Escolar Documentos

Profissional Documentos

Cultura Documentos

6.0 Transportation System in High-Rise Building: PSMZA Course Note (Chapter 6)

Enviado por

syakirohTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

6.0 Transportation System in High-Rise Building: PSMZA Course Note (Chapter 6)

Enviado por

syakirohDireitos autorais:

Formatos disponíveis

PSMZA Course Note (Chapter 6)

6.0 TRANSPORTATION SYSTEM IN HIGH-RISE BUILDING

The high-rise building is generally defined as one that is taller than the maximum height

which people are willing to walk up; it thus requires mechanical vertical transportation. The

building or structure used as a residential and/or office building. In some areas they may be

referred to as "MDU" standing for "Multi Dwelling Unit". High-rise buildings became possible

with the invention of the elevator (lift) and cheaper, more abundant building materials. The

materials used for the structural system of high-rise buildings are reinforced concrete and

steel. Most style skyscrapers have a steel frame, while residential blocks are usually

constructed of concrete. There is no clear definition of any difference between a tower block

and a skyscraper, although a building with fifty or more storeys is generally considered a

skyscraper.

High-rise structures pose particular design challenges for structural and geotechnical

engineers, particularly if situated in a seismically active region or if the underlying soils have

geotechnical risk factors such as high compressibility or bay mud. They also pose serious

challenges to firefighters during emergencies in high-rise structures. New and old building

design, building systems like the building standpipe system, HVAC systems (heating,

ventilation and air conditioning), fire sprinkler system and other things like stairwell and

elevator evacuations pose significant problems.

6.1 Types and Function of Transportation System In High-Rise Building

Transportation systems form integral building blocks for a modern society. Efficient and

safe movement of people and goods ensures a thriving economy and provides for an

improved quality of life. Because transportation systems are interrelated with many other

activities, the challenges of creating and managing transportation systems must be addressed

in an interdisciplinary manner.

There are two types transportation in high-rise building; it’s vertical and horizontal

movement. Vertical and horizontal transportation means that transportation that is used to

transport people and goods from one level to another for example vertical, and one point to

another same level point such as horizontal. The used of this transportation will save time and

energy of human being in our everyday life.

Other than that, it is also useful and convenient especially to elderly and people who are

lugged down by their shopping load or luggage. This type of transportations can be found in

various office buildings, shopping complexes, airport terminal, and many more. There are

various types of vertical and horizontal transportations, some may only serve the purpose of

transporting, and others are installed as part of the aesthetic value, for example in exhibition

halls, zoos, museum, and many more.

For vertical transportation consists of elevator and escalator, while for horizontal is

travelator or walkway. This transportation is a slow moving conveyor mechanism that

transports people, across a horizontal or inclined plane, over a short distance.

6.2 Escalator

An escalator is a moving staircase a conveyor transport device for carrying people

between floors of a building. The device consists of a motor-driven chain of individual, linked

steps that move up or down on tracks, allowing the step treads to remain horizontal.

Escalators are used around the world to move pedestrian traffic in places where elevators

would be impractical. Principal areas of usage include department stores, shopping malls,

airports, transit systems, convention centers, hotels, arenas, stadiums and public buildings.

Ver. 1 (MSH-Jun2013): CC608 Building Services 1

PSMZA Course Note (Chapter 6)

Figure 6.1: Moving staircase transform

6.2.1 The Advantages and Disadvantages of Escalator

Escalators, like moving walkways, are often powered by constant-speed alternating

current motors and move at approximately 0.3 - 0.6 m per second. The typical angle of

inclination of an escalator to the horizontal floor level is 30 degrees with a standard

rise[clarification needed] up to about 18 m. Modern escalators have single-piece aluminum or

stainless steel steps that move on a system of tracks in a continuous loop. There are the

advantages and disadvantages when use this transportation, it’s:

i. The advantages

a. Have the capacity to transport large number of people at shorter time.

b. Faster mode of transportation for short vertical distances.

c. Can be placed/substituted as normal staircase even during malfunction.

d. No waiting internal except during heavy traffic.

e. May be weather – proved for outdoor use.

f. Power – driven, continuously moving staircase.

g. Moves at a constant speed at approximately 0.3-0.6m per second with a standard

rise up to about 18m.

ii. The Disadvantages

a. Only convenient for short vertical distance, better to use lifts for lengthier vertical

distance

b. Takes up space to install

c. Higher risk of injuries

6.2.2 Design and Layout Consideration of Escalator

Escalators are required to have moving handrails that keep pace with the movement of

the steps. This helps riders steady themselves, especially when stepping onto the moving

stairs. Occasionally, a handrail will move at a slightly different speed from the steps, causing it

to "creep" slowly forward or backward relative to the steps. Riders may find this effect

disconcerting and this problem should be fixed.

Escalators have three typical configuration options

i. Parallel (up and down escalators side by side or separated by a distance)

ii. Crisscross (minimizes space requirements by "stacking" escalators that go in one

direction)

iii. Multiple parallel (two or more escalators together that travel in one direction next to

one or two escalators)

iv. Spiral (develop more comfortable public environments for humankind and a

pioneering technology)

Ver. 1 (MSH-Jun2013): CC608 Building Services 2

PSMZA Course Note (Chapter 6)

Figure 6.2: Parallel escalator Figure 6.3: Multiple parallel escalator

Figure 6.4: Spiral escalator Figure 6.5: Crisscross escalator

The direction of escalator movement (up or down) can be permanently set, or be

controlled by personnel according to the predominant flow of the crowd, or be controlled

automatically. In some setups, direction is controlled automatically by whoever arrives first,

whether at the bottom or at the top (the system is programmed so that the direction is not

reversed while a passenger is on the escalator). A number of factors affect escalator design,

including:

i. Physical requirements

Physical factors like the vertical and horizontal distance to be spanned must be

considered. These factors will determine the pitch of the escalator and its actual

length. The ability of the building infrastructure to support the heavy components is

also a critical physical concern.

ii. Location

Location is important because escalators should be situated where they can be easily

seen by the general public. In department stores, customers should be able to view

the merchandise easily.

Ver. 1 (MSH-Jun2013): CC608 Building Services 3

PSMZA Course Note (Chapter 6)

iii. Traffic patterns

Up and down escalator traffic should be physically separated and should not lead into

confined spaces. Traffic patterns must also be anticipated in escalator design. In

some buildings, the objective is simply to move people from one floor to another, but

in others there may be a more specific requirement, such as funneling visitors

towards a main exit or exhibit. The number of passengers is important because

escalators are designed to carry a certain maximum number of people.

For example, a single-width escalator traveling at about 0.46 m per second can move

an estimated 170 persons per five minute period. The carrying capacity of an

escalator system must match the expected peak traffic demand, presuming that

passengers ride single file. This is crucial for applications in which there are sudden

increases in the number of riders. For example, escalators at stations must be

designed to cater for the peak traffic flow discharged from a train, without causing

excessive bunching at the escalator entrance

iv. Safety considerations

Escalators help in controlling traffic flow of people. For example, an escalator to an

exit effectively discourages most people from using it as an entrance, and may

reduce security concerns. Similarly, escalators often are used as the exit of airport

security checkpoints. Such an egress point would generally be staffed to prevent its

use as an entrance, as well. It is preferred that staircases be located adjacent to the

escalator if the escalator is the primary means of transport between floors. It may also

be necessary to provide an elevator lift adjacent to an escalator for wheelchairs and

disabled persons.

v. Aesthetic preferences

Consideration should be given to the aesthetics of the escalator. The architects and

designers can choose from a wide range of styles and colors for the handrails and

balustrades.

