Escolar Documentos

Profissional Documentos

Cultura Documentos

Structural 51019

Enviado por

Dave LicerioDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Structural 51019

Enviado por

Dave LicerioDireitos autorais:

Formatos disponíveis

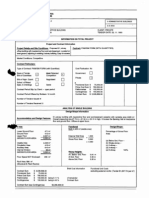

NOTE:

PURSUANT 70 SECTION 4 OF ANNEX "A" OF THE

REVISED NPLEMBVIING RULES AND REGULATION OF RA. Mt

APPROK BY RE AUTHORIZED OPIVH OfF7CLALS OF DETAILED

OVGINEERING SLAMS AND DESIGN UNDERTAKEN BY CONSULTANTS

NEITHER LYAIMESHES THE RESPONSIBILITY OF THE LATTER

GENERAL CONSTRUCTION NOTES

FOR 77 ETECHMLYLIA7EGRITYOF THE SURVEYSAND DESIGN

(ION TRANSFER ANY PART OF THAT RESPONSITILITY TO THE

APPROVINGOFFICIALS

RE DIMON =SWAP? SHALL BE HELD FULLY RESPONSIBLE

GENERAL NOTES NOTES ON CONCRETE MIXES & PLACING TYPICAL BAR BENDING AND CUTTING DETAILS FOR SLABS FOR THE FAILURE OF ME FACILITY/TES/STRUCTURES

DUE TO FAULTY DESIGN EXCEPT FEW THE CHANGES WOE

3. IF SLABS ARE REINFORCED BOTHWAYS BARS ALONG THE SHORTER SPAN SHALL BE PLACED

WITHOUT RECONFORAIITYOF RE CONSULTANTS

1.0 STANDARDS AND REFERENCES 1. ALL CONCRETE SHALL DEVELOP A MIN. COMPRESSIVE STRENGTH AT THE END OF TWENTY

EIGHT (28) DAYS W/ CORRESPONDING MAXIMUM SIZE AGGREGATE & SLUMPS AS FOLLOWS. BELOW THOSE ALONG THE LONG SPAN AT THE CENTER AND OVER THE LONGER SPAN

THE FOLLOWING SHALL GOVERN THE DESIGN, FABRICATION AND CONSTRUCTION OF THE PROJECT. FOR REINFORCING BARS NEAR THE SUPPORTS. THE SPACING OF THE BARS AT THE COLUMN

LOCATION 28 DAYS STRENGTH MAX. SIZE OF MAX. SLUMP STRIPS SHALL NOT BE MORE THAN ONE AND A HALF (1 1/2) SLAB THICKNESS

1.1 NATIONAL STRUCTURAL CODE OF THE PHIUPPINES (N.S.C.P.). VOL. 1, 6TH EDITION, AGGREGATE

2010. 4. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY PLACED NEAR THE FACE IN TENSION

2.0 DESIGN CRITERIA ALL OTHERS. INCLUDING AND SHALL NOT BE LESS THAN 0.0025 x GROSS CROSS-SECTIONAL AREA (Ag) OF THE SLAB JOINT HOOP SPACE 0 "2Sh" WHEN THERE

SUSPENDED SLABS. 3000 PSI (20.7 MPa) 20mm 100mm (SEE SCHEDULE BELOW) ARE BEAMS HAVING WIDTH OF AT LEAST

2.1 LOADINGS COLUMNS 3000 PSI (20.7 MPa) 20mm 100mm ONE-HALF THE COLUMN WIDTH & DEPTHS

A. DEAD LOAD NOT LESS THAN THREE QUARTERS OF THE

CONCRETE 23.56kN/m BEAMS. SLABS 3000 PSI (20.7 MPa) 20mm 100mm SCHEDULE OF MINIMUM SLAB REINFORCEMENT DEEPEST BEAM THAT FRAME INTO FOUR

STEEL 76.93kN/rn SLAB ON FILL 2500 PSI 20mm 100mm SIDES OF THE COLUMN. ALL OTHER

150mm THK. CHB WALL

(17.5 MPa) THICKNESS MINIMUM TEMPERATURE BARS

2.73 kPa CONDITIONS USE HOOPS 0 "Sh" CENTERS.

100mm THK. CHB WALL 2.11 kPa 100 mm 10 mm 0 0 250mm EACH WAY

2. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS.

