Escolar Documentos

Profissional Documentos

Cultura Documentos

Plastic Spur Gears: PS PS

Enviado por

Rahman AbdurrahimDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Plastic Spur Gears: PS PS

Enviado por

Rahman AbdurrahimDireitos autorais:

Formatos disponíveis

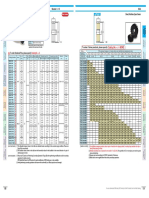

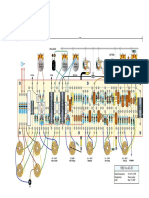

PS Module 1 PS

Plastic Spur Gears Series Plastic Spur Gears

G G G

Specifications

E E F E F

F

JIS grade N9 (JIS B1702-1: 1998) * J J

Precision grade G

JIS grade 5 (JIS B1702: 1976)

Gear teeth Standard full depth

Gears

Gears

Pressure angle 20°

Spur

Spur

Material MC901

D

A

B

C

A

B

C

A

B

C

Heat treatment ―

Tooth hardness (115 ∼ 120HRR)

10

Helical

Helical

Face width (E)

Gears

Gears

S1 S1T S1K

Hub width (F) 10

Total length (G) 20

To order J Series products, please specify; Catalog No. + J + BORE

Screw offset (J) 5

* The precision grade of J Series products is equivalent Bore H7 * The product shapes of J Series items are identified by background color.

to the value shown in the table.

Internal

Internal

6 8 10 12 14 15 16 17 18 19 20 22 25 28 30

Gears

Gears

Keyway Js9

Bore Hub dia. Pitch dia. Outside dia. Allowable torque (N·m) Allowable torque (kgf·m) Backlash Weight Screw size ― 4 × 1.8 5 × 2.3 6 × 2.8 8 × 3.3

Catalog No. No. of teeth Shape

AH7 B C D Bending strength Bending strength (mm) (kg) Catalog No. M4 M5 M4 M5 M6

PS1-15 15 12 15 17 0.41 0.042 0.0027 PS1-15 J BORE

PS1-16 16 12 16 18 0.45 0.046 0.0030 PS1-16 J BORE

6 0~0.32

PS1-18 18 14 18 20 0.53 0.054 0.0041 PS1-18 J BORE

Racks

Racks

PS1-20 20 16 20 22 0.61 0.063 0.0053 PS1-20 J BORE

PS1-22 22 18 22 24 0.69 0.071 0.0062 PS1-22 J BORE

PS1-24 24 20 24 26 0.77 0.079 0.0077 PS1-24 J BORE

PS1-25 25 20 25 27 0.82 0.083 0.0082 PS1-25 J BORE

CP Racks

CP Racks

& Pinions

& Pinions

PS1-26 26 20 26 28 0.86 0.088 0.0086 PS1-26 J BORE

PS1-28 28 8 22 28 30 0.94 0.096 0.010 PS1-28 J BORE

PS1-30 30 25 30 32 1.03 0.10 0.013 PS1-30 J BORE

PS1-32 32 26 32 34 1.11 0.11 0~0.34 0.014 PS1-32 J BORE

PS1-35 35 26 35 37 1.25 0.13 0.016 PS1-35 J BORE

PS1-36 36 28 36 38 1.30 0.13 0.018 PS1-36 J BORE

PS1-40 40 S1 35 40 42 1.48 0.15 0.024

Gears

Gears

PS1-40 J BORE

Miter

Miter

PS1-45 45 35 45 47 1.71 0.17 0.028 PS1-45 J BORE

PS1-48 48 48 50 1.86 0.19 0.030 PS1-48 J BORE

PS1-50 50 50 52 1.96 0.20 0.032 PS1-50 J BORE

PS1-55 55 35 55 57 2.18 0.22 0.037 PS1-55 J BORE

PS1-60 60 60 62 2.41 0.25 0.042 PS1-60 J BORE

Gears

Gears

Bevel

Bevel

PS1-65 65 65 67 2.64 0.27 0.048 PS1-65 J BORE

10

PS1-70 70 70 72 2.87 0.29 0.057 PS1-70 J BORE

PS1-75 75 75 77 3.11 0.32 0.064 PS1-75 J BORE

0~0.36

PS1-80 80 40 80 82 3.34 0.34 0.071 PS1-80 J BORE

PS1-85 85 85 87 3.57 0.36 0.079 PS1-85 J BORE

Screw

Screw

Gears

Gears

PS1-90 90 90 92 3.80 0.39 0.087 PS1-90 J BORE

PS1-95 95 95 97 4.03 0.41 0.095 PS1-95 J BORE

40

PS1-100 100 100 102 4.27 0.44 0.10 PS1-100 J BORE

[Caution on Product Characteristics] ① Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), including bore size (H8 when pro- [Caution on J series] ① As available-on-request products, requires a lead-time for shipping within 2 working-days (excludes the day ordered), after placing an order.

duced), tooth diameter, and backlash. Please see the section Design of Plastic Gears in separate technical reference book. (Page 101). Please allow additional shipping time to get to your local distributor.

Products Gearboxes Gear Pair

Products Gearboxes Gear Pair

② The allowable torques shown in the table are calculated values according to the assumed usage conditions. Please see Page 31 for more details. ② Number of products we can process for one order is 1 to 20 units. For quantities of 21 or more pieces, we need to quote price and lead time.

Worm

Worm

③ Without lubrication, using plastic gears in pairs may generate heat and dilation. It is recommended to mate them with steel gears. ③ Keyways are made according to JIS B1301 standards, Js9 tolerance.

④ The backlash values shown in the table are the theoretical values for the backlash in the normal direction of a pair of identical gears in mesh. ④ Certain products which would otherwise have a very long tapped hole are conterbored to reduce the length of the tap.

⑤ For products having a tapped hole, a set screw is included.

[Caution on Secondary Operations] ①Please read Caution on Performing Secondary Operations (Page 32) when performing modifications and/or secondary operations for safety concerns. ⑥ Since tapped holes of plastic products are easily broken, avoid too much tightening when fastening screws. For products which have a short tapped

KHK Quick-Mod Gears, the KHK's system for quick modification of KHK stock gears is also available. hole (Products marked with ** are the tap size), fasten with torques less than 0.12N・m for M4, and 0.38N・m for M5.

②Plastic gears are susceptible to the effects of temperature and moisture. Dimensional changes may occur while performing secondary operations and

Bevel

Bevel

during post-machining operations.

