Escolar Documentos

Profissional Documentos

Cultura Documentos

Iso 3302

Enviado por

Ahsan Farooq0%(1)0% acharam este documento útil (1 voto)

2K visualizações2 páginasTolerance m class mold rubber

Título original

iso 3302

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoTolerance m class mold rubber

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0%(1)0% acharam este documento útil (1 voto)

2K visualizações2 páginasIso 3302

Enviado por

Ahsan FarooqTolerance m class mold rubber

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

EJAY INDUSTRY CO., LTD.

Molded & Extruded Rubber Products

Tel: +86-532-68950060 Fax: +86-532-68950070

www.ejayrubber.com

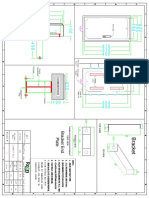

3302--1 Classes and Tolerances for Products Molded in Solid Rubber

ISO 3302

M Classes

Classes determine the fixed and closure dimensional tolerances for products molded in solid rubber.

The table below shows the 4 classes that are used by ISO 3302-1.

Metric Tolerances (mm)

Nominal Dimension Class M1 Class M2 Class M3 Class M4

Closure Closure Closure Fixed and

above up to and including Fixed ± Fixed ± Fixed ±

± ± ± closure±

0 4 0.08 0.1 0.1 0.15 0.25 0.4 0.5

4 6.3 0.1 0.12 0.15 0.2 0.25 0.4 0.5

6.3 10 0.1 0.15 0.2 0.2 0.3 0.5 0.7

10 16 0.15 0.2 0.2 0.25 0.4 0.6 0.8

16 25 0.2 0.2 0.25 0.35 0.5 0.8 1

25 40 0.2 0.25 0.35 0.4 0.6 1 1.3

40 63 0.25 0.35 0.4 0.5 0.8 1.3 1.6

63 100 0.35 0.4 0.5 0.7 1 1.6 2

100 160 0.4 0.5 0.7 0.8 1.3 2 2.5

160 - 0.30% 0.40% 0.50% 0.70% 0.80% 1.30% 1.50%

Inch Tolerances (in)

Nominal Dimension Class M1 Class M2 Class M3 Class M4

Closure Closure Closure Fixed and

above up to and including Fixed ± Fixed ± Fixed ± closure±

± ± ±

0 0.157 0.0031 0.0039 0.0039 0.0059 0.0079 0.0079 0.0098

0.157 0.248 0.0039 0.0047 0.0059 0.0079 0.0079 0.0098 0.0138

0.248 0.394 0.0039 0.0059 0.0079 0.0079 0.0098 0.0138 0.0157

0.394 0.63 0.0059 0.0079 0.0079 0.0098 0.0138 0.0157 0.0197

0.63 0.984 0.0079 0.0079 0.0098 0.0138 0.0157 0.0197 0.0276

0.984 1.575 0.0079 0.0098 0.0138 0.0157 0.0197 0.0276 0.0315

1.575 2.48 0.0098 0.0138 0.0157 0.0197 0.0276 0.0315 0.0512

2.48 3.937 0.0138 0.0157 0.0197 0.0276 0.0315 0.0512 0.0787

3.937 6.299 0.0157 0.0197 0.0276 0.0315 0.0512 0.0787 0.0984

6.299 - 0.30% 0.40% 0.50% 0.70% 0.80% 1.30% 1.50%

EJAY INDUSTRY CO., LTD.

Molded & Extruded Rubber Products

Tel: +86-532-68950060 Fax: +86-532-68950070

www.ejayrubber.com

Class Name Definition

This is the tightest tolerance classification and indicates a

high precision rubber product. Such moldings require

precision molds, fewer cavities per mold, close mix controls,

M1 Precision etc., which results in high cost. Optical comparators or other

measuring devices may be required to minimize distortion of

the rubber part by the measuring instrument. This part

requires expensive control and inspection procedures.

These moldings involve much of the close controls required

for the above class. Molds must be precision machined and

M2 High Quality

kept in good repair. While measurement methods may be

simpler than the above class, careful inspection will usually

This class indicates a general grade or commercial product.

M3 Good Quality

This is the most commonly used class.

Molds by this class apply to products were control is non-

M4 Non-critical critical and secondary to cost.

Based on the class selected, use the corresponding table below to apply tolerances as follows:

1. Fixed tolerances are related by size to each dimension but all closure tolerances are determined by

the largest closure dimension.