B. LIVE LOAD SUSPENDED SLABS ------------------------------------------------------------------------------ 125 mm 10 mm 0 0 225mm EACH WAY

20mm

ROOF 1.00 kPa

1.90 kPa

SLAB ON GRADE------------------------------------------------------------------------------------------- 4Ornm 150 mm 10 mm 0 0 185mm EACH WAY

CLASSROOMS

TOILETS 2.40 kPa WALLS ABOVE GRADE ---------------------------------------------------------------------------------- 25rnrn

4Ornm 175 mm 10 mm 0 0 150mm EACH WAY

CORRIDORS ABOVE, STAIRS 3.80 kPa BEAM STIRRUPS AND COLUMN TIES -------------------------------------------------------

CORRIDORS ON GROUND 4.80 kPa WHERE CONCRETE IS EXPOSED TO 200 mm 10 mm 0 0 140mm EACH WAY FOR COL. BAR SPLICES SEE TABLE

EARTH BUT POURED AGAINST FORMS ----------------------------------------------------- 5Ornm OF MIN. LAP SPUCE LENGTH OF

C. WIND LOAD (NSCP 2010) COLUMN REINFORCEMENT

WHERE CONCRETE IS DEPOSITED

BASIC WIND VELOCITY. V = 250 KPH DIRECTLY AGAINST EARTH -------------------------------------------------------------------------- 75mm (SPACING OF TIES ALONG THIS REGION

P = qh [(GCpf)-(GCpi)] (DESIGN WIND PRESSURE) 5. UNLESS OTHERWISE NOTED IN THE PLANS ALL BEDDED SLABS SHALL BE REINFORCED

SHALL NOT BE LESS THAN 100mm)

3. CONCTRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT SEGREGATION. RE-HAND WITH 10mm 0 AT 250rnrn O.0 EACH WAY TO CENTER OF SLAB AND CONSTRUCTION

WHERE: qh = VELOCITY PRESSURE. kPa)

GCpf = EXTERNAL PRESSURE COEFFICIENT LING OR PLACING SHALL BE DONE PREFERABLY WITH BUGGIES, BUCKETS OR JOINTS FOR SAME SHALL NOT BE LESS THAN 3.65 METER APART

GCpi = INTERNAL PRESSURE COEFFICIENT WHEELBARROWS. NO CHUTES WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE FROM 6. PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLAB (TWO ADJACENT DISCONTINUOUS

D. SEISMIC LOAD (NSCP 2010)

HOPPERS TO BUGGIES, WHEELBARROWS OR BUCKETS IN WHICH CASE THEY SHALL NOT

EXCEED SIX (6) METERS IN AGGREGATE LENGTH.

EDGES) AS SHOWN BELOW.

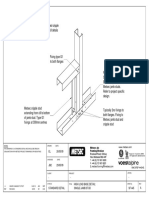

NOTE:

7. CONCRETE SLAB REINFORCEMENTS SHALL BE PROPERLY SUPPORTED WITH 10rnrn0 STEEL ALL CONCRETE REINF. DETAIL SHOULD BE

Cvl 4. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE USE OF VIBRATORS CHAIR OR APPROVED EQUIVALENT SPACED AT 1.0 METER ON CENTER BOTHWAYS

V= W (DESIGN BASE SHEAR) DONE IN ACCORDANCE WITH THE LATEST

RT UNLESS AUTHORIZED IN WRITING BY THE DESIGNERS AND ONLY FOR UNUSUAL CONDITIONS EDITION OF ACI DETAILING MANUAL

WHERE VIBRATIONS ARE EXTREMELY DIFFICULT TO ACCOMPLISH.

2.50 Cal

Vmax W Vrnin = 0.11 CalW

R 5. ALL ANCHOR BOLTS, DOWELS. AND OTHER INSERTS, SHALL BE PROPERLY POSITIONED &

0.80 ZNvI 012x1000 LONG AT

Vrnin 0 . 8

W (ZONE 4) SECURED IN PLACE PRIOR TO PLACING OF CONCRETE.

MID-DEPTH OF SLAB

6. ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF SEVEN CONSECUTIVE DAYS DOWN INTO EDGE BEAM. EXTENDED 4-

AT EACH CORNER

WHERE: W = TOTAL DEAD LOAD 0 120 1800 LONG TOP BARS BEND

IMMEDIATELY AFTER POURING BY THE USE OF WET BURLAP, FOG SPRAYING, CURING 1 -0 2 TO P &

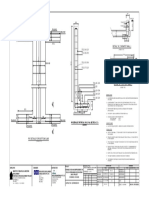

TYPICAL COLUMN ELEV. SHOWING

T = NATURAL PERIOD = (h r ,) 2 / 3 ; BARS MIN. OF 1.200 (4 . -0") INTO BARS.

COMPOUNDS OR OTHER APPROVED METHODS. BOTT. BARS

WHERE: C = NUMERICAL COEFFICIENT

h = BUILDING HEIGHT 4-012 BOTT. BARS DOWELS AND TIES SPACING

7. STRIPPING OF FORMS AND SHORES:

I = IMPORTANCE FACTOR = 1.50 FOUNDATION ------------------------------------------------------------------------------------- 2 4 HRS. Ar 1-012 EA.

