Escolar Documentos

Profissional Documentos

Cultura Documentos

ECM 1500 H1-48300 116 kw-48V Outdoor PDF

Enviado por

PavelKuzovkinTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ECM 1500 H1-48300 116 kw-48V Outdoor PDF

Enviado por

PavelKuzovkinDireitos autorais:

Formatos disponíveis

ECM1500 Outdoor Cabinet

Technical Manual

Version V1.0

Revision date January 7, 2010

BOM 31020751

Emerson Network Power provides customers with technical support. Users may contact the nearest

Emerson local sales office or service center.

Copyright © 2010 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Contents

Chapter 1 Product Introduction ........................................................................................................................................... 1

1.1 Model Description ................................................................................................................................................. 1

1.2 Composition & Configuration ................................................................................................................................ 1

1.3 Technical Parameters ........................................................................................................................................... 4

1.4 Operating Theory .................................................................................................................................................. 5

1.5 Features ................................................................................................................................................................ 6

Chapter 2 AC & DC Distribution Units And Signal Output ................................................................................................... 7

2.1 AC & DC Distribution Unit ..................................................................................................................................... 7

2.2 Signal Output ........................................................................................................................................................ 8

Chapter 3 Forced Ventilation Model Thermal Control Unit .................................................................................................. 9

3.1 Configuration......................................................................................................................................................... 9

3.2 Heat-exchanging Function Under High Temperature Environment....................................................................... 9

3.2.1 Heat Control Board .................................................................................................................................... 9

3.2.2 Fan Timing Scheme ................................................................................................................................ 11

3.2.3 Temperature Characteristic Under High Temperature ............................................................................. 12

3.3 Noise Of The Thermal Control Unit ..................................................................................................................... 13

Chapter 4 Heat Exchanger Model Thermal Control Unit ................................................................................................... 14

4.1 Configuration....................................................................................................................................................... 14

4.2 Heat-exchanging Function Under High Temperature Environment..................................................................... 14

4.2.1 Environment Climate Control Unit ........................................................................................................... 14

4.2.2 Fan Timing Scheme ................................................................................................................................ 16

4.2.3 Temperature Characteristic Under High Temperature ............................................................................. 17

4.3 Heating Function Under Low Temperature Environment .................................................................................... 17

4.4 Noise Of The Thermal Control Unit ..................................................................................................................... 18

Chapter 5 Air-condition Model Thermal Control Unit ......................................................................................................... 19

5.1 Configuration....................................................................................................................................................... 19

5.2 Heat-exchanging Function Under High Temperature Environment ..................................................................... 19

5.2.1 EC Series Air-condition............................................................................................................................ 19

5.2.2 Refrigeration Scheme .............................................................................................................................. 20

5.2.3 Emergent Ventilation Scheme ................................................................................................................. 20

5.2.4 Temperature Characteristic Under High Temperature ............................................................................. 20

5.3 Heating Function Under Low Temperature Environment .................................................................................... 21

5.4 Noise Of The Thermal Control Unit ..................................................................................................................... 22

Chapter 6 Structure Design Feature Of The System ......................................................................................................... 23

6.1 Sunproof And Adiabatic ...................................................................................................................................... 23

6.2 Airproof Design ................................................................................................................................................... 24

6.3 Antiseptic Design ................................................................................................................................................ 25

6.3.1 Metallic Corrosion Protection ................................................................................................................... 25

6.3.2 Metalloid Corrosion Protection ................................................................................................................. 25

6.3.3 Biological Corrosion Protection ................................................................................................................ 25

6.4 Windproof Design ............................................................................................................................................... 25

6.5 Theftproof Design ............................................................................................................................................... 25

6.5.1 Theftproof Design Of The Door Lock And Gemel .................................................................................... 26

6.5.2 Theftproof Design Of The Door Panel & Cabinet And Exposed Mounting Sets ....................................... 26

6.6 Noise Reduction Design ..................................................................................................................................... 27

6.7 Quakeproof Design ............................................................................................................................................. 28

Chapter 7 Engineering Design Reference ......................................................................................................................... 29

7.1 Reference Parameters ........................................................................................................................................ 29

7.2 Grounding Design ............................................................................................................................................... 30

Appendix 1 Wiring Diagram............................................................................................................................................... 32

Appendix 2 Schematic Diagram ........................................................................................................................................ 35

Chapter 1 Product Introduction 1

Chapter 1 Product Introduction

ECM1500 outdoor cabinet (outdoor cabinet for short) is a power supply system used outdoors. It provides outdoor

protection and operation environment. It contains thermal control units and AC power distribution units. The cabinet

can accommodate different Emerson power supply subracks according to your requirement so as to form power

supply systems with different capacities.

This chapter introduces the model description, composition & configuration, operating theory and features of the

outdoor cabinet.

1.1 Model Description

The outdoor cabinet is available in three models, configured with different models of thermal control unit (forced

ventilation, heat exchanger and air-condition). Taking the forced ventilation model for example, the model description

of the outdoor cabinet is given in Figure 1-1.

EC M 1500 F 1 - 48 300

Internal power capacity: 300A, 150A, 120A

Internal power voltage:48Vdc

Version No.

Thermal control method: F (forced ventilation), H (heat exchanger), A (air-condition)

Maximum heat productivity in cabinet:1500W

Application: mobile network integrated cabinet

Emerson outdoor cabinet

Figure 1-1 Model description

1.2 Composition & Configuration

Composition

The outdoor cabinet is composed of thermal control units, power distribution units and related structures. Three

models of thermal control units are available: forced ventilation, heat exchanger and air-condition.

Configuration

1. The configuration of the forced ventilation model outdoor cabinet is given in Table 1-1.

Table 1-1 Configuration list of the forced ventilation model outdoor cabinet

Component Configuration

Fan Four pieces

Thermal control

Heat control board One piece

unit

Heat control extension board One piece

One route 10A single-phase AC socket; one route 25A single-phase AC input

Power AC distribution

MCB; one grounding busbar

distribution unit

DC distribution DC input terminals

Power and reserved space Sharing space: 15U, you can adjust space according to requirement

Door status sensor One piece

ECM1500 Outdoor Cabinet Technical Manual

2 Chapter 1 Product Introduction

The structure of the forced ventilation model outdoor cabinet is shown in Figure 1-2.

Figure 1-2 Structure of the forced ventilation model outdoor cabinet

2. The configuration of the heat exchanger model outdoor cabinet is given in Table 1-2.

Table 1-2 Configuration list of the heat exchanger model outdoor cabinet

Component Configuration

Fan Four pieces

Thermal control

Environment climate

unit One piece

control unit

One route 10A single-phase AC socket; one route 25A single-phase AC input MCB;

Power AC distribution

one grounding busbar

distribution unit

DC distribution DC input terminals

Power and reserved space Sharing space: 15U, you can adjust space according to requirement

Door status sensor One piece

The structure of the heat exchanger model outdoor cabinet is shown in Figure 1-3.

Figure 1-3 Heat exchanger model outdoor cabinet

ECM1500 Outdoor Cabinet Technical Manual

Chapter 1 Product Introduction 3

3. The configuration of the air-condition model outdoor cabinet is given in Table 1-3.

Table 1-3 Configuration list of the air-condition model outdoor cabinet

Component Configuration

Thermal control Outdoor air-condition One piece, refrigeration power: 1500W, input electric power: 910W

unit Emergent ventilation unit One set

One route 10A single-phase AC socket; one route 25A single-phase AC input

Power AC distribution

MCB; one grounding busbar

distribution unit

DC distribution DC input terminals

Power and reserved space Sharing space: 15U, you can adjust space according to requirement

Door status sensor One piece

The structure of the air-condition model outdoor cabinet is shown in Figure 1-4.

Figure 1-4 Air-condition model outdoor cabinet

4. Configuration in the cabinet.

The outdoor cabinet can be configured with three types of power supply subracks: 300A, 150A and 120A. Configured

with different battery layers and power supply subrack (subrack for short), the reserved spaces will differ, as given in

Table 1-4.