Installment : Parallel axes gears

GCU-S Spur Gear Kit (Two-stage)

Gear Type : Spur Gears

Other

Other

Gears : 2 units of SS1.5-16

* In regards to MC Nylon gears, other materials are available for plastic gears, 2 units of PS1.5-22

Gear Ratio : 1.89

including Ultra High Molecular Weight Polyethylene (UHMW-PE), which has Weight : Approx. 1kg

excellent abrasion resistance. Poly Ether Ether Ketone (PEEK) also has quality

properties. A single piece order is acceptable and will be produced as a

The Gear Kit contains two-stage spur

custom-made gear. For details on quotations and orders please see page 8. gears and allows speed increases /

reductions, and includes the most

commonly used combinations of gears.

140 Technical information on gears is available on KHK Web Site. 141

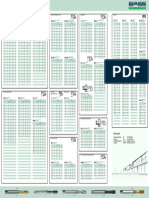

PS Module 1.5 PS

Plastic Spur Gears Series Plastic Spur Gears

G G G

Specifications

E E F E F

F

JIS grade N9 (JIS B1702-1: 1998) * J J

Precision grade G

JIS grade 5 (JIS B1702: 1976)

Gear teeth Standard full depth

Gears

Gears

Pressure angle 20°

Spur

Spur

Material MC901

D

A

B

C

A

B

C

A

B

C

Heat treatment ―

Tooth hardness (115 ∼ 120HRR)

15

Helical

Helical

Face width (E)

Gears

Gears

S1 S1T S1K

Hub width (F) 10

Total length (G) 25

To order J Series products, please specify; Catalog No. + J + BORE

Screw offset (J) 5

* The precision grade of J Series products is equivalent Bore H7 * The product shapes of J Series items are identified by background color.

to the value shown in the table.

Internal

Internal

6 8 10 12 14 15 16 17 18 19 20 22 25 28 30

Gears

Gears

Keyway Js9

Bore Hub dia. Pitch dia. Outside dia. Allowable torque (N·m) Allowable torque (kgf·m) Backlash Weight Screw size ― 4 × 1.8 5 × 2.3 6 × 2.8 8 × 3.3

Catalog No. No. of teeth Shape

AH7 B C D Bending strength Bending strength (mm) (kg) Catalog No. M4 M5 M4 M5 M6

PS1.5-15 15 18 22.5 25.5 1.39 0.14 0.0084 PS1.5-15 J BORE

PS1.5-16 16 20 24 27 1.53 0.16 0.010 PS1.5-16 J BORE

PS1.5-18 18 22 27 30 1.79 0.18 0.013 PS1.5-18 J BORE

Racks

Racks

PS1.5-20 20 24 30 33 2.07 0.21 0.016 PS1.5-20 J BORE

PS1.5-22 22 26 33 36 2.34 0.24 0.020 PS1.5-22 J BORE

PS1.5-24 24 28 36 39 2.61 0.27 0~0.38 0.023 PS1.5-24 J BORE

PS1.5-25 25 8 30 37.5 40.5 2.76 0.28 0.026 PS1.5-25 J BORE

CP Racks

CP Racks

& Pinions

& Pinions

PS1.5-26 26 32 39 42 2.91 0.3 0.029 PS1.5-26 J BORE

PS1.5-28 28 36 42 45 3.18 0.32 0.034 PS1.5-28 J BORE

PS1.5-30 30 38 45 48 3.46 0.35 0.039 PS1.5-30 J BORE

PS1.5-32 32 40 48 51 3.76 0.38 0.045 PS1.5-32 J BORE

PS1.5-35 35 42 52.5 55.5 4.22 0.43 0.052 PS1.5-35 J BORE

PS1.5-36 36 45 54 57 4.38 0.45 0.057 PS1.5-36 J BORE

S1

Gears

Gears

PS1.5-40 40 45 60 63 5.00 0.51 0.065 PS1.5-40 J BORE

Miter

Miter

PS1.5-45 45 45 67.5 70.5 5.79 0.59 0.078 PS1.5-45 J BORE

PS1.5-48 48 45 72 75 6.27 0.64 0~0.40 0.087 PS1.5-48 J BORE

10

PS1.5-50 50 45 75 78 6.60 0.67 0.093 PS1.5-50 J BORE

PS1.5-55 55 45 82.5 85.5 7.36 0.75 0.11 PS1.5-55 J BORE

PS1.5-60 60 50 90 93 8.14 0.83 0.13 PS1.5-60 J BORE

Gears

Gears

Bevel

Bevel

PS1.5-65 65 50 97.5 100.5 8.91 0.91 0.15 PS1.5-65 J BORE

PS1.5-70 70 50 105 108 9.69 0.99 0.17 PS1.5-70 J BORE

PS1.5-75 75 50 112.5 115.5 10.5 1.07 0.19 PS1.5-75 J BORE

PS1.5-80 80 55 120 123 11.3 1.15 0.22 PS1.5-80 J BORE

12

PS1.5-85 85 55 127.5 130.5 12.0 1.23 0~0.42 0.25 PS1.5-85 J BORE

Screw

Screw

Gears

Gears

PS1.5-90 90 55 135 138 12.8 1.31 0.27 PS1.5-90 J BORE

PS1.5-95 95 60 142.5 145.5 13.6 1.39 0.31 PS1.5-95 J BORE

PS1.5-100 100 60 150 153 14.4 1.47 0.34 PS1.5-100 J BORE

[Caution on Product Characteristics] ① Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), including bore size (H8 when pro- [Caution on J series] ① As available-on-request products, requires a lead-time for shipping within 2 working-days (excludes the day ordered), after placing an order.

duced), tooth diameter, and backlash. Please see the section Design of Plastic Gears in separate technical reference book. (Page 101). Please allow additional shipping time to get to your local distributor.

Products Gearboxes Gear Pair

Products Gearboxes Gear Pair

② The allowable torques shown in the table are calculated values according to the assumed usage conditions. Please see Page 31 for more details. ② Number of products we can process for one order is 1 to 20 units. For quantities of 21 or more pieces, we need to quote price and lead time.

Worm

Worm

③ Without lubrication, using plastic gears in pairs may generate heat and dilation. It is recommended to mate them with steel gears. ③ Keyways are made according to JIS B1301 standards, Js9 tolerance.

④ The backlash values shown in the table are the theoretical values for the backlash in the normal direction of a pair of identical gears in mesh. ④ Certain products which would otherwise have a very long tapped hole are conterbored to reduce the length of the tap.

