Escolar Documentos

Profissional Documentos

Cultura Documentos

Hemple Specification Sheet

Enviado por

TVP_contechDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hemple Specification Sheet

Enviado por

TVP_contechDireitos autorais:

Formatos disponíveis

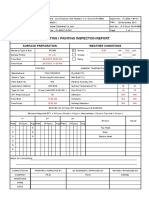

Specification sheet

Hempel (Belgium) N.V.

SF 10-01 HQ 10

Project: Con. Tech. - paintspecification hoising traverse - 17 june 2009

Area: Area size: 4688 sqm

hoisting columns (2x 174,5 m² _ 2x 70,4 _ 2x 18,84 _ 2x 29,16

Dulplex Paintsytem (zink+paint) with 80µm metallization (zinc/alu 85/15)

Surface preparation:

Oil and grease etc. to be removed by emulsion cleaning. Salts and other contamination to

be removed by high pressure fresh water hosing with surface conductivity (Bresle test)

below max 40 mg/m² NaCl. . When the surface is dry grit abrasive blasting to Sa 3 (on

metzallization areas) and Sa 2,5 (remaining area) according to ISO 8501-1:1988 with a

surface profile corresponding to Rugotest No 3 - BN10a - BN11. Removal of fine dust

need to take place by adequate vacuumcleaning in correspndence with ISO 8502-3 rating

0.

In order to avoid the risk of popping - a mist coat with a thin closed layer of the

intermediate coat (Multi-Strength 45751 can be advised, after air escaping (which take

place the first minutes after applying mistcoat) the remainder of the Multi-Strength 45751

up till the specified 200wft can be applied

Film thickness Theoretical spreading Application methods Recommended

Treated area Shade no. (micron) rate Roller Nozzle Nozzle

Product name (including quality number) % Shade Wet Dry (sqm/ltr) Brush Spray orifice pressure

HEMPADUR MULTI-STRENGTH 45753 f/c Red 50630 200 150 5.3 (X) X .021"-.023" 250 bar

HEMPATHANE HS 55610 f/c To Be Advised T.B.A 75 50 13.0 X (X) X .017"-.021" 175 bar

t/u: touch up f/c: full coat Total d.f.t. 200 X: Recommended (X): Possible

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended

D.F.T.

Recoated with 40°C 30°C 20°C 10°C 0°C -10°C

Quality no (micron) quality no Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

45753 150 55610 95 Min 22 Hrs 3 Hrs 36 Hrs 5 Hrs 72 Hrs 13 Hrs 7½ Day N/R N/R N/R N/R

Remarks and Product information see next page.

Hempel's PreSale System 2.6.16 (Build 656) User name: Hans Gonlag Quality Code:

Printed at:

Created/Last modified:

17.06.2009 21:44

17.06.2009 21:44

Department name:

BEJFG5059 Page:

TSD

1

Environment : Severe

HEMPEL

Specification sheet

Hempel (Belgium) N.V.

SF 10-01 HQ 10

Project: Con. Tech. - paintspecification hoising traverse - 17 june 2009

Area: Area size: 4688 sqm

hoisting columns (2x 174,5 m² _ 2x 70,4 _ 2x 18,84 _ 2x 29,16

Remarks:

Normal good painting practice must be followed throughout the entire painting procedure.

Product information: Mixing ratio Pot life Dry to touch Flash Application restrictions

Volume Curing volume point Min. Temp. Max. RH%

Shade no. solids % agent 20°C 20°C °C Thinner °C

HEMPADUR MULTI-STRENGTH 45753 50630 79 98750 3:1 1h 4h 27 08450 -10 90

HEMPATHANE HS 55610 T.B.A 65 97050 7:1 2h 5h 31 08080

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the best of our

knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not guarantee the accuracy,

completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and all claims arising out of or in

connection with the use of the Product as recommended above, overleaf or otherwise.