Table 1-4 Configuration in the cabinet

Configuration of the battery and subrack Reserved space

Three battery layers No space to configure with subrack 0U

Non-configured with Emerson subrack 15U

Configured with Emerson 300A subrack 6U

Two battery layers

Configured with Emerson 150A subrack 9U

Configured with Emerson 120A subrack 9U

Non-configured with Emerson subrack 24U

Configured with Emerson 300A subrack 15U

One battery layer

Configured with Emerson 150A subrack 18U

Configured with Emerson 120A subrack 18U

Non-configured with Emerson subrack 30U

Configured with Emerson 300A subrack 21U

No batteries

Configured with Emerson 150A subrack 24U

Configured with Emerson 120A subrack 24U

For detailed technical parameters and configuration of the subrack, see EPC48120/1800-HA(B)2 Technical Manual

and NetSure 501 A50, NetSure 501 AA0, NetSure 701 A51 19-Inch Subrack Power Supply Technical Manual.

ECM1500 Outdoor Cabinet Technical Manual

4 Chapter 1 Product Introduction

1.3 Technical Parameters

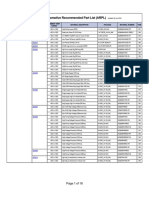

The technical parameters of the outdoor cabinet are given in Table 1-5.

Table 1-5 Technical parameters

Parameter

Parameter Description

category

-10°C ~ +45°C (forced ventilation model), -40°C ~ +45°C (heat exchanger

Operating temperature

model), -40°C ~ +50°C (air-condition model)

Storage temperature -40°C ~ +70°C

Environmental

Relative humidity 5%RH ~ 100%RH

Altitude ≤ 2,000m (derating is required above 2,000m)

Others No conductive dust or erosive gases. No possibility of explosion

Conducted emission

Class A EN55022

Radiated emission

Immunity to EFT Level 3 EN61000-4-4

EMC Immunity to ESD Level 3 EN61000-4-2

Immunity to Surges Level 4 EN61000-4-5

Immunity to radiation Level 3 EN61000-4-3

Immunity to conduction Level 3 EN61000-4-6

Safety regulation Compliant with IEC60950-1, IEC60950-22

At temperature of 15°C ~ 35°C and relative humidity not bigger than 90%RH,

apply a test voltage of 500Vdc. The insulation resistances between AC circuit

Insulation resistance

and earth, DC circuit and earth, and AC and DC circuits are all not less than

10MΩ

(Remove the SPD, monitoring module and rectifiers from the system before the

test.)

Others AC to DC circuits: 50Hz, 3,000Vac

AC circuit to earth: 50Hz, 2,500Vac

Insulation strength

DC circuit to earth: 50Hz, 1,000Vac

Assistant circuit (not directly connected to the host circuit): 50Hz, 500Vac

For all the three tests above, there should be no breakdown or flashover within

1min, with leakage current not bigger than 10mA

MTBF 100,000h

ROHS Compliant with R5 requirement

Cabinet 700 (W) × 700 (D) ×1800 (H)

Dimensions (mm) Internal space of battery

613 (W) × 570 (D) × 350 (H)

compartment

Forced ventilation

≤ 125 (excluding subrack and battery string)

Mechanical model cabinet

Heat exchanger model

Weight (kg) ≤ 180 (excluding subrack and battery string)

cabinet

Air-condition model

≤ 175 (excluding subrack and battery string)

cabinet

ECM1500 Outdoor Cabinet Technical Manual

Chapter 1 Product Introduction 5

1.4 Operating Theory

Heat dissipation theory for forced ventilation model outdoor cabinet

The cold air is sucked in through the front door air filter at the lower part of the outdoor cabinet. It passes through the

battery compartment, user equipment and power supply subrack in turn. Finally, the hot air is discharged by the fans

at the top of the outdoor cabinet. In this way, the equipment and power modules in the cabinet are cooled, as shown

in Figure 1-5.

Heat dissipation fan Air outlet

Power supply subrack

Sharing space

Air inlet

Figure 1-5 Heat dissipation access for forced ventilation model outdoor cabinet

Heat dissipation theory for heat exchanger model outdoor cabinet

A heat exchanger is fitted on the door of the outdoor cabinet. It can exchange the heat between the cold air outside

the cabinet and the hot air inside the cabinet. In this way, the equipment and power modules in the cabinet are cooled,

as shown in Figure 1-6.

Internal circulation air

inlet of heat exchanger

Internal circulation air

outlet of heat exchanger

Figure 1-6 Heat dissipation theory for heat exchanger model outdoor cabinet

ECM1500 Outdoor Cabinet Technical Manual

6 Chapter 1 Product Introduction

Heat dissipation theory for air-condition model outdoor cabinet

An outdoor air-conditioner is fitted on the door of the outdoor cabinet to cool the cabinet. It is in this that the

equipment and power modules in the cabinet are cooled. In case of air-conditioner fault or AC mains failure, the

emergent ventilation units automatically startup to dissipate heat emergently, as shown in Figure 1-7.

Top emergent ventilation fan

Return air inlet of air-condition

Outdoor air-condition

Air outlet of air-condition

Figure 1-7 Heat dissipation theory for air-condition model outdoor cabinet

1.5 Features

Variable power supply subrack: The outdoor cabinet can accommodate standard 19” and 23” power supply

subrack.

Variable space: The power space, reserved space and the battery compartment space are interchangeable. You

can adjust the space according to the actual requirement.

Thermal control unit: Three different models are available for your selection according to the local, environment

and requirement.

Safety guideline: The equipment compartment satisfies IP*5 waterproof requirement and IP5* dustproof

requirement.

Environment pollution level within the outdoor cabinets is 2.

ECM1500 Outdoor Cabinet Technical Manual

Chapter 2 AC & DC Distribution Units And Signal Output 7

Chapter 2 AC & DC Distribution Units And Signal Output

This chapter introduces the configurations, positions and functions of the AC & DC distribution units, and the signal

output.

2.1 AC & DC Distribution Unit

Configuration

The configurations of the AC & DC distribution units are given in Table 2-1.

Table 2-1 Configuration list of the AC $ DC distribution units

Part name Configuration

One route 10A single-phase AC socket; one route 25A single-phase AC input

AC & DC AC distribution unit

MCB; one grounding busbar

distribution units

DC distribution unit DC input terminals

Position

The positions of the AC & DC distribution units are shown in Figure 2-1.

交流输入空开

AC input MCB

直流输入端子

DC input terminal

信号输出端子排

Signal output

terminal block

接地汇流排busbar

Grounding

进出线孔

Entry hole

Figure 2-1 Positions of the AC & DC distribution units

The functions of the AC input ports are described in Table 2-2.

Table 2-2 Functions of the AC input ports

Port name Function

Used to connect with the thermal control unit and AC power for user sockets and control them on and

AC input MCB

off. Adopting single-phase 3-wire system. MCB: 1×25A/2P

Used to connect with protective ground, lightning ground and working ground together. Connecting this

Grounding busbar

grounding busbar to the external grounding bar of the cabinet

The functions of the DC input ports are described in Table 2-3.

Table 2-3 Functions of the DC input ports

Port name Function

DC input terminal Used to connect with the thermal control unit and signal control device

ECM1500 Outdoor Cabinet Technical Manual

8 Chapter 2 AC & DC Distribution Unit And Signal Output

Function

Customer connection and maintenance are accessible from the front. Lead the load cables of the user equipment and

AC input cables into the cabinet through the entry holes (see Figure 2-1) on the both sides of the bottom plate of the

cabinet, and connect them to the AC & DC distribution units.

The AC & DC distribution units being independent of the power supply system merely guarantee the normal operation

of the thermal control unit and the normal outputs of the various alarm signals. When Emerson power supply subrack

is purchased, the AC & DC cables between the power supply subrack and the outdoor cabinet have been connected

in factory. If you purchase the power supply subrack by yourself, ensure that the AC & DC cables are connected to

the AC & DC distribution units.

2.2 Signal Output

The outdoor cabinet can output alarm signals through the dry contacts on the signal output terminal block. The

functions of the dry contacts are described in Table 2-4.

