Escolar Documentos

Profissional Documentos

Cultura Documentos

Kamra Pumps

Enviado por

TariqMahmood0 notas0% acharam este documento útil (0 voto)

26 visualizações5 páginasPUMP PROPOSAL

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoPUMP PROPOSAL

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

26 visualizações5 páginasKamra Pumps

Enviado por

TariqMahmoodPUMP PROPOSAL

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 5

=

xsB 0!

50 Hz

UPA 200, 200B, 250C

Applications

Handling lean or slightly contaminated water.

= in general water supply systems,

= inirigation and spray inigation systems,

~ inpressure boosting systems,

~ in emergency water supply systems,

~ in installations for lowering and maintaining ground water

levels

Also used in

= mining,

~ sprinkler installations,

= fountains, ete.

Permissible sand content inthe uid handled: 50 gim®

‘Aso suitable for aggressive seawater supplied In material

variant 63 (duple).

Operating Data

Capacity up to. 330 mh (92 I/s)

Head H upto 460 m

‘Temperature offud handled t) upto =80°C

Speed n= 2900 rpm

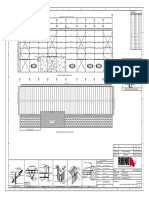

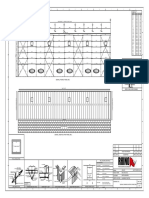

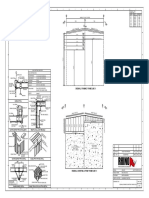

Design

Single or multistage, single-entry centrifugal pumps in

fing-section design. Mixed flow hydraulic systems with

impellers that can be turned down, Stage casings connected by

means of studs. Suction casing fitted between pump and motor.

Suction casing equipped with strainer to protect the pump from

‘coarse particles in the fui.

Pumps with non-return valve or connection branch on option.

Both models available with either threaded or flanged end

Particularly suitable for vertical installation in narrow deep

wells,

Designation (Example)

UPA 200 8 - 808/54

‘ype series. ———_|

Minimum well diameter (mm)

Design status

Capacity (m*sh)

Impeller material")

material variants other than base variant

(eg B= Bronze)

Number of stages

Reduced impeller diameters

Ags 19 UPA 2008 on

Certification

Quality management certfed to ISO 9001

Submersible Borehole Pumps

for Well Diameters

of 200 mm (8 inches)

and of 250 mm (10 inches)

Product Features

= Very sturdy design

~ Suitable for installation in narrow deep wells

= High efficiency

= Motor designed for maximum pump output

= Low noise level

= For vertical or horizontal installation

= Check vaive protected against blocking

~ Precfiled motor; no risk of contamination of the

pumped water

87

KSB 6) 50 Hz UPA 200, 200B, 250C

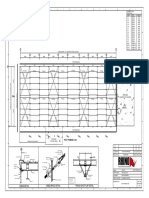

Selection Chart (Ranges on Otter) n= 2900 rpm

110 180 200 300 400 500600 US.gpm 1000 1400

100 190 200 300 400-500-600 Imp.gpm. 10001200

500

UPA 250C-150 =

400 UPA 2500-120

‘UPA 200-14

300: 1006

UPA 2008-80 800

eee n UPA 2506-250

200

600

180 500

a 400

100

300

80 H

ft

ro 200

50

180

40

a 100

80

20

©

16. £0

4

10.

20

8.

24 30 40 50 60 80 100 150 200 Qmh 300 340

0

bs UBA 2506-120 | UPA 250¢-150 | UPA 2500-250

80

%

74

60

230 45080 80 200 mm 300 340

8 0 15 2 30 4 5060 Oils 80

Note:

The diagram shows the AQ range on offer. The pumps can be offered for any duty point within this range. The AQg operating

ranges of the individual pump sizes are given in the characteristic curves for diffrent stage numbers on the following pages.

Selection charts or performance curves for UPA in materlal variant C3 (duplex) on request only.

58

xse b,) 50 Hz UPA 200, 200, 2506

Material Variants - UPA 200 Thweadedend Flanged end

‘Component G B T 751

wine et! (UB

Casing Cast iron Bronze potest

dtte30) (ccabox-Gs) 2 11

Impeller Glass fibre reinforced NORYL (PPO) 520.01— sat

Diffuser Glass fibre reinforced NORYL (PPO) 550.01 1-39.21

‘Shaft Cr steel (1.4021) | CrNiMo steel (1.4462) 156— 752.12

Wear ring ‘Alo steel (14401) — isn

Screws,

Cio ste sis

bots and

nuts Leathe — 932.01

T DIN mat code: GG20 2) DIN mat. code: GuSnt0 900.01— 529

ma en

Bearings / Lubrication 408.01“ IN :

Plain bearing in the end stage, lubricated by the fluid handled. _|hes 81-3922

‘Asal thrusts balanced by a trust bearing inthe motor. 25

ee 520.01

Direction of Rotation of the Pump ma —10 "

Clockwise rotation (when looking atthe drive shat end) mE 940.0

an

; on a

Pump End (Discharge Nozzle) H an

UPA 200 - 11 + 14: internal thread G 3” (DN 80). 502 = —195

Flanged end with adapter aso avalable (see Accessories). 55,91!

