinda não há avaliações

- Beet ArmywormDocumento7 páginasBeet ArmywormDương Minh MẫnAinda não há avaliações

- The Effect of Pre Germinated Brown Rice Intake On Blood Glucose and PAI 1 Levels in Streptozotocin Induced Diabetic RatsDocumento5 páginasThe Effect of Pre Germinated Brown Rice Intake On Blood Glucose and PAI 1 Levels in Streptozotocin Induced Diabetic RatsDương Minh MẫnAinda não há avaliações

- Crop Protection: Augusto Ramírez-Godoy, Gina Puentes-Peréz, Hermann Restrepo-DíazDocumento10 páginasCrop Protection: Augusto Ramírez-Godoy, Gina Puentes-Peréz, Hermann Restrepo-DíazDương Minh MẫnAinda não há avaliações

- 2015 - Hristov, Mahon, DawsonDocumento14 páginas2015 - Hristov, Mahon, DawsonDương Minh MẫnAinda não há avaliações

- Impact of surfactants on ZnO nanoparticles for solution-processed transistorsDocumento20 páginasImpact of surfactants on ZnO nanoparticles for solution-processed transistorsDương Minh MẫnAinda não há avaliações

- Diallo 2016Documento11 páginasDiallo 2016Dương Minh MẫnAinda não há avaliações

- 2013 - Nouri-Khezrabad Et AlDocumento20 páginas2013 - Nouri-Khezrabad Et AlDương Minh MẫnAinda não há avaliações

- (Chittaranjan Kole, D. Sakthi Kumar, Mariya v. Kho (B-Ok - Xyz)Documento6 páginas(Chittaranjan Kole, D. Sakthi Kumar, Mariya v. Kho (B-Ok - Xyz)Dương Minh MẫnAinda não há avaliações

- Technical Data Sheet: Colloidal Sulfur 50 %Documento2 páginasTechnical Data Sheet: Colloidal Sulfur 50 %Dương Minh MẫnAinda não há avaliações

- Costa 2013Documento8 páginasCosta 2013Dương Minh MẫnAinda não há avaliações

- Impact of surfactants on ZnO nanoparticles for solution-processed transistorsDocumento20 páginasImpact of surfactants on ZnO nanoparticles for solution-processed transistorsDương Minh MẫnAinda não há avaliações

- 2018 - Tatarchuk Et Al PDFDocumento10 páginas2018 - Tatarchuk Et Al PDFDương Minh MẫnAinda não há avaliações

- J.G.K. Coetzee ZINC 12 Zinc: 12.1 Role in Citrus ProductionDocumento2 páginasJ.G.K. Coetzee ZINC 12 Zinc: 12.1 Role in Citrus ProductionDương Minh MẫnAinda não há avaliações

- J.G.K. Coetzee Foliar Sprays: Chapter 25: Foliar Sprays © 2007 Citrus Research International (Pty) Ltd. 91Documento6 páginasJ.G.K. Coetzee Foliar Sprays: Chapter 25: Foliar Sprays © 2007 Citrus Research International (Pty) Ltd. 91Dương Minh MẫnAinda não há avaliações

- Potassium deficiency symptoms in citrus treesDocumento5 páginasPotassium deficiency symptoms in citrus treesDương Minh MẫnAinda não há avaliações

- 2018 - Tatarchuk Et Al PDFDocumento10 páginas2018 - Tatarchuk Et Al PDFDương Minh MẫnAinda não há avaliações

- 2011 - Tachikawa Et AlDocumento12 páginas2011 - Tachikawa Et AlDương Minh MẫnAinda não há avaliações

- Effect of nutrient solutions on plant growthDocumento1 páginaEffect of nutrient solutions on plant growthDương Minh MẫnAinda não há avaliações

- Crop Protection: Augusto Ramírez-Godoy, Gina Puentes-Peréz, Hermann Restrepo-DíazDocumento10 páginasCrop Protection: Augusto Ramírez-Godoy, Gina Puentes-Peréz, Hermann Restrepo-DíazDương Minh MẫnAinda não há avaliações

- Comparison of Chelated Calcium With Nano Calcium On Alleviation of Salinity Negative Effects On Tomato PlantsDocumento6 páginasComparison of Chelated Calcium With Nano Calcium On Alleviation of Salinity Negative Effects On Tomato PlantsDương Minh MẫnAinda não há avaliações

- Impact of Calcium Phosphate Nanoparticles On Rice PlantDocumento10 páginasImpact of Calcium Phosphate Nanoparticles On Rice PlantDương Minh MẫnAinda não há avaliações

- 2013 - Hsu Et Al PDFDocumento12 páginas2013 - Hsu Et Al PDFDương Minh MẫnAinda não há avaliações