Table 2-4 Dry contact function

Terminal No. Definition Remark

1, 2 Over temperature alarm Default value

3, 4 Thermal control unit failure Default value

5, 6 Door alarm Default value

7, 8 Spare Configurable

ECM1500 Outdoor Cabinet Technical Manual

Chapter 3 Forced Ventilation Model Thermal Control Unit 9

Chapter 3 Forced Ventilation Model Thermal Control Unit

This chapter introduces the configuration, heat-exchanging function under high temperature environment and noise of

the forced ventilation model thermal control unit.

3.1 Configuration

The configuration of the forced ventilation model thermal control unit is given in Table 3-1.

Table 3-1 Configuration list of the forced ventilation model thermal control unit

Part name Configuration

Fan Four pieces

Forced ventilation model

Heat control board One piece

thermal control unit

Heat control extension board One piece

3.2 Heat-exchanging Function Under High Temperature Environment

3.2.1 Heat Control Board

The heat control board acquires the equipment compartment temperature through the external temperature sensor,

and takes it as a base for fan startup, stop and timing. The heat control board can report the fan fault and has

indications through the alarm indicators at the same time. The connection diagram of the heat control board is shown

in Figure 3-1.

Digital value (AC

Controlled by two mains off)

groups of fan SCU

Fan

(upstream

Four routes of equipment)

Heat control alarm value

One route of board

analogy value

Temperature sensor

DIP switch setting

Serial

communication port

Figure 3-1 Connection diagram of the heat control board

Fan: Adjustable varying-speed fan, fan timing signal: PWM pulse

Temperature sensor: Current type sensor, temperature detection range: -40°C ~ 100°C

Serial communication port: Educed from the singlechip. Needed a conversion equipment when using this port.

Applicable to test board only

Digital value: Dry contact signal, signal: AC mains off

Four routes of alarm value: Output alarm signals about heat control board

DIP switch setting: Setting working mode of the heat control board

ECM1500 Outdoor Cabinet Technical Manual

10 Chapter 3 Forced Ventilation Model Thermal Control Unit

The heat control board is fitted on the top of the equipment compartment. Loosen the two fixing screws to remove the

cover (see Figure 3-2), and then you can see the heat control board.

Fixing screw of cover

Cover

Figure 3-2 Cover position

The appearance and terminal layout of the heat control board are shown in Figure 3-3; the corresponding ports are

described in Table 3-2.

H1 H2

J11

J12

J10

J2

SW2

ON

SW1 SW2

SW1

J6

J7

J3

H4

B H3

Alarm indicator

Heat control board appearance Terminal layout

Figure 3-3 Appearance and terminal layout of the heat control board

Table 3-2 Port difinition

Port name Pin No. Signal name Definition Remark

1 POWER+

J2 (POWER) 48V power Power voltage range: 40V ~ 60V

2 POWER-

1 ALM1+

Fan alarm

2 ALM1-

3 ALM2+

Spare alarm Alarms output from optocoupler

4 ALM2+ secondary side, ALMn+, ALMn-:

J3 (ALMOUT)

5 ALM3+ normal when breakover, alarm when

Temperature sensor failure

open

6 ALM3- alarm

7 ALM4+

Over temperature alarm

8 ALM4-

1 VCC 1

Serial communication port of the

J10 2 TXD 2

singlechip

3 RXD 3

ECM1500 Outdoor Cabinet Technical Manual

Chapter 3 Forced Ventilation Model Thermal Control Unit 11

Port name Pin No. Signal name Definition Remark

4 GND 4

1 + Temperature (equipment

J6 (TEMP) 2 TEMP_SIGNAL compartment)

3 GND Ground

1 SWIN State value under AC mains off, dry

J7 (SWIN) Input digital value contact alarm output, AC mains off

2 GND

alarm when open, normal when closed

1 FAN_48V Power+ of fan group 1

2 SGND Power- of fan group 1

J11 (FANA) 3 FANA_SPEED Timing signal of fan group 1 PWM pulse signal

4 FAN1_ALM Alarm signal of fan group 1 Pulse when normal

5 FAN2_ALM Alarm signal of fan group 2 Pulse when normal

1 FAN_48V Power+ of fan group 2

2 SGND Power- of fan group 2

J12 (FANB) 3 FANB_SPEED Timing signal of fan group 2 PWM pulse signal

4 FAN3ALM Alarm signal of fan group 3 Pulse when normal

5 FAN4ALM Alarm signal of fan group 4 Pulse when normal

The settings of the SW1 button and SW2 DIP switch are described in Table 3-3.

Table 3-3 SW1 and SW2 setting description

Label on the Silk print on the

Name corresponding corresponding Setting description

plastic cover heat control board

Upon ‘ON’, the fan is forced to stop after AC mains fails,

Bit ‘1’ on the DIP

otherwise, the fan will maintain normal on/off control. Put the

switch

Switch SW2 switch to the ‘ON’ position, see Figure 3-3

Bit ‘2’ on the DIP

Put the switch to the ‘ON’ position, see Figure 3-3

switch

Self switch Button SW1 Pressing this button to test the fans

3.2.2 Fan Timing Scheme

The forced ventilation model outdoor cabinet has two-group four axial flow fans with the same specifications

(120mm×120mm). The max. power and startup inrush current of each fan are 26W and 0.82A (at DC side)

respectively. Under the control of the heat control board, the two-group fans can regulate speeds along with the

environmental temperature. The timing scheme is given in Table 3-4.

Table 3-4 Fan timing scheme

Fan Startup temperature (°C) Stop temperature (°C) Remark

Temperature: +35°C ~ +45°C

Fan speed (linear): 57.5% ~ 100%

Fan group 1 (fans Temperature: +25°C ~ +35°C

+35±3 +25±3

1, 2) Fan speed (linear): 57.5% ~ 15%

Temperature: -40°C ~ +25°C

Fan speed (linear): 0%

Temperature: +40°C ~ +45°C

Fan speed (linear): 72% ~ 100%

Fan group 2 (fans Temperature: +30°C ~ +40°C

+40±3 +30±3

3, 4) Fan speed (linear): 72% ~ 15%

Temperature: -40°C ~ +30°C

Fan speed (linear): 0%

Note: When the temperature sensor fails, the two-group fans will work at full speeds

ECM1500 Outdoor Cabinet Technical Manual

12 Chapter 3 Forced Ventilation Model Thermal Control Unit

The relation curve between the fan speed and temperature is shown in Figure 3-4.

Speed Speed

100% 100%

72%

57.5%

15% 15% °C

°C

25 35 45 30 40 45

Relation curve between the speed of the Relation curve between the speed of the

fan group 1 and temperature fan group 2 and temperature

Figure 3-4 Relation between the fan speed and temperature

Control method of the fan group 1: The fan starts when the environmental temperature is higher than 35°C; works at

full speed when the environmental temperature is higher than 45°C and stops when the environmental temperature

drops down to 25°C.

Control method of the fan group 2: The fan starts when the environmental temperature is higher than 40°C; works at

full speed when the environmental temperature is higher than 45°C and stops when the environmental temperature

drops down to 30°C.

3.2.3 Temperature Characteristic Under High Temperature

When the four fans works at the same time, simulating the heat consumption 1000W, 1500W and 2000W in the

cabinet, the layout of the typical temperature in the cabinet (air outlet and air inlet of the equipment) is shown in

Figure 3-5.

Air inlet temperature of the

equipment in the cabinet (°C)

54

1000W heat consumption

51

48 1500W heat consumption

45 2000W heat consumption

42

39

36

33

30 Environmental

35 40 45 temperature (°C )

Figure 3-5 Layout of the typical temperature in the cabinet when four fans work

For some cabinets with small heat consumption and customer equipment with wide range of temperature, we just

simulate two fans work, when the heat consumption is 1000W and 1500W, the layout of the typical temperature in the

cabinet (air outlet and air inlet of the equipment) is shown in Figure 3-6. Under this instance, we can reduce the

configurations of the fans.

ECM1500 Outdoor Cabinet Technical Manual

Chapter 3 Forced Ventilation Model Thermal Control Unit 13

Air inlet temperature of the

equipment in the cabinet (°C)

59

56 1000W heat consumption

53

1500W heat consumption

50

47

44

41

38

35 Environmental

35 40 45 temperature ( °C )

Figure 3-6 Layout diagram of the typical temperature in the cabinet when two fans work

3.3 Noise Of The Thermal Control Unit

For different temperatures in the cabinet, the fans work with different speeds, therefore, the generated noises are

different. The system noise curve is shown in Figure 3-7.