⑤ For products having a tapped hole, a set screw is included.

[Caution on Secondary Operations] ①Please read Caution on Performing Secondary Operations (Page 32) when performing modifications and/or secondary operations for safety concerns. ⑥ Since tapped holes of plastic products are easily broken, avoid too much tightening when fastening screws. For products which have a short tapped

KHK Quick-Mod Gears, the KHK's system for quick modification of KHK stock gears is also available. hole (Products marked with ** are the tap size), fasten with torques less than 0.12N・m for M4, and 0.38N・m for M5.

②Plastic gears are susceptible to the effects of temperature and moisture. Dimensional changes may occur while performing secondary operations and

Bevel

Bevel

during post-machining operations.

Installment : Parallel axes gears

GCU-S Spur Gear Kit (Two-stage)

Gear Type : Spur Gears

Other

Other

Gears : 2 units of SS1.5-16

* In regards to MC Nylon gears, other materials are available for plastic gears, 2 units of PS1.5-22

Gear Ratio : 1.89

including Ultra High Molecular Weight Polyethylene (UHMW-PE), which has Weight : Approx. 1kg

excellent abrasion resistance. Poly Ether Ether Ketone (PEEK) also has quality

properties. A single piece order is acceptable and will be produced as a

The Gear Kit contains two-stage spur

custom-made gear. For details on quotations and orders please see page 8. gears and allows speed increases /

reductions, and includes the most

commonly used combinations of gears.

142 Technical information on gears is available on KHK Web Site. 143

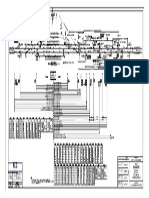

PS・PSA Module 2 PS・PSA

Plastic Spur Gears Series Plastic Spur Gears

G E G G E

Specifications

E E F E F

F

JIS grade N9 (JIS B1702-1: 1998) * J J

Precision grade

JIS grade 5 (JIS B1702: 1976)

Gear teeth Standard full depth

Gears

Gears

Pressure angle 20°

Spur

Spur

Material MC901

D

C

C

A

A

D

D

A

B

C

A

B

C

A

B

C

Heat treatment ―

Tooth hardness (115 ∼ 120HRR)

20

Helical

Helical

Face width (E)

Gears

Gears

S1 S5 S1T2 S1K S5K

Hub width (F) 10 (Shape S1)

Total length (G) 30 (Shape S1)

To order J Series products, please specify; Catalog No. + J + BORE

Screw offset (J) 5 (Shape S1)

* The precision grade of J Series products is equivalent Bore H7 * The product shapes of J Series items are identified by background color.

to the value shown in the table.

Internal

Internal

10 12 14 15 16 17 18 19 20 22 25 28 30 32 35 40 45 50

Gears

Gears

Keyway Js9

Bore Hub dia. Pitch dia. Outside dia. Allowable torque (N·m) Allowable torque (kgf·m) Backlash Weight Screw size 4 × 1.8 5 × 2.3 6 × 2.8 8 × 3.3 10 × 3.3 12 × 3.3 14 × 3.8

Catalog No. No. of teeth Shape

AH7 B C D Bending strength Bending strength (mm) (kg) Catalog No. M4 M5 M6 M8 ―

PS2-12 12 18 24 28 2.25 0.23 0.011 PS2-12 J BORE

PS2-13 13 20 26 30 2.59 0.26 0.013 PS2-13 J BORE

PS2-14 14 20 28 32 2.96 0.30 0.015 PS2-14 J BORE

Racks

Racks

PS2-15 15 24 30 34 3.29 0.34 0.019 PS2-15 J BORE

PS2-16 16 26 32 36 3.63 0.37 0.022 PS2-16 J BORE

0~0.42

PS2-18 18 30 36 40 4.24 0.43 0.029 PS2-18 J BORE

PS2-20 20 S1 10 32 40 44 4.91 0.50 0.036 PS2-20 J BORE

CP Racks

CP Racks

& Pinions

& Pinions

PS2-22 22 35 44 48 5.55 0.57 0.044 PS2-22 J BORE

PS2-24 24 38 48 52 6.19 0.63 0.052 PS2-24 J BORE

PS2-25 25 40 50 54 6.54 0.67 0.057 PS2-25 J BORE

PS2-26 26 42 52 56 6.90 0.70 0.063 PS2-26 J BORE

PS2-28 28 45 56 60 7.54 0.77 0.073 PS2-28 J BORE

PS2-30 30 50 60 64 8.20 0.84 0.086 PS2-30 J BORE

Gears

Gears

PSA2-32 32 64 68 8.91 0.91 0.075 PSA2-32 J BORE

Miter

Miter

PSA2-35 35 70 74 10.0 1.02 0.089 PSA2-35 J BORE

0~0.44

PSA2-36 36 72 76 10.4 1.06 0.094 PSA2-36 J BORE

PSA2-40 40 80 84 11.9 1.21 0.12 PSA2-40 J BORE

PSA2-45 45 90 94 13.7 1.40 0.15 PSA2-45 J BORE

PSA2-48 48 96 100 14.9 1.52 0.17 PSA2-48 J BORE

Gears

Gears

Bevel

Bevel

PSA2-50 50 100 104 15.7 1.60 0.18 PSA2-50 J BORE

PSA2-55 55 110 114 17.5 1.78 0.22 PSA2-55 J BORE

PSA2-60 60 S5 12 ― 120 124 19.3 1.97 0.26 PSA2-60 J BORE

PSA2-65 65 130 134 21.1 2.15 0.31 PSA2-65 J BORE

PSA2-70 70 140 144 23.0 2.34 0.36 PSA2-70 J BORE

Screw

Screw

Gears

Gears

PSA2-75 75 150 154 24.9 2.54 0.41 PSA2-75 J BORE

0~0.46

PSA2-80 80 160 164 26.7 2.72 0.47 PSA2-80 J BORE

PSA2-85 85 170 174 28.5 2.91 0.53 PSA2-85 J BORE

PSA2-90 90 180 184 30.4 3.10 0.59 PSA2-90 J BORE

PSA2-95 95 190 194 32.3 3.29 0.66 PSA2-95 J BORE

Products Gearboxes Gear Pair

Products Gearboxes Gear Pair

PSA2-100 100 200 204 34.2 3.48 0.73 PSA2-100 J BORE

Worm

Worm

[Caution on Product Characteristics] ① Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), including bore size (H8 when pro- [Caution on J series] ① As available-on-request products, requires a lead-time for shipping within 2 working-days (excludes the day ordered), after placing an order.

duced), tooth diameter, and backlash. Please see the section Design of Plastic Gears in separate technical reference book. (Page 101). Please allow additional shipping time to get to your local distributor.