R = NUMERICAL FACTOR = 8.50

SEISMIC COEFFICIENT Cv = 0 . 4 4 Nv SUSPENDED SLAB EXCEPT WHEN

Ca = 0.64N ADDITIONAL LOADS ARE IMPOSED --------------------------------------------------------------- B DAYS

NEAR SOURCE FACTOR (10krn) Nv = 1.2 WALLS ------------------------------------------------------------------------------------------------------------- 21 DAYS

TOP & BOT.

Na = 1.0 BEAMS ------------------------------------------------------------------------------------------------------------- 14 DAYS

I

CLE LAP SPLICE LENGTH:

Z = SEISMIC ZONE = 0.40 (ZONE 4) COLUMNS --------------------------------------------------------------------------------------------------------- 21 DAYS AT ANY LEVEL NO MORE THAN

S = SOIL TYPE = D ALTERNATE BARS SHOULD BE

8. THE CONTRACTOR SHALL SUBMIT THE SCHEDULE OF POURING AND THE LOCATION OF THE _____ 1-012 EA. SPUCED. MIN. DISTANCE BET.

CONSTRUCTION JOINTS TO THE STRUCTURAL ENGINEER AT LEAST (4) DAYS PRIOR TO THE TOP & BOT. TWO ADJACENT BARS SPUCES

-

.1

2.2 DESIGN STRESSES POURING FOR APPROVAL. -

A. CONCRETE FOR FOOTING, COLUMNS, BEAMS AND SLAB ON FILL SECTION "A" SHALL BE 600rnrn.

I

COMPRESSIVE STRENGTH 0 28 DAYS fc' = 20.7 MPa (3.000 psi ) 9. THE CONTRACTOR SHALL FURNISH AND MAINTAIN ADEQUATE FORMS AND SHORINGS UNTIL THE IN TWO WAY SLAB EXTEND

B. REINFORCING STEEL BARS fy = 275 MPa (41000 pal ) CONCRETE MEMBERS HAVE ATTAINED THEIR WORKING CONDITION AND STRENGTH. BARS UP TO BEAM SUPPORT L/4

a. FOR BARS 15mrne MID GREATER INTERMEDIATE GRADE DEFORMED BAR

fy ■ 230 MPa (33. 000 psi) OMIT TRIMMER BARS WHERE

b. FOR BARS LESS THAN 16mm0 (STRUCTURAL GRADE DEFORMED BAR)

C. STRUCTURAL STEEL, ASTM -A36

OPENING IS FRAMED BY BEAM TOP BARS 0 SUPP RT (CONT.)

FOR TRUSSES. BRACINGS. & STRUTS

fy - 248 MIN. (38.800 psi ) NOTES ON FOOTINGS TYPICAL SLAB REQ'D. BOTT. BARS 0 SUPPORT

D. PURUNS fy = 248 MIN. (38.000 peD

TYPICAL CORNER SLAB DETAIL OPENING DET

COLD FORMED UGHT GAGE SHAPES 1. FOOTINGS ARE DESIGNED FOR AN AL LOW ABLE SOIL BEARING PRESSURE OF 96

E. MASONRY UNIT (CHB) fm' ■ 3. 45 MPa (500 psi)

KPa ( 2000 psf). CONTRACTOR SHALL REPORT TO THE ENGINEER, IN WRMNG, THE ACTUAL

NON- LOAD BEARING CHB WALLS

SOIL CONDITIONS UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY OF SOIL BEFORE

F. WELDS-USED E-60xx ELECTRODE

G. STRUCTURAL BOLTS. ASTM -A307 DEPOSITING CONCRETE.

a. Ft = 96.60 MPa (1 4.000 psi) b. Fv = 69 MPa (10,000 psi) 2. FOOTING SHALL REST AT LEAST 1500rnm BELOW NATURAL GRADE LINE UNLESS OTHERWISE

NOTES ON COLUMNS

INDICATED IN PLANS. NO FOOTING SHALL REST ON FILL. PUC BOTTOM BARS

1. PROVIDE EXTRA SETS OF TIES AT 100rnrn O.C. FOR TIED COLUMN REINFORCEMENT AT MID SPAN

3. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENTS SHALL BE 75mm CLEAR ABOVE AND BELOW BEAM-COLUMN CONNECTIONS FOR A DISTANCE FROM FACE OF

FOR CONCRETE DEPOSITED THE GROUND AND 50nun FOR CONCRETE CONNECTION EQUAL TO THE GREATER OF THE OVERALL THICKNESS OF COLUMN, EXTRA TOP BARS

3. IN THE INTERPRETATION OF THE DRAWING. INDICATED DIMENSIONS SHALL GOVERN AND DEPOSITED AGAINST A FORMWORK. 1/6 THE CLEAR HEIGHT OF COLUMN OR 450rnrn. 0 SUPPORT

DISTANCES AND SIZES SHALL NOT BE SCALED FOR CONSTRUCTION PURPOSES. IN CASES WHERE THE SOIL CONDITION IS SUCH THAT THE MINIMUM ALLOWABLE SOIL