System noise (dB)

64

62

60

58

56

54

52 Temperature in

35 40 45 the cabinet (°C )

Figure 3-7 System noise curve

ECM1500 Outdoor Cabinet Technical Manual

14 Chapter 4 Heat Exchanger Model Thermal Control Unit

Chapter 4 Heat Exchanger Model Thermal Control Unit

This chapter introduces the configuration, heat-exchanging function under high temperature environment, heating

function under low temperature environment and noise of the heat exchanger model thermal control unit.

4.1 Configuration

The configuration of the heat exchanger model thermal control unit is given in Table 4-1.

Table 4-1 Configuration list of the heat exchanger model thermal control unit

Part name Configuration

Fan Four pieces

Heat exchanger model

Environment climate control unit One piece

thermal control unit

Heater One piece

4.2 Heat-exchanging Function Under High Temperature Environment

4.2.1 Environment Climate Control Unit

The connection diagram of the environment climate control unit (that is ECCU) is shown in Figure 4-1.

Environment

Fan control

value acquiring

Dry contact alarm

AC mains off signal ECCU

CAN

communication

RS232

Serial port

communication

Figure 4-1 Connection diagram of the ECCU

Environment value acquiring: Environment value including smoke sensor, water sensor, infrared sensor, temperature

sensor and door sensor, one route of each environment value

AC mains off signal: Dry contact input, one route

Serial port: Used to connect with temperature & humidity sensor with serial port

Fan control: Two groups, each group including two fans, supporting 10V PWM pulse alarm fans

Dry contact alarm: four outputs, alarm when open, normal when closed or normal when open, alarm when closed,

optional

CAN communication: Used to communicate with monitoring unit, an internal communication port

RS232 communication: Used to background monitor, an external communication port

ECM1500 Outdoor Cabinet Technical Manual

Chapter 4 Heat Exchanger Model Thermal Control Unit 15

ECCU is fitted on the top of the equipment compartment. Loosen the two fixing screws to remove the cover, and then

you can see the ECCU, as shown in Figure 4-2.

Fixing screw of cover

Cover

Figure 4-2 Cover position

The terminal layout of the ECCU is shown in Figure 4-3.

J1 J2 J3 J4 J14 J8

FAN1 FAN2 FAN3 FAN4 TEMP.

T E M P .& H U M .

AC_OFF J12

J5

A LM O U T

SW101 J10

W A TE R

LED_FAULT

P O W E R D O O R S M O K E IN FR A R E D

LED_ALM J11

LED_RUN

J6

R S 232

SW100 J9

J13

J7

CAN

J15

Figure 4-3 ECCU terminal layout

The DIP switch function and setting method are described as follows:

1. Bit 1 ~ Bit 4 are used to set addresses of the ECCU. OFF: 0, ON: 1. Default address: 16. The setting method of the

ECCU is given in Table 4-2.

Table 4-2 Setting method of the ECCU address

Bit 4 Bit 3 Bit 2 Bit 1 ECCU address

0 0 0 0 16

0 0 0 1 1

0 0 1 0 2

… … … … …

1 1 1 1 15

Note: Bit 1 ~ Bit 4 have been set in factory. You can change the settings according to your communication requirement

ECM1500 Outdoor Cabinet Technical Manual

16 Chapter 4 Heat Exchanger Model Thermal Control Unit

2. The function description and setting method of Bit 5 ~ Bit 8 are given in Table 4-3.

Table 4-3 Function sescription and setting method of Bit 5 ~ Bit 8

Bit No. Function Setting method Default value

OFF: heat exchanger model

5 Choose cabinet model OFF

ON: forced ventilation

OFF: normal when open; alarm when closed

6 Choose dry contact alarm mode ON

ON: normal when closed; alarm when open

OFF: serial port termperature & humidity sensor

7* Choose sensor ON

ON: temperature sensor

Choose whether stopping fans OFF: No

8 OFF

when AC mains fails ON: Yes

Note*: When Bit 7 is placed to ON position, ECCU has no humidity acquisition function

4.2.2 Fan Timing Scheme

The heat exchanger model outdoor cabinet has four centrifugal internal and external fans with the same

specifications (175mm×69mm). The max. power and startup inrush current of each fan are 43W and 1.5A (at DC side)

respectively. Under the control of the ECCU, the internal and external fans can regulate speeds along with the

environmental temperature. The timing scheme is given in Table 4-4.

Table 4-4 Fan timing scheme

Fan Startup temperature (°C) Stop temperature (°C) Remark

Temperature: -40°C ~ +25°C

Internal fan (fans 1, Fan speed: 50%

2) Temperature: +25°C ~ +45°C

Fan speed (linear): 50% ~ 100%

Temperature: +35°C ~ +45°C

Fan speed (linear): 57.5% ~ 100%

External fan (fans Temperature: +25°C ~ +35°C

+35±3 +25±3

3, 4) Fan speed (linear): 57.5% ~ 15%

Temperature: -40°C ~ +25°C

Fan speed (linear): 0%

Note: When the temperature sensor fails, the internal and external fans will work at full speeds

The relations between the speeds of the internal & external fans and environmental temperature are shown in Figure

4-4.

Speed Speed

100% 100%

50% 57.5%

15% °C

°C

0 25 45 25 35 45

Relation between the speed of the internal Relation between the speed of the external

fan and environmental temperature fan and environmental temperature

Figure 4-4 Relation between the speeds of the internal & external fans and environmental temperature

The internal fans are not stopped working. When the environmental temperature is lower than 25°C (default value),

the internal fans work at the half speed. The timing range is 20°C (default value), that is, when the environmental

temperature increase from 25°C to 45°C, the internal fans will accelerate linearly from half speeds to full speeds.

When the environmental temperature is higher than 45°C, the internal fans work at full speeds. The temperature point

and timing range at the half speed of the internal fan can be set through the background software.

ECM1500 Outdoor Cabinet Technical Manual

Chapter 4 Heat Exchanger Model Thermal Control Unit 17

The external fans work at half speeds when the environmental temperature is higher than 35°C (default value); work

at full speeds when the environmental temperature is higher than 45°C (default value) and stop when the

environmental temperature decreases to 25°C (default value).

4.2.3 Temperature Characteristic Under High Temperature

When the four fans works at the same time, simulating the heat consumption 1500W and 2000W in the cabinet, the

layout of the typical temperature in the cabinet (air outlet and air inlet of the equipment) is shown in Figure 4-5.

Air inlet temperature of the

equipment in the cabinet (°C)

59

56 1500W heat consumption

53

2000W heat consumption

50

47

44

41

38

35 Environmental

temperature ( °C )

35 40 45

Figure 4-5 Layout of the typical temperature in the cabinet when four fans work

For some cabinets with small heat consumption and customer equipment with wide range of temperature, we

simulate two external fans and one internal fan work only. When the heat consumption is 1000W and 1500W, the

layout of the typical temperature in the cabinet (air outlet and air inlet of the equipment) is shown in Figure 4-6. Under

this instance, we can reduce the configurations of the fans. However, it will bring unpredictable influence to the heat

exchanger life, please consider appropriately.

Air inlet temperature of the

equipment in the cabinet (°C)

59

56 1000W heat consumption

53

1500W heat consumption

50

47

44

41

38

35 Environmental

temperature ( °C )

35 40 45

Figure 4-6 Layout of the typical temperature in the cabinet when configured with one internal fan only

4.3 Heating Function Under Low Temperature Environment

The heater, accommodated in the system heat-exchanging unit, configures two heating bars with 315W and 220Vac

input. The installation position of the heater is shown in Figure 4-7. The heater is controlled by temperature relay and

uses air outlets of the internal fans to improve the heating efficiencies of the heating bars.

ECM1500 Outdoor Cabinet Technical Manual

18 Chapter 4 Heat Exchanger Model Thermal Control Unit

Heater

Figure 4-7 Heater position

The startup and stop temperature points of the heater are given in Table 4-5.