Hempel's PreSale System 2.6.16 (Build 656) User name: Hans Gonlag Quality Code:

Printed at:

Created/Last modified:

17.06.2009 21:44

17.06.2009 21:44

Department name:

BEJFG5059 Page:

TSD

2

Environment : Severe

HEMPEL

Você também pode gostar

- Startup Checklist IntroDocumento31 páginasStartup Checklist IntroTVP_contech0% (2)

- Water-Soluble Salts On Substrate - Bresle MethodDocumento5 páginasWater-Soluble Salts On Substrate - Bresle Methodjasminnee100% (1)

- Iso 8502 - 9-2001Documento14 páginasIso 8502 - 9-2001smupy_122-1Ainda não há avaliações

- Painting StandardDocumento47 páginasPainting StandardMajid DixonAinda não há avaliações

- Rice Husk Solid Fuel Boilers PDFDocumento2 páginasRice Husk Solid Fuel Boilers PDFSUNDAR BAinda não há avaliações

- SaltDocumento5 páginasSaltNhu Nguyen100% (1)

- Buna EP LanxessDocumento51 páginasBuna EP LanxessANHVUDRCAinda não há avaliações

- Saudi Aramco Painting Project APCSDocumento104 páginasSaudi Aramco Painting Project APCSsmart_onyx1792% (13)

- 000Documento32 páginas000TamerGalhoumAinda não há avaliações

- SSPC Tu 4Documento7 páginasSSPC Tu 4anoopkumarAinda não há avaliações

- Vacuum Pump DrawingDocumento8 páginasVacuum Pump DrawingChiranjeevi VijayaraghavanAinda não há avaliações

- Salt Contamination Check ISO 8502-6Documento2 páginasSalt Contamination Check ISO 8502-6Danar Tri Yurindatama0% (1)

- Pretreatment Paint TrainingDocumento143 páginasPretreatment Paint TrainingIslam Fawzy100% (1)

- Paint CharacterisationDocumento81 páginasPaint CharacterisationDivyansh Sisodia100% (1)

- Iso 8502-11-06 PDFDocumento12 páginasIso 8502-11-06 PDFEdwinMauricioMacabeo100% (1)

- Maintenence - SpecificationsDocumento38 páginasMaintenence - SpecificationsVilius BukysAinda não há avaliações

- Hempel SpecDocumento46 páginasHempel SpecLong Bui VietAinda não há avaliações

- SPEC - Shell - Qatar - Multi Disciplinary Construction 2020-09-24 15-22-16Documento53 páginasSPEC - Shell - Qatar - Multi Disciplinary Construction 2020-09-24 15-22-16RAJESHAinda não há avaliações

- TA004 - 04 Terophon 112 DB - English (Sound Deadener)Documento2 páginasTA004 - 04 Terophon 112 DB - English (Sound Deadener)rataothiago86Ainda não há avaliações

- EPICON MARINE HB Rev (1409)Documento2 páginasEPICON MARINE HB Rev (1409)Rifat AzadAinda não há avaliações

- Reem Takrouri PDF - Results PDFDocumento5 páginasReem Takrouri PDF - Results PDFريم تكروريAinda não há avaliações

- Paint - Technical Specification 2022-01...Documento1 páginaPaint - Technical Specification 2022-01...Weng Hoe ChooAinda não há avaliações

- Jotun ARAMCO SystemsDocumento6 páginasJotun ARAMCO SystemsMuneer ShaAinda não há avaliações

- Humidur FPDocumento6 páginasHumidur FPWalter LlanosAinda não há avaliações

- PDS Hempaprime Multi 500 Summer en-GBDocumento2 páginasPDS Hempaprime Multi 500 Summer en-GBFreddyAinda não há avaliações

- Ep 280 WHG PDS EngDocumento5 páginasEp 280 WHG PDS EngMajdi ShannibAinda não há avaliações

- Appendices A) WWTP HanovilleDocumento7 páginasAppendices A) WWTP HanovilleAHMEDAinda não há avaliações

- Biscon HB NT L CSPDocumento1 páginaBiscon HB NT L CSPc rkAinda não há avaliações

- Chugoku Univan NT TDS JIS K5674Documento1 páginaChugoku Univan NT TDS JIS K5674Moh. Andy Rahman HakimAinda não há avaliações