② The allowable torques shown in the table are calculated values according to the assumed usage conditions. Please see Page 31 for more details. ② Number of products we can process for one order is 1 to 20 units. For quantities of 21 or more pieces, we need to quote price and lead time.

③ Without lubrication, using plastic gears in pairs may generate heat and dilation. It is recommended to mate them with steel gears. ③ Keyways are made according to JIS B1301 standards, Js9 tolerance.

④ The backlash values shown in the table are the theoretical values for the backlash in the normal direction of a pair of identical gears in mesh. ④ Certain products which would otherwise have a very long tapped hole are conterbored to reduce the length of the tap.

⑤ For products having a tapped hole, a set screw is included.

Bevel

Bevel

[Caution on Secondary Operations] ①Please read Caution on Performing Secondary Operations (Page 32) when performing modifications and/or secondary operations for safety concerns. ⑥ Since tapped holes of plastic products are easily broken, avoid too much tightening when fastening screws. For products which have a short tapped

KHK Quick-Mod Gears, the KHK's system for quick modification of KHK stock gears is also available. hole (Products marked with ** are the tap size), fasten with torques less than 0.12N・m for M4, and 0.38N・m for M5.

②Plastic gears are susceptible to the effects of temperature and moisture. Dimensional changes may occur while performing secondary operations and

during post-machining operations.

Other

Other

* In regards to MC Nylon gears, other materials are available for plastic gears,

Stainless Steel Hubs for PSA

are now available!

■ How to attach gears to shafts MC nylon MC nylon

including Ultra High Molecular Weight Polyethylene (UHMW-PE), which has Standardized sectional stainless steel hubs.

It enhances a secure fastening to the shaft. To attach gears to shafts, in case of light loads, methods include using keys, taper pins,

excellent abrasion resistance. Poly Ether Ether Ketone (PEEK) also has quality spring pins, and press fitting after mounting the setscrews. While looseness tends to

occur in the conditions below, plastic gears are fastened by applying a steel hub.

properties. A single piece order is acceptable and will be produced as a 1. When the circumferential temperature is high

Metal

Metal

2. For large diameter gears

custom-made gear. For details on quotations and orders please see Page 8. 3. If forward-reverse motion impacts keys

For fastening steel hubs into plastic gears with bolts, see below for various methods.

For gears, which cannot be fasten with bolts due to their shape; it is recommended

Fastening with a steel hub bolt

to use the method of fusion bonding with metal cores.

For details, please see Page 150.

144 Technical information on gears is available on KHK Web Site. 145

PS・PSA Module 2.5 PS・PSA

Plastic Spur Gears Series Plastic Spur Gears

G E G G E

Specifications

E E F E F

F

JIS grade N9 (JIS B1702-1: 1998) * J J

Precision grade

JIS grade 5 (JIS B1702: 1976)

Gear teeth Standard full depth

Gears

Gears

Pressure angle 20°

Spur

Spur

Material MC901

D

C

C

A

A

D

D

A

B

C

A

B

C

A

B

C

Heat treatment ―

Tooth hardness (115 ∼ 120HRR)

20

Helical

Helical

Face width (E)

Gears

Gears

S1 S5 S1T2 S1K S5K

Hub width (F) 12 (Shape S1)

Total length (G) 37 (Shape S1)

To order J Series products, please specify; Catalog No. + J + BORE

Screw offset (J) 6 (Shape S1)

* The precision grade of J Series products is equivalent Bore H7 * The product shapes of J Series items are identified by background color.

to the value shown in the table.

Internal

Internal

10 12 14 15 16 17 18 19 20 22 25 28 30 32 35 40 45 50

Gears

Gears

Keyway Js9

Bore Hub dia. Pitch dia. Outside dia. Allowable torque (N·m) Allowable torque (kgf·m) Backlash Weight Screw size 4 × 1.8 5 × 2.3 6 × 2.8 8 × 3.3 10 × 3.3 12 × 3.3 14 × 3.8

Catalog No. No. of teeth Shape

AH7 B C D Bending strength Bending strength (mm) (kg) Catalog No. M4 M5 M6 M8 ―

PS2.5-12 12 23 30 35 4.39 0.45 0.023 PS2.5-12 J BORE

PS2.5-13 13 10 25 32.5 37.5 5.06 0.52 0.028 PS2.5-13 J BORE

PS2.5-14 14 25 35 40 5.77 0.59 0.031 PS2.5-14 J BORE

Racks

Racks

PS2.5-15 15 30 37.5 42.5 6.42 0.65 0~0.44 0.037 PS2.5-15 J BORE

PS2.5-16 16 32 40 45 7.09 0.72 0.043 PS2.5-16 J BORE

PS2.5-18 18 38 45 50 8.28 0.84 0.057 PS2.5-18 J BORE

PS2.5-20 20 S1 40 50 55 9.59 0.98 0.070 PS2.5-20 J BORE

CP Racks

CP Racks

& Pinions

& Pinions

PS2.5-22 22 44 55 60 10.8 1.11 0.085 PS2.5-22 J BORE

12

PS2.5-24 24 48 60 65 12.1 1.23 0.10 PS2.5-24 J BORE

PS2.5-25 25 50 62.5 67.5 12.8 1.30 0.11 PS2.5-25 J BORE

PS2.5-26 26 55 65 70 13.5 1.37 0.12 PS2.5-26 J BORE

PS2.5-28 28 60 70 75 14.7 1.50 0.15 PS2.5-28 J BORE

0~0.46

PS2.5-30 30 65 75 80 16.0 1.63 0.17 PS2.5-30 J BORE

Gears

Gears

PSA2.5-32 32 80 85 17.4 1.77 0.15 PSA2.5-32 J BORE

Miter

Miter

PSA2.5-35 35 87.5 92.5 19.5 1.99 0.17 PSA2.5-35 J BORE

PSA2.5-36 36 90 95 20.3 2.07 0.18 PSA2.5-36 J BORE

PSA2.5-40 40 100 105 23.2 2.36 0.23 PSA2.5-40 J BORE

PSA2.5-45 45 S5 15 ― 112.5 117.5 26.8 2.73 0.29 PSA2.5-45 J BORE

PSA2.5-48 48 120 125 29.0 2.96 0.33 PSA2.5-48 J BORE

Gears

Gears

Bevel

Bevel

PSA2.5-50 50 125 130 30.6 3.12 0~0.48 0.36 PSA2.5-50 J BORE

PSA2.5-55 55 137.5 142.5 34.1 3.48 0.43 PSA2.5-55 J BORE

PSA2.5-60 60 150 155 37.7 3.84 0.51 PSA2.5-60 J BORE

[Caution on Product Characteristics] ① Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), including bore size (H8 when [Caution on J series] ① As available-on-request products, requires a lead-time for shipping within 2 working-days (excludes the day ordered), after placing an order.