Table 4-5 Startup and stop temperature points of the heater

Part name Startup temperature (°C) Stop temperature (°C)

Heater +5±5 +15±5

When the environmental temperature is -40°C, the outdoor cabinet, fitted with a 100W user equipment and

accommodated 50A loads, can start normally. The heater can heat the temperature of the equipment compartment

higher than -10°C in two hours, and the temperature of the battery compartment higher than -15±5°C in eight hours.

4.4 Noise Of The Thermal Control Unit

For different temperatures in the cabinet, the fans work with different speeds, therefore, the generated noises are

different. The system noise curve is shown in Figure 4-8.

System noise (dB)

66

64

62

60

58

56

54

52 Temperature in

the cabinet (°C )

35 40 45

Figure 4-8 System noise curve

ECM1500 Outdoor Cabinet Technical Manual

Chapter 5 Air-condition Model Thermal Control Unit 19

Chapter 5 Air-condition Model Thermal Control Unit

This chapter introduces the configuration, heat-exchanging function under high temperature environment, heating

function under low temperature environment and noise of the air-condition model thermal control unit.

5.1 Configuration

The configuration of the air-condition model thermal control unit is given in Table 5-1.

Table 5-1 Configuration list of the air-condition model thermal control uni

Part name Configuration

Air-condition model thermal Air-condition One piece

control unit Emergent ventilation unit One set

5.2 Heat-exchanging Function Under High Temperature Environment

5.2.1 EC Series Air-condition

EC series air-condition is a refrigeration product developed for the cabinet. Its cooling power, rated input power and

max. startup inrush current are 1500W, 910W and 15A (at AC side) respectively. It is applicable to the cabinet whose

internal equipment has great heat productivity application and is sensitive to environmental temperature, and

applications with internal and external environment complete isolation. The air-conditon has high reliability, and is

easy to install. After power-on, the air-condition can work and not do any complex test.

The internal circulation of the air-condition housing sucks hot air from upside, and cold air is discharged out of the

air-condition from the bottom. The external circulation sucks outside cold air from the bottom, after heat exchanging,

the hot air is discharged out of the air-condition from the upside, as shown in Figure 5-1.

Cabinet

External environment

External circulation

hot air outlet

EC series air-condition

Hot air inlet in

the cabinet

Cold air outlet External circulation

in the cabinet air inlet

Figure 5-1 Schematic diagram of the air-condition functions

ECM1500 Outdoor Cabinet Technical Manual

20 Chapter 5 Air-condition Model Thermal Control Unit

5.2.2 Refrigeration Scheme

Cooling startup point = cooling stop point + cooling sensitivity. The air-condition starts to cool when the temperature in

the cabinet is higher than cooling startup point, and stops to cool when the temperature is lower than cooling stop

point. The setting points of the cooling parameters are described in Table 5-2.

Table 5-2 Setting points of the cooling parameters

Parameter Default value Setting range unit Setting point description

Cooling stop point 25 20 ~ 40 °C Temperature point of cooling stop

Cooling sensitivity 10 1 ~ 15 °C Temperature control sensitivity

5.2.3 Emergent Ventilation Scheme

The emergent ventilation unit of the air-condition model outdoor cabinet is composed of one heat control board and

two 120mm×120mm axial fans. For the introductions of the heat control board and fans, see 3.2.1 Heat Control

Board and 3.2.2 Fan Timing Scheme respectively.

When the air-condition fails or AC input is off, the air-condition will generate dry contact fault alarm. After receiving

this signal, the heat control board will start emergent ventilation fans if the fans meet startup condition. The startup

temprature condition of the emergent ventilation is shown in Figure 5-2.

Speed

100%

72%

15% °C

30 40 45

Figure 5-2 Startup temprature condition of the emergent ventilation

Under air-condition alarm, the fans starts and when the environmental temperature is higher than 40°C; work at full

speed when the temperature is higher than 45°C; and stop when the temperature drops down to 30°C.

5.2.4 Temperature Characteristic Under High Temperature

When the air-condition starts to work, simulating the heat consumption 1000W, 1500W and 2000W in the cabinet, the

layouts of the typical temperature in the equipment compartment (air outlet and air inlet of the equipment) and battery

compartment in the cabinet are respectively shown in Figure 5-3 and Figure 5-4.

Air inlet temperature of the

equipment in the cabinet (°C)

49

1000W heat consumption

46

43 1500W heat consumption

40 2000W heat consumption

37

34

31

28

25 Environmental

temperature ( °C )

35 40 45 50 55

Figure 5-3 Layout of the typical temperature in the equipment compartment when air-condition works

ECM1500 Outdoor Cabinet Technical Manual

Chapter 5 Air-condition Model Thermal Control Unit 21

Temperature of the battery

compartment in the cabinet(°C)

49

1000W heat consumption

46

43 1500W heat consumption

40 2000W heat consumption

37

34

31

28

25 Environmental

35 40 45 50 55 temperature ( °C )

Figure 5-4 Layout of the typical temperature in the battery compartment when air-condition works

When the air-condition fails or AC input is off, the emergent ventilation system starts. Simulation the heat

consumption 500W, 1000W and 1500W in the cabinet, the layout of the typical temperature in the cabinet (air outlet

and air inlet of the equipment) is shown in Figure 5-5.

Air inlet temperature of the

emergent ventilation equipment

under emergent instance(°C)

500W heat consumption

1000W heat consumption

59

56 1500W heat consumption

53

50

47

44

41

38

35 Environmental

40 45 50 55 temperature ( °C )

Figure 5-5 Layout of the typical temperature in the cabinet when emergent ventilation unit works

5.3 Heating Function Under Low Temperature Environment

The heater, accommodated in the outdoor air-condition of the system, configures one heating bar with 1000W and

220Vac input. The heater is controlled by internal control board in the air-condition automatically and uses air outlets

of the internal fans to improve the heating efficiencies of the heating bars.

Heating stop point = heating startup point + heating sensitivity. The heat starts to heat when the temperature in the

cabinet is lower than heating startup point, and stops to heat when the temperature is higher than heating stop point.

The setting points of the heating parameters are described in Table 5-3.

Table 5-3 Setting points of the heating parameters

Parameter Default value Setting range unit Setting point description

Heating startup point 5 -10 ~ 15 °C Temperature point of heating startup

Heating sensitivity 10 0 ~ 10 °C Temperature control sensitivity

When the environmental temperature is -40°C, the outdoor cabinet, fitted with a 100W user equipment and

accommodated 50A loads, can start normally. The heater can heat the temperature of the equipment compartment

ECM1500 Outdoor Cabinet Technical Manual

22 Chapter 5 Air-condition Model Thermal Control Unit

higher than -5°C (error: ±5°C) in two hours, and the temperature of the battery compartment higher than -10°C (error:

±5°C) in eight hours.

5.4 Noise Of The Thermal Control Unit

For different temperatures in the cabinet, the difference is that whether the air-condition works. The system noise is

65dB when the air-condition works.

ECM1500 Outdoor Cabinet Technical Manual

Chapter 6 Structure Design Feature Of The System 23

Chapter 6 Structure Design Feature Of The System

The outdoor cabinet is exclusively used in outdoors. Because of outdoors terrible environment in, the outdoor cabinet

provides various protections, such as sunproof & adiabatic, dustproof & waterproof, tri-proof (dampproof, mildewproof

and fogproof), windproof and theftproof. This chapter gives a brief introduction to the related structure designs of the

outdoor cabinet.

6.1 Sunproof And Adiabatic

The heat exchanger fitted on the top of the cabinet provides sunproof and adiabatic protection. After the outdoor

cabinet stands the solar radiation of the area with altitude lower than 3000m described in GB/T 4797.4-2006 (for solar

radiation level, see Table 6-1 and Figure 6-1), the difference in environmental temperature between the air inlet of the

rectifier in the cabinet and outside of the cabinet is not higher than 10°C.