2. Tolerances not shown should be determined in consultation with the manufacturer.

3. Take special care when applying standard tolerances to products having wide sectional variations.

Você também pode gostar

- DIN ISO 3302-1: Nominal Dimension Class M1 Class M2 Class M3 Class M4Documento1 páginaDIN ISO 3302-1: Nominal Dimension Class M1 Class M2 Class M3 Class M4Augusto PeinadoAinda não há avaliações

- Formteile-Toleranzen DIN-ISO-3302-1 PDFDocumento1 páginaFormteile-Toleranzen DIN-ISO-3302-1 PDFMarcos Antonio RossiAinda não há avaliações

- Din 2393-2Documento0 páginaDin 2393-2Yalavarthi ChandrasekharAinda não há avaliações

- TL 256 en 2022Documento8 páginasTL 256 en 2022Michal BílekAinda não há avaliações

- M 3031 (2013-06)Documento16 páginasM 3031 (2013-06)Hatada FelipeAinda não há avaliações

- VW2.8.1 en 2009-12-01Documento17 páginasVW2.8.1 en 2009-12-01mehmet ustunAinda não há avaliações

- GS 97038 FlammabilityDocumento5 páginasGS 97038 FlammabilitySandra Rios100% (3)

- ATE N 553 81.09 (En)Documento11 páginasATE N 553 81.09 (En)Miguel QueirosAinda não há avaliações

- Iso 11997-1 - 2005Documento8 páginasIso 11997-1 - 2005Khin Khin Thaw100% (2)

- Din 2393-2 PDFDocumento5 páginasDin 2393-2 PDFKarthikeyan NAinda não há avaliações

- ISO 3302-2 - 1998 - Tolerancia Dimensional BorrachasDocumento6 páginasISO 3302-2 - 1998 - Tolerancia Dimensional BorrachasEngineerMecAinda não há avaliações

- ISO 3302-1:1996 (E) : M-ClassDocumento2 páginasISO 3302-1:1996 (E) : M-ClassMarcos Antonio RossiAinda não há avaliações

- International Standard: ISO 105-X12Documento10 páginasInternational Standard: ISO 105-X12Tahir NizamAinda não há avaliações

- Preparing, Cleaning, and Evaluating Corrosion Test SpecimensDocumento9 páginasPreparing, Cleaning, and Evaluating Corrosion Test Specimensalucard375Ainda não há avaliações

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsDocumento5 páginasCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- PV 3 3 3Documento3 páginasPV 3 3 3Francesco Vignali100% (1)

- GMW3001Documento1 páginaGMW3001skgolban0% (1)

- D 1415 - 88 R99 - Rde0mtu - PDFDocumento5 páginasD 1415 - 88 R99 - Rde0mtu - PDFGyna SHAinda não há avaliações

- Iso Update: Supplement To IsofocusDocumento22 páginasIso Update: Supplement To IsofocusdeivisonfrancoAinda não há avaliações

- GM 6194M 2004Documento7 páginasGM 6194M 2004JOVANY LOPEZAinda não há avaliações

- Din en 13599 - 2014Documento23 páginasDin en 13599 - 2014alfered100% (1)

- Es X56901Documento5 páginasEs X56901PongsanAinda não há avaliações

- Astm B765Documento4 páginasAstm B765Purushottam Sutar100% (2)

- VW TL 217 2016Documento8 páginasVW TL 217 2016Bartek HajaAinda não há avaliações

- Technical Cleanliness - Gasket SealingDocumento8 páginasTechnical Cleanliness - Gasket SealingLOGANATHAN V0% (1)

- Harmonized "Cluster" Document: Fasteners Property Classes of Special ServiceDocumento7 páginasHarmonized "Cluster" Document: Fasteners Property Classes of Special ServiceIBRAinda não há avaliações

- PPAP 4th EdDocumento11 páginasPPAP 4th EdEd Ri0% (1)

- Nes M0135-2001Documento22 páginasNes M0135-2001farhad pashaei mehr80% (5)

- ISO 7452-2013-01 Hot-Rolled Steel Plates - TolerancesDocumento20 páginasISO 7452-2013-01 Hot-Rolled Steel Plates - TolerancesIrwan PriyambodoAinda não há avaliações

- ISO-n Exponent PDFDocumento12 páginasISO-n Exponent PDFjavidokAinda não há avaliações

