Escolar Documentos

Profissional Documentos

Cultura Documentos

Biomass-Based Catalysts for Biodiesel Production

Enviado por

Yu Hui0 notas0% acharam este documento útil (0 voto)

8 visualizações1 páginaName: Choi Yu Hui

ID: 1402693

The document discusses a research study that synthesized heterogeneous solid catalysts from biomass sources like oil palm frond for biodiesel production. The study investigated the effect of pretreatment conditions like carbonization temperature, impregnation weight ratios, and impregnation temperatures on catalytic performance. The optimum pretreatment conditions achieved the highest fatty acid methyl ester yield and conversion of 92.27% and 96.53% respectively at 600°C carbonization, 1:1.5 impregnation ratio, and 90°C impregnation temperature. Characterization techniques were used to analyze the raw materials, activated carbons, and catalysts.

Descrição original:

FYP project Gui

Título original

Abstract

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoName: Choi Yu Hui

ID: 1402693

The document discusses a research study that synthesized heterogeneous solid catalysts from biomass sources like oil palm frond for biodiesel production. The study investigated the effect of pretreatment conditions like carbonization temperature, impregnation weight ratios, and impregnation temperatures on catalytic performance. The optimum pretreatment conditions achieved the highest fatty acid methyl ester yield and conversion of 92.27% and 96.53% respectively at 600°C carbonization, 1:1.5 impregnation ratio, and 90°C impregnation temperature. Characterization techniques were used to analyze the raw materials, activated carbons, and catalysts.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

8 visualizações1 páginaBiomass-Based Catalysts for Biodiesel Production

Enviado por

Yu HuiName: Choi Yu Hui

ID: 1402693

The document discusses a research study that synthesized heterogeneous solid catalysts from biomass sources like oil palm frond for biodiesel production. The study investigated the effect of pretreatment conditions like carbonization temperature, impregnation weight ratios, and impregnation temperatures on catalytic performance. The optimum pretreatment conditions achieved the highest fatty acid methyl ester yield and conversion of 92.27% and 96.53% respectively at 600°C carbonization, 1:1.5 impregnation ratio, and 90°C impregnation temperature. Characterization techniques were used to analyze the raw materials, activated carbons, and catalysts.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 1

Name: Choi Yu Hui

ID: 1402693

The implementation of biomass sources as carbon precursor to synthesise heterogeneous solid

catalyst for biodiesel production has drawn attention from researchers because it is less expensive

and can reduce the biomass waste. In this research, the biomass-based catalysts were synthesised

and the effect of pretreatment conditions on catalytic performance was investigated. In

preliminary study, oil palm frond (OPF) with particles size of 300μm was selected as the most

promising biomass source and size whereas potassium hydroxide (KOH) was chosen as an

activating agent due to its better impregnation effect as compared to phosphoric acid (H3 PO4 ).

Afterward, the effect of pretreatment conditions was studied by manipulating the carbonisation

temperatures (400℃, 600℃ and 800℃), impregnation weight ratios of OPF to KOH (1:0.5, 1:1

and 1:1.5) and impregnation temperatures (50℃, 70℃ and 90℃). Esterification was carried out

using palm fatty acid distillate (PFAD) at reaction condition of 100℃ for 6h, 1wt% catalyst

loading and methanol to oil molar ratio of 10:1. Other than pretreatment parameters, various

sulfonation methods such as direct sulfonation, 4-BDS and decomposition of ammonium

persulfate were implemented to synthesis catalyst and the effect of sulfonation methods on

catalytic performance was compared. The biodiesel yield and conversion were determined by gas

chromatography (GC) and acid value test. The results showed that the optimum pretreatment

condition was achieved at maximum FAME yield and conversion of 92.27% and 96.53%,

respectively, at carbonisation temperature of 600℃, impregnation ratio of 1:1.5 and impregnation

temperature of 90℃. In order to study the effect of pretreatment on samples, characterisation of

raw OPF, impregnated OPF, activated carbon and catalyst were done to investigate the surface

morphology with SEM, elemental composition with EDX, the presence of functional groups with

FTIR, thermal stability with TGA and effective reduction temperature with TPR.

