Escolar Documentos

Profissional Documentos

Cultura Documentos

Course Plan:Computer Integrated Manufacturing (TH) : Dr. Syed Farhan Raza CIM 2015 8 3 3

Enviado por

Ali Noraiz0 notas0% acharam este documento útil (0 voto)

28 visualizações3 páginascim theory

Título original

CIM Theory Prforma

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentocim theory

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

28 visualizações3 páginasCourse Plan:Computer Integrated Manufacturing (TH) : Dr. Syed Farhan Raza CIM 2015 8 3 3

Enviado por

Ali Noraizcim theory

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 3

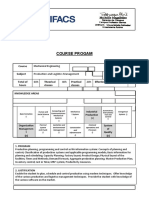

Course Plan:Computer Integrated Manufacturing (Th)

Teacher’s Name Dr. Syed Farhan Raza

Subject’s Name CIM

Session 2015

Semester 8th

Contact Hours 3

Credit Hours 3

Books Automation, Production system and Computer Integrated

Manufacturing by Mike P. Groover.Pearson Education, 4th

Edition 2015. (Text Book)

CIM, Principles of Computer Integrated Manufacturingby

Waldner and Jean BaptiseCharles 2013. (Recommended Book)

Principles of Computer Integrated Manufacturing by S Kant

Vajpayee, 2015. (Recommended Book)

Total Marks 100

Course Learning Outcomes, Mapping with PLOs and Assessment

Course Learning Learning Domain and Mapping with Assessment

Outcome (CLOs) Level Program Learning

(C = Cognitive; P = Outcomes (PLOs)

Psychomotor; A =

Affective)

1. To understand the C2(Comprehension) PLO-1 Quiz 1

importance and (Engineering

justification of Knowledge)

industrial automation.

2. To use concepts of C3(Application) PLO- 3 (Design and Mid Term

material handling and development of

identification solutions)

technologies for

problem solving

3. To analyze various C4(Anlysis) PLO 2 (Problem End term (Q1 +

types of analysis) Q2)& Complex

manufacturing engineering

systems for solving. problem

engineering problems

related to these

systems.

4. To Participate in A2 (Responding) PLO 12 (Life Long Class Participation

class discussion with Learning)

motivation

Assessment tools:

Quiz 1: 10 marks

Mid Term: 30 marks

Quiz 2: 10 marks

End term: 40 marks

Class Participation: 5 marks

Complex Engineering Problem: 5 marks

Weekly lecture plan

Week Content CLOs

1 Introduction to CIM, Role of 1,5

CIM at factory level and at

enterprise level

2 Conventional storage methods 1,5

and equipment

3 Types of Automated storage 1,5

systems

4 Industrial trucks, automated 2,5

guided vehicle systems,

5 Conveyor systems, cranes and 2,5

Hoists

6 Automatic Data Capture (ADC) 2,5

methods and its salient features

and components

7 Bar Codes and other ADC 2,5

technologies

8 Mid Term Exam

9 Introduction to Manufacturing 3,5

systems, single station

manufacturing systems

10 Cellular manufacturing, group 3,5

technology, part families

11 Composite part concept, From 3,5

To Charts, Rank Order

clustering

12 Flexible Manufacturing system, 3,5

features and characteristics

13 Manual Assembly lines 4,5

14 Transfer lines 4,5

15 Automated Assembly system 4,5

16 Introduction to Programmable 4,5

Logic controller

17 Introduction to Industrial 4,5

Robotics

18 End Term Exam

Você também pode gostar

- CAD Systems in Mechanical and Production EngineeringNo EverandCAD Systems in Mechanical and Production EngineeringNota: 4.5 de 5 estrelas4.5/5 (3)

- MtvsemDocumento24 páginasMtvsemEnemyAinda não há avaliações

- CIM Course PlanDocumento8 páginasCIM Course PlanKamal Vijay Ram R SAinda não há avaliações

- Computer Organization and ArchitectureDocumento12 páginasComputer Organization and ArchitectureYaseen 777Ainda não há avaliações

- MP403 ComputerintegratedmanufacturingDocumento3 páginasMP403 ComputerintegratedmanufacturingAbhay SajeevAinda não há avaliações

- CIM Course Out LineDocumento3 páginasCIM Course Out LineAb AnAinda não há avaliações

- Computer Science and Engineering S7 & S8Documento11 páginasComputer Science and Engineering S7 & S8wastebasketAinda não há avaliações

- OS SyllabusDocumento10 páginasOS Syllabusneena joiceAinda não há avaliações

- Computer Programing PDFDocumento3 páginasComputer Programing PDFEthio Video SchoolAinda não há avaliações

- Gujarat Technological University Mechanical (Cad/Cam) (08) : Computer Aided Process Planning 2720813 Semester: IiDocumento3 páginasGujarat Technological University Mechanical (Cad/Cam) (08) : Computer Aided Process Planning 2720813 Semester: IiGeorge CamachoAinda não há avaliações

