Escolar Documentos

Profissional Documentos

Cultura Documentos

Nextgen Batteries

Enviado por

Nitin BiradarDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Nextgen Batteries

Enviado por

Nitin BiradarDireitos autorais:

Formatos disponíveis

news & views

FuEL CELLS

Engineering the next generation

A silicon-based membrane for fuel cells offers significant advantages over Nafion-based membranes.

Steven K. Buratto

P

roton-exchange membrane (PEM) a e– to fabricate a fuel cell incorporating an

fuel cells, which convert chemical inorganic membrane with performance

energy into electricity using an superior to that of a Nafion-based PEM

electrochemical cell (Fig. 1a), could be fuel cell over the entire range of relative

Anode H2

used as efficient power sources, offering humidity. The porous silicon-based

high power density and low environmental membrane showed proton conductivity

impact. An essential component of PEM H+ three times higher than that of Nafion

such fuel cells is the membrane. This O2 at high relative humidity (where the

Cathode

is a quintessential nanomaterial, with H2O conductivity of Nafion is highest), and

hydrophilic pores of around 10 nm in size conductivity an astounding 100 times higher

through which protons are transported at 20% relative humidity.

(Fig. 1b). The most common PEM material The fabrication of these silicon

is the polymer electrolyte Nafion, which b PEM cross-section membranes can also be readily integrated

is composed of a hydrophobic Teflon H+ into silicon-processing infrastructure,

backbone and side chains terminated with which can be easily scaled up with the

hydrophilic sulphonic acid (SO3H) groups. potential to lower the overall cost of

In a Nafion film, the hydrophilic pores form 5 nm production. Furthermore, nearly every

by phase separation of the side chains from processing step can be tuned. The pore

the polymer backbone. The performance size and structure can be controlled by

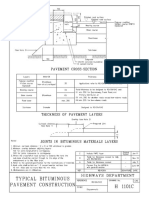

of the proton-conducting channels in Figure 1 | Proton-exchange membranes. adjusting the etching conditions, such as

these films is strongly dependent on a, Schematic of a PEM fuel cell. At the anode, the current density or etchant concentration.

the environmental conditions. At high fuel (hydrogen gas, methanol or formic acid) is The acidity of the pores can be controlled

temperature and low relative humidity, broken down to produce protons, which are then by changing the composition of the

the proton-conducting channels shrink transported through the membrane to the cathode self-assembled monolayer. For example,

and the conductivity decreases markedly. where they react with oxygen to produce water. by introducing electron-withdrawing

This means that under high-temperature The electrons transferred in the reaction carry the groups such as fluorine, it should be

conditions — where the catalysts in the electric current and drive the load, represented possible to increase the overall acidity of

electrodes perform at their best — the here by a light bulb. b, Schematic cross-section the –SO3H groups and further enhance

membrane performs at its worst. Therefore, of a PEM. The proton-conducting channels are the conductivity.

to optimize the performance of fuel cells depicted in white. Finally, it is worth noting that Nafion

it is useful to design a membrane with materials have been used in fuel cells

high conductivity at high temperature and for over 40 years (ref. 5). They have

low humidity. to O2 and washing in deionized water; been optimized and re-optimized many

Writing in Nature Nanotechnology, the hydroxylated surface is then treated times, which has led to considerable

Saeed Moghaddam, Mark Shannon and with HS–(CH2)3–Si–(OCH3)3 to produce a improvements in the performance

colleagues1 at the University of Illinois self-assembled monolayer; and finally the of Nafion-based devices. It is thus

at Urbana-Champaign, Sandia National terminal –SH groups are oxidized to –SO3H conceivable that optimization of the porous

Laboratories, Surface Measurement groups. To ensure high proton conductivity silicon membrane will lead to similar

Systems Ltd and the University of New at low humidity, the researchers encapsulate enhancements in performance of this next-

Mexico report a new silicon-based proton- each side of the membrane with a thin generation PEM for fuel cells. ❐

exchange membrane with high proton (2 nm) layer of hydrophilic silica. The silica

conductivity over a wide range of relative layer effectively shrinks the size of the Steven K. Buratto is in the Department of Chemistry

humidity and temperature. The PEM is pores at the membrane surface and keeps and Biochemistry, University of California, Santa

constructed by first preparing a bulk silicon the larger pores from drying out as the Barbara, California 93106, USA.

membrane using standard processing humidity drops. The resulting membrane e‑mail: buratto@chem.ucsb.edu

techniques. The pore structure is then is mechanically robust, the pore volume is

formed by etching the silicon membrane independent of temperature and relative References

using hydrofluoric acid, resulting in ordered humidity, and the proton conductivity 1. Moghaddam S. et al. Nature Nanotech. 5, 230–236 (2010).

pores with sizes in the range 7–10 nm. remains constant over a wide range of 2. Gold, S., Chu, K.-L., Lu, C., Shannon, M. A. & Mase, R. I.

J. Power Sources 135, 198–203 (2004).

Once the pore structure is produced, temperature and relative humidity.

3. Pichonat, T. & Gauthier-Manuel, B. J. Power Sources

the surface inside the pores is rendered The preparation of proton-exchange 154, 198–201 (2006).

acidic using three chemical processing membranes from inorganic materials 4. Athens, G. L., Ein-Eli, Y. & Chmelka, B. F. Adv. Mater.

steps: the hydrogen-terminated surface is has been demonstrated before2–4, but 19, 2580–2587 (2007).

hydroxylated by exposing the membrane Moghaddam and colleagues are the first 5. Devanathan, R. Energy Environ. Sci. 1, 101–119 (2008).