6.2.3 Escalator Component

Escalator is a stairway whose steps move continually on a circulating belt or simply they

are the moving stairs. An electrical services engineer should also know something about

escalator. The main component an escalator:

i. Landing platforms

These two platforms house the curved sections of the tracks, as well as the gears

and motors that drive the stairs. The top platform contains the motor assembly and

the main drive gear, while the bottom holds the step return idler sprockets. These

sections also anchor the ends of the escalator truss. In addition, the platforms contain

a floor plate and a comb plate. The floor plate provides a place for the passengers to

stand before they step onto the moving stairs.

This plate is flush with the finished floor and is either hinged or removable to allow

easy access to the machinery below. The comb plate is the piece between the

stationary floor plate and the moving step. It is so named because its edge has a

series of cleats that resemble the teeth of a comb. These teeth mesh with matching

cleats on the edges of the steps. This design is necessary to minimize the gap

between the stair and the landing, which helps prevent objects from getting caught in

the gap.

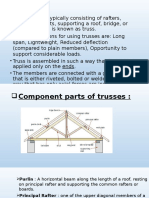

ii. Truss

The truss is a hollow metal structure that bridges the lower and upper landings. It is

composed of two side sections joined together with cross braces across the bottom

and just below the top. The ends of the truss are attached to the top and bottom

landing platforms via steel or concrete supports. The truss carries all the straight track

sections connecting the upper and lower sections.

Ver. 1 (MSH-Jun2013): CC608 Building Services 4

PSMZA Course Note (Chapter 6)

iii. Tracks

The track system is built into the truss to guide the step chain, which continuously

pulls the steps from the bottom platform and back to the top in an endless loop. There

are actually two tracks: one for the front wheels of the steps (called the step-wheel

track) and one for the back wheels of the steps (called the trailer-wheel track). The

relative positions of these tracks cause the steps to form a staircase as they move out

from under the comb plate.

Along the straight section of the truss the tracks are at their maximum distance apart.

This configuration forces the back of one step to be at a 90-degree angle relative to

the step behind it. This right angle bends the steps into a shape resembling a

staircase. At the top and bottom of the escalator, the two tracks converge so that the

front and back wheels of the steps are almost in a straight line. This causes the stairs

to lay in a flat sheet like arrangement, one after another, so they can easily travel

around the bend in the curved section of track.

The tracks carry the steps down along the underside of the truss until they reach the

bottom landing, where they pass through another curved section of track before

exiting the bottom landing. At this point the tracks separate and the steps once again

assume a staircase configuration. This cycle is repeated continually as the steps are

pulled from bottom to top and back to the bottom again.

Figure 6.6: Escalator components

iv. Steps

The steps themselves are solid, one piece, die-cast aluminum or steel. Yellow

demarcation lines may be added to clearly indicate their edges. "step-type" escalators

featured flat treads and smooth risers; other escalator models have cleated treads

and smooth risers. The steps are linked by a continuous metal chain that forms a

closed loop. The front and back edges of the steps are each connected to two

wheels. The rear wheels are set further apart to fit into the back track and the front

wheels have shorter axles to fit into the narrower front track. As described above, the

position of the tracks controls the orientation of the steps.

Ver. 1 (MSH-Jun2013): CC608 Building Services 5

PSMZA Course Note (Chapter 6)

v. Handrail

The handrail provides a convenient handhold for passengers while they are riding the

escalator. In an escalator, the handrail is pulled along its track by a chain that is

connected to the main drive gear by a series of pulleys. It is constructed of four

distinct sections. At the center of the handrail is a "slider", also known as a "glider

ply", which is a layer of a cotton or synthetic textile.

The purpose of the slider layer is to allow the handrail to move smoothly along its

track. The next layer, known as the "tension member", consists of either steel cable

or flat steel tape, and provides the handrail with tensile strength and flexibility. On top

of tension member are the inner construction components, which are made of

chemically treated rubber designed to prevent the layers from separating.

In the factory, handrails are constructed by feeding rubber through a computer-

controlled extrusion machine to produce layers of the required size and type in order

to match specific orders. The component layers of fabric, rubber, and steel are

shaped by skilled workers before being fed into the presses, where they are fused

together.

Table 6.2: Escalator step width and energy usage

Width (between Power

No. Size Single-step capacity Applications

balustrade panels) consumption

A rare historic design

Very One passenger, 3.7 kW

1 400 mm found mostly in older

small with feet together (5 hp)

department stores

Low-volume sites,

uppermost levels of 3.7 kW

2 Small 600 mm One passenger

department stores, (5 hp)

when space is limited

One passenger +

Shopping malls,

one package or 7.5 kW

3 Medium 800 mm department stores,

one piece of (10 hp)

smaller airports

luggage

Mainstay of metro

Two passengers

systems, larger airports, 7.5 kW

4 Large 1,000 mm – one may walk

train stations, some (10 hp)

past another

retail usage

6.2.4 Safety Procedures in Handling Escalator

Incidents involving elevators and escalators kill about 30 and seriously injure about

17,100 people each year in the United States. Injuries to people working on or near escalator

including those installing, repairing, and maintaining, and working in or near shafts account for

almost half of the deaths. The two major causes of death are falls and being caught

in/between moving parts of escalators.

For the safety when used the escalator follow by:

i. Wear Safe Clothes and Shoes

Wearing long sweaters, mittens, long skirts, untied shoelaces, drawstrings in

waistbands or sweatshirts, wide pants, scarves and soft-sided shoes are very

dangerous as they can get stuck in escalators. So remove these types of things

during your escalator ride to protect yourself from an accident.

ii. Always Hold the Handrail

Handrails are designed to keep you in place while moving so always hold them.

Handrails decrease the risk of slipping and tripping accidents. While the escalator

moves, they will help you to remain on place.

Ver. 1 (MSH-Jun2013): CC608 Building Services 6

PSMZA Course Note (Chapter 6)

iii. Always Face Forward

When standing on the escalator, always face forward on the middle of the step. Also

keep the feet somewhat apart and don’t touch the stationary sides. Facing forward

will also help you to take necessary actions if the person riding in front of you falls by

accident.

iv. Keep Space

Always keep space between you and the person riding in front of you to decrease the

chances of injury. To avoid injury, just wait for some steps to pass over after the

person riding the escalator in front you climbs on. This will also avoid crowding at the

exit of the escalator.

v. Don’t Put Children in Strollers, carts, or walkers

During an escalator ride, never use walkers, strollers or carts as they can create

danger for you and other people. So before climbing on an escalator, remove babies

and toddlers from walkers, strollers or carts.

vi. Always Secure Children

When riding on escalator, allow children to stand on the same step or in front of you

so that you can easily reach to them in case of an emergency. Also hold hand of your

children and don’t let them to play, jump or sit on the steps as even a simple fall can

cause cut on the jagged metal steps.

vii. Avoid the Edges of Steps

When riding on the escalator always avoid the edges of steps where entrapment may

occur. All the escalators are designed to show the edges where you may entrap. To

avoid entrapments, there are yellow lines on the sides of the escalator steps which

show where you have to keep your feet.

viii. Know Emergency Shut-off Buttons

You should know where the emergency shut-off buttons are placed in case you want

to stop escalator. Generally, these buttons are at the top and bottom of escalators on

the right side when facing the steps.

ix. Others Safety Tips

a. Don’t ride on escalator with barefoot.

b. Never ride in the opposite direction of the escalator.

c. People who are wearing bifocals should pay particular attention.

d. Watch the direction of the moving step while climbing or exiting the escalator.

e. Always hold small packages tightly in one hand and hold the handrail with other

hand.

f. Make your kids aware of how to get off and on the escalator by verbal commands

and modeling the action with them.

g. Never allow the children to use an escalator unattended as well as don’t let them

to drag their feet on the sides.