- Untitled 1Documento1 páginaUntitled 1Jishnujayan33 9747883533Ainda não há avaliações

- PDS Hempaprime Multi 500 Winter en-GBDocumento2 páginasPDS Hempaprime Multi 500 Winter en-GBFreddyAinda não há avaliações

- Seaflo Neo SL Z (1606) PDFDocumento2 páginasSeaflo Neo SL Z (1606) PDFTrịnh Minh KhoaAinda não há avaliações

- Dimensioning of POLFLAME VN: Basis DataDocumento3 páginasDimensioning of POLFLAME VN: Basis DataIrshad HussainAinda não há avaliações

- TDS 44902 Tankguard NCV N Euk GBDocumento5 páginasTDS 44902 Tankguard NCV N Euk GBzattie89Ainda não há avaliações

- Profile Requirements: 30 75 in Case of Full or Partial Blast CleaningDocumento3 páginasProfile Requirements: 30 75 in Case of Full or Partial Blast CleaningIsabelo AbaoAinda não há avaliações

- Dual Fuel Genset - Heat Recovery-1-2Documento2 páginasDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- Hex Bonde A 9394 Structi L PDFDocumento2 páginasHex Bonde A 9394 Structi L PDFFlorian Le MaoAinda não há avaliações

- Shapeshell - Steel Structure Painting Technical Specification 2020-02-10 PDFDocumento4 páginasShapeshell - Steel Structure Painting Technical Specification 2020-02-10 PDFmorisAinda não há avaliações

- Shapeshell - Steel Structure Painting Technical Specification 2020-02-10Documento4 páginasShapeshell - Steel Structure Painting Technical Specification 2020-02-10morisAinda não há avaliações

- EQ 5100 18 Rev0 PDFDocumento24 páginasEQ 5100 18 Rev0 PDFRichard PaulAinda não há avaliações

- Ea 101Documento2 páginasEa 101Najmul SaqibAinda não há avaliações

- Fibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Documento1 páginaFibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Luis Alberto GutiérrezAinda não há avaliações

- TDS MD en 5402C Epicon Finish HBDocumento1 páginaTDS MD en 5402C Epicon Finish HBcelescopitoAinda não há avaliações

- MULTI-V - INDOOR - 36k-48k - Common Exploded - View 2015.11.11 EU and LATDocumento8 páginasMULTI-V - INDOOR - 36k-48k - Common Exploded - View 2015.11.11 EU and LATfhelfenstellerAinda não há avaliações

- BlastPainting Report R.1Documento1 páginaBlastPainting Report R.1คุณพ่อน้อง บิ๊กบอสAinda não há avaliações

- Paint Schedule HELIDECKDocumento24 páginasPaint Schedule HELIDECKAsongwe HansAinda não há avaliações

- Japan Bannoh 1500Documento2 páginasJapan Bannoh 1500oleksandr shevchenkoAinda não há avaliações

- RE10 Injection ArgucardDocumento2 páginasRE10 Injection Argucardomar cisséAinda não há avaliações

- Ace Multi Axes Systems Ltd. Coating Inspection ReportDocumento6 páginasAce Multi Axes Systems Ltd. Coating Inspection ReportCorrosion FactoryAinda não há avaliações

- CONTRACTING OFFICE COMPANY LTD - (CONTRACO) Saudi A 2020-05-31 10-54-23Documento68 páginasCONTRACTING OFFICE COMPANY LTD - (CONTRACO) Saudi A 2020-05-31 10-54-23Ramil LazAinda não há avaliações

- Begg Cousland Envirotec - Oil & Gas - 2017Documento8 páginasBegg Cousland Envirotec - Oil & Gas - 2017Wili Nur RahmanAinda não há avaliações

- HiMSEN Technical Circular - Information For Combusion Diagram (Documento6 páginasHiMSEN Technical Circular - Information For Combusion Diagram (Sergey shapovalovAinda não há avaliações

- 5913i Seaflo Neo-S Premium (2111)Documento2 páginas5913i Seaflo Neo-S Premium (2111)S M HasanAinda não há avaliações