- Computer Programming Lab Course OverviewDocumento3 páginasComputer Programming Lab Course OverviewcrazeAinda não há avaliações

- Microprocessors and Microcontrollers Course OverviewDocumento3 páginasMicroprocessors and Microcontrollers Course OverviewEngnrMemonAinda não há avaliações

- Course OutlineDocumento3 páginasCourse OutlineBilisumaAinda não há avaliações

- Computer Integrated Manufacturing CourseDocumento3 páginasComputer Integrated Manufacturing CoursesatheeshAinda não há avaliações

- CS404 Embedded Systems 3-0-0-3 2016: Course Code Course Name L-T-P - Credits Year of Course ObjectivesDocumento2 páginasCS404 Embedded Systems 3-0-0-3 2016: Course Code Course Name L-T-P - Credits Year of Course ObjectivesSipin CPAinda não há avaliações

- Cam 25062016 030053amDocumento4 páginasCam 25062016 030053amRemi KwetchaAinda não há avaliações

- Mechanical - VI. Sem Syllabus GtuDocumento115 páginasMechanical - VI. Sem Syllabus GtukishormechAinda não há avaliações

- Introduction To Computer Laboratory Experiments ManualDocumento139 páginasIntroduction To Computer Laboratory Experiments ManualJunaid NazirAinda não há avaliações

- IE362 Group Technology and Flexible Manufacturing SystemDocumento2 páginasIE362 Group Technology and Flexible Manufacturing SystemloshidhAinda não há avaliações

- Gujarat Technological University: Page 1 of 3Documento3 páginasGujarat Technological University: Page 1 of 3ashish patelAinda não há avaliações

- MANUFACTURING AUTOMATION COURSEDocumento2 páginasMANUFACTURING AUTOMATION COURSEAtul NarayananAinda não há avaliações

- 13mca11-Problem Solving Using CDocumento13 páginas13mca11-Problem Solving Using CKeerthana SudarshanAinda não há avaliações

- Sem Vi Csdlo6023 Erp Lessonplan 2018-2019Documento13 páginasSem Vi Csdlo6023 Erp Lessonplan 2018-2019Asep JoniAinda não há avaliações

- CS11102 Introduction To Computer Science 2023-2024Documento5 páginasCS11102 Introduction To Computer Science 2023-2024Maya DanaAinda não há avaliações

- CS404 Embedded SystemsDocumento2 páginasCS404 Embedded SystemsanupvasuAinda não há avaliações

- CSCP1013 Introduction To Computing TheoryDocumento9 páginasCSCP1013 Introduction To Computing TheoryAli GhauriAinda não há avaliações

- ICC 0102.1 - 1 (Fundamentals of Programming - LAB)Documento4 páginasICC 0102.1 - 1 (Fundamentals of Programming - LAB)Erwin MarceloAinda não há avaliações

- Gujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIDocumento4 páginasGujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIKrupal VithlaniAinda não há avaliações

- Institute - Department - : Uiet MechatronicsDocumento10 páginasInstitute - Department - : Uiet Mechatronicsbhav tech vinesAinda não há avaliações

- Introduction to Computing Lab ManualDocumento145 páginasIntroduction to Computing Lab ManualJunaid NazirAinda não há avaliações

- Course Outline of CSE 309 - Section A PDFDocumento5 páginasCourse Outline of CSE 309 - Section A PDFSafialIslamAyonAinda não há avaliações

- Gujarat Technological University: W.E.F. AY 2018-19Documento3 páginasGujarat Technological University: W.E.F. AY 2018-19Bamania ChiragAinda não há avaliações

- Yildiz Teknik Üniversitesi Course Syllabus Mekatronik Mühendisliği Bölümü S P R I N G 2 0 2 0 - 2 0 2 1Documento2 páginasYildiz Teknik Üniversitesi Course Syllabus Mekatronik Mühendisliği Bölümü S P R I N G 2 0 2 0 - 2 0 2 1Olcay KılıçkoçAinda não há avaliações

- CDP Finalized Format AIDocumento16 páginasCDP Finalized Format AICSE HODAinda não há avaliações

- Introduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMDocumento12 páginasIntroduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMKiranRao BiradarAinda não há avaliações

- Fundamentals of Computing and Programming Course OverviewDocumento53 páginasFundamentals of Computing and Programming Course OverviewNiaz Ali MohmandAinda não há avaliações

- Lass Rientation Ession: by Anand Partheeban C.M Asst Professor Mechanical United Institute of TechnologyDocumento18 páginasLass Rientation Ession: by Anand Partheeban C.M Asst Professor Mechanical United Institute of TechnologyotakoothanAinda não há avaliações