Ver. 1 (MSH-Jun2013): CC608 Building Services 7

PSMZA Course Note (Chapter 6)

Figure 6.7: Escalator innovation

Ver. 1 (MSH-Jun2013): CC608 Building Services 8

PSMZA Course Note (Chapter 6)

Figure 6.8: Escalator safety device

Ver. 1 (MSH-Jun2013): CC608 Building Services 9

PSMZA Course Note (Chapter 6)

6.3 Elevators (Lift)

The elevator is a type of vertical transport equipment that efficiently moves people or

goods between floors (levels, decks) of a building, vessel or other structures. Lift system

installation requirements are based on the needs of the use of a building. There are several

types of lifts used. Refer table 6.3 below.

Elevators are generally powered by electric motors that either drive traction cables or

counterweight systems like a hoist, or pump hydraulic fluid to raise a cylindrical piston like a

jack. The elevators can be broadly classified as either electric traction type or hydraulic type.

i. Traction elevators (Electric)

An elevator car and counterweight attached to opposite ends of hoist ropes. The hoist

ropes pass over a driving machine that raises and lowers the car. Traction elevators

run on load-bearing rails in the elevator hoist way. Traction elevators are most often

used in mid-rise and high-rise buildings with five or more floors. Virtually limitless rise

(high and mid rise), it’s also found a gear and gearless traction.

ii. Hydraulic elevators

Raised by forcing pressurized oil through a valve into a steel cylinder located above

ground or underground. The pressure forces a piston to rise, lifting the elevator

platform and car enclosure mounted on it. The car is lowered by opening the valve

and allowing the weight of the car to force oil from the cylinder in a controlled manner.

When the valve is closed the car is stopped. Since the weight of hydraulic elevator

cars is borne by the piston, there is no need for a structural framework or load-

bearing rails. Hydraulic elevators are commonly found in low-rise buildings with two to

five floors or six stories. Lower speeds and cost in a higher power consumption.

Ver. 1 (MSH-Jun2013): CC608 Building Services 10

PSMZA Course Note (Chapter 6)

Figure 6.9: Traction

elevator

Figure 6.10: Hydraulic

elevator

Ver. 1 (MSH-Jun2013): CC608 Building Services 11

PSMZA Course Note (Chapter 6)

Table 6.3: Types of elevator or lift

No Types of lift Diagram Description

It works using a lift cab for the passengers to access

and travel on, raising vertically between floors. It’s

Passenger

1 rather than bespoke so follows a well-established

lift

method of creating lifts and will suit a wide variety of

needs.

This elevators are distinguished by wider doors and

Hospital/bed

2 larger platform sizes to allow faster, more secure of

lift

people and equipment. Commonly used at hospital.

View of the artistic style and the surrounding sights in

Panorama riding the elevator. It usually has a glass door, or is

3

lift entirely made of glass, and can be situated either

inside or outside of buildings.

Used for lifting & lowering of gifts and can carry up to

4 Goods lift

three tons of load at one go.

Used for lifting & lowering options for either passengers

Good/passe

5 or goods

nger lift

Commonly used at hotels, restaurants and other food

6 Service lift service to make sure the food gets to the customer

piping hot and without getting dropped on the stairs.

Ver. 1 (MSH-Jun2013): CC608 Building Services 12

PSMZA Course Note (Chapter 6)

Residential homes almost exclusively for disabled

Residential individuals who need a lift to easily reach upper floors

7

lift of their home, helping them retain their independence

and carry on living in their own home

Owners can design according to their own preferences

8 Bespoke lift for use at home or shopping mall.

This lift type will be alongside an existing, short internal

staircase or external steps, to allow access to the

9 Platform lift

building with a wheelchair, or by people who have

difficulty using steps.

Usually used in parking garages and car repair. Lift is

built in accordance with the maximum size and weight

10 Car lift

of the car.

An mechanical device for lifting people and wheelchairs

up and down stairs. For sufficiently wide stairs, a rail is

Stair chair

11 mounted to the treads of the stairs or on the wall beside

lift

the stairs. A chair or lifting platform is attached to the

rail.

Ver. 1 (MSH-Jun2013): CC608 Building Services 13

PSMZA Course Note (Chapter 6)

6.3.1 The Advantages and Disadvantages of Elevator

i. The Advantages

a. Suitable for high-rise building

b. Vertical transport that efficiently moves people or good between floor of a building

c. Safest mode of transportation

d. Faster mode of vertical transportation for lengthier vertical distance

e. Statistic shows lesser risk of injuries/accident

f. Traction lift more faster than hydraulic lift

g. Convenient – does not take much space except for the maintenance room

h. Elevator doors protect building tenants from falling into the shaft

i. Hydraulic mechanism is cheaper, but installing cylinder greater than a certain

length becomes impractical

ii. The Disadvantages

a. Expensive to maintain

b. In case of malfunction, need to use other mean of transportation

c. Longer waiting period especially heavy traffic

d. Lesser capacity to transport people and good at a certain time

e. Hydraulic lift is slow movement

6.3.2 Design and Layout Consideration of Elevator/Lift

Several numbers of passenger elevators are usually required in most buildings in order to

cope with the traffic density. The number of elevators is derived from a traditional traffic

calculation during morning up peak. In this scenario, an elevator loads at the lobby, delivers

passengers to their floors, and returns empty for the next trip. The number of elevators

required shall be selected on the basis of a 25 to 30 second response waiting time interval

between elevators.

The main design considerations for choosing either electric traction drive or hydraulic for

a particular project are the number of floors, the height of the building, the number of people

to be transported, desired passenger waiting times and frequency of use. The major

components were machine room, cabs and hoistway/pits.

Figure 6.11: Three major elevator component part

Ver. 1 (MSH-Jun2013): CC608 Building Services 14

PSMZA Course Note (Chapter 6)

The other mode of vertical building transportation is “Escalator”. It can be described as

moving stairs typically used to carry large number of people at high volumes through a limited

no of floors. These are commonly used in high density areas or where sudden traffic surges

are expected at times; for example at discharge times from offices, railways underground

stations, airport terminals, theaters, shopping malls and departmental stores. In such

applications, escalators will provide shorter travel time than elevators because elevator cars

are limited in size and passengers have to wait longer for the service.

Other typical parameter in design of elevator includes:

i. Characteristics of the premises

a. Type and use of building

b. Floor plate size and height of the building

c. Size of population and its distribution in the premises

d. Fire safety and regulations

e. The house keeping of the premises

f. Comfortable

g. Aesthetics value

ii. Circulation efficiency/performance

a. Number of cars and their capacity

b. Location and configuration of elevators in entrance lobby

c. Travel length, number of stops and maximum acceptable waiting time

d. Arrangement with the combination of elevator, escalator and emergency stairs

iii. Characteristic of the equipment

a. Type of transportation systems

b. Rated load and car dimensions

c. The speed of the lift/escalator system

d. The type of motor drive control system of the machine

e. Mode of group supervisory control and safety features

f. Cab enclosure and hoist way door finishes

g. Emergency power supplies and fire protection systems

h. Requirements of the local regulations on vertical transport system

i. Zoning of elevators

j. Elevator doors

The elevators capacity is derived from up-peak traffic analysis. The nominal capacity of

the elevator and the rated maximum passenger capacity is than known from manufacturer’s

catalogues. Table below provides standard nominal capacities and passenger relationship:

Table 6.4: Passenger Elevator Service Capacities

Nominal Rated Max Passenger Passengers Per Trip (Normal

Capacity Capacity Peak)*

1140 kg 17 13

1360 kg 20 16

1600 kg 23 19

1800 kg 27 21

2250 kg 33 27

2730 kg 40 32

3180 kg 47 37

3640 kg 53 43

*Peak passengers per trip (normal peak = 80% of rated capacity).