PRESSURE OF 96 KPa (2,000 psf) CAN NOT BE ATTAINED AT PRACTICAL DEPTHS, THE USE OF 2. COLUMN TIES SHALL BE PROTECTED EVERYWHERE BY A COVERING OF CONCRETE CAST TYP. DETAIL OF COL. LAP SPLICE

4. IN REFERENCE TO OTHER DRAWINGS, SEE ARCHITECTURAL DRAWINGS FOR

DEPRESSIONS IN FLOOR SLABS, OPENINGS IN THE WALLS AND SLABS, INTERIOR

MICROPILES, BORED PILES, OR DRIVEN PILES MAY BE ADOPTED IN LIEU OF STANDARD ISOLATED MONOLITHICALLY WITH THE CORE WITH THE MINIMUM THICKNESS OF 40rnrn AND NOT

LESS THAN 40 TIMES THE MAXIMUM SIZE OF COARSE AGGREGATE IN MILLIMETERS. & EXT. GIRDER TO COL. CONNECT.

FOOTINGS.

PARTIONS, LOCATION OF DRAINS ETC.

3. WHERE COLUMNS CHANGE IN SIZE, VERTICAL REINFORCEMENTS SHALL SHALL BE OFFSET

5. IN CASE OF DISCREPANCIES AS TO THE LAYOUT, DIMENSIONS. AND ELEVATIONS BETWEEN AT A SLOPE OF NOT MORE THAN 1 IN 6 AND EXTRA 10mm TIES AT 100mm SHALL BE

THE STRUCTURAL PLANS, AND ARCHITECTURAL DRAWINGS, THE CONTRACTOR SHALL NOTIFY PROVIDED THRU OUT THE OFFSET REGION. NOTES ON BEAMS AND GIRDERS

BOTH THE STRUCTURAL ENGINEER AND THE ARCHITECT.

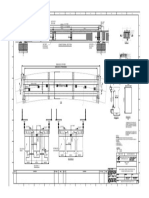

NOTES ON REINFORCEMENT 4. UNLESS OTHERWISE INDICATED IN THE PLANS. LAP SPUCES FOR VERTICAL COLUMN

6. ALL CONCRETE WORK SHALL BE DONE IN ACCORDANCE WITH THE ACI.318 95 BUILDING REINFORCEMENT SHALL BE MADE WITHIN THE CENTER HALF OF COLUMN HEIGHT, AND 1. UNLESS , OTHERWISE NOTED IN PLANS. CAMBER ALL BEAMS AND GIRDER AT LEAST &writ.

CODE REQUIREMENTS FOR REINFORCED CONCRETE AND ALL STRUCTURAL STEEL WORK 1. UNLESS OTHERWISE NOTED IN PLANS, THE YIELD STRENGTH OF REINFORCING BARS SHALL BE: THE SPLICE LENGTH SHALL NOT BE LESS THAN 40 BAR DIAMETERS. WELDING OR FOR EVERY 4.50M OF SPAN , EXCEPT CANTILEVERS FOR WHICH THE CAMBER SHALL BE

ACCORDING WITH AISC SPECIFICATION (9th EDITION) IN SO FAR AS THEY DO NOT CONFLICT A. FOOTINGS, FOOTING BEAMS AND GIRDERS ----- f y = 2 7 5 M P a ( 4 0 . 0 0 0 p s i ) APPROVED MECHANICAL DEVICES MAY BE USED PROVIDED THAT NOT MORE THAN AS NOTED IN PLANS OR AS ORDERED BY THE ENGINEER BUT IN NO CASE LESS THAN

WITH THE LOCAL BUILDING CODE REQUIREMENT. B. CO L UMNS AND SHEA R W AL L S - - - - - - - - - - - - - - - - - - - f y = 2 7 5 M P a ( 4 0 . 0 0 0 p s i ) ALTERNATE BARS ARE WELDED OR MECHANICALLY SPUCED AT ANY LEVEL AND THE 20mm FOR EVERY 3.0M OF FREE SPAN.

VERTICAL DISTANCES BETWEEN THESE WELDS OR SPLICES OF ADJACENT BARS IS NOT

C. BEAMS AND GI RDER ------------------------ fy = 275 MPa ( 40.000 psi ) LESS THAN 600mm. 2. TYPICAL BARS BENDING AND CUTTING DETAILS FOR BEAMS SHALL BE AS

7. ACI REFERS TO AMERICAN CONCRETE INSTITUTE. AISC TO AMERICAN INSTITUTE OF STEEL

SHOW N IN FIG. B-1.