Você também pode gostar

- Measurement of Antioxidant Activity and Capacity: Recent Trends and ApplicationsNo EverandMeasurement of Antioxidant Activity and Capacity: Recent Trends and ApplicationsResat ApakAinda não há avaliações

- Kinetic study of esterification of free fatty acid in low grade crude palm oilDocumento8 páginasKinetic study of esterification of free fatty acid in low grade crude palm oilSABER FARHANAinda não há avaliações

- Physicochemical Properties of Phosphate Ester From Palm Kernel OilDocumento8 páginasPhysicochemical Properties of Phosphate Ester From Palm Kernel Oilvictor japposanAinda não há avaliações

- Effect of Modification ZSM-5 Catalyst in Upgrading Quality of Organic Liquid Product Derived From Catalytic Cracking of Indonesian Nyamplung Oil (Calophyllum Inophyllum)Documento7 páginasEffect of Modification ZSM-5 Catalyst in Upgrading Quality of Organic Liquid Product Derived From Catalytic Cracking of Indonesian Nyamplung Oil (Calophyllum Inophyllum)Yusran KheryAinda não há avaliações

- Phenol-Formaldehyde Resols Modified by Boric Acid: 386 POLIMERY 2006, 51, NR 5Documento3 páginasPhenol-Formaldehyde Resols Modified by Boric Acid: 386 POLIMERY 2006, 51, NR 5cera primaAinda não há avaliações

- Catalizatori Eterogeni Pentru Productia de BiodieselDocumento4 páginasCatalizatori Eterogeni Pentru Productia de BiodieselElly GloriaAinda não há avaliações

- Ultrasound-Assisted Synthesis of Biodiesel From Palm Fatty Acid DistillateDocumento5 páginasUltrasound-Assisted Synthesis of Biodiesel From Palm Fatty Acid Distillatedstar13Ainda não há avaliações

- 1 s2.0 S1876610214011266 MainDocumento10 páginas1 s2.0 S1876610214011266 MainHendriyana StAinda não há avaliações

- Reduction of Free Fatty Acids in Crude Jatropha Curcas Oil Via An Esterification ProcessDocumento7 páginasReduction of Free Fatty Acids in Crude Jatropha Curcas Oil Via An Esterification Processu085264Ainda não há avaliações

- Candida Antarctica As A Novel Catalyst: Full Length ArticleDocumento8 páginasCandida Antarctica As A Novel Catalyst: Full Length ArticleFikka RuhaiyaAinda não há avaliações

- Wenlei 2006Documento7 páginasWenlei 2006Hajarul MassiAinda não há avaliações

- Sian Ournal of HemistryDocumento5 páginasSian Ournal of HemistryYlm PtanaAinda não há avaliações

- Phosphorus in Oil. Production of Molybdenum Blue Derivative at Ambient Temperature Using Noncarcinogenic ReagentsDocumento4 páginasPhosphorus in Oil. Production of Molybdenum Blue Derivative at Ambient Temperature Using Noncarcinogenic ReagentsAhmed IsmailAinda não há avaliações

- 1 s2.0 S0165237019300294 Main PDFDocumento11 páginas1 s2.0 S0165237019300294 Main PDFNatashaA.CuencaSchillingAinda não há avaliações

- Synthesis of Biodiesel From Soybean Oil Using Heterogeneous Kf/Zno CatalystDocumento7 páginasSynthesis of Biodiesel From Soybean Oil Using Heterogeneous Kf/Zno CatalystitzelselAinda não há avaliações

- Neff1994 Article OxidativeStabilityOfBlendsAndI PDFDocumento6 páginasNeff1994 Article OxidativeStabilityOfBlendsAndI PDFTowhid HasanAinda não há avaliações

- Neff1994 Article OxidativeStabilityOfBlendsAndI PDFDocumento6 páginasNeff1994 Article OxidativeStabilityOfBlendsAndI PDFTowhid HasanAinda não há avaliações