Ver. 1 (MSH-Jun2013): CC608 Building Services 15

PSMZA Course Note (Chapter 6)

In modern high rise buildings each lift is not usually required to service every level, as this

would imply a large number of stops during each trip. The effect is to increase the round trip

time, which in turn increases the interval and the passenger waiting time and the passengers

have to endure long journey times. The solution is to limit the number of floors served by the

lifts.

A rule of thumb is to serve a maximum of 15-16 floors with a lift, or a group of lifts. This

introduces the concept of zoning. Zoning is where a building is divided so that a lift or group of

lifts is constrained to only serve a designated set of floors. There are two forms of zoning:

interleaved and stacked. An interleaved zone is where the whole building is served by lifts,

which are arranged to serve either the even floors or the odd floors. This has been a

common practice in public housing and has been used in some office buildings.

Many tall buildings are divided into several zones: low zone, mid zone, high zone, etc.

with service direct from the main terminal floor, situated at ground level. These are called

`local' zones. This becomes impractical with very tall buildings and shuttle lifts are employed

to take passengers from the ground level main lobby to a `sky lobby'. Four basic sky lobby

configurations:

i. Single deck shuttles, single deck locals, eg: World Trade Center, USA

ii. Double deck shuttles, single deck locals, eg: Sears Tower, USA

iii. Double deck shuttles, double deck locals, eg: Petronas Towers, Malaysia.

iv. Single deck shuttles, single deck top/down locals, eg: none

v. Double deck shuttles, single deck top/down locals, eg: UOB Plaza, Singapore.

Configuration 4 would be difficult to engineer, as offset lobbies would be required.

Generally shuttle lifts serve between two stops only, hence the term `shuttle', but sometimes

they serve three stops, ie: with two sky lobbies (Sears Tower, USA). The number of shuttle

lifts that are installed world wide is not large. Their traffic design is relatively simple, but their

application in a building requires expert consideration.

Figure 6.12: The elevator design concept

Ver. 1 (MSH-Jun2013): CC608 Building Services 16

PSMZA Course Note (Chapter 6)

This elevator system will corresponds to the demand by distinguishing the peak hours

such as early of working hours and lunch time from the non-peak hours. The latest elevator

group control system allows multiple elevators to work together systematically and optimally

while providing maximum conveniences to the passengers.

Figure 6.13: The possibilities of lift grouping arrangement concept

Elevator doors protect riders from falling into the shaft. The most common configuration is

to have two panels that meet in the middle, and slide open laterally. In a cascading telescopic

configuration (potentially allowing wider entryways within limited space), the doors run on

independent tracks so that while open, they are tucked behind one another, and while closed,

they form cascading layers on one side.

Figure 6.14: Types of

an elevator doors

Ver. 1 (MSH-Jun2013): CC608 Building Services 17

PSMZA Course Note (Chapter 6)

6.3.3 Safety Procedures in Handling Elevators

Elevators are potential sources of serious injuries and deaths to the general public and to

workers installing, repairing, and maintaining them and fire and rescue personnel. Common

injuries are tripping, caught clothing, being hit by closing elevator doors, or falling down an

elevator shaft when trying to exit a stalled elevator car. Accidents can occasionally occur as a

result of unsafe riding practices. Though elevators are one of the safest forms of

transportation, following simple guidelines can help further improve passenger safety. It’s

important to not only know how to properly ride elevators, but also what to do if the elevator

becomes stalled.

i. When waiting for elevators

a) Know your destination.

b) Push the elevator call button once for the direction you want to go in.

c) Look and listen for the signal announcing your car’s arrival.

d) Be aware of health conditions that could contribute to falls or accidents.

e) Stand clear of the elevator doors and stand aside for exiting passengers.

f) If the arriving car is full, wait for the next car.

g) Don’t attempt to maneuver in or stop closing doors, wait for the next car.

h) In the event of a fire or other situation that could lead to a disruption in electrical

services, take the stairs.

ii. When boarding elevators

a) Watch your step – the elevator car may not be perfectly level with the floor.

b) Stand clear of the doors – keep clothes and carry-ons away from the opening.

c) Hold children and pets firmly.

d) Passengers nearest to the doors should move first when the car arrives.

e) Push and hold the DOOR OPEN button if doors need to be held open, or ask

someone to push the button for you.

f) Never try to stop a closing door, wait for the next car.

g) Once on board, quickly press the button for your floor and move to the back of

the car to make room for other passengers.

iii. When riding elevators

a) Hold the handrail, if available.

b) Stand next to the elevator wall, if available.

c) Pay attention to the floor indications.

d) If the doors do not open when the elevator stops, push the DOOR OPEN button.

iv. When exiting elevators

a) Exit immediately at your floor. Do not wait for others behind you.

b) Do not push the people in front of you when exiting.

c) Watch your step – the elevator car may not be perfectly level with the floor.

v. In the event of an elevator emergency

a) If the elevator should ever stop between floors, do not panic. There is plenty of air

in the elevator.

b) Never climb out of a stalled elevator.

c) Use the ALARM or HELP button, the telephone or the intercom to call for

assistance.

d) Above all, wait for qualified help to arrive and never try to leave an elevator that

has not stopped normally.

e) Emergency lighting will come on in the event of a power failure.

vi. What to do if you are stalled in an elevator

a) Push the "Door Open" Button - If you are near the landing the door will open. You

can slowly and carefully step out of the elevator. Be sure to watch your step as

the elevator floor may, or may not, be level with the landing.

b) Remain Calm - If the door does not open, you are still safe. Do not try to exit the

elevator. Wait for trained emergency personnel to arrive. Even if the air

Ver. 1 (MSH-Jun2013): CC608 Building Services 18

PSMZA Course Note (Chapter 6)

temperature feels warm, there is plenty of air circulating in the elevator and its

shaft way.

c) Press the Alarm or Help Button, and use any available communication systems

Push the alarm button and wait for someone to respond to you.

In newer elevators, there will be a "PHONE" or "HELP" button instead of an

alarm button this will place a call to a party that is trained to take action (i.e.

elevator company, alarm company, etc.). It will give the exact location of the

building and elevator you are in. Trained emergency personnel will answer

the call for service within several minutes.

Some elevators have a two-way speaker system or telephone that will allow

for communication between you and the building or rescue personnel. Do not

be alarmed if you cannot be heard or if the phone does not work. Some

phones are designed to only receive calls. Trained personnel should call

when they arrive at the building.

vii. Relax, and do not try to extract yourself from the elevator

a) Never try to exit a stalled elevator car. It is extremely dangerous. always wait

for trained emergency personnel.

b) Your best course of action is to relax, get comfortable, and wait for

professional assistance.

c) You may be inconvenienced but you are safe.