176 nature nanotechnology | VOL 5 | MARCH 2010 | www.nature.com/naturenanotechnology

© 2010 Macmillan Publishers Limited. All rights reserved

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Komposit UHMWPE Sebagai Alternatif Bantalan Rel Kereta Api: Abel Evan, Alia Kristika, Farid Mulia LatiefDocumento11 páginasKomposit UHMWPE Sebagai Alternatif Bantalan Rel Kereta Api: Abel Evan, Alia Kristika, Farid Mulia LatiefAlia KristikaAinda não há avaliações

- Module 1.6 Settling and SedimentationDocumento37 páginasModule 1.6 Settling and SedimentationLong EAinda não há avaliações

- UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161Documento4 páginasUCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161sriatul2006Ainda não há avaliações

- Compositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanDocumento13 páginasCompositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanNatalia KovalovaAinda não há avaliações

- POUR CARD New FormatDocumento5 páginasPOUR CARD New FormatCivil Site 1775% (4)

- (Lec6) Phase EquilibriaDocumento52 páginas(Lec6) Phase EquilibriadinurjAinda não há avaliações

- Dievar D20140715 PDFDocumento16 páginasDievar D20140715 PDFRizal IephoAinda não há avaliações

- Analisis Cacat Las Incomplete Fusion Dan Retak Memanjang Pada Waterwall Tube Boiler PLTU Paiton Unit 1Documento11 páginasAnalisis Cacat Las Incomplete Fusion Dan Retak Memanjang Pada Waterwall Tube Boiler PLTU Paiton Unit 1Mursidil KamilAinda não há avaliações

- Lecture-Unit 7 Chemical EnergeticsDocumento5 páginasLecture-Unit 7 Chemical EnergeticsKemoy FrancisAinda não há avaliações

- 2 Open ChannelDocumento1 página2 Open ChannelAhmed NabilAinda não há avaliações

- Wearing Coat ThicknessDocumento1 páginaWearing Coat ThicknessanjanaAinda não há avaliações

- Dust Control Handbook (Osha) - CompleteDocumento214 páginasDust Control Handbook (Osha) - CompleteRaul SilanesAinda não há avaliações

- SXK New Price ListDocumento5 páginasSXK New Price ListidchandraAinda não há avaliações

- What Is Column Chromatography?Documento4 páginasWhat Is Column Chromatography?rajeev KumarAinda não há avaliações

- DVS Technical Codes On Plastics Joining TechnologiesDocumento11 páginasDVS Technical Codes On Plastics Joining TechnologiesjavierAinda não há avaliações

- Weld Metal CertificateDocumento1 páginaWeld Metal CertificatePhương Do QuangAinda não há avaliações

- ArtofWoodworking Porch SwingDocumento8 páginasArtofWoodworking Porch SwingsalulaiAinda não há avaliações

- Experiments To WriteDocumento53 páginasExperiments To WriteSUMAIRA ALTAFAinda não há avaliações

- Smith Industries WaterBath Indirect Heater PDFDocumento29 páginasSmith Industries WaterBath Indirect Heater PDFcassindromeAinda não há avaliações

- 110411020Documento6 páginas110411020nishantk93Ainda não há avaliações

- "Grating" - Grating Analysis / Design: Program DescriptionDocumento32 páginas"Grating" - Grating Analysis / Design: Program DescriptionJuan PulidoAinda não há avaliações

- Eng SS Tec-138-702 AaDocumento34 páginasEng SS Tec-138-702 AaZorbanfrAinda não há avaliações

- Mathalino: E N W S G S V V V V V W W W D Γ Γ Γ Γ Γ Γ Γ Γ Ll Pl Li Pi GiDocumento8 páginasMathalino: E N W S G S V V V V V W W W D Γ Γ Γ Γ Γ Γ Γ Γ Ll Pl Li Pi GiLovely Joy ArdanielAinda não há avaliações

- SECTION 05530 Gratings Rev 1Documento17 páginasSECTION 05530 Gratings Rev 1Mohsin ShaikhAinda não há avaliações

- CIVL311 - CIVL 911 - 2023 - Week 5 - Design of Columns and Walls - 4 Slides Per PageDocumento19 páginasCIVL311 - CIVL 911 - 2023 - Week 5 - Design of Columns and Walls - 4 Slides Per PageAsfin HaqueAinda não há avaliações

- Steel Connections Show Final Version 20-6-2008 ModifiedDocumento76 páginasSteel Connections Show Final Version 20-6-2008 ModifiedyahAinda não há avaliações

- Thermal Design Analysis of A Liquid Hydrogen VesselDocumento9 páginasThermal Design Analysis of A Liquid Hydrogen Vessel이경률Ainda não há avaliações

- Major ProjectsDocumento80 páginasMajor ProjectslisahunAinda não há avaliações

- Orsat ApparatusDocumento7 páginasOrsat ApparatusTejas Desai100% (1)

- Pip Vesv1003-2014Documento9 páginasPip Vesv1003-2014d-fbuser-93320248Ainda não há avaliações