- Catalysts: Study The E Catalytic Activity of Carbohydrate-Derived Catalysts For Ester ProductionDocumento13 páginasCatalysts: Study The E Catalytic Activity of Carbohydrate-Derived Catalysts For Ester ProductionBeatriz MartinsAinda não há avaliações

- Castor Oil Transesterification Kinetic StudyDocumento7 páginasCastor Oil Transesterification Kinetic StudyMuhammad WahyudiAinda não há avaliações

- Energy Conversion and Management: Hu Pan, Hu Li, Heng Zhang, Anping Wang, Duo Jin, Song YangDocumento11 páginasEnergy Conversion and Management: Hu Pan, Hu Li, Heng Zhang, Anping Wang, Duo Jin, Song YangjohnkirubaAinda não há avaliações

- The Physicochemical and Thermal Properties of Malaysian High Free Fatty Acid Crude Palm OilDocumento8 páginasThe Physicochemical and Thermal Properties of Malaysian High Free Fatty Acid Crude Palm OilTomTomAinda não há avaliações

- Bioresources.: Upgrading of Bio-Oil in Supercritical Ethanol: Using Furfural and Acetic Acid As Model CompoundsDocumento19 páginasBioresources.: Upgrading of Bio-Oil in Supercritical Ethanol: Using Furfural and Acetic Acid As Model CompoundsJohn ShipAinda não há avaliações

- 1 s2.0 S2666893922000391 MainDocumento8 páginas1 s2.0 S2666893922000391 Mainmohammed seidAinda não há avaliações

- Production of Aromatic Hydrocarbons From Catalytic Co-PyrolysisDocumento7 páginasProduction of Aromatic Hydrocarbons From Catalytic Co-PyrolysisTan Nakaphan100% (1)

- Synthesis and Study of Ni-Mo-Co Catalysts For Hydroprocessing of Oil FractionsDocumento14 páginasSynthesis and Study of Ni-Mo-Co Catalysts For Hydroprocessing of Oil FractionsYerlin VásquezAinda não há avaliações

- Abuk Had Ra 2017Documento6 páginasAbuk Had Ra 2017Alfia WahyuniAinda não há avaliações

- Synthesis of Waste Cooking Oil-Based Biodiesel Via Effectual RecyclableDocumento8 páginasSynthesis of Waste Cooking Oil-Based Biodiesel Via Effectual RecyclableDiko FernandoAinda não há avaliações

- Epoxidation of FameDocumento4 páginasEpoxidation of FameAhmad SyahmiAinda não há avaliações

- Methyl Ester Synthesis of Crude Palm Oil Off GradeDocumento11 páginasMethyl Ester Synthesis of Crude Palm Oil Off GradeDiar RickiAinda não há avaliações

- Abstract - enDocumento1 páginaAbstract - enRicco AdityaAinda não há avaliações

- Bionature 2011 2 20 60105Documento4 páginasBionature 2011 2 20 60105annak143Ainda não há avaliações

- Novel Hierarchical HZSM-5 Zeolites Prepared by Combining Desilication and Steaming Modification For Converting Methanol To Propylene ProcessDocumento19 páginasNovel Hierarchical HZSM-5 Zeolites Prepared by Combining Desilication and Steaming Modification For Converting Methanol To Propylene Processbruno barrosAinda não há avaliações

- NNResinDocumento8 páginasNNResinNonny Dwitasari SiregarAinda não há avaliações

- Bioresource Technology: Ming Li, Yan Zheng, Yixin Chen, Xifeng ZhuDocumento4 páginasBioresource Technology: Ming Li, Yan Zheng, Yixin Chen, Xifeng ZhuArif HidayatAinda não há avaliações

- New Method for Determining Free Fatty Acid Content in Edible Oils Using ECDocumento6 páginasNew Method for Determining Free Fatty Acid Content in Edible Oils Using ECFoo He XuanAinda não há avaliações

- Biodiesel Production From Acidic Crude Palm Oil Using Perchloric AcidDocumento5 páginasBiodiesel Production From Acidic Crude Palm Oil Using Perchloric AcidRonaldo CMAinda não há avaliações