6.4 Walkway/Travelator

A moving walkway or moving sidewalk is a slow moving conveyor mechanism that

transports people, across a horizontal or inclined plane, over a short distance. Moving

walkways can be used by standing or walking on them. They are often installed in pairs, one

for each direction.

A travelator, moving

ramp or escalator for

transporting people,

comprises a people

mover; a balustrade

extending alongside

the people mover

throughout its length.

The balustrade

comprises a handrail

belt formed as an

endless loop and

having an upper

handhold portion,

which the passenger

can grasp with a hand

for support, a lower

return portion, and a

turn-around portion

between the handhold

portion and the return

portion.

Figure 6.15: Travelator schematic

Ver. 1 (MSH-Jun2013): CC608 Building Services 19

PSMZA Course Note (Chapter 6)

The balustrade frame comprises a turn-around guide at the end of the balustrade to form a

turn-around to support and guide the turn-around portion of the handrail belt. The turn-around

guide comprises a number of pressure rollers spaced at a distance from each other and

arranged in a sequence in the form of a circular arc. In addition, a drive assembly is arranged

to move the handrail belt.

The drive assembly comprises a drive belt formed as an endless loop and having a

contact portion which is in driving contact with the handrail belt over a predetermined length,

and a power mechanism for driving the drive belt. The contact portion of the drive belt is

passed over the sequence of pressure rollers between the pressure rollers and the turn-

around portion of the handrail belt. The Features were:

i. Lays on existing floors - No floor pits Low Profile - 150mm Slashes civil engineering

costs.

ii. Quick installation and removal

iii. Easy to re-locate

iv. Modular and extendible

v. Walk-on, walk-off

vi. Easy gradient, non-slip ramps

vii. Only 150mm deep ± no need to dig expensive pits into the floor

viii. Double Handrail Walkway

Figure 6.16: Airport travelator

Ver. 1 (MSH-Jun2013): CC608 Building Services 20

PSMZA Course Note (Chapter 6)

6.5 Best of Practices in Handling Escalator and Elevator

i. Safety Procedures During Repair Work or Maintenance

Maintenance includes the inspecting, cleaning oiling and adjusting of a lift or an

escalator in order to keep the equipment and their accessories in good working order

and prevent faults from occurring. Some overhaul/repair works in the industry such as

the replacement of main hoisting ropes in traction drive lift, the replacement of

hydraulic jack in hydraulic lift, the replacement of safety gear etc. require special

attention on the employees’ safety and health at work.

A proprietor/contractor should devise a safe system of work for a special

overhaul/repair work by taking into consideration the current legal safety

requirements and the instructions, in particular, the safety precautions and warnings

included in the maintenance manuals published by the lift/ escalator manufacturers.

All the engineers/supervisors and workers should observe and follow strictly the safe

system of work and the safety instructions of the maintenance manuals.

Any alteration and deviation to the safe system of work and/or the safety

instructions in the maintenance manual should be made only under the instructions

and supervision of persons who are competent and having the appropriate technical

skill and experience. In addition to the relevant safety precautions as mentioned in

the previous section, special attentions should be paid to the following when carrying

out the special overhaul/repair works:

a) During the special overhaul/repair works, safe method of lifting or mechanical

handling of spare parts such as the lift car or hydraulic jack, etc. should be

devised in advance in the site safety assessment. Reference should be made to

the recommended method of the maintenance manual published by the

manufacturers.

b) The wire rope used for rigging a lift car should be of adequate strength and

length. The sharp corners of the lift car should be padded to avoid any damage to

the wire rope.

c) During the lifting of a lift car, the wire rope should be fixed at the anchorage

points for the frame instead of tying around the top beam of the lift car. The wire

rope should preferably be of simple 1:1 suspension system at the anchorage

points in order to eliminate the relative movement of wire rope with respect to the

anchorages.

d) If the wire rope is tied around a diverter pulley for lifting a lift car with a 2:1

suspension system, the wire rope should be placed in the groove of the pulley.

e) Lifting hook speeded beyond the allowable limit should be discarded immediately.

f) When a wire rope is required to be looped or is making short bend, thimbles

should be used in the application. U-bolts of all clamp fastening should be on the

dead end of the wire rope.

g) In clamping a wire rope into an eye, the loose end should be clamped against the

main rope with minimum three clamps. The distance between two clamps should

be 6 to 7 times the rope diameter apart. Clamp fastenings should be inspected

and maintained regularly.

h) As a safety precaution, when the lift car (with its car top as the working platform)

is hoisted up to the required position for working purposes, the safety gear of the

lift car should be immediately activated so as to securely fix the lift car in position.

i) Main Hoisting Rope Replacement Work.

Replacement of all the old main hoisting ropes in one goal for a traction drive

lift is not recommended. For the sake of safety during the rope replacement

work, at least some numbers of the old hoisting ropes should remain intact to

hold the lift car in case of emergency.

The main switch of the lift should be turned off, locked out and tagged.

Proper warning notices warning that the lift is out of service should also be

Ver. 1 (MSH-Jun2013): CC608 Building Services 21

PSMZA Course Note (Chapter 6)

posted at prominent positions so as to avoid any disturbances caused by the

persons in the building intending to use the lift.

The counterweight should be set at the lowest level at the lift pit and should

be securely and adequately supported to prevent it from moving during the

replacement work.

For easy and safe handling of new hoisting ropes during the rope

replacement work, the new ropes to be used should first be cut to the

required length before delivering to the work site.

For safety sake, the old hoisting ropes should be replaced with the new

hoisting ropes one after the other.

In replacement of the main hoisting ropes, the old ropes should be properly

transported down to the ground for removal from the work site.

j) Hydraulic Jack Replacement Work

The main switch to the hydraulic lift should be turned off, locked out and

tagged.

The pressure at the hydraulic jack to be replaced should be released and the

jack should retract completely to the lowest position after the hydraulic lift car

has been supported by the lifting appliance installed at the top of the lift well

or at the machine room located above.

k) Safety Gear Replacement Work

The lift car should be set near the bottom terminal landing to reduce the risk

of falling from height during the replacement of safety gear at the bottom of

the lift car.

Proper working platform erected from the lift pit should be provided for the

working personnel carrying out the safety gear replacement work.

After the special overhaul/repair work, the lifting appliance and the lifting gear

for lifting/rigging purposes should be dismantled properly and the support for

counterweight should also be removed before putting back the lift to normal

service in the building.

ii. Best of Practices in Handling Escalator and Elevator

Safety is the elevator and escalator industry’s first priority. The industry has

stringent codes in place to help ensure the safety of its products, and to make certain

that machinery is maintained and inspected according to its respective codes.

a) Duties of The Company Safety Authority

Issue annual operating permits.

Issue contractors licenses and approve qualification of contractors.

Inspects all new elevator systems before they can be used.

Inspects all new equipment for elevators and escalators.

Approve all elevator and escalator renovations.

Investigate accidents and incidents.

Record and monitor schedule inspections.

b) Duties of The Owner’s and Owner’s Representatives

To keep onsite all manuals, construction prints, schematics, shop drawings

plus a disk copy of proprietary software.

Annual operating permits must be mounted in the elevator machine room.

(check web site for fee schedule)

Keep on file current elevator contract. Give a copy to whoever is responsible

for the elevators for your company. Make sure they understand all the details

of the contract.

Keep a hardbound logbook for each elevator. All work done on an elevator

must be recorded and signed. All records must be kept 6 years.

If the contract is terminated, request from the Safety Authority all elevator

records.