produced), tooth diameter, and backlash. Please see the section Design of Plastic Gears in separate technical reference book. (Page 101). Please allow additional shipping time to get to your local distributor.

② The allowable torques shown in the table are calculated values according to the assumed usage conditions. Please see Page 31 for more details. ② Number of products we can process for one order is 1 to 20 units. For quantities of 21 or more pieces, we need to quote price and lead time.

Screw

Screw

Gears

Gears

③ Without lubrication, using plastic gears in pairs may generate heat and dilation. It is recommended to mate them with steel gears. ③ Keyways are made according to JIS B1301 standards, Js9 tolerance.

④ The backlash values shown in the table are the theoretical values for the backlash in the normal direction of a pair of identical gears in mesh. ④ Certain products which would otherwise have a very long tapped hole are conterbored to reduce the length of the tap.

⑤ For products having a tapped hole, a set screw is included.

[Caution on Secondary Operations] ①Please read Caution on Performing Secondary Operations (Page 32) when performing modifications and/or secondary operations for safety concerns. ⑥ Since tapped holes of plastic products are easily broken, avoid too much tightening when fastening screws. For products which have a short tapped

KHK Quick-Mod Gears, the KHK's system for quick modification of KHK stock gears is also available.

Products Gearboxes Gear Pair

Products Gearboxes Gear Pair

hole (Products marked with ** are the tap size), fasten with torques less than 0.12N・m for M4, and 0.38N・m for M5.

②Plastic gears are susceptible to the effects of temperature and moisture. Dimensional changes may occur while performing secondary operations and

Worm

Worm

during post-machining operations.

* In regards to MC Nylon gears, other materials are available for plastic gears,

including Ultra High Molecular Weight Polyethylene (UHMW-PE), which has

Bevel

Bevel

excellent abrasion resistance. Poly Ether Ether Ketone (PEEK) also has quality

properties. A single piece order is acceptable and will be produced as a

custom-made gear. For details on quotations and orders please see Page 8.

Other

Other

GCU-S Spur Gear Kit Stainless Steel Hubs for PSA

Installment : Parallel axes gears

are now available!

(Two-stage)

Standardized sectional stainless steel hubs. ■ How to attach gears to shafts MC nylon MC nylon

Gear Type : Spur Gears It enhances a secure fastening to the shaft. To attach gears to shafts, in case of light loads, methods include using keys, taper pins,

Gears : 2 units of SS1.5-16 spring pins, and press fitting after mounting the setscrews. While looseness tends to

2 units of PS1.5-22 occur in the conditions below, plastic gears are fastened by applying a steel hub. Metal

Gear Ratio : 1.89 1. When the circumferential temperature is high

Metal

Weight : Approx. 1kg 2. For large diameter gears

3. If forward-reverse motion impacts keys

The Gear Kit contains two-stage spur

gears and allows speed increases / For fastening steel hubs into plastic gears with bolts, see below for various methods.

reductions, and includes the most For gears, which cannot be fasten with bolts due to their shape; it is recommended

Fastening with a steel hub bolt

commonly used combinations of to use the method of fusion bonding with metal cores.

gears.

For details, please see Page 150.

146 Technical information on gears is available on KHK Web Site. 147

PS・PSA Module 3 PS・PSA

Plastic Spur Gears Series Plastic Spur Gears

G E G G E

Specifications

E E F E F

F

JIS grade N9 (JIS B1702-1: 1998) * J J

Precision grade

JIS grade 5 (JIS B1702: 1976)

Gear teeth Standard full depth

Gears

Gears

Pressure angle 20°

Spur

Spur

Material MC901

D

C

C

A

A

D

D

A

B

C

A

B

C

A

B

C

Heat treatment ―

Tooth hardness (115 ∼ 120HRR)

30

Helical

Helical

Face width (E)

Gears

Gears

S1 S5 S1T2 S1K S5K

Hub width (F) 15 (Shape S1)

Total length (G) 45 (Shape S1)

To order J Series products, please specify; Catalog No. + J + BORE

Screw offset (J) 7.5 (Shape S1)

* The precision grade of J Series products is equivalent Bore H7 * The product shapes of J Series items are identified by background color.

to the value shown in the table.

Internal

Internal

10 12 14 15 16 17 18 19 20 22 25 28 30 32 35 40 45 50

Gears

Gears

Keyway Js9

Bore Hub dia. Pitch dia. Outside dia. Allowable torque (N·m) Allowable torque (kgf·m) Backlash Weight Screw size 4 × 1.8 5 × 2.3 6 × 2.8 8 × 3.3 10 × 3.3 12 × 3.3 14 × 3.8