- Applied Catalysis B: EnvironmentalDocumento11 páginasApplied Catalysis B: EnvironmentalTan NakaphanAinda não há avaliações

- Sustainable Production of Biodiesel From Tallow, Lard and Poultry Fat and Its Quality EvaluationDocumento6 páginasSustainable Production of Biodiesel From Tallow, Lard and Poultry Fat and Its Quality EvaluationNidia CaetanoAinda não há avaliações

- Bambang Veriansyah, Jae Young Han, Seok Ki Kim, Seung-Ah Hong, Young Jun Kim, Jong Sung Lim, Young-Wong Shu, Seong-Geun Oh, Jaehoon KimDocumento8 páginasBambang Veriansyah, Jae Young Han, Seok Ki Kim, Seung-Ah Hong, Young Jun Kim, Jong Sung Lim, Young-Wong Shu, Seong-Geun Oh, Jaehoon Kimscorpion2001glaAinda não há avaliações

- Preparation of Biodiesel Catalyzed by Solid Super Base of Calcium Oxide and Its Refining ProcessDocumento6 páginasPreparation of Biodiesel Catalyzed by Solid Super Base of Calcium Oxide and Its Refining ProcessdGAinda não há avaliações

- Rahimi 2014 Optimization SoyabeanDocumento7 páginasRahimi 2014 Optimization Soyabeaninfimech. idAinda não há avaliações

- IOP Conference: Production of High Octane Gasoline from Petroleum and Palm OilDocumento9 páginasIOP Conference: Production of High Octane Gasoline from Petroleum and Palm OilZulvia KhaerunnisaAinda não há avaliações

- Farmani2015 3Documento9 páginasFarmani2015 3Fikka RuhaiyaAinda não há avaliações

- Experimental Study On Influence of Operating Parameters OnDocumento10 páginasExperimental Study On Influence of Operating Parameters On63011273Ainda não há avaliações

- Aura Naza Arimbi Wijaya - Tugas Metopel Check SimilarityDocumento3 páginasAura Naza Arimbi Wijaya - Tugas Metopel Check SimilarityAura NazaAinda não há avaliações

- Synthesis of Trimethylolpropane Esters of Oleic Acid Using A Multi-SO3H-Functionalized Ionic Liquid As An Efficient CatalystDocumento7 páginasSynthesis of Trimethylolpropane Esters of Oleic Acid Using A Multi-SO3H-Functionalized Ionic Liquid As An Efficient CatalystAldi IgnielAinda não há avaliações

- Acido Kojico SisntesisDocumento0 páginaAcido Kojico SisntesisJosafath VenturaAinda não há avaliações

- Epoxidation of Soybean Oil in Toluene WithDocumento7 páginasEpoxidation of Soybean Oil in Toluene WithDaniella DenleschiAinda não há avaliações

- 168328-Article Text-433057-1-10-20180316Documento12 páginas168328-Article Text-433057-1-10-20180316Umar Farouq Mohammed GalibAinda não há avaliações

- Eco-Friendly Esterification of Oxalic Acid With Ethanol Using Mesoporous MgAlPO4 CatalystDocumento4 páginasEco-Friendly Esterification of Oxalic Acid With Ethanol Using Mesoporous MgAlPO4 CatalystHoly RazgrizAinda não há avaliações

- FAME From Rapeseed OilDocumento9 páginasFAME From Rapeseed OilmakarelAinda não há avaliações

- Palm Kernel Oil TMP Esters SynthesisDocumento8 páginasPalm Kernel Oil TMP Esters SynthesisAsnan BY100% (1)

- Synthesis of Aspirin Catalyzed by Supramolecular Compound Based On Keggin-Type Phosphomolybates With Flexible 1,3-Bis (4-Pyridyl) PropaneDocumento9 páginasSynthesis of Aspirin Catalyzed by Supramolecular Compound Based On Keggin-Type Phosphomolybates With Flexible 1,3-Bis (4-Pyridyl) PropaneAndres Gonzalez EspinosaAinda não há avaliações