- Technical Data Sheet: Epoguard EnamelDocumento3 páginasTechnical Data Sheet: Epoguard Enameltrường phạmAinda não há avaliações

- Thebault Dop01 Teboply Ext GBDocumento2 páginasThebault Dop01 Teboply Ext GBDumitrache IulianAinda não há avaliações

- Dehniso Spacers Accessories: Dist 16 3000 GFK (106 125)Documento1 páginaDehniso Spacers Accessories: Dist 16 3000 GFK (106 125)beimar_nalAinda não há avaliações

- Specification Sheet: Project: AreaDocumento15 páginasSpecification Sheet: Project: AreaWildan RAinda não há avaliações

- Calculation MOLDocumento2 páginasCalculation MOLIrsyad RosyidiAinda não há avaliações

- Paints For ShipsDocumento2 páginasPaints For ShipssachinAinda não há avaliações

- 001.17056.000028-AK008-01 1st Stage PreheaterDocumento5 páginas001.17056.000028-AK008-01 1st Stage PreheaterQuy RomAinda não há avaliações

- Ep 150 PDS EngDocumento4 páginasEp 150 PDS EngMajdi ShannibAinda não há avaliações

- DECIBEL InterimsverfahrenDocumento8 páginasDECIBEL InterimsverfahrenAbdelKarim BaariniAinda não há avaliações

- HIT-HY 150 Injection Mortar With RebarDocumento8 páginasHIT-HY 150 Injection Mortar With RebarNguyễn AnhAinda não há avaliações

- Product Specifications: HBX-6511DS-T10MDocumento3 páginasProduct Specifications: HBX-6511DS-T10MRaluca Roxana SzaszAinda não há avaliações

- Etp Ticknical Data ReportDocumento18 páginasEtp Ticknical Data Reportshaik abidAinda não há avaliações

- L-R Intercambiador Coraza y Tubos PDFDocumento1 páginaL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioAinda não há avaliações

- Supraschwank UK DE 0309Documento2 páginasSupraschwank UK DE 0309Cassiano OlveiraAinda não há avaliações

- Техническая спецификация S21-IG10-33-TK-SteamDocumento1 páginaТехническая спецификация S21-IG10-33-TK-SteamArtur AsaturyanAinda não há avaliações

- 240-05-DTS-XXX Flare StackDocumento18 páginas240-05-DTS-XXX Flare StackEmran NazirAinda não há avaliações

- 2400-05-DTS-005cooling TowerDocumento19 páginas2400-05-DTS-005cooling TowerEmran NazirAinda não há avaliações

- Noise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionNo EverandNoise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionAinda não há avaliações

- Full Text 01Documento86 páginasFull Text 01TVP_contechAinda não há avaliações

- Rules: For The Cargo Handling Gear of Sea-Going ShipsDocumento110 páginasRules: For The Cargo Handling Gear of Sea-Going ShipsTVP_contechAinda não há avaliações

- Wpiea2019275 Print PDFDocumento34 páginasWpiea2019275 Print PDFTVP_contechAinda não há avaliações

- Collection: of The Rules For ContainersDocumento233 páginasCollection: of The Rules For ContainersTVP_contechAinda não há avaliações

- Stasinopoulos P. Return On Investment in Newly Built and Second Hand Vessels and Portfolio Risk Management in Shipping The Case of Equity Financed BuDocumento133 páginasStasinopoulos P. Return On Investment in Newly Built and Second Hand Vessels and Portfolio Risk Management in Shipping The Case of Equity Financed BuTVP_contechAinda não há avaliações

- Econometric Modelling of Newbuilding and Secondhand Ship PricesDocumento42 páginasEconometric Modelling of Newbuilding and Secondhand Ship PricesTVP_contechAinda não há avaliações

- (20837429 - Polish Maritime Research) Group-Bay Stowage Planning Problem For Container ShipDocumento8 páginas(20837429 - Polish Maritime Research) Group-Bay Stowage Planning Problem For Container ShipTVP_contechAinda não há avaliações

- PacificAdventurer AtsbDocumento82 páginasPacificAdventurer AtsbTVP_contechAinda não há avaliações