Catalog No. No. of teeth Shape

AH7 B C D Bending strength Bending strength (mm) (kg) Catalog No. M4 M5 M6 M8 ―

PS3-12 12 28 36 42 7.58 0.77 0.040 PS3-12 J BORE

PS3-13 13 12 30 39 45 8.74 0.89 0.048 PS3-13 J BORE

PS3-14 14 32 42 48 9.97 1.02 0~0.52 0.056 PS3-14 J BORE

Racks

Racks

PS3-15 15 36 45 51 11.1 1.13 0.065 PS3-15 J BORE

PS3-16 16 38 48 54 12.3 1.25 0.075 PS3-16 J BORE

PS3-18 18 40 54 60 14.3 1.46 0.094 PS3-18 J BORE

PS3-20 20 S1 50 60 66 16.6 1.69 0.12 PS3-20 J BORE

CP Racks

CP Racks

& Pinions

& Pinions

PS3-22 22 54 66 72 18.7 1.91 0.15 PS3-22 J BORE

14

PS3-24 24 58 72 78 20.9 2.13 0.18 PS3-24 J BORE

PS3-25 25 60 75 81 22.1 2.25 0~0.54 0.19 PS3-25 J BORE

PS3-26 26 65 78 84 23.3 2.37 0.22 PS3-26 J BORE

PS3-28 28 70 84 90 25.5 2.60 0.25 PS3-28 J BORE

PS3-30 30 75 90 96 27.7 2.82 0.29 PS3-30 J BORE

Gears

Gears

PSA3-32 32 96 102 30.1 3.07 0.25 PSA3-32 J BORE

Miter

Miter

PSA3-35 35 105 111 33.8 3.44 0.30 PSA3-35 J BORE

PSA3-36 36 108 114 35.1 3.57 0.32 PSA3-36 J BORE

PSA3-40 40 120 126 40.0 4.08 0.39 PSA3-40 J BORE

PSA3-45 45 S5 18 ― 135 141 46.3 4.72 0.50 PSA3-45 J BORE

0~0.56

PSA3-48 48 144 150 50.2 5.12 0.57 PSA3-48 J BORE

Gears

Gears

Bevel

Bevel

PSA3-50 50 150 156 52.8 5.39 0.61 PSA3-50 J BORE

PSA3-55 55 165 171 58.9 6.01 0.74 PSA3-55 J BORE

PSA3-60 60 180 186 65.1 6.64 0.89 PSA3-60 J BORE

[Caution on Product Characteristics] ① Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), including bore size (H8 when [Caution on J series] ① As available-on-request products, requires a lead-time for shipping within 2 working-days (excludes the day ordered), after placing an order.

produced), tooth diameter, and backlash. Please see the section Design of Plastic Gears in separate technical reference book. (Page 101). Please allow additional shipping time to get to your local distributor.

② The allowable torques shown in the table are calculated values according to the assumed usage conditions. Please see Page 31 for more details. ② Number of products we can process for one order is 1 to 20 units. For quantities of 21 or more pieces, we need to quote price and lead time.

Screw

Screw

Gears

Gears

③ Without lubrication, using plastic gears in pairs may generate heat and dilation. It is recommended to mate them with steel gears. ③ Keyways are made according to JIS B1301 standards, Js9 tolerance.

④ The backlash values shown in the table are the theoretical values for the backlash in the normal direction of a pair of identical gears in mesh. ④ Certain products which would otherwise have a very long tapped hole are conterbored to reduce the length of the tap.

⑤ For products having a tapped hole, a set screw is included.

[Caution on Secondary Operations] ①Please read Caution on Performing Secondary Operations (Page 32) when performing modifications and/or secondary operations for safety concerns. ⑥ Since tapped holes of plastic products are easily broken, avoid too much tightening when fastening screws. For products which have a short tapped

KHK Quick-Mod Gears, the KHK's system for quick modification of KHK stock gears is also available.

Products Gearboxes Gear Pair

Products Gearboxes Gear Pair

hole (Products marked with ** are the tap size), fasten with torques less than 0.12N・m for M4, and 0.38N・m for M5.

②Plastic gears are susceptible to the effects of temperature and moisture. Dimensional changes may occur while performing secondary operations and

Worm

Worm

during post-machining operations.

* In regards to MC Nylon gears, other materials are available for plastic gears,

including Ultra High Molecular Weight Polyethylene (UHMW-PE), which has

Bevel

Bevel

excellent abrasion resistance. Poly Ether Ether Ketone (PEEK) also has quality

properties. A single piece order is acceptable and will be produced as a

custom-made gear. For details on quotations and orders please see Page 8.

Other

Other

GCU-S Spur Gear Kit Stainless Steel Hubs for PSA

Installment : Parallel axes gears

are now available!

(Two-stage)

Standardized sectional stainless steel hubs. ■ How to attach gears to shafts MC nylon MC nylon

Gear Type : Spur Gears To attach gears to shafts, in case of light loads, methods include using keys, taper pins,

It enhances a secure fastening to the shaft.

Gears : 2 units of SS1.5-16 spring pins, and press fitting after mounting the setscrews. While looseness tends to

2 units of PS1.5-22 occur in the conditions below, plastic gears are fastened by applying a steel hub. Metal

Gear Ratio : 1.89 1. When the circumferential temperature is high

Metal

Weight : Approx. 1kg 2. For large diameter gears

3. If forward-reverse motion impacts keys

The Gear Kit contains two-stage spur

gears and allows speed increases / For fastening steel hubs into plastic gears with bolts, see below for various methods.

reductions, and includes the most For gears, which cannot be fasten with bolts due to their shape; it is recommended

Fastening with a steel hub bolt

to use the method of fusion bonding with metal cores.

commonly used combinations of gears.

For details, please see Page 150.

148 Technical information on gears is available on KHK Web Site. 149

Você também pode gostar

- Pinion CatalogueDocumento8 páginasPinion CatalogueMarlon EvangelistaAinda não há avaliações

- Ground Spur Gears: Made To OrderDocumento9 páginasGround Spur Gears: Made To OrderJohn Fake Last NameAinda não há avaliações

- Especificaciones Tecnicos de Los EngranajesDocumento1 páginaEspecificaciones Tecnicos de Los EngranajesGary Hans Aüe AnteloAinda não há avaliações

- SH PDFDocumento1 páginaSH PDFchandraAinda não há avaliações

- Spur Gears Spur GearsDocumento5 páginasSpur Gears Spur Gearszbhp zAinda não há avaliações

- Hardened Spur Gears: Thermal Refined RacksDocumento1 páginaHardened Spur Gears: Thermal Refined Racksqwerty 12345Ainda não há avaliações

- Gear SsaDocumento4 páginasGear Ssa3DSAinda não há avaliações

- Spur Pinion Shafts: Spur Gears Spur GearsDocumento1 páginaSpur Pinion Shafts: Spur Gears Spur GearsJohn Fake Last NameAinda não há avaliações

- Steel Helical Gears: Spur Gears Spur GearsDocumento1 páginaSteel Helical Gears: Spur Gears Spur GearsjaseAinda não há avaliações

- Sma SMB SMCDocumento1 páginaSma SMB SMCKen MaglinteAinda não há avaliações

- Ground Zerol Miter Gears: SMZG SMZGDocumento1 páginaGround Zerol Miter Gears: SMZG SMZGShahadin QajaniAinda não há avaliações