- Lienda A. Handojo - Calcium Oxide Particles SizeDocumento4 páginasLienda A. Handojo - Calcium Oxide Particles SizeBonaventura FernaldiAinda não há avaliações

- Biodiesel Production by Transesterification of Duck Tallow With Methanol On Alkali CatalystsDocumento4 páginasBiodiesel Production by Transesterification of Duck Tallow With Methanol On Alkali Catalystschtanhull_1988Ainda não há avaliações

- Jokwanu WoDocumento10 páginasJokwanu WoTsunami IntelligenceAinda não há avaliações

- Extractive Oxidative Desulfurization of Model Oil/crude Oil Using KSF Montmorillonite-Supported 12-Tungstophosphoric AcidDocumento10 páginasExtractive Oxidative Desulfurization of Model Oil/crude Oil Using KSF Montmorillonite-Supported 12-Tungstophosphoric AcidTsunami IntelligenceAinda não há avaliações

- Literature Servey-1Documento5 páginasLiterature Servey-1Me 172Ainda não há avaliações

- Energies 12 02473Documento16 páginasEnergies 12 02473Andry SianturiAinda não há avaliações

- Journal of Natural Gas Science and EngineeringDocumento7 páginasJournal of Natural Gas Science and Engineeringmanuel cabarcasAinda não há avaliações

- ProcedureDocumento2 páginasProcedureYu HuiAinda não há avaliações

- PD SlidesDocumento20 páginasPD SlidesYu HuiAinda não há avaliações

- Jan 16Documento4 páginasJan 16Yu HuiAinda não há avaliações

- LEE KONG CHIAN FACULTY ENGINEERING AND SCIENCE RESEARCHDocumento21 páginasLEE KONG CHIAN FACULTY ENGINEERING AND SCIENCE RESEARCHYu HuiAinda não há avaliações

- Nanocellulose Recent Advances and Its Prospects PDFDocumento20 páginasNanocellulose Recent Advances and Its Prospects PDFYu HuiAinda não há avaliações

- URS ReportDocumento1 páginaURS ReportYu HuiAinda não há avaliações

- Effect of Pretreatment On Synthesis of Oil Palm Frond Derived Catalyst For Biodiesel ProductionDocumento1 páginaEffect of Pretreatment On Synthesis of Oil Palm Frond Derived Catalyst For Biodiesel ProductionYu HuiAinda não há avaliações

- Room RentalDocumento1 páginaRoom RentalYu HuiAinda não há avaliações

- Time TableDocumento3 páginasTime TableYu HuiAinda não há avaliações

- ProcedureDocumento2 páginasProcedureYu HuiAinda não há avaliações

- Cancionero YamahaDocumento212 páginasCancionero YamahaPedro Scherrer Gomez100% (2)

- A Review: Bioprocess of Microalgae Using Ionic Liquid-Based Aqueous Two-Phase SystemDocumento1 páginaA Review: Bioprocess of Microalgae Using Ionic Liquid-Based Aqueous Two-Phase SystemYu HuiAinda não há avaliações

- Receipt of Lab Report Submission (To Be Keep by Student)Documento2 páginasReceipt of Lab Report Submission (To Be Keep by Student)Yu HuiAinda não há avaliações

- WordsDocumento16 páginasWordsYu HuiAinda não há avaliações

- ResultDocumento7 páginasResultYu HuiAinda não há avaliações

- WordsDocumento1 páginaWordsYu HuiAinda não há avaliações

- Method 1: (Method I Am Using Now, But Not Sure It Is Correct or Not, If Wrong I Can Redo The Experiment)Documento2 páginasMethod 1: (Method I Am Using Now, But Not Sure It Is Correct or Not, If Wrong I Can Redo The Experiment)Yu HuiAinda não há avaliações

- Beth and AdamDocumento4 páginasBeth and AdamYu HuiAinda não há avaliações

- Heat-Exchanger Bypass Control: William L. LuybenDocumento9 páginasHeat-Exchanger Bypass Control: William L. LuybenYu Hui100% (1)