- 1-1/4" Diameter Cable: M40 SeriesDocumento3 páginas1-1/4" Diameter Cable: M40 SeriesTVP_contechAinda não há avaliações

- Ver It Cal HeaveDocumento15 páginasVer It Cal HeaveTVP_contechAinda não há avaliações

- Yixing Tinic Shipping Accessories Co.,LtdDocumento62 páginasYixing Tinic Shipping Accessories Co.,LtdTVP_contechAinda não há avaliações

- Mechan GalvanizingDocumento1 páginaMechan GalvanizingTVP_contechAinda não há avaliações

- BBE15 EP5 Instar GE PowerDocumento37 páginasBBE15 EP5 Instar GE PowerTVP_contechAinda não há avaliações

- Breakbulk Europe: Benefitting From The Middle East's Drive To DiversifyDocumento25 páginasBreakbulk Europe: Benefitting From The Middle East's Drive To DiversifyTVP_contechAinda não há avaliações

- FinDocumento3 páginasFinTVP_contechAinda não há avaliações

- Marine Department Notice No. 135 of 2005Documento1 páginaMarine Department Notice No. 135 of 2005TVP_contechAinda não há avaliações

- Coating StandartDocumento15 páginasCoating StandartJandy PratamaAinda não há avaliações

- Surface Preparation For Coating. Good Practice in Corrosion ControlDocumento34 páginasSurface Preparation For Coating. Good Practice in Corrosion ControlLla Vvi InniaAinda não há avaliações

- Kit 138 New Bresle Salt PDFDocumento2 páginasKit 138 New Bresle Salt PDFDian FaraAinda não há avaliações

- Iso 08502-2-2017Documento14 páginasIso 08502-2-2017Francisco Raro AlmuzaraAinda não há avaliações

- Bresle Chloride Test KitDocumento2 páginasBresle Chloride Test KitManoj SarafAinda não há avaliações

- Bresle Test Kit PDFDocumento4 páginasBresle Test Kit PDFmuthukumarAinda não há avaliações

- ISO 8502-6 Salt TestDocumento12 páginasISO 8502-6 Salt TestNauthizAinda não há avaliações

- How02 V01uab12 Aqa023 C02Documento64 páginasHow02 V01uab12 Aqa023 C02Okinawa Teak100% (1)

- F941-99 (2013) Standard Practice For Inspection of Marine Surface Preparation and Coating ApplicationDocumento3 páginasF941-99 (2013) Standard Practice For Inspection of Marine Surface Preparation and Coating ApplicationislamakthamAinda não há avaliações

- Iso 8502-9Documento13 páginasIso 8502-9DARYONO sudaryonoAinda não há avaliações

- Validating Equivalence To ISO 8502-9 On Measurement of Levels of Water Soluble Salts Using Candidate NST Center Salt Test StripDocumento10 páginasValidating Equivalence To ISO 8502-9 On Measurement of Levels of Water Soluble Salts Using Candidate NST Center Salt Test StripFantasma Do CaribeAinda não há avaliações

- Hold TightDocumento2 páginasHold Tightsaubu8xAinda não há avaliações

- AN 400 Part 2 - Corrosion Protection of Purchased PartsDocumento15 páginasAN 400 Part 2 - Corrosion Protection of Purchased PartschristopherAinda não há avaliações

- Procedure For Salt TestDocumento27 páginasProcedure For Salt TestLâm ThanhAinda não há avaliações

- Airblast Coating Inspection Equipment - The Guide - LR PDFDocumento20 páginasAirblast Coating Inspection Equipment - The Guide - LR PDFMohsen Halweni100% (2)

- Bresle Test Kit - Proper ProcedureDocumento4 páginasBresle Test Kit - Proper ProcedureMuthuKumarAinda não há avaliações

- M-501 Rev 5 Surface Prep & CoatingDocumento24 páginasM-501 Rev 5 Surface Prep & Coatingmareepierre003Ainda não há avaliações

- Iso 8502 6 2006Documento9 páginasIso 8502 6 2006Evan YushavaAinda não há avaliações