Table 6-1 Max. direct solar radiation quantity of China

2

level/(W/m ) Applicable range Remark

1000 Sub-damp-heat and damp-heat areas

Excluding sub-damp-heat and damp-heat regions, but

1120 Area altitude: ≤ 3000m

including the mountains of them

Including cold-warm mostly regions and west marginal areas

1180 Area altitude: 3000m ~ 5000m

of warm temperature zone

Figure 6-1 Climate region and solar radiation layout of China

ECM1500 Outdoor Cabinet Technical Manual

24 Chapter 6 Structure Design Feature Of The System

6.2 Airproof Design

The equipment compartment satisfies IP55 waterproof requirement in GB 4208-1993, and the battery compartment

satisfies IP44 waterproof requirement in GB 4208-1993.

The structure design of the outdoor cabinet are as follows:

1. Cabinet door and cabinet

A gland strip is fixed between the cabinet door and cabinet doorframe. The cabinet doorframe adopts a mazy

structure which can satisfy IP requirement of the front door, as shown Figure 6-2.

Cabinet doorframe

Gland strip Front door

Figure 6-2 Protective structure of the front door (cross section of the cabinet and door)

2. Selection and installation of the door lock and gemel

The door lock satisifies IP55 requirement. Coat with waterproof glue on the jont point between the door lock and the

front door when installing door lock. Coat with waterproof glue on the joint point between the gemel and the cabinet

when installing gemel, as shown in Figure 6-3.

Coating with

waterproof glue

Coating with

waterproof glue

Figure 6-3 Coating with waterproof glue on the door lock and gemel

ECM1500 Outdoor Cabinet Technical Manual

Chapter 6 Structure Design Feature Of The System 25

6.3 Antiseptic Design

Because the the enivronment and climate of the outdoor cabinet installation site are various, it requires the outdoor

cabinet withstand multifarious corrosions. According to the corroded material types, the corrosions are classifies into

three types: metallic corrosion, metalloid corrosion and biological corrosion.

6.3.1 Metallic Corrosion Protection

To realize metallic corrosion protection cost-effectively when designing the outdoor cabinet, we adopt the following

designs:

1. The part of the cabinet exposed outdoor adopts pot galvanizing board and does spray treatment on surface (spray

color: Emerson outdoor gray G108), therefore, the antiseptic life of the cabinet surface is 8 ~ 15 years.

2. The environment in the cabinet is better than the that of the outside. For the installation part of the cabinet, the

structural components adopt pot galvanizing board, but do not do surface treatment. The ports are coated with

anticorrosion paint.

3. The parts with special requirements adopt copperplate and stainless steel materials.

6.3.2 Metalloid Corrosion Protection

Metalloid corrosion mainly represents for aging. The main factors leading to aging are: sunlight, oxygen, ozone, heat,

water and industrial harmful gases, microorganism and atmospheric environmental factors. Mechanical stress, impact

of the forming conditions may also cause aging. Therefore, the metalloid parts are installed in the cabinet to avoid

rain and sun, and increase age inhibitor and coat with protective layers on the surfaces, such as paint, metallic

coating, and age inhibitor.

6.3.3 Biological Corrosion Protection

Biological corrosion mainly represents for biological invasion and mould. For biological invasion, we adopt separate

net and sealed structure which can prevent rodent, birds, insect, seaweed and moss from moving on the materials

and equipment, so as to avoid corrosion. Taking biological corrosion protection measures about the outdoor cabinet,

it is to install filters on the air inlet and air outlet of the system for preventing biology from entering.

6.4 Windproof Design

Under normal use state, the cabinet should withstand 60m/s wind. After the 60m/s wind, the cabinet also can meet

the following requirement:

1. No deformation or damage exist to affect the function, cooperation and shape.

2. No structures in the cabinet are undone, warping, bended, damaged, or permanent deformation.

3. The door can open and close flexibly and reliably.

4. No undone, dehiscent or bouffant phenomena exist on the sealing or sealing parts.

5. No bended, loose, displacement or damage exist on the mounting sets or fasteners.

6. The functions of the active connectors are normal, such as gemel, lock and pin hinge.

6.5 Theftproof Design

The theftproof design of the outdoor cabinet includes two aspects:

1. Theftproof design of the door lock and gemel.

2. Theftproof design of the door panel & cabinet and exposed mounting sets.

ECM1500 Outdoor Cabinet Technical Manual

26 Chapter 6 Structure Design Feature Of The System

6.5.1 Theftproof Design Of The Door Lock And Gemel

Theftproof design of the door lock

1. The lock satisfies class B anti-destructive requirement in GB/T73-1994.

2. The outdoor cabinet uses multi-lock, whose terminals are gripped in the internal edge of the doorframe, therefore

the clearance between the door panel and cabint is small, so as to prevent the multi-lock from damage through

stealing tools.

Theftproof design of the gemel

1. Do not stick out or expose the gemel on the outside of the cabinet.

2. The structures of the gemel, such as axes and pin hinge, can prevent the unexcused tools from disassembling, as

shown in Figure 6-4.

Kirksite gemel with high strength

(exclusively used in outdoors), bolts and

axes adopt stainless steel materials, and

meet theftproof requirement

Figure 6-4 Theftproof design of the gemel

6.5.2 Theftproof Design Of The Door Panel & Cabinet And Exposed Mounting Sets

The outdoor cabinet chassis can prevent the unexcused tools from entering, such as screwdriver, pliers and sinkers.

The exposed mounting sets are installed and disassambled by special tools. The clearance between the door panel

and cabinet is 2mm ~ 4mm, which can prevent stealing tools from entering the door panel to cause damaged. The

door panel has enough structure strength which can prevent it from being bended and distortion through stealing

tools, as shown in Figure 6-5 and Figure 6-6.

Clearance between the

front door and the

cabinet: 2mm ~ 4mm

Figure 6-5 Clearance between the door panel and cabinet

ECM1500 Outdoor Cabinet Technical Manual

Chapter 6 Structure Design Feature Of The System 27

All around the door panel adopt

bending treatment, which can

effectively prevent the door panel

from damage by common tools

Figure 6-6 Door panel structure processing

6.6 Noise Reduction Design

The thermal control unit of the outdoor cabinet adopts fans to realize assistant heat ventilation, thus the noise is

mainly generated by fans. The working site and air volume of the fan will affect the noise. In system design, the air

inlet and air outlet keep away from the installation position of the fan and air outlet of the thermal control unit, and

noise reduction cotton are pasted on the required area, as shown in Figure 6-7 and Figure 6-8.

Cover of the counterflow

heat-exchanging unit

Air outlet of the counterflow

heat-exchanging unit core

External circulation air

outlet of the counterflow

heat-exchanging unit Area pasted sound-

absorbing cotton

Clapboard

Centrifugal fan

External circulation air

inlet of the counterflow Gland strip of the cover

heat-exchanging unit

Figure 6-7 Noise reduction design of the heat-exchanging unit

ECM1500 Outdoor Cabinet Technical Manual

28 Chapter 6 Structure Design Feature Of The System

Front air outlet of

the air-condition

Air outlet of the

air-condition

Side air outlet of

the air-condition

Air-condition

Air inlet of the Area pasted sound-

air-condition absorbing cotton

Gland strip of the cover

Air-condition cover

Filter used for

emergent ventilation

Emergent

ventilation unit

Figure 6-8 Noise reduction design of the air-condition model outdoor cabinet

6.7 Quakeproof Design

The relevant requirements have been made for the outdoor cabinet earthquake proof. When the system is subjected

to the earthquake influence that meets the region seismic fortification intensity, the cabinet installation rack or the

related reinforcing point does not produce the destructive damage; when the system is subjected to the rare

earthquake influence that meets the region seismic fortification intensity, the cabinet installation rack or the related

reinforcing point may have partial damage and shift, but does not produce the scattered and fallen phenomena. For

the battery earthquake proof, the system design uses a steel anti-shock frame or other materials anti-shock frame for

the battery installation. M10 expansion bolts can be used to fix the frame and the ground, so as to meet the degree 6

and degree 7 quakeprood requirements, as shown in Figure 6-9.

底座

Base

地脚螺栓

Anchor bolt

Four M10 expansion

bolts for4个M10膨胀

fixing base

螺栓固定底座 地面

Ground

Figure 6-9 Base installation

ECM1500 Outdoor Cabinet Technical Manual

Chapter 7 Engineering Design Reference 29

Chapter 7 Engineering Design Reference

This chapter introduces referrible parameters and system grounding design in the engineering design.