Ver. 1 (MSH-Jun2013): CC608 Building Services 22

PSMZA Course Note (Chapter 6)

iii. Rules by The Local Authority

Elevators design shall comply with the latest edition of ASME A17.1, “Safety Code for

Elevators and Escalators” with amendments and Uniform Building Code (UBC).

Therefore, The adoption of the EN Standard as a Malaysian Standard was

recommended by the Working Group on Lifts and Escalators under the authority of

the Industry Standards Committee on Mechanical Engineering.

This Malaysian Standard is the first revision of MS 2021-1, Safety rules for the

construction and installation of lifts - Part 1: Electric lifts.

This Malaysian Standard is identical with EN 81-1:1998, Safety rules for the

construction and installation of lifts - Part 1: Electric lifts, including its Corrigendum

1:1999, Amendment 1:2005, Amendment 2:2004 and Amendment 3:2009, published

by the European Committee for Standardization (CEN) with the exceptions as listed

below. In the source text, “this European Standard” should read “this Malaysian

Standard”;

6.6 References

Books

Egan M David (1986). The Building Fire Safety Concept. University Technology Malaysia,

Skudai.

Fullerton R. L. (1979). Building Construction in Warm Climates. Volume 1, 2, 3. Oxford

University Press, United Kingdom.

Hall F. (2000). Building Services & Equipment. Pearson Limited, England.

MS EN 81-1:2012. Malaysian Standard. Safety Rules for the Construction and Installation of

Lift- Part1: electric Lifts (first revision). Department of Standards Malaysia.

Nor Rizman (2010). Risk Assessment for Demolition Works In Malaysia. Faculy of Civil

Engineering and Earth Resources, Universiti Malaysia Pahang. Undergraduate

thesis.

Prashant A/L Tharmarajan (2007(. The Essential Aspects of Fire Safety Management In Hihg-

Rise Buildings. University Teknologi Malaysia. Degree of master science thesis.

Riger W. Haines, Douglas C. Hittle (2006). Control System for Heating, Ventilating and Air

Conditioning. Springer-Verlag, New York.

Stein, Benjamin, Reynolds, John S., Grondzik, Walter T., and Alison G. Kwok, (2006).

Mechanical and Electrical Equipment for Buildings. 10th ed. Hoboken, New Jersey:

John Wiley and Sons, Inc., 2006.

Tan, C. W. and Hiew, B.K., (2004), “Effective Management of Fire Safety in a High-Rise

Building”, Buletin Ingenieur vol. 204, 12-19.

Journals

N.H. Salleh and A.G. Ahmad. (2009). Fire Safety Management In Heritage Buildings: The

Current Scenario In Malaysia. CIPA Symposium Kyoto Japan. UIAM and USM.

Ver. 1 (MSH-Jun2013): CC608 Building Services 23

PSMZA Course Note (Chapter 6)

Code of Practices

Approved Code Of Practice For Demolition: Health And Safety In Employment Act 1992.

Issued And Approved By The Minister Of Labour September 1994.

Code of Practice for Lift Works and Escalator Works. (2002 ed).

Code Of Practice For Demolition Of Buildings 2004. Published by the Building Department.

Printed by Taiwan Government Logistics Department.

Code Of Practice For Demolition Of Buildings (2009). Malaysia Standard Supersede Ms 282

Part 1: 1975. Technical Committee For Construction Practices Under The

Supervision Of Construction Industry Development Board, Malaysia.

Demolition Work Code Of Practice (July 2012). Australian Government.

Work Health and Safety (Demolition Work Code of Practice) Approval 2012. Australian

Capital Territory. By Dr Chris Bourke, Minister for Industrial Relations.

Others Publishing

Coby Frampton. Benchmarking World-class maintenance. CMC Charles Brooks Associates,

Inc.

Electrical Installation and Systems (2006). Training Package UEE06. Industry Skills Council,

Australia.

Fire Safety Manual (2002). Florida Atlantic University USA.

Garis panduan Pendawaian Elektrik di bangunan Kediaman (2008). Suruhanjaya Tenaga

Malaysia. Jabatan Keselamatan Elektrik.

Laws of Malaysia. Act 341: Fire Services Act 1988. Publish by The Commissioner Of Law

Revision, Malaysia Under The Authority Of The Revision Of Laws Act 1968 In

Collaboration With Percetakan Nasional Malaysia Bhd 2006.

Operations & Maintenance Best Practices: A Guide to Achieving Operational Efficiency.

(August 2010). Release 3.0.

Principles of Home Inspection: Air Conditioning and Heat Pumps. (2010). Educational Course

Note.

Routine Maintenance Modules. Part II.

Uniform Building By Law 1984. (1996). MDC Legal Advisers: MDC Publishers Printers

Guidelines For Applicants For A Demolition Licence Issued Under The Occupational Safety

And Health Regulations 1996. Occupational Safety And Health Act 198. The

Government of Commerce, Western Autralia.

Ver. 1 (MSH-Jun2013): CC608 Building Services 24

PSMZA Course Note (Chapter 6)

Websites

http://en.wikipedia.org/wiki/Electricity

http://science.howstuffworks.com/electricity.htm

http://en.wikipedia.org/wiki/Electricity_generation

https://en.wikipedia.org/wiki/Fire_safety

http://www.usfa.fema.gov/citizens/home_fire_prev/

https://en.wikipedia.org/wiki/Maintenance,_repair,_and_operations

http://academia.edu/406774/Demolition_Work_in_Malaysia_The_Safety_Provisions

http://www.mbam.org.my/mbam/doc/news/010-05Oct09-COP%20Demolition%20Works-

corrected%20on%20%2030th%20sept%202009-1.doc

http://en.wikipedia.org/wiki/Demolition

http://www.safeworkaustralia.gov.au/sites/SWA/about/Publications/Documents/700/Demolitio

n%20Work.pdf

https://en.wikipedia.org/wiki/Air_conditioning

http://www.nasa.gov/topics/earth/features/heat-island-sprawl.html

http://www.projectnoah.org/education

http://unfccc.int/files/methods_and_science/other_methodological_issues/interactions_with_o

zone_layer/application/pdf/subgene.pdf

http://www.cibse.org/Docs/barney2.doc

http://en.wikibooks.org/wiki/Building_Services/Vertical_Transportation

Ver. 1 (MSH-Jun2013): CC608 Building Services 25

Você também pode gostar

- Https WWW - Archsd.gov - HK Media 11350 E172 PDFDocumento236 páginasHttps WWW - Archsd.gov - HK Media 11350 E172 PDFjackAinda não há avaliações

- Understanding the Building Construction Process: Simply ExplainedNo EverandUnderstanding the Building Construction Process: Simply ExplainedAinda não há avaliações

- Road Design Papidp 1Documento39 páginasRoad Design Papidp 1Amirul AdamAinda não há avaliações

- Optimal Preventive Maintenance Planning - Yamashina 2001Documento25 páginasOptimal Preventive Maintenance Planning - Yamashina 2001Rimberg TavaresAinda não há avaliações

- Body Corporate Guidelines PDFDocumento17 páginasBody Corporate Guidelines PDFmaAinda não há avaliações

- Stormwater Analysis and Solution of Waterlogging in Kothrud Region, PuneDocumento11 páginasStormwater Analysis and Solution of Waterlogging in Kothrud Region, PuneIJRASETPublicationsAinda não há avaliações

- 8.building Services Technology PDFDocumento84 páginas8.building Services Technology PDFRrgs Bandara100% (2)