CONSTRUCTION AND ASTM TO AMERICAN SOCIETY FOR TESTING MATERIALS. D. NON-LOAD BEARING WALL PARTITIONS, BEDDED SLABS, FLOOR & ROOF SLABS,

CONSTRUCTION NOTES AND TYPICAL DETAILS APPLY TO ALL DRAWINGS UNLESS OTHERWISE PARAPETS, CATCH BASIN, SIDE WALK. ----------------- f y = 2 2 7 . 5 M P a ( 3 3 , 0 0 0 p s i )

SHOWN OR NOTED. MODIFY TYPICAL DETAILS AS DIRECTED TO MEET SPECIAL CONDITIONS. 2. ALL REINFORCING BARS SIZE 10mm OR LARGER SHALL BE DEFORMED IN ACCORDANCE WITH

ASTM A 706. BARS SMALLER THAN 10mm MAY BE PLAIN.

9. SHOP DRAWINGS WITH ERECTION AND PLACING DIAGRAMS OF ALL STRUCTURAL STEELS,

MISCELLANEOUS IRON. PRE-CAST CONCRETE. ETC. SHALL BE SUBMITTED FOR ENGINEERS 3. SPLICES SHALL BE SECURELY WIRED TOGETHER & SHALL LAP OR EXTEND IN ACCORDANCE

APPROVAL BEFORE FABRICATION. WI TABLE A & TABLE B (TABLE OF LAP SPLICE & ANCHORAGE LENGTH) UNLESS OTHERWISE

L2

SHOWN ON DRAWINGS, SPLICES SHALL BE STAGGERED WHENEVER POSSIBLE.

10 CONTRACTOR SHALL NOTE AND PROVIDE ALL MISCELLANEOUS CURBS. SILLS, STOOLS, L2/3 L3/3

EQUIPMENT'S AND MECHANICAL BASES THAT ARE REQUIRED BY THE ARCHITECTURAL

ELECTRICAL, AND MECHANICAL DRAWINGS. NOTES ON CONCRETE SLABS

11. ALL RESULTS OF MATERIAL TESTING FOR CONCRETE, REINFORCING BARS, & STRUCTURAL ................. =NENE ....

STEEL MUST BE NOTED & APPROVED BY THE STRUCTURAL DESIGNER. 1. ALL SLAB REINFORCEMENTS SHALL BE 20mm CLEAR MINIMUM FROM BOTTOM AND FROM 111111!IIINNA

THE TOP OF SLAB.

2. UNLESS OTHERWISE SHOWN, REINFORCEMENT IN CONTINUOUS ELEVATED SLAB

SHALL BE CUT AS FOLLOWS:

BENT BAR BENT BAR

L1

L2

L1/4

FIG. B-1

1114 r TOP BAR 1-TOP BAR

fp

L BOTTOM BAR

L BOTTOM BAR

JOINT VE NTURE OF DESIGNED: SU BM ITT ED, REVIEWED AS TO RECOMMENDING APPROVAL APPROVED:(FOR ISSUANCE) PROJECT & LOCATION / BARANGAY: SHEET CONTENTS: SET NO. SHEET NO

DESIGN CONCEPT:

UNITEDTECHNOLOGIESCONSOLIDATEDPARTNERSHIP

I VARIOUS DPWH

ABLO . RACINES- REPUBLIC OF THE PHILIPPINES PROPOSED PROJECTS

PBL RACINES (SEE COVER SHEET) (SEE COVER SHEET)

STANDARD TWO-STOREY

PERTCONSULTINTERNATIONAL DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

JOSOIHINE P. ISTURIS DANTE B. POTANTE RAUL C. ASIS GENERAL NOTES

STRUCTURAL DESIGN MANAGING PARTNER

d,NCH I E F,

SCHOOL BUILDING

SCHEMA ENGINEERS AND ASSOCIATES POSITION: STRUCTURAL ENGINEER

PRC No.: 0014064 TIN No.: 108.321.474

BUILDINGS DIVISION, Kt DIRECTOR IV, BOD UNDERSECRETARY ( 6-CLASSROOMS )

PTR No.:2181624

(REVISED 3-24-17)

• lib. ap04

a .

Você também pode gostar

- Drilled Cast-In-Place Pile Design Based On ACI 318-05Documento2 páginasDrilled Cast-In-Place Pile Design Based On ACI 318-05wifjwoijAinda não há avaliações

- Heat Load Calculations SampleDocumento15 páginasHeat Load Calculations SampleleelaAinda não há avaliações

- Structural Notes PDFDocumento158 páginasStructural Notes PDFAin ZulkefliAinda não há avaliações

- New Fulcrum Canopies - Structural Drawings - PermitDocumento6 páginasNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezAinda não há avaliações

- FB Hotel Tower and Convention Center Structural Drawings: Oudie SsociatesDocumento36 páginasFB Hotel Tower and Convention Center Structural Drawings: Oudie Ssociatesabet hilarioAinda não há avaliações

- Ramp AreaDocumento1 páginaRamp AreaAhmed KowaiderAinda não há avaliações

- QCS 2014 Glass UvalueDocumento1 páginaQCS 2014 Glass UvalueRaoofAinda não há avaliações