Variants Available on Request LAR {

= Pumps with langed end Vv ——s40.02

Bumps with connection branch with either threaded or 904.01 }

ftanged end \ | — ss

wt N

500,02 —

404.02 iN

901.01— 4

$20.03

HD seas

PartNo

Example: UPA 200 - 14/3 with UMA 150D ../2.

Description

“08/108 | Suction casing / Stage casing

143__| Suction strainer

171 [Diffuser

2i1__ [Pump shaft

232 | Clockwise impeller

503 [Impeller wear ring

'529/545 | Bearing sleeve / Bearing bush

751___|Valve body

349__| Sleeve coupling

917 __[Tiebot

59

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Week 02 - Geology Earth's Interior & Branches of GeologyDocumento28 páginasWeek 02 - Geology Earth's Interior & Branches of GeologyTariqMahmoodAinda não há avaliações

- Week 01 - Introduction & Importance of Geology in Civil EngineeringDocumento26 páginasWeek 01 - Introduction & Importance of Geology in Civil EngineeringTariqMahmoodAinda não há avaliações

- Hassan AssignmentDocumento4 páginasHassan AssignmentTariqMahmoodAinda não há avaliações

- Special Stipulations NUTECH UniversityDocumento2 páginasSpecial Stipulations NUTECH UniversityTariqMahmoodAinda não há avaliações

- Axpert VM IV - Ficha TécnicaDocumento1 páginaAxpert VM IV - Ficha TécnicaTariqMahmoodAinda não há avaliações

- Lahore Test ReportsDocumento4 páginasLahore Test ReportsTariqMahmoodAinda não há avaliações

- Ashfaq C.VDocumento4 páginasAshfaq C.VTariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 4 4Documento1 páginaRB A225 Approval Rev 1 - 4 4TariqMahmoodAinda não há avaliações

- PRTCL PrintDupBill1Documento1 páginaPRTCL PrintDupBill1TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 3 3Documento1 páginaRB A225 Approval Rev 1 - 3 3TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 5 5Documento1 páginaRB A225 Approval Rev 1 - 5 5TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 2 2Documento1 páginaRB A225 Approval Rev 1 - 2 2TariqMahmoodAinda não há avaliações

- Detailed Price ComparisonDocumento1 páginaDetailed Price ComparisonTariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 1 1Documento1 páginaRB A225 Approval Rev 1 - 1 1TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 11 11Documento1 páginaRB A225 Approval Rev 1 - 11 11TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 9 9Documento1 páginaRB A225 Approval Rev 1 - 9 9TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 10 10Documento1 páginaRB A225 Approval Rev 1 - 10 10TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 6 6Documento1 páginaRB A225 Approval Rev 1 - 6 6TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 12 12Documento1 páginaRB A225 Approval Rev 1 - 12 12TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 8 8Documento1 páginaRB A225 Approval Rev 1 - 8 8TariqMahmoodAinda não há avaliações

- ID WBS Task Mode Task Name Duration Start 1 2 3Documento8 páginasID WBS Task Mode Task Name Duration Start 1 2 3TariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 7 7Documento1 páginaRB A225 Approval Rev 1 - 7 7TariqMahmoodAinda não há avaliações

- Petition Under 199Documento8 páginasPetition Under 199TariqMahmoodAinda não há avaliações

- Kamram Project Nov 2017Documento2 páginasKamram Project Nov 2017TariqMahmoodAinda não há avaliações

- Mall of Sargodha: RCC Pipe Design For Disposal From Site 3 To OutletDocumento5 páginasMall of Sargodha: RCC Pipe Design For Disposal From Site 3 To OutletTariqMahmoodAinda não há avaliações

- Before The Registerar Cooperatives Punjab LahoreDocumento3 páginasBefore The Registerar Cooperatives Punjab LahoreTariqMahmoodAinda não há avaliações

- RB A225 Approval Rev 1 - 13 13Documento1 páginaRB A225 Approval Rev 1 - 13 13TariqMahmoodAinda não há avaliações

- RB A225 APPROVAL REV 1 - 14 EndDocumento1 páginaRB A225 APPROVAL REV 1 - 14 EndTariqMahmoodAinda não há avaliações

- Mind.: Lachesis Mutus Bushmaster or Surucucu (Lachesis)Documento2 páginasMind.: Lachesis Mutus Bushmaster or Surucucu (Lachesis)TariqMahmoodAinda não há avaliações

- Ghouri VIP ModelDocumento1 páginaGhouri VIP ModelTariqMahmoodAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)