- Din 50018 Sulfur Dioxide Corrosion TestDocumento3 páginasDin 50018 Sulfur Dioxide Corrosion TestJoao Pedro Rendeiro Correia de SousaAinda não há avaliações

- Iso-10664 PDFDocumento10 páginasIso-10664 PDFPrabu ArAinda não há avaliações

- D271389 F' PDFDocumento13 páginasD271389 F' PDFReza AbdolahiAinda não há avaliações

- Bsi BS Iso 11359-1 - 2014Documento14 páginasBsi BS Iso 11359-1 - 2014alferedAinda não há avaliações

- Organic Coat GMW 14670 PDFDocumento4 páginasOrganic Coat GMW 14670 PDFYosua Dimas Agus SriyantoAinda não há avaliações

- FCA - PS.50009 (2014) - Ex PS.5570Documento7 páginasFCA - PS.50009 (2014) - Ex PS.5570FeliceAinda não há avaliações

- Nissan Design Specification (NDS) : (Contents)Documento6 páginasNissan Design Specification (NDS) : (Contents)Maryana cAinda não há avaliações

- Surface Comparator Chart Sa 2 5Documento5 páginasSurface Comparator Chart Sa 2 5Vebryan SyahAinda não há avaliações

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedDocumento7 páginasAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzAinda não há avaliações

- Wss-m2p177 - Paint Performance, Chassis Low Level Visible - A1 A A5Documento5 páginasWss-m2p177 - Paint Performance, Chassis Low Level Visible - A1 A A5Fab CarvalAinda não há avaliações

- Ifi 536Documento2 páginasIfi 536Bomb20001Ainda não há avaliações

- VW 011 03Documento22 páginasVW 011 03Alexandre UrquizaAinda não há avaliações

- TSB1503G 9 P 1Documento18 páginasTSB1503G 9 P 1kk_pammu_915176926Ainda não há avaliações

- 11.03 Iso-6272-1-2011Documento9 páginas11.03 Iso-6272-1-2011hoanvuAinda não há avaliações

- (BS en ISO 1520-2006) - Paints and Varnishes. Cupping Test.Documento18 páginas(BS en ISO 1520-2006) - Paints and Varnishes. Cupping Test.Towkir AhmmadAinda não há avaliações

- Din 50942-96Documento13 páginasDin 50942-96RONALD100% (2)

- M0140 2009 N PDFDocumento11 páginasM0140 2009 N PDFhand42100% (1)

- VW 13750 Englisch Superficial TratamentDocumento16 páginasVW 13750 Englisch Superficial Tratamentrgi178Ainda não há avaliações

- TL245 English 2004Documento8 páginasTL245 English 2004Elliott RussellAinda não há avaliações

- DIN 55633 Recubrimiento AnclajesDocumento29 páginasDIN 55633 Recubrimiento Anclajesdeybi resarteAinda não há avaliações

- Engineering Material Specification: Printed Copies Are UncontrolledDocumento6 páginasEngineering Material Specification: Printed Copies Are UncontrolledChandrajeet ShelkeAinda não há avaliações

- International Standard: Stainless Steels For Springs - WireDocumento8 páginasInternational Standard: Stainless Steels For Springs - WireAfzal ImamAinda não há avaliações

- Ford We 910 - 2001Documento6 páginasFord We 910 - 2001Jason-chungAinda não há avaliações

- GPS1 enDocumento5 páginasGPS1 enKlocAinda não há avaliações

- Iso 1-2016Documento7 páginasIso 1-2016ProfRyu11100% (1)

- Rubber Extrusion GuideDocumento3 páginasRubber Extrusion Guidefimmee2006Ainda não há avaliações

- Rubber TolerancesDocumento2 páginasRubber TolerancesmuammeryaziciAinda não há avaliações

- How To Choose The Right Gauge Block ComparatorDocumento15 páginasHow To Choose The Right Gauge Block ComparatorneramopAinda não há avaliações

- Tolerances vs. Dimension: ISO 3302 Classification SystemDocumento2 páginasTolerances vs. Dimension: ISO 3302 Classification SystemrafecarAinda não há avaliações

- KRA 3.8 Travelling Crane ProcedureDocumento11 páginasKRA 3.8 Travelling Crane ProcedureAhsan Farooq100% (1)

- Documentation Requirement - Salaried Segment OriginalDocumento2 páginasDocumentation Requirement - Salaried Segment OriginalAhsan FarooqAinda não há avaliações