- Sheetpile Handbook ch2Documento90 páginasSheetpile Handbook ch2Raihan Harun ArrasyidAinda não há avaliações

- TSC21-214 Apartments - 14 Prowse Street WEST PERTH - Structural - 2021-05-26Documento38 páginasTSC21-214 Apartments - 14 Prowse Street WEST PERTH - Structural - 2021-05-26Carent AyuAinda não há avaliações

- TH-50-BLOCK 4 - STR - Drawings PDFDocumento16 páginasTH-50-BLOCK 4 - STR - Drawings PDFSales ConstructionAinda não há avaliações

- Recreation Block: First FloorDocumento1 páginaRecreation Block: First FloorMohammad FajarAinda não há avaliações

- GYPROCK 547 Residential - Installation - Guide 201111 PDFDocumento56 páginasGYPROCK 547 Residential - Installation - Guide 201111 PDFduckeAinda não há avaliações

- BS 5268 - 7.7 Structural Use of Timber PDFDocumento22 páginasBS 5268 - 7.7 Structural Use of Timber PDFTom YeeAinda não há avaliações

- PPVCDocumento1 páginaPPVClow Yi JunAinda não há avaliações

- Environment and Hazard Risk Reduction AnalysisDocumento81 páginasEnvironment and Hazard Risk Reduction AnalysisDave LicerioAinda não há avaliações

- Architecture Yr2 Industrial TrainingDocumento33 páginasArchitecture Yr2 Industrial TrainingKintu Philly100% (2)

- Harmer Drainage Price ListDocumento144 páginasHarmer Drainage Price ListZuberYousufAinda não há avaliações

- Proposed 5 Storey Office BuildingDocumento4 páginasProposed 5 Storey Office BuildingmrlobboAinda não há avaliações

- Timber Note 4 Timber Frame Structures - Platform Construction-Part 2Documento7 páginasTimber Note 4 Timber Frame Structures - Platform Construction-Part 2Sanjeev BundhunAinda não há avaliações

- Cargo Wharf Structural DrawingsDocumento8 páginasCargo Wharf Structural Drawingssteveh2401100% (1)

- BS 5502 22 2003+a1 2013Documento28 páginasBS 5502 22 2003+a1 2013geraldmia50% (2)

- Constn Price List January 2011 FinalDocumento40 páginasConstn Price List January 2011 FinalBurak BaşAinda não há avaliações

- Architect Magazine - Jan 2019Documento108 páginasArchitect Magazine - Jan 2019Dave LicerioAinda não há avaliações

- Trapezoidal Sheet As A Bracing Preventing Flat Trusses From Out-Of-Plane BucklingDocumento7 páginasTrapezoidal Sheet As A Bracing Preventing Flat Trusses From Out-Of-Plane BucklingWilliam Pol100% (1)

- Corporate Circular: Bridge Technical Direction Btd2013/01Documento2 páginasCorporate Circular: Bridge Technical Direction Btd2013/01scribdarell100% (1)

- Double U Pile BehaviorDocumento18 páginasDouble U Pile Behaviorvinod_commentAinda não há avaliações

- 13 Housing Typology Row Town 02Documento51 páginas13 Housing Typology Row Town 02lullabys100% (2)

- Construction Report Project ManagementDocumento7 páginasConstruction Report Project ManagementTony ValdezAinda não há avaliações

- Sci P166Documento139 páginasSci P166Tiago CastelaniAinda não há avaliações

- Metsec Framing Detail sf445 PDFDocumento1 páginaMetsec Framing Detail sf445 PDFBanditAkosAinda não há avaliações

- Abu Dhabis Sustainability by Department of Municipal Affairs PDFDocumento40 páginasAbu Dhabis Sustainability by Department of Municipal Affairs PDFDave LicerioAinda não há avaliações

- AD 261 - Elastic Modulus of AnglesDocumento1 páginaAD 261 - Elastic Modulus of Anglessymon ellimacAinda não há avaliações

- 10 Ribbed Slab DesignDocumento32 páginas10 Ribbed Slab DesignSarah HaiderAinda não há avaliações

- Can Csa S806-02 (115-119)Documento5 páginasCan Csa S806-02 (115-119)JEISON CALIXTO VARGASAinda não há avaliações

- LMW Engineering Group, LLC.: Revision Comment No. DateDocumento16 páginasLMW Engineering Group, LLC.: Revision Comment No. DatenelsonAinda não há avaliações

- Removal of ChimneysDocumento2 páginasRemoval of ChimneysThe Lone GunmanAinda não há avaliações

- Tandemloc Iso Container InfoDocumento4 páginasTandemloc Iso Container InfoDon LariviereAinda não há avaliações

- 304 To 305 PDFDocumento1 página304 To 305 PDFAnonymous GoJpm9WbAinda não há avaliações