- Dhembezor Konik PDFDocumento1 páginaDhembezor Konik PDFShahadin QajaniAinda não há avaliações

- Ground Helical Gears: Spur Gears Spur GearsDocumento5 páginasGround Helical Gears: Spur Gears Spur Gearsmanoj4709Ainda não há avaliações

- Hardened Ground Racks: Carburized Ground Racks, The Highest Performance Ever in The KHK Rack Series!Documento1 páginaHardened Ground Racks: Carburized Ground Racks, The Highest Performance Ever in The KHK Rack Series!Azis Fajar RiyadiAinda não há avaliações

- Stainless Steel Bevel Gears: Spur Gears Spur GearsDocumento1 páginaStainless Steel Bevel Gears: Spur Gears Spur Gearsdenizbademci31Ainda não há avaliações

- Ground Helical Gears: Spur Gears Spur GearsDocumento3 páginasGround Helical Gears: Spur Gears Spur GearsChaimaeAinda não há avaliações

- Finished Bore Spiral Bevel Gears: Mbsa MbsaDocumento2 páginasFinished Bore Spiral Bevel Gears: Mbsa Mbsamoath farrajAinda não há avaliações

- Steel Worms: Spur Gears Spur GearsDocumento5 páginasSteel Worms: Spur Gears Spur Gearsmariamalloney1730Ainda não há avaliações

- Stainless Steel Worms: Spur Gears Spur GearsDocumento3 páginasStainless Steel Worms: Spur Gears Spur GearsOriental BearingAinda não há avaliações

- Ground Internal Gears Are Available. Ground Internal Gears Are AvailableDocumento1 páginaGround Internal Gears Are Available. Ground Internal Gears Are AvailableAdrian ValerianAinda não há avaliações

- SSR Steel Ring Gears (Spur Gears)Documento1 páginaSSR Steel Ring Gears (Spur Gears)dindo_waeAinda não há avaliações

- Ground Helical Gears: KHG 1 KHGDocumento5 páginasGround Helical Gears: KHG 1 KHGGustavo SouzaAinda não há avaliações

- GR80 MR647092 - en - 2018-06Documento5 páginasGR80 MR647092 - en - 2018-06lapan111Ainda não há avaliações

- Steel Worms: Bronze Worm Wheels & Gray Iron Worm WheelsDocumento7 páginasSteel Worms: Bronze Worm Wheels & Gray Iron Worm WheelsKresnaFajarAinda não há avaliações

- Replacement Wheels For Casters Wheel Shafts / Grooved Wheels / Caster HoldersDocumento1 páginaReplacement Wheels For Casters Wheel Shafts / Grooved Wheels / Caster HoldersPugynAinda não há avaliações

- Manual de Servicio Equipo SD Pato Primo JVC - Ux-G355 - g357Documento43 páginasManual de Servicio Equipo SD Pato Primo JVC - Ux-G355 - g357AULIS LOORAinda não há avaliações

- Wiring Diagram (SD-509)Documento1 páginaWiring Diagram (SD-509)Emerson Fonte Dos Santos FreireAinda não há avaliações

- SRD2 ADocumento1 páginaSRD2 ApangkiAinda não há avaliações

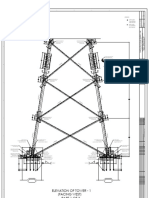

- Proposed Soccer Field: Side Elevation Side ElevationDocumento1 páginaProposed Soccer Field: Side Elevation Side ElevationanzaniAinda não há avaliações

- NB 174E A Slide GuideDocumento1 páginaNB 174E A Slide Guidetewobo6594Ainda não há avaliações

- Grande É o SenhorDocumento6 páginasGrande É o SenhorJosué CardosoAinda não há avaliações

- PURITAS RGB UsermanualDocumento2 páginasPURITAS RGB UsermanualMadolfsAinda não há avaliações

- Riser New Update 300622Documento4 páginasRiser New Update 300622Anh Khoa LeAinda não há avaliações

- For Continuation Refer To DWG No. Mdd1C-Dsi-A01-Sdw-Mep-Cs-M1965Documento1 páginaFor Continuation Refer To DWG No. Mdd1C-Dsi-A01-Sdw-Mep-Cs-M1965Jule LobresAinda não há avaliações

- Power Grid - MP: PROJECT - 132kV-D/C Monopole (Enquiry For PGICL TBCB MP PHASE-I/TL01) Summary SheetDocumento1 páginaPower Grid - MP: PROJECT - 132kV-D/C Monopole (Enquiry For PGICL TBCB MP PHASE-I/TL01) Summary SheetMOHAMMAD ZUEF - SKIPPER LIMITEDAinda não há avaliações

- 40G/43G Technical Poster: Section Overhead Line Overhead High-Order Path Overhead Low-Order Path OverheadDocumento2 páginas40G/43G Technical Poster: Section Overhead Line Overhead High-Order Path Overhead Low-Order Path Overheadchuang xuAinda não há avaliações

- LFST/SXB Strasbourg, France LFST/SXB Strasbourg, France: Rwy 23 Arrivals Epl 6V, GTQ 6U, GTQ 6V Lul 6V, Lupen 6VDocumento11 páginasLFST/SXB Strasbourg, France LFST/SXB Strasbourg, France: Rwy 23 Arrivals Epl 6V, GTQ 6U, GTQ 6V Lul 6V, Lupen 6VboobaAinda não há avaliações

- Misc RW 001Documento1 páginaMisc RW 001Tanveer IqbalAinda não há avaliações

- 2017 Motorsport Catalogue Feb07Documento12 páginas2017 Motorsport Catalogue Feb07Italo BaratellaAinda não há avaliações

- Telescopic CylinderDocumento2 páginasTelescopic CylinderReference mapiyeAinda não há avaliações

- Schematic Arduino+Solar+Charge+Controller+V2.0 Sheet 1 20200320104815Documento1 páginaSchematic Arduino+Solar+Charge+Controller+V2.0 Sheet 1 20200320104815Taha Chergui MouaneAinda não há avaliações

- G. S Unreal Sweep SoloDocumento6 páginasG. S Unreal Sweep SoloGeorge SavingstonAinda não há avaliações

- Vac 30Documento1 páginaVac 30John govanAinda não há avaliações

- Vac30 4Documento2 páginasVac30 4guillermo cordobaAinda não há avaliações

- Bore Hole DiametersDocumento1 páginaBore Hole DiametersVladislavAinda não há avaliações