- ReportDocumento181 páginasReportHumairah ShabriAinda não há avaliações

- DBKL Grade A SpecsDocumento24 páginasDBKL Grade A SpecsDennis Lai Zhan Wen100% (1)

- Bs II KLCC ReportDocumento31 páginasBs II KLCC ReportChin HongruiAinda não há avaliações

- Authority Requirement and DocumentationDocumento9 páginasAuthority Requirement and DocumentationRomeo CorneliezAinda não há avaliações

- Akta Air 1920Documento20 páginasAkta Air 1920Dinar Ismail100% (1)

- 11 HDB Requirements For A&a Work On HDB PremisesDocumento16 páginas11 HDB Requirements For A&a Work On HDB PremisesasdasAinda não há avaliações

- A1286-2007 Street Drainage Building AmendmentDocumento12 páginasA1286-2007 Street Drainage Building AmendmentJulie Tan100% (1)

- 2007 - LCC As A Contribution To Sustainable Construction - A Common Methodology PDFDocumento113 páginas2007 - LCC As A Contribution To Sustainable Construction - A Common Methodology PDFcm08909Ainda não há avaliações

- Request For Proposals To Install, Operate, and Maintain The Vehicle Parking System in (CITY)Documento59 páginasRequest For Proposals To Install, Operate, and Maintain The Vehicle Parking System in (CITY)Raj Kumar100% (1)

- UAE Roadway Design ManualDocumento247 páginasUAE Roadway Design ManualRAZNAS ASLAM A K100% (1)

- Wastewater Treatment Plants-Part 1: General Construction PrinciplesDocumento16 páginasWastewater Treatment Plants-Part 1: General Construction Principlesdaprc100% (1)

- 1.16-G Parking Design GuidelinesDocumento77 páginas1.16-G Parking Design GuidelinesN V Sumanth Vallabhaneni100% (1)

- Note 1 - LAM, ArchitectDocumento29 páginasNote 1 - LAM, Architectn_euda100% (1)

- SOLAR PUMP Technical Specification WPS JNNSMDocumento8 páginasSOLAR PUMP Technical Specification WPS JNNSMJP GuptaAinda não há avaliações

- Elevators TechnologyDocumento25 páginasElevators Technologyengineer63Ainda não há avaliações

- Sample PreQua DocumentsDocumento64 páginasSample PreQua DocumentsdvduronAinda não há avaliações

- (A) Training and Experience Report: Documents To Be SubmittedDocumento2 páginas(A) Training and Experience Report: Documents To Be SubmittedGiriDharanAinda não há avaliações

- Labour Based Methods For EarthworksDocumento32 páginasLabour Based Methods For EarthworksJBMRMM100% (1)

- Chapter 1 - Ubbl QasDocumento19 páginasChapter 1 - Ubbl QasTayaabaranAinda não há avaliações

- Building Assesment ReportDocumento7 páginasBuilding Assesment Reportamir_rundingAinda não há avaliações

- Inertia Blok PDFDocumento14 páginasInertia Blok PDFmohdzamryAinda não há avaliações

- INSTALLATION PROCEDURE of EsclatorsDocumento2 páginasINSTALLATION PROCEDURE of EsclatorsRuchira Anand PimpalkhuteAinda não há avaliações

- TR 515 PDFDocumento135 páginasTR 515 PDFMohamedAinda não há avaliações

- BIM - SPESIFIKASI PARAMETER JKR (1) (001-033) .Ms - enDocumento33 páginasBIM - SPESIFIKASI PARAMETER JKR (1) (001-033) .Ms - enPigmy LeeAinda não há avaliações

- 2014 Standard Technical Method StatementDocumento19 páginas2014 Standard Technical Method StatementTAHER AMMAR100% (1)

- Section 01830 - Operation and Maintenance: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocumento3 páginasSection 01830 - Operation and Maintenance: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDAinda não há avaliações

- ElevatorDocumento10 páginasElevatorfatemeh100% (1)

- Construction Technology AssignmentDocumento5 páginasConstruction Technology AssignmentAbubakar DanmashiAinda não há avaliações

- Hill Cannon Car Park Consultancy Design 2011Documento27 páginasHill Cannon Car Park Consultancy Design 2011kurtrobbinsAinda não há avaliações

- Request For Quotation - Temporary Bridge On Kabul River (Final 11feb11) PDFDocumento14 páginasRequest For Quotation - Temporary Bridge On Kabul River (Final 11feb11) PDFsubbaraoAinda não há avaliações

- The First Draft of A Presentation On The Design & Construction of An Automatic Solar-Powered StreetlightDocumento23 páginasThe First Draft of A Presentation On The Design & Construction of An Automatic Solar-Powered StreetlightAyo MorakinyoAinda não há avaliações

- The Comparison of LEED and BREEAM To Find A Universal Way of Rating Sustainable BuildingsDocumento51 páginasThe Comparison of LEED and BREEAM To Find A Universal Way of Rating Sustainable BuildingsTetiana KanashchukAinda não há avaliações

- Safety Aspect in Installation Industrialized Building SystemDocumento24 páginasSafety Aspect in Installation Industrialized Building SystemReeve Wong Jing JyhAinda não há avaliações

- HongKong SPC Library 2018 PDFDocumento3.866 páginasHongKong SPC Library 2018 PDFAzharudin ZoechnyAinda não há avaliações

- 229756Documento126 páginas229756Karpaga MoorthyAinda não há avaliações

- Silt CurtainDocumento8 páginasSilt Curtainwilliam pasamonteAinda não há avaliações

- 8110-400-030 - Procedure - Utility Crossing(s) Under Future and Existing Rail ReserveDocumento34 páginas8110-400-030 - Procedure - Utility Crossing(s) Under Future and Existing Rail ReserveVenkatesan NarayanaswamyAinda não há avaliações

- ProfessionalPractice - FAQ (For BEM's Website) PDFDocumento17 páginasProfessionalPractice - FAQ (For BEM's Website) PDFgilbert850507Ainda não há avaliações

- 28) Bahagian 10 - Guideline Construction ActivitiesDocumento39 páginas28) Bahagian 10 - Guideline Construction ActivitiesSham AranAinda não há avaliações

- Civil+Defence+Technical+Requirements+Guide+2023+ ( (+LAST+OFFICAL+UPDATE) )Documento465 páginasCivil+Defence+Technical+Requirements+Guide+2023+ ( (+LAST+OFFICAL+UPDATE) )shaikmohdhajiAinda não há avaliações

- Building Code Regulations - Building Code Act (Nova Scotia)Documento93 páginasBuilding Code Regulations - Building Code Act (Nova Scotia)Angel E. German100% (1)

- Tech Spec - Lifts 20.12.08Documento16 páginasTech Spec - Lifts 20.12.08jiguparmar1516Ainda não há avaliações

- Ubbl Part ViiDocumento49 páginasUbbl Part ViiChazWeeWeeIIAinda não há avaliações

- Maintenance Management Framework: Policy For The Maintenance of Queensland Government BuildingsDocumento24 páginasMaintenance Management Framework: Policy For The Maintenance of Queensland Government BuildingsqasimAinda não há avaliações

- ms133 E10 2012preDocumento6 páginasms133 E10 2012prelelouch0120Ainda não há avaliações

- Manual Aircond Rumah PDFDocumento115 páginasManual Aircond Rumah PDFazizmcp2Ainda não há avaliações

- Design of Hydraulic Road Blocker PDFDocumento52 páginasDesign of Hydraulic Road Blocker PDFMohamad Tawfiq100% (1)