- 4 Busbar Combiner BoxDocumento1 página4 Busbar Combiner BoxAhsan FarooqAinda não há avaliações

- Pipe Sizes Copper PDFDocumento2 páginasPipe Sizes Copper PDFAhsan FarooqAinda não há avaliações

- 536570-316 Rev A Web PDFDocumento1 página536570-316 Rev A Web PDFAhsan FarooqAinda não há avaliações

- Sun Nuclear 3D SCANNERDocumento7 páginasSun Nuclear 3D SCANNERFranco OrlandoAinda não há avaliações

- 7Documento101 páginas7Navindra JaggernauthAinda não há avaliações

- RCC Design of Toe-Slab: Input DataDocumento2 páginasRCC Design of Toe-Slab: Input DataAnkitaAinda não há avaliações

- Leeka Kheifets PrincipleDocumento6 páginasLeeka Kheifets PrincipleAlexandreau del FierroAinda não há avaliações

- Delta PresentationDocumento36 páginasDelta Presentationarch_ianAinda não há avaliações

- Unit 5 Andhra Pradesh.Documento18 páginasUnit 5 Andhra Pradesh.Charu ModiAinda não há avaliações

- Design & Construction of New River Bridge On Mula RiverDocumento133 páginasDesign & Construction of New River Bridge On Mula RiverJalal TamboliAinda não há avaliações

- Power For All - Myth or RealityDocumento11 páginasPower For All - Myth or RealityAshutosh BhaktaAinda não há avaliações

- Nissan E-NV200 Combi UKDocumento31 páginasNissan E-NV200 Combi UKMioMaulenovoAinda não há avaliações

- Question Paper: Hygiene, Health and SafetyDocumento2 páginasQuestion Paper: Hygiene, Health and Safetywf4sr4rAinda não há avaliações

- CSA Report Fahim Final-1Documento10 páginasCSA Report Fahim Final-1Engr Fahimuddin QureshiAinda não há avaliações

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaDocumento10 páginasA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungAinda não há avaliações

- Chapter 3 Searching and PlanningDocumento104 páginasChapter 3 Searching and PlanningTemesgenAinda não há avaliações

- SMK Techno ProjectDocumento36 páginasSMK Techno Projectpraburaj619Ainda não há avaliações

- Capsule Research ProposalDocumento4 páginasCapsule Research ProposalAilyn Ursal80% (5)

- QCM Part 145 en Rev17 310818 PDFDocumento164 páginasQCM Part 145 en Rev17 310818 PDFsotiris100% (1)

- Bismillah SpeechDocumento2 páginasBismillah SpeechanggiAinda não há avaliações

- The Concept of ElasticityDocumento19 páginasThe Concept of ElasticityVienRiveraAinda não há avaliações

- Steam Source Book PDFDocumento108 páginasSteam Source Book PDFJose Levican A100% (1)

- Shopnil Tower 45KVA EicherDocumento4 páginasShopnil Tower 45KVA EicherBrown builderAinda não há avaliações

- Petitioner's Response To Show CauseDocumento95 páginasPetitioner's Response To Show CauseNeil GillespieAinda não há avaliações

- Hierarchy of The Inchoate Crimes: Conspiracy Substantive CrimeDocumento18 páginasHierarchy of The Inchoate Crimes: Conspiracy Substantive CrimeEmely AlmonteAinda não há avaliações

- Document 3Documento3 páginasDocument 3AdeleAinda não há avaliações

- Exercise 23 - Sulfur OintmentDocumento4 páginasExercise 23 - Sulfur OintmentmaimaiAinda não há avaliações

- Chapter Two Complexity AnalysisDocumento40 páginasChapter Two Complexity AnalysisSoressa HassenAinda não há avaliações

- Pilot'S Operating Handbook: Robinson Helicopter CoDocumento200 páginasPilot'S Operating Handbook: Robinson Helicopter CoJoseph BensonAinda não há avaliações

- AutoCAD Dinamicki Blokovi Tutorijal PDFDocumento18 páginasAutoCAD Dinamicki Blokovi Tutorijal PDFMilan JovicicAinda não há avaliações

- Service ManualDocumento30 páginasService ManualYoni CativaAinda não há avaliações

- Gis Tabels 2014 15Documento24 páginasGis Tabels 2014 15seprwglAinda não há avaliações

- PPB 3193 Operation Management - Group 10Documento11 páginasPPB 3193 Operation Management - Group 10树荫世界Ainda não há avaliações