- TaiwanDocumento2 páginasTaiwanYu HuiAinda não há avaliações

- Presentation Rev02Documento41 páginasPresentation Rev02Yu HuiAinda não há avaliações

- RefereDocumento1 páginaRefereYu HuiAinda não há avaliações

- Preparation of Activated Carbon from BiomassDocumento2 páginasPreparation of Activated Carbon from BiomassYu HuiAinda não há avaliações

- Pipe Sizing StepsDocumento1 páginaPipe Sizing StepsYu HuiAinda não há avaliações

- Universiti Tunku Abdul Rahman: UEMK 3223 Particle TechnologyDocumento6 páginasUniversiti Tunku Abdul Rahman: UEMK 3223 Particle TechnologyYu HuiAinda não há avaliações

- TimetableDocumento1 páginaTimetableYu HuiAinda não há avaliações

- Coursework MarkDocumento4 páginasCoursework MarkYu HuiAinda não há avaliações

- References: Journal of Modern Engineering Research (IJMER), p.2Documento1 páginaReferences: Journal of Modern Engineering Research (IJMER), p.2Yu HuiAinda não há avaliações

- Imperfection in SolidDocumento11 páginasImperfection in SolidYu HuiAinda não há avaliações

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaAinda não há avaliações

- Highest Duty: My Search for What Really MattersNo EverandHighest Duty: My Search for What Really MattersAinda não há avaliações

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNo EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNota: 4 de 5 estrelas4/5 (28)

- The Fabric of Civilization: How Textiles Made the WorldNo EverandThe Fabric of Civilization: How Textiles Made the WorldNota: 4.5 de 5 estrelas4.5/5 (56)

- A Place of My Own: The Architecture of DaydreamsNo EverandA Place of My Own: The Architecture of DaydreamsNota: 4 de 5 estrelas4/5 (241)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureNo EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureNota: 5 de 5 estrelas5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceNo EverandPale Blue Dot: A Vision of the Human Future in SpaceNota: 4.5 de 5 estrelas4.5/5 (586)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980No Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Nota: 4 de 5 estrelas4/5 (21)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationNo EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationNota: 4.5 de 5 estrelas4.5/5 (46)

- Sully: The Untold Story Behind the Miracle on the HudsonNo EverandSully: The Untold Story Behind the Miracle on the HudsonNota: 4 de 5 estrelas4/5 (101)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesNo EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesAinda não há avaliações

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseNo EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseNota: 3.5 de 5 estrelas3.5/5 (12)

- The Future of Geography: How the Competition in Space Will Change Our WorldNo EverandThe Future of Geography: How the Competition in Space Will Change Our WorldNota: 4.5 de 5 estrelas4.5/5 (4)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraNo EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraNota: 3 de 5 estrelas3/5 (10)

- Packing for Mars: The Curious Science of Life in the VoidNo EverandPacking for Mars: The Curious Science of Life in the VoidNota: 4 de 5 estrelas4/5 (1395)

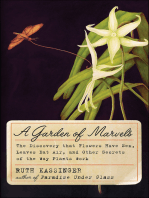

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsNo EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsAinda não há avaliações

- Reality+: Virtual Worlds and the Problems of PhilosophyNo EverandReality+: Virtual Worlds and the Problems of PhilosophyNota: 4 de 5 estrelas4/5 (24)

- The End of Craving: Recovering the Lost Wisdom of Eating WellNo EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellNota: 4.5 de 5 estrelas4.5/5 (80)

- The Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsNo EverandThe Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsNota: 4 de 5 estrelas4/5 (139)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansAinda não há avaliações

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNo EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsAinda não há avaliações

- Inventor of the Future: The Visionary Life of Buckminster FullerNo EverandInventor of the Future: The Visionary Life of Buckminster FullerNota: 4 de 5 estrelas4/5 (10)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindAinda não há avaliações

- Artificial Intelligence: A Guide for Thinking HumansNo EverandArtificial Intelligence: A Guide for Thinking HumansNota: 4.5 de 5 estrelas4.5/5 (30)