- Jimny 19Documento3 páginasJimny 19Marc Abi HannaAinda não há avaliações

- Bas 03Documento1 páginaBas 03David GarciaAinda não há avaliações

- KHK SBDocumento3 páginasKHK SB3DSAinda não há avaliações

- Sharp Cef171a A5x504g240 Power SCHDocumento1 páginaSharp Cef171a A5x504g240 Power SCHAlex Urbina SanchezAinda não há avaliações

- p1475 MisumiDocumento1 páginap1475 MisumidmalfazAinda não há avaliações

- Falco Oz14720Documento1 páginaFalco Oz14720Itzel ColqueAinda não há avaliações

- GWM - ABS-CCP ApprovedDocumento1 páginaGWM - ABS-CCP Approvedtapa kumar nayakAinda não há avaliações

- GCU Gear Assembly KitDocumento1 páginaGCU Gear Assembly KitNagy ChristianAinda não há avaliações

- Tudo É NatalDocumento4 páginasTudo É NatalJuliana RosaAinda não há avaliações

- Steel Sun and Planet GearDocumento1 páginaSteel Sun and Planet GearAmarnathAinda não há avaliações

- FAST MDT GSU Solenoids FPC: Release Process Documentation in EDM. Level and Status Information in WatermarkDocumento1 páginaFAST MDT GSU Solenoids FPC: Release Process Documentation in EDM. Level and Status Information in WatermarkkitakishishiokoAinda não há avaliações

- Elevation of Tower - 1 (Facing West) Part 1 of 3: Section A-ADocumento1 páginaElevation of Tower - 1 (Facing West) Part 1 of 3: Section A-AHozien OnofreAinda não há avaliações

- Big Beast Stage DrawingsDocumento30 páginasBig Beast Stage DrawingsEngr Muhammad Azam ThaheemAinda não há avaliações

- Circle BarrelDocumento9 páginasCircle BarrelDarmawan PutrantoAinda não há avaliações

- The Minimum Ultimate Tensile Strength of No. 41 Lightweight Machinery Chain Is: A. 2000 LB B. 1000 LB C. 1800 LB D. 2500 LBDocumento69 páginasThe Minimum Ultimate Tensile Strength of No. 41 Lightweight Machinery Chain Is: A. 2000 LB B. 1000 LB C. 1800 LB D. 2500 LBJerome BalatbatAinda não há avaliações

- Me8513 MMDocumento2 páginasMe8513 MMSiva RamanAinda não há avaliações

- Training ReportDocumento31 páginasTraining ReportN.K. ChoudharyAinda não há avaliações

- 04 Fault Analysis 2006Documento57 páginas04 Fault Analysis 2006peach5Ainda não há avaliações

- Gear Measurement CMMDocumento4 páginasGear Measurement CMMSanjay MehrishiAinda não há avaliações

- Spacecraft Mechanisms: Mechanism FunctionsDocumento21 páginasSpacecraft Mechanisms: Mechanism FunctionsNikhilAinda não há avaliações

- P9736 (1) (1) 000000000000000000000000Documento29 páginasP9736 (1) (1) 000000000000000000000000WASEM ANWARAinda não há avaliações

- MDSP - February 2022Documento7 páginasMDSP - February 2022Joshua Gagate100% (1)

- Moments Levers and Gears Answer SchemeDocumento2 páginasMoments Levers and Gears Answer SchemeMr. SuitAinda não há avaliações

- Scope and Checklist - Propulsion SystemDocumento4 páginasScope and Checklist - Propulsion SystemNavnath GawasAinda não há avaliações

- MD2 PDFDocumento222 páginasMD2 PDFAbhishekAinda não há avaliações

- Chapter11 Prob01Documento13 páginasChapter11 Prob01imranakhtarAinda não há avaliações

- Kinematics of Machinery November Am Rr222105Documento12 páginasKinematics of Machinery November Am Rr222105Nizam Institute of Engineering and Technology LibraryAinda não há avaliações

- 4.2 Method of Measurement With Overballs OrRollers TechnicalData KGSTOCKGEARSDocumento6 páginas4.2 Method of Measurement With Overballs OrRollers TechnicalData KGSTOCKGEARSAna Gabriela OjedaAinda não há avaliações

- VDDC 13 NBADocumento14 páginasVDDC 13 NBANIKASH maniAinda não há avaliações

- Classic Ford May 2011 Ford Type 9 Five Speed GuideDocumento5 páginasClassic Ford May 2011 Ford Type 9 Five Speed GuideDatomarMarquez0% (1)

- 13 1964 CH-Auto TransDocumento32 páginas13 1964 CH-Auto TransJose LaproviteraAinda não há avaliações

- 2001 Polaris Sportsman 500 H.O. Owners Info 1Documento2 páginas2001 Polaris Sportsman 500 H.O. Owners Info 1Mandy HarmonAinda não há avaliações

- Final Drive UnitDocumento8 páginasFinal Drive UnitIsaiah Lule100% (5)

- 500 TransDocumento5 páginas500 TransRodney WellsAinda não há avaliações

- Speed Time Curve - TractionDocumento36 páginasSpeed Time Curve - TractionAlok Jain100% (2)

- Rudder CourseDocumento88 páginasRudder CourseMaxwell gonzàlezAinda não há avaliações

- Tutorial Spur GearDocumento2 páginasTutorial Spur GearMayankVijayAinda não há avaliações

- Chapter 2: Maintenance and Repairing A Motor GraderDocumento14 páginasChapter 2: Maintenance and Repairing A Motor Gradersameera19911014Ainda não há avaliações

- Design of Electronic Wedge Braking System For Go-KartDocumento4 páginasDesign of Electronic Wedge Braking System For Go-KartHassan AAinda não há avaliações

- Semi Automatic Baby Diaper Machine 2011-07-09Documento6 páginasSemi Automatic Baby Diaper Machine 2011-07-09ZakAinda não há avaliações

- Centrifugal PumpsDocumento48 páginasCentrifugal PumpsDevendra BangarAinda não há avaliações

- 205-03 Front Drive Axle and Differential - Removal and Installation - Drive Pinion Flange and SealDocumento7 páginas205-03 Front Drive Axle and Differential - Removal and Installation - Drive Pinion Flange and SealCARLOS LIMADAAinda não há avaliações

- Magazine Farmax enDocumento24 páginasMagazine Farmax enAbdi LadiantoAinda não há avaliações