- ME6703 SCAD MSM by WWW - Learnengineering.inDocumento88 páginasME6703 SCAD MSM by WWW - Learnengineering.inAnonymous VC2zZcPCivAinda não há avaliações

- Computer OrganisationDocumento12 páginasComputer OrganisationSachuAinda não há avaliações

- Drive 123Documento6 páginasDrive 123Karen AyeskaAinda não há avaliações

- Puter Integrated ManufacturingDocumento11 páginasPuter Integrated ManufacturingNIKHIL ASAinda não há avaliações

- BS (CS, CE) CS101-Introduction To Computing and AIDocumento3 páginasBS (CS, CE) CS101-Introduction To Computing and AITalha ShafiAinda não há avaliações

- Acfrogc-2fxav9gqeh7lou4vnecfg0nzotc-Xh Baqmrecl0pv1mazifv1ea2woiegc0mwdjga3m5nvk 9inrccr7spq4v7mltveufxibsx1als6ygbivarfz Ihtbx Wluwwszv-Swp KhawrnyDocumento392 páginasAcfrogc-2fxav9gqeh7lou4vnecfg0nzotc-Xh Baqmrecl0pv1mazifv1ea2woiegc0mwdjga3m5nvk 9inrccr7spq4v7mltveufxibsx1als6ygbivarfz Ihtbx Wluwwszv-Swp KhawrnyRebecca MathewsAinda não há avaliações

- Functional and Non-Functional Testing: CO4: The Use of Various Test ToolsDocumento5 páginasFunctional and Non-Functional Testing: CO4: The Use of Various Test Toolsraghav dhamaniAinda não há avaliações

- Paf-Karachi Institute of Economics & Technology Spring - 2021Documento3 páginasPaf-Karachi Institute of Economics & Technology Spring - 2021Basic Knowledge Basic KnowledgeAinda não há avaliações

- Bca Scheme and SyllabusDocumento76 páginasBca Scheme and SyllabusAbcd GoogleAinda não há avaliações

- Automation and Computer Integrated Manufacturing SyllabusDocumento2 páginasAutomation and Computer Integrated Manufacturing SyllabusMulu GirmayAinda não há avaliações

- MCA Syllabus - 1st Sem PDFDocumento32 páginasMCA Syllabus - 1st Sem PDFshatabdi mukherjeeAinda não há avaliações

- Course Outline CIM 14Documento3 páginasCourse Outline CIM 14Bizuayehu TadesseAinda não há avaliações

- 03-Credits (3:0:0) : Principles, Collaborative Approaches, Collaboration Tools, Collaborative Design SystemsDocumento2 páginas03-Credits (3:0:0) : Principles, Collaborative Approaches, Collaboration Tools, Collaborative Design SystemsPRAVEEN GAinda não há avaliações

- European University of Bangladesh - IPE 410 Lab ModuleDocumento35 páginasEuropean University of Bangladesh - IPE 410 Lab ModuleIrfan KhanAinda não há avaliações

- Gauhati University Post Graduate Diploma in Computer ApplicationDocumento14 páginasGauhati University Post Graduate Diploma in Computer ApplicationGaryAinda não há avaliações

- Department of Computer Science and Engineering Kathmandu UniversityDocumento4 páginasDepartment of Computer Science and Engineering Kathmandu UniversityAcharya SuyogAinda não há avaliações

- Laboratory Manual: Object Oriented Software EngineeringDocumento58 páginasLaboratory Manual: Object Oriented Software Engineeringrsingh1987Ainda não há avaliações

- FOP SyllabusDocumento5 páginasFOP SyllabuskhushbuceAinda não há avaliações

- Vardhaman College of EngineeringDocumento3 páginasVardhaman College of Engineeringvenucse@indiatimes.comAinda não há avaliações

- Lecture01 - CAD CAM - CAE - Introduction of The CourseDocumento21 páginasLecture01 - CAD CAM - CAE - Introduction of The CourseSameer shaikhAinda não há avaliações

- PPS Course MaterialDocumento177 páginasPPS Course MaterialSURYA VFC100% (1)

- Formal Methods Applied to Complex Systems: Implementation of the B MethodNo EverandFormal Methods Applied to Complex Systems: Implementation of the B MethodAinda não há avaliações

- Chapter 1Documento14 páginasChapter 1Ali NoraizAinda não há avaliações

- Rubrics For Computer Integrated Manufacturing Lab Assessment: Video Based Case Study PresentationsDocumento1 páginaRubrics For Computer Integrated Manufacturing Lab Assessment: Video Based Case Study PresentationsAli NoraizAinda não há avaliações

- Rubrics For Assessment - THDocumento2 páginasRubrics For Assessment - THAli NoraizAinda não há avaliações

- Rubrics For Semester Project - CEPDocumento1 páginaRubrics For Semester Project - CEPAli NoraizAinda não há avaliações