- 01 43 39 MockupsDocumento5 páginas01 43 39 MockupsShahid AkramAinda não há avaliações

- Terms of Reference For Dilapidation SurveyDocumento1 páginaTerms of Reference For Dilapidation SurveyHasrina Mohd RamaziAinda não há avaliações

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers ADV-31Documento8 páginasBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers ADV-31Kaiser EdwardAinda não há avaliações

- Draft Mie A GL 20140324bernDocumento241 páginasDraft Mie A GL 20140324bernbernardabatayoAinda não há avaliações

- ContractsDocumento233 páginasContractsRaju AketiAinda não há avaliações

- Building Services: Assignment: Enhancement of Green Technology Via Air ConditioningDocumento16 páginasBuilding Services: Assignment: Enhancement of Green Technology Via Air ConditioningsyakirohAinda não há avaliações

- Pengujian Lift / Elevator PDFDocumento136 páginasPengujian Lift / Elevator PDFWidya AnugrahAinda não há avaliações

- Hirarc NoteDocumento35 páginasHirarc NotesyakirohAinda não há avaliações

- Building Services Airconditioning, VentilationDocumento111 páginasBuilding Services Airconditioning, Ventilationsyakiroh100% (2)

- Population ForecastingDocumento29 páginasPopulation Forecastingsyakiroh100% (2)

- Principal of Osh-Assignment OshDocumento37 páginasPrincipal of Osh-Assignment OshsyakirohAinda não há avaliações

- Masonry Properties Compatibility ModeDocumento32 páginasMasonry Properties Compatibility ModesyakirohAinda não há avaliações

- Sand Cement Brick Containing Recycled PDFDocumento7 páginasSand Cement Brick Containing Recycled PDFsyakirohAinda não há avaliações

- Sand Cement Brick Containing Recycled PDFDocumento7 páginasSand Cement Brick Containing Recycled PDFsyakirohAinda não há avaliações

- Masonry Properties Compatibility ModeDocumento32 páginasMasonry Properties Compatibility ModesyakirohAinda não há avaliações

- COMBO Glossary Lexicon 122011Documento388 páginasCOMBO Glossary Lexicon 122011syakirohAinda não há avaliações

- Existing Pile Capacity Analysis: ABD Memo 08.1 "Pile Capacity Increase Table" Computed Increase 0% 6% 0% 4% 2% 4%Documento1 páginaExisting Pile Capacity Analysis: ABD Memo 08.1 "Pile Capacity Increase Table" Computed Increase 0% 6% 0% 4% 2% 4%syakirohAinda não há avaliações

- Steel BS4360 43A PDFDocumento1 páginaSteel BS4360 43A PDFsyakiroh100% (1)

- Bore Pile Design in SandDocumento4 páginasBore Pile Design in SandsyakirohAinda não há avaliações

- Pil Raft Spring DeterminDocumento14 páginasPil Raft Spring DeterminsyakirohAinda não há avaliações

- Pile Driving Chart2Documento3 páginasPile Driving Chart2syakirohAinda não há avaliações

- VastuSamvad Jan Apr2016Documento12 páginasVastuSamvad Jan Apr2016Saurabh KesarwaniAinda não há avaliações

- Usb ClearDocumento8 páginasUsb ClearDanielsYautibugAinda não há avaliações

- Paynow 3rd Party Site and Link Integration DocumentationDocumento8 páginasPaynow 3rd Party Site and Link Integration DocumentationMarshall MahachiAinda não há avaliações

- CSC 35Documento4 páginasCSC 35Nguyen NguyenAinda não há avaliações

- (2018) SGHC 254 MCST 940 V Lim Florence MajorieDocumento27 páginas(2018) SGHC 254 MCST 940 V Lim Florence MajorieterencebctanAinda não há avaliações

- Technical Drawing StandardsDocumento20 páginasTechnical Drawing StandardsGeorge Maliaris57% (14)

- HVAC ComparisonDocumento283 páginasHVAC Comparisonmilindskulkarni2005@yahoo.co.in100% (1)

- Islamic ColonialDocumento4 páginasIslamic ColonialMargarette Ramos NatividadAinda não há avaliações

- Lecture Rearing House and Rearing Appliances of Mulberry Silkworm, Methods of Disinfection and HygieneDocumento13 páginasLecture Rearing House and Rearing Appliances of Mulberry Silkworm, Methods of Disinfection and HygieneVIVEK SUTARAinda não há avaliações

- Heat Load CalculationDocumento3 páginasHeat Load Calculationapi-3728508100% (2)

- Penang07 - CheongfattzeDocumento14 páginasPenang07 - Cheongfattzemohd qistiAinda não há avaliações

- Irc Gov in 109 1997 PDFDocumento28 páginasIrc Gov in 109 1997 PDFKishore AinavilliAinda não há avaliações

- Microsoft Online Services Global Criminal Compliance HandbookDocumento22 páginasMicrosoft Online Services Global Criminal Compliance Handbookesq21Ainda não há avaliações

- AXI To AHB BridgeDocumento5 páginasAXI To AHB BridgePhilomathi AmbroseAinda não há avaliações

- Final Annual Report 2018Documento31 páginasFinal Annual Report 2018Nirmal Kumar SharmaAinda não há avaliações

- Fortigate Transparent Mode 56Documento49 páginasFortigate Transparent Mode 56Log BwdAinda não há avaliações

- Mascoat - Thermal Insulation Coating 02-MI-DTI Spec Sheet 0113Documento2 páginasMascoat - Thermal Insulation Coating 02-MI-DTI Spec Sheet 0113Ying Kei ChanAinda não há avaliações

- Wsi PSDDocumento18 páginasWsi PSDДрагиша Небитни ТрифуновићAinda não há avaliações

- Code of Professional Conduct - 1989Documento15 páginasCode of Professional Conduct - 1989Shivam AroraAinda não há avaliações

- Alver AaltoDocumento5 páginasAlver AaltoJayant RajAinda não há avaliações

- Types of TrussesDocumento30 páginasTypes of TrussesPrajwal85% (13)

- Java4s Com HibernateDocumento5 páginasJava4s Com HibernatevijayAinda não há avaliações

- 8.1.4.8 Lab - Identifying IPv4 Addresses-1Documento3 páginas8.1.4.8 Lab - Identifying IPv4 Addresses-1Luis Renato GarciaAinda não há avaliações

- 02 - Theory of Architecture2 - Historic and Classical StylesDocumento29 páginas02 - Theory of Architecture2 - Historic and Classical Styleskyle vincentAinda não há avaliações

- Ccna4 7.5.1Documento5 páginasCcna4 7.5.1Mark ManingasAinda não há avaliações

- Variable Speed Drives: Smart Ideas For Your BusinessDocumento2 páginasVariable Speed Drives: Smart Ideas For Your BusinessSamiYousifAinda não há avaliações

- NSN Lte ParameterDocumento44 páginasNSN Lte ParameterRocky100% (1)

- CS601 Final Term Mega Quiz File With RefrencesDocumento43 páginasCS601 Final Term Mega Quiz File With RefrencesRed FlowerAinda não há avaliações

- Beginner Programming Lesson: Introduction To The EV3 Brick and SoftwareDocumento12 páginasBeginner Programming Lesson: Introduction To The EV3 Brick and SoftwareMenandro JumpaladAinda não há avaliações

- Xy PCDocumento34 páginasXy PCtimbe08Ainda não há avaliações