7.1 Reference Parameters

Mechanical parameters

The mechanical parameters of the outdoor cabinet are listed in Table 7-1.

Table 7-1 Mechanical parameters of the outdoor cabinet

Parameter name Description

Cabinet 700 (W) × 700 (D) × 1800 (H)

Dimensions (mm)

Internal space of battery compartment 613 (W) × 570 (D) × 350 (H)

Forced ventilation model cabinet ≤ 125 (excluding subrack and battery string)

Weight (kg) Heat exchanger model cabinet ≤ 180 (excluding subrack and battery string)

Air-condition model cabinet ≤ 175 (excluding subrack and battery string)

Engineering parameters

The engineering parameters of the outdoor cabinet are listed in Table 7-2.

Table 7-2 Engineering parameters of the outdoor cabinet

Connector specification

Part name Connection description

Capacity Connection terminal specification

Cable cross-sectional area (CSA): The live line and neutral line of

AC input MCB 25A/2P

≤ 25mm2 AC power

Two M8 bolts Connected to the grounding bar

AC Grounding busbar Cable CSA: ≤ 35mm2

Three M6 bolts in the equipment room

distribution

Different region customers

Connected to a socket provided

AC socket 10A configured with the corresponding

for user equipment

sockets

DC

DC input terminal 2P

distribution

Clearances

It is recommended to determine the installation position in compliance with the clearance requirements given in Table

7-3.

Table 7-3 Installation clearances

Front Top Left Right Back

Clearances 750mm 700mm 100mm 100mm 100mm

ECM1500 Outdoor Cabinet Technical Manual

30 Chapter 7 Engineering Design Reference

Installation dimensions

The base installation dimensions of the forced ventilation model outdoor cabinet are shown in Figure 7-1, and that of

the heat exchanger model and air-condition model outdoor cabinets are shown in Figure 7-2.

657

480

650

88.5

700

Figure 7-1 Base installation dimensions of the forced ventilation model outdoor cabinet (unit: mm)

900

650± 0.5

130

480± 0.5

1100

Expansion bolt

Front door

Figure 7-2 Base installation dimensions of the heat exchanger model and air-condition model outdoor cabinets (unit: mm)

Preparing cables

The cable selection should meet relevant industry standards. It is recommended to use the RVVZ cables as AC

cables. The cable should reach at least +70°C temperature durability. With cable shorter than 30m, the CSA

2 2

calculation should be based on the current density of 2.5A/mm . The suggested CSA value is not less than 16mm . If

the AC input cable is longer than 30m, confirm the cable specification according to the electrician manual and make

sure that the voltage drop on the cable is within requirement of system operation.

The CSA of DC cable depends on the current flowing through the cable and the allowable voltage drop.

7.2 Grounding Design

The grounding design of the outdoor cabinet adopts common grounding principle, that is, the working grounding,

lightning grounding and protective grounding share one group of grounding body. The cabinet has a separate

grounding busbar which is located on the right side of the bottom plate and labeled striking sample ‘grounding

busbar’. The connection of the grounding busbar is convenient. The lightning grounding and protective grounding

cables are educed from the grounding busbar. The grounding busbar is also used to connect protective grounding

and directly fitted on the frame of the cabinet. The surface of the grounding busbar should not have paint and other

faulty conduction impurities.

ECM1500 Outdoor Cabinet Technical Manual

Chapter 7 Engineering Design Reference 31

The grounding busbar provides five connection bolts, among which two M8 bolts and three M6 bolts, as shown in

Figure 7-3.

接ro地u 汇

G n d流

in g排b u s b a r

Figure 7-3 Position of the grounding busbar

Moreover, the cabinet door is connected to the cabinet through grounding cables, so as to keep good grounding

continuity. The protective grounding, lightning grounding and DC power grounding have been connected to the

grounding busbar of the outdoor cabinet in factory, therefore, in installation, you just need to connect the grounding

busbar to the user ground bar in the equipment room.

ECM1500 Outdoor Cabinet Technical Manual

Appendix 1 Wiring Diagram 32

Appendix 1 Wiring Diagram

AC Input

L N

1 3

1

QFA1 9 10 11 12

FAN1 FAN2 FAN3 FAN4

2 4

Mains Input

W09

W01

W01

Bottom cross control board door line

2 19 20

1 3 5

PE L N X1 XT XT

2 4 6

4

PE Bar MS

FAN1 FAN2 FAN3 FAN4

3 PE

1

PE BUS

W09

2

N L

Bottom cross back door line

3

W02 17 18

4

NOTE:

XT XT

W02_A for Europen standard socket. Blue Yellow Red Black Blue Yellow Red Black Blue Yellow Red Black Blue Yellow Red Black

5

W02_B for American standard socket. solder solder solder

W05 solder W05

6

W02_C for Chinese and British standard socket.

Blue Yellow Red Black Blue Yellow Red Black Blue Yellow Red Black Blue Yellow Red Black

7

W09

DC Input

Bottom cross front door line

W05 15 16

XT XT

5 1 3

X2 + -

W07

2 4

14

1 2 3 4 5 1 2 3 4 5 6

7-J3-7 1 2 X3

W04

7

6 7-J3-8 3 4

14-3

14-7

14-1

14-5

J11 J12 U2

U1 W07 7-J3-1 5 6 Temperature sensor I

7-J3-2 7 8

6-J6

8 7 6 5 4 3 2 1 J3

8-1 9 10 13

W03

W08 8-2 11 12 T1

2 1

13 14

J10

J2 W06 15 16

17 18

7-J1 Temperature sensor I

W04

19 20

P344309U1 P345314X1 21 22

23 24 Door alarm

1 2 3

J6

14-9

1 2

1 2

J7 W07

J2 J1

J3

8 7 6 5 4 3 2 1 1 2 8

W08

8 7 6 5 4 3 2 1 MJ

6-J3 6-J10

14-11

W06 W06

W20

7-J2

W06

Figure 1 Wiring diagram of forced ventilation model outdoor cabinet

ECM1500 Outdoor Cabinet Technical Manual

Appendix 1 Wiring Diagram 33

AC Input

L N

1 3

1

QFA1

2 4

Mains Input W09

W01

Bottom cross back door line

W09 17 18

W01 22

H1 XT XT

2

PE

1

L

3

N

5

X1 Bottom cross control board door line

2 4 6 Blue Black 19 20

4 1

MS Blue solder Heater1 XT XT

PE Bar Black Red

2 W09

3 PE W03

1 2 23 Bottom cross front door line

1

W03

H2 15 16

2

N L Black W03 XT XT

3

Black Red

W02 21 solder 2

Heater2

4

KT1 1

Blue Black

5

NOTE: 11 12

6

FAN4

W02_A for Europen standard socket. 9 10

FAN3

7

W02_B for American standard socket. FAN1 FAN2

W02_C for Chinese and British standard socket.

DC Input

FAN1 FAN2 FAN3 FAN4

5

1 3

X2 + -

2 4

FAN1 Blue Yellow Red Black FAN2 Blue Yellow Red Black FAN3 Blue Yellow Red Black FAN4 Blue Yellow Red Black

solder solder solder solder

FAN1* Blue Yellow Red Black FAN2* Blue Yellow Red Black FAN3* Blue Yellow Red Black FAN4* Blue Yellow Red Black

Door alarm

- PWM ALARM - PWM ALARM - PWM ALARM - PWM ALARM

+ + + +

14-9 6-J15-2

W04

1 2

6-J15-1

8

W08

MJ

14-11

5-4 5-2 5-4 5-2 5-4 5-2 5-4 5-2

W06 W07

W05

Temperature sensor I

J1 J2 J3 J4 J14 J8

W07 14

6-J5-1 1 2 X3

1 2 3 4 1 2 3 4 1 2 3 4 5 1 2 3 4 5 1 2 1 2 3

6-J5-2 3 4

14-1 6

8 7 6 5 4 3 2 1

J5 W07 6-J5-3 5 6

14-3 U1

W05 14-5 6-J5-4 7 8

14-7 8-1 9 10

W08 8-2 11 12

Temperature sensor I

13 14

6-J8

13 15 16

T1 17 18

ECCU11U1 19 20

1 2 3 4

W07

J11 21 22

23 24

1 2

J13 W07

5-4

POWER 2

J15 W04

1

5-2

Figure 2 Wiring diagram of heat exchanger model outdoor cabinet

ECM1500 Outdoor Cabinet Technical Manual

Appendix 1 Wiring Diagram 34

W05

AC Input

Temperature sensor I

6-J6

9 10

L N 13 14

FAN1 FAN2

3 T1 X3

1

1

QFA1

7-J3-7 1 2

Mains Input W08 7-J3-8 3 4

2 4

19-J2-9 5 6

W01 W06

19-J2-10 7 8

8-1 9 10

W01 W17

8-2 11 12

2

PE

1

L

3

N

5

X1

13 14 FAN1 FAN2

2 4 6 15 16

4

17 18

PE Bar MS Door alarm 19 20

3

14-9 21 22

PE 23 24

1

1 2

2

N L

Blue Yellow Red Black Blue Yellow Red Black

3

8

W17

NOTE: W02 MJ solder W06 solder

4

W02_A for Europen standard socket. 14-11 Blue Yellow Red Black Blue Yellow Red Black

5

W02_B for American standard socket.