- CIM Lab ProformaDocumento3 páginasCIM Lab ProformaFaria KhanAinda não há avaliações

- CEP Write-Up Format TemplateDocumento5 páginasCEP Write-Up Format TemplateAli NoraizAinda não há avaliações

- Eligibility Conditions Qualification / Age Category of Selection Qualification AgeDocumento4 páginasEligibility Conditions Qualification / Age Category of Selection Qualification AgeAtharrizwanAinda não há avaliações

- Successful Organizational Change FactorsDocumento13 páginasSuccessful Organizational Change FactorsKenneth WhitfieldAinda não há avaliações

- AssDocumento9 páginasAssJane SalvanAinda não há avaliações

- Namal College Admissions FAQsDocumento3 páginasNamal College Admissions FAQsSauban AhmedAinda não há avaliações

- Formal 17 12 04 PDFDocumento184 páginasFormal 17 12 04 PDFJose LaraAinda não há avaliações

- PDS-1st PageDocumento1 páginaPDS-1st PageElmer LucreciaAinda não há avaliações

- For-tea Tea Parlour Marketing Strategy Targets 40+ DemographicDocumento7 páginasFor-tea Tea Parlour Marketing Strategy Targets 40+ Demographicprynk_cool2702Ainda não há avaliações

- 63db2cf62042802 Budget Eco SurveyDocumento125 páginas63db2cf62042802 Budget Eco SurveyNehaAinda não há avaliações

- ApudDocumento53 páginasApudlatifahAinda não há avaliações

- "Corbel" - Concrete Corbel Analysis: Program DescriptionDocumento4 páginas"Corbel" - Concrete Corbel Analysis: Program DescriptioniuliandurdureanuAinda não há avaliações

- fr1177e-MOTOR CUMMINS 195HPDocumento2 páginasfr1177e-MOTOR CUMMINS 195HPwilfredo rodriguezAinda não há avaliações

- Guardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicDocumento110 páginasGuardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicTarun BharadwajAinda não há avaliações

- Major Swine BreedsDocumento1 páginaMajor Swine BreedsDana Dunn100% (1)

- Brightline Guiding PrinciplesDocumento16 páginasBrightline Guiding PrinciplesdjozinAinda não há avaliações

- Storage Reservior and Balancing ReservoirDocumento19 páginasStorage Reservior and Balancing ReservoirNeel Kurrey0% (1)

- (NTA) SalaryDocumento16 páginas(NTA) SalaryHakim AndishmandAinda não há avaliações

- Dubai Healthcare Providers DirectoryDocumento30 páginasDubai Healthcare Providers DirectoryBrave Ali KhatriAinda não há avaliações

- Numark MixTrack Pro II Traktor ProDocumento3 páginasNumark MixTrack Pro II Traktor ProSantiCai100% (1)

- Stage 1 Isolating Boiler Feed Pump 1. PurposeDocumento3 páginasStage 1 Isolating Boiler Feed Pump 1. Purposejoseph kamwendoAinda não há avaliações

- LeasingDocumento2 páginasLeasingfollow_da_great100% (2)

- EE3331C Feedback Control Systems L1: Overview: Arthur TAYDocumento28 páginasEE3331C Feedback Control Systems L1: Overview: Arthur TAYpremsanjith subramani0% (1)

- Evan Gray ResumeDocumento2 páginasEvan Gray Resumeapi-298878624Ainda não há avaliações

- HetNet Solution Helps Telcos Improve User Experience & RevenueDocumento60 páginasHetNet Solution Helps Telcos Improve User Experience & RevenuefarrukhmohammedAinda não há avaliações

- Virgilio S. Delima V. Susan Mercaida Gois GR NO. 178352 - June 17, 2008 FactsDocumento6 páginasVirgilio S. Delima V. Susan Mercaida Gois GR NO. 178352 - June 17, 2008 FactsNikki BarenaAinda não há avaliações

- DX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Documento6 páginasDX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Welissa ChicanequissoAinda não há avaliações

- Enhancing reliability of CRA piping welds with PAUTDocumento10 páginasEnhancing reliability of CRA piping welds with PAUTMohsin IamAinda não há avaliações

- M Series CylindersDocumento61 páginasM Series CylindersAndres SantanaAinda não há avaliações

- Iso 4624Documento15 páginasIso 4624klkopopoonetdrghjktl100% (2)

- Corena s2 p150 - Msds - 01185865Documento17 páginasCorena s2 p150 - Msds - 01185865Javier LerinAinda não há avaliações

- PHASE 2 - Chapter 6 Object ModellingDocumento28 páginasPHASE 2 - Chapter 6 Object Modellingscm39Ainda não há avaliações

- Cagayan Electric Company v. CIRDocumento2 páginasCagayan Electric Company v. CIRCocoyPangilinanAinda não há avaliações