- Nanoparticles: Case Studies of Their Synthesis, Properties and Biological InteractionDocumento91 páginasNanoparticles: Case Studies of Their Synthesis, Properties and Biological InteractionDương Minh MẫnAinda não há avaliações

- 2006 - Vũ Ngọc HảiDocumento4 páginas2006 - Vũ Ngọc HảiDương Minh MẫnAinda não há avaliações

- 2016 - Neaime Et AlDocumento5 páginas2016 - Neaime Et AlDương Minh MẫnAinda não há avaliações

- 2015 - Ashraf Et AlDocumento5 páginas2015 - Ashraf Et AlDương Minh MẫnAinda não há avaliações

- Rubber: ASTM D412 Tensile Properties of Vulcanized Rubber and Thermoplastic ElastomersDocumento2 páginasRubber: ASTM D412 Tensile Properties of Vulcanized Rubber and Thermoplastic ElastomersPrabhakar KambleAinda não há avaliações

- W. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFDocumento1 páginaW. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFahmed shakerAinda não há avaliações

- Curl Activator GelDocumento1 páginaCurl Activator GelNemanja NikolicAinda não há avaliações

- Safety Data Sheet: Masteremaco S 5400ciDocumento10 páginasSafety Data Sheet: Masteremaco S 5400ciSolomon AhimbisibweAinda não há avaliações

- ANTHE 2021 (Engineering) Sample PaperDocumento17 páginasANTHE 2021 (Engineering) Sample PaperDida CowernAinda não há avaliações

- ACRYREX® CM-211: Chi Mei CorporationDocumento3 páginasACRYREX® CM-211: Chi Mei CorporationPhuoc Thinh TruongAinda não há avaliações

- Collected By: Prof: Abdul Samad Mechanical Engineering Department. 2017Documento19 páginasCollected By: Prof: Abdul Samad Mechanical Engineering Department. 2017Ans ahmedAinda não há avaliações

- Contrac BloxDocumento4 páginasContrac Bloxwahyu99Ainda não há avaliações

- Chemistry, Mathematics & Physics: All India Internal Test SeriesDocumento15 páginasChemistry, Mathematics & Physics: All India Internal Test Seriesmadhav aggarwalAinda não há avaliações

- KapilDocumento69 páginasKapilPraveen SrivastavaAinda não há avaliações

- Quantum-Mechanical Aspects of The L. Pauling's Resonance Theory.Documento4 páginasQuantum-Mechanical Aspects of The L. Pauling's Resonance Theory.Bezverkhniy VolodymyrAinda não há avaliações

- Mech-HT 15.0 WS05 SolenoidDocumento16 páginasMech-HT 15.0 WS05 SolenoidAndres Felipe Salas VillalvaAinda não há avaliações

- Turton - Appb 30 37Documento8 páginasTurton - Appb 30 37asadAinda não há avaliações

- QS607 220310Documento3 páginasQS607 220310Jet ToledoAinda não há avaliações

- AJODO Eliades2006 - Orthodontic Materials Research and Applications Part 1-Current Status and Projected Future Developments in Bonding and Adhesives.Documento7 páginasAJODO Eliades2006 - Orthodontic Materials Research and Applications Part 1-Current Status and Projected Future Developments in Bonding and Adhesives.drgeorgejose7818Ainda não há avaliações

- Anderol General BrochureDocumento12 páginasAnderol General BrochureepesanoAinda não há avaliações

- A3 Classification of Elements and Periodicity in Properties MinDocumento1 páginaA3 Classification of Elements and Periodicity in Properties MinKarthikeyan LakshmananAinda não há avaliações

- Combustion in SI & CI EnginesDocumento25 páginasCombustion in SI & CI EnginesVenkatesh KabraAinda não há avaliações

- Manufacturing and Metal Working Process ClassificationDocumento5 páginasManufacturing and Metal Working Process ClassificationPeeka Prabhakara RaoAinda não há avaliações

- VAPOR AND COMBINED POWER CYCLESDocumento9 páginasVAPOR AND COMBINED POWER CYCLESzabidullahAinda não há avaliações

- Selective Laser SinteringDocumento24 páginasSelective Laser SinteringRahul GandhiAinda não há avaliações

- Materials Used in Automotive Manufacture and Material Selection Using Ashby ChartsDocumento15 páginasMaterials Used in Automotive Manufacture and Material Selection Using Ashby ChartsHanumantAinda não há avaliações

- Chap 7 PDFDocumento45 páginasChap 7 PDFSuharto Masacal AmpasoAinda não há avaliações

- Nuclear Power: Pros, Cons and FutureDocumento4 páginasNuclear Power: Pros, Cons and FutureSamarthAinda não há avaliações

- BDA30603 Tutorial 4Documento7 páginasBDA30603 Tutorial 4Firdaus JannahAinda não há avaliações