6

W02_C for Chinese and British standard socket.

7

6-J12-3

FAN1

19-J2-8

W06 19-J2-14

DC Input

6-J12-3

Temperature sensor II

FAN2

W03

14-7

14-5

W06

W09

Cable from Air-condition 5 19-J2-7

X2 19-J2-13

W08

Bottom cross control board door line L N PE 1 3 7

8 7 6 5 4 3 2 1 + -

19 20

U2

14-3

1 2 3 4 5 15 14 1312 11 10 9

14-1

XT 2 4

XT 19

J1 J2 J3 1 2 3 4 5 1 2 3 4 5 6

AC

6

J11 J12 8 7 6 5 4 3 2 1 J3

U1

W08

W04

2 1

Bottom cross back door line

17 18

Air-condition J10

J2

XT XT

7-J1

Temperature sensor I P345314X1

W07 W05

P344309U1

W08

1 2 3

J6

J2 J1

Bottom cross front door line

1 2

1 2

J7 W08 8 7 6 5 4 3 2 1

15 16

XT XT

J3 6-J3 6-J10

8 7 6 5 4 3 2 1

W07 W07

7-J2 W07

Figure 3 Wiring diagram of air-condition model outdoor cabinet

ECM1500 Outdoor Cabinet Technical Manual

Appendix 2 Schematic Diagram 35

Appendix 2 Schematic Diagram

X1

L

QFA1 XS Door Alarm

L

to Dry Contact Terminal

AC Input N

N PE

to PE bar

Dry Contact Terminal

Forced Ventilation Unit Over Temperature

X2

0V

……

V- V-

Fan Fan Climate unit fault

DC Input A

V+

C A

V+

C

CONTROL

CONTROL

ALARM

ALARM

-48V

+

+

-

-

Door Alarm

FCU FCUX Spare

X3

Figure 4 Schematic diagram of forced ventilation model outdoor cabinet

QFA1 X1 XS

L Door Alarm to Dry Contact Terminal

L

AC Input N

N

PE

to PE bar KT1

Dry Contact Terminal

Heat Exchanger Unit Over Temperature

X2 Internal fan External fan

0V V- V-

DC Input A

V+

C …… A

V+

C Climate unit fault

CONTROL

CONTROL

ALARM

ALARM

-48V

+

+

-

AC Door Alarm

Heater

Spare

ECCU

X3

Figure 5 Schematic diagram of heat exchanger model outdoor cabinet

ECM1500 Outdoor Cabinet Technical Manual

36 Appendix 2 Schematic Diagram

X1

L

QFA1 XS

L

AC Input N

N

PE

Door Alarm to Dry Contact Terminal

to PE bar

Air-condition Unit

Dry Contact Terminal

Over Temperature

Fan contral Alarm

Climate unit fault

Emergent Ventilation Unit Door Alarm

X2

0V

……

V+

Fan Spare

DC Input V-

-48V

FCU FCUX

X3

Figure 6 Schematic diagram of air-condition model outdoor cabinet

ECM1500 Outdoor Cabinet Technical Manual

Você também pode gostar

- Powerwave 5755.00Documento1 páginaPowerwave 5755.00Punky HeroAinda não há avaliações

- FHELDocumento5 páginasFHELPavelKuzovkin100% (3)

- Flexi Fibre FSFBDocumento1 páginaFlexi Fibre FSFBPavelKuzovkinAinda não há avaliações

- RFS APXV9RxxBDocumento2 páginasRFS APXV9RxxBPavelKuzovkinAinda não há avaliações

- Andrew EWP132 144Documento2 páginasAndrew EWP132 144PavelKuzovkinAinda não há avaliações

- Alcatel-Lucent 9500 MPR PDFDocumento3 páginasAlcatel-Lucent 9500 MPR PDFPavelKuzovkinAinda não há avaliações

- Certificate ISR Family 7-38-2013-2016Documento1 páginaCertificate ISR Family 7-38-2013-2016PavelKuzovkinAinda não há avaliações

- Allgon UXM-65-90 - 7701Documento5 páginasAllgon UXM-65-90 - 7701PavelKuzovkinAinda não há avaliações

- May 2011 9500 MPR Etsi r3 en DatasheetDocumento3 páginasMay 2011 9500 MPR Etsi r3 en DatasheetmghjghjghAinda não há avaliações

- TP48200A-D12A1 Quick Installation Guide V300R001 01 PDFDocumento2 páginasTP48200A-D12A1 Quick Installation Guide V300R001 01 PDFPavelKuzovkinAinda não há avaliações

- PowerWave 7233.04Documento2 páginasPowerWave 7233.04PavelKuzovkinAinda não há avaliações

- RFS Apxv9r13b-C-A20Documento2 páginasRFS Apxv9r13b-C-A20PavelKuzovkin0% (1)

- Kathrein 800 10426Documento2 páginasKathrein 800 10426PavelKuzovkinAinda não há avaliações

- Comba CM-DW2-ODxxDocumento1 páginaComba CM-DW2-ODxxPavelKuzovkinAinda não há avaliações

- CNT Cable - AndrewDocumento2 páginasCNT Cable - Andrewsutawijaya_masAinda não há avaliações

- Comba CM-KY2-OD4BDocumento1 páginaComba CM-KY2-OD4BPavelKuzovkinAinda não há avaliações

- Andrew AL4RPV-50 PDFDocumento3 páginasAndrew AL4RPV-50 PDFPavelKuzovkinAinda não há avaliações

- Eltek-2 Outdoor Instal GuideDocumento20 páginasEltek-2 Outdoor Instal GuidePavelKuzovkin100% (1)

- Kathrein 730 378Documento1 páginaKathrein 730 378PavelKuzovkinAinda não há avaliações

- NSN 3g Flexi ModulesDocumento15 páginasNSN 3g Flexi Moduleskipkoech_rotichAinda não há avaliações

- Kathrein SCA 800-10622Documento2 páginasKathrein SCA 800-10622Natalia PeraltaAinda não há avaliações

- RGCADocumento1 páginaRGCAPavelKuzovkinAinda não há avaliações

- 3900 Series Base Station Product Description V1Documento43 páginas3900 Series Base Station Product Description V1engrifaatAinda não há avaliações

- Allgon 9215.01Documento1 páginaAllgon 9215.01PavelKuzovkinAinda não há avaliações

- Tongyu TDQ-172718DE-65FDocumento1 páginaTongyu TDQ-172718DE-65FPavelKuzovkinAinda não há avaliações

- Амплитудно Фазовый Преобразователь Du g2525 d01Documento4 páginasАмплитудно Фазовый Преобразователь Du g2525 d01EugeneZarubinAinda não há avaliações

- Kathrein 732 690Documento2 páginasKathrein 732 690PavelKuzovkinAinda não há avaliações

- MI-201nn: Specifications Mass™Documento1 páginaMI-201nn: Specifications Mass™PavelKuzovkinAinda não há avaliações

- Comba CM-DW2-ODxxDocumento1 páginaComba CM-DW2-ODxxPavelKuzovkinAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)