- Architectural Drawing of Proposed Three Storey BuildingDocumento7 páginasArchitectural Drawing of Proposed Three Storey BuildingMuhammad Wazim AkramAinda não há avaliações

- Tied Foundations-Portal FrameDocumento3 páginasTied Foundations-Portal FrameJaime Manalili LandinginAinda não há avaliações

- 8 Truss Connection SystemDocumento27 páginas8 Truss Connection SystemyoooAinda não há avaliações

- P 2Documento1 páginaP 2AZTRID PEREZAinda não há avaliações

- Introduction To Eurocode 2Documento14 páginasIntroduction To Eurocode 2LUUVANDONG48XFAinda não há avaliações

- Pile Analysis Summary:: Input DataDocumento2 páginasPile Analysis Summary:: Input DataPatrick HenriAinda não há avaliações

- 09b Eurocodes Steel Workshop LANDOLFODocumento119 páginas09b Eurocodes Steel Workshop LANDOLFOhongvuthyAinda não há avaliações

- Ghomes - Techincal Design - 25 Dec PDFDocumento350 páginasGhomes - Techincal Design - 25 Dec PDFTanluan NguyenAinda não há avaliações

- Post TensioningDocumento3 páginasPost TensioningMaheerah Gamieldien-MohamedAinda não há avaliações

- (07039) - BS 6399-3-1988 Loading For Buildings - Part 3 Code of Practice For Imposed Roof Loads - BRITISH STANDARDDocumento30 páginas(07039) - BS 6399-3-1988 Loading For Buildings - Part 3 Code of Practice For Imposed Roof Loads - BRITISH STANDARDYanin WadkhienAinda não há avaliações

- Material Properties C28-35 & C32-40 (EC2)Documento4 páginasMaterial Properties C28-35 & C32-40 (EC2)a96lhfAinda não há avaliações

- Eurocode 3 Manual For The Design of Steelwork Building Structures (November 1989)Documento110 páginasEurocode 3 Manual For The Design of Steelwork Building Structures (November 1989)Thiago LoiolaAinda não há avaliações

- Hilti White Paper - FinalDocumento7 páginasHilti White Paper - Finalnoodlehead675Ainda não há avaliações

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Documento1 páginaDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanAinda não há avaliações

- 2.8 Foundation DesignDocumento583 páginas2.8 Foundation DesignchamilcjAinda não há avaliações

- Geo Syit93 Port KelangDocumento1 páginaGeo Syit93 Port KelangpasifikAinda não há avaliações

- Failure of Structures: by Ir. Tee Horng Hean, B.Eng. (Hons), MSC (Eng.), Mba, M.I.E.MDocumento7 páginasFailure of Structures: by Ir. Tee Horng Hean, B.Eng. (Hons), MSC (Eng.), Mba, M.I.E.MRajarshi ChakrabortyAinda não há avaliações

- Pitzl - Design Manual Connectors - HVP Connectors, SPP ConnectorsDocumento32 páginasPitzl - Design Manual Connectors - HVP Connectors, SPP ConnectorsStefan IonitaAinda não há avaliações

- Structural Use of Bamboo. Part 4: Element Design Equations: SynopsisDocumento4 páginasStructural Use of Bamboo. Part 4: Element Design Equations: SynopsisVictor OmotoriogunAinda não há avaliações

- Left Side View Rear View Right Side View: SFL Soffit LVLDocumento2 páginasLeft Side View Rear View Right Side View: SFL Soffit LVLHomer TiongcoAinda não há avaliações

- Efficiency Formula For Pile GroupDocumento11 páginasEfficiency Formula For Pile GroupsenhuAinda não há avaliações

- Macau Wind CodeDocumento53 páginasMacau Wind CodeJack WenAinda não há avaliações

- Modal Mass, Stiffness and DampingDocumento5 páginasModal Mass, Stiffness and Dampingkudrilya100% (1)

- HyD Technical Circular No. 3-90Documento5 páginasHyD Technical Circular No. 3-90Gary LoAinda não há avaliações

- 3S Structural Engineering Design Manual - Revision 5Documento74 páginas3S Structural Engineering Design Manual - Revision 5Lampard ChenAinda não há avaliações

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionAinda não há avaliações

- ODEC Ventilation Layout UKDocumento1 páginaODEC Ventilation Layout UKsondeepyadav4873Ainda não há avaliações

- Captură de Ecran Din 2024-02-26 La 10.56.19Documento1 páginaCaptură de Ecran Din 2024-02-26 La 10.56.19samuelantonoviciAinda não há avaliações

- SIMON18012: Call Before You DigDocumento1 páginaSIMON18012: Call Before You DigBALAKRISHNANAinda não há avaliações

- P02-Abd-U06-Nu3-Ltg-Acc-5100 Abd2Documento1 páginaP02-Abd-U06-Nu3-Ltg-Acc-5100 Abd2mohammadAinda não há avaliações

- Release / Revision: NW Blvd. & Plum Street VINELAND, NJ 08360Documento47 páginasRelease / Revision: NW Blvd. & Plum Street VINELAND, NJ 08360Michael MinisterioAinda não há avaliações

- Transportation Demand Management - 1Documento43 páginasTransportation Demand Management - 1Dave LicerioAinda não há avaliações

- 1.1 Poverty Rates at National Poverty LinesDocumento5 páginas1.1 Poverty Rates at National Poverty LinesDave LicerioAinda não há avaliações

- GB Code Spreadsheet Technical Training 2017-04-27Documento17 páginasGB Code Spreadsheet Technical Training 2017-04-27Dave LicerioAinda não há avaliações

- ASEAN Cities Buildings v5Documento4 páginasASEAN Cities Buildings v5Dave LicerioAinda não há avaliações

- Sustainable Street Network Principles: Cnu Project For Transportation ReformDocumento32 páginasSustainable Street Network Principles: Cnu Project For Transportation ReformDave LicerioAinda não há avaliações

- The Urban Network: A New Framework For Growth: by Peter CalthorpeDocumento6 páginasThe Urban Network: A New Framework For Growth: by Peter CalthorpeDave LicerioAinda não há avaliações

- Parking Policy in IndiaDocumento11 páginasParking Policy in IndiaDave LicerioAinda não há avaliações

- (2013) ECLUP Vol.1 Planning Process - HLURBDocumento264 páginas(2013) ECLUP Vol.1 Planning Process - HLURBArnoldAlarcon100% (1)

- As-Built Drawing: Roof Beam LevelDocumento1 páginaAs-Built Drawing: Roof Beam LevelFahmie SuhaimiAinda não há avaliações

- Surface Water DrainageDocumento5 páginasSurface Water DrainageNazirah NazeriAinda não há avaliações

- Bsc071 - Glamz - Civil - Submittal LogDocumento16 páginasBsc071 - Glamz - Civil - Submittal Logقاسم ابرار محمدAinda não há avaliações

- The Soil Pipe: Chapter 6 of Plumbing Design and EstimateDocumento22 páginasThe Soil Pipe: Chapter 6 of Plumbing Design and EstimateJohnRowenPerjeDianaAinda não há avaliações

- Woodspec Final - Section BDocumento58 páginasWoodspec Final - Section BAnonymous hprsT3WlPAinda não há avaliações

- GIB Fire Rated Systems Nov.18 ONLINEDocumento108 páginasGIB Fire Rated Systems Nov.18 ONLINEAhmedAinda não há avaliações

- Building Construction MCQs 216 To 271Documento11 páginasBuilding Construction MCQs 216 To 271epe civil100% (1)

- ConcreteDocumento62 páginasConcreteMahmoud ShakerAinda não há avaliações

- Bill of MaterialsDocumento2 páginasBill of Materialsshakib TarafderAinda não há avaliações

- Bhojpur Haat Bazaar Building EstimationDocumento8 páginasBhojpur Haat Bazaar Building EstimationRam Krishna AdhikariAinda não há avaliações

- Preliminary Report On Tall BuildingDocumento15 páginasPreliminary Report On Tall BuildingG V krishnaAinda não há avaliações

- PM Range Brochure - NORELDocumento4 páginasPM Range Brochure - NORELESUSTENTALAinda não há avaliações

- 6 Cladding (A2) - Layout1 PDFDocumento1 página6 Cladding (A2) - Layout1 PDFHarshit Gupta100% (1)

- Using Gypsum Board For Walls and Ceilings Section IDocumento19 páginasUsing Gypsum Board For Walls and Ceilings Section INdi MvogoAinda não há avaliações

- Thermal Block Construction BrochureDocumento4 páginasThermal Block Construction BrochurejosephfulwoodAinda não há avaliações

- Staad Etc HelpINDDocumento28 páginasStaad Etc HelpINDMohit NatuAinda não há avaliações

- Manual For Civil WorkDocumento48 páginasManual For Civil WorkHamayet RaselAinda não há avaliações

- CPP7563 Trimapanel BrochureDocumento36 páginasCPP7563 Trimapanel BrochureMiruna MaziluAinda não há avaliações

- Quantity Surveying Lecture NotesDocumento8 páginasQuantity Surveying Lecture NotesSam SamAinda não há avaliações

- Tables - Simplified Construction EstimateDocumento6 páginasTables - Simplified Construction EstimatejeromeespirituAinda não há avaliações

- SMACNA Technical Manuals and Standards: Combination CD-ROM/Book Price ListDocumento1 páginaSMACNA Technical Manuals and Standards: Combination CD-ROM/Book Price ListKhalid ImamAinda não há avaliações

- Work Breakdown StructuresDocumento2 páginasWork Breakdown StructuresCLESENT CHARVY CABUYAOAinda não há avaliações