Escolar Documentos

Profissional Documentos

Cultura Documentos

Low Hydrogen Electrode Atom Arc 7018-1

Enviado por

HORACIOTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Low Hydrogen Electrode Atom Arc 7018-1

Enviado por

HORACIODireitos autorais:

Formatos disponíveis

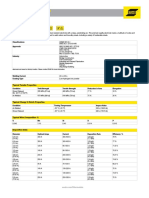

COVERED (STICK) ELECTRODES (SMAW)

LOW HYDROGEN ELECTRODES

Atom Arc 7018-1

Atom Arc 7018-1 is an all-position, low hydrogen electrode that provides exceptional impact toughness at low service

temperatures. Atom Arc 7018-1 provides smooth metal transfer, minimal spatter, and easy slag removal. Atom Arc 7018-1

is used to join a wide variety of carbon and low alloy steels. It is also an excellent choice for welding higher strength steels

if undermatching welds are specified.

Classifications: AWS A5.1:E7018-1 H4R, ASME SFA 5.1

Approvals: CWB CSA W48: E4918-1-H4, DNV 3Y(H10), LR 3m,3Ym(H10),

ABS 3,3Y(H10)/A5.1: E7018-1

Industry or Segmentation: Mobile Equipment, Railcars, Industrial and General Fabrication, Automotive, Civil Construction

Approvals are based on factory location. Please contact ESAB for more information.

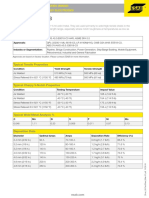

Typical Tensile Properties

Condition Yield Strength Tensile Strength Reduction in Area Elongation

As Welded 475 MPa (69 ksi) 565 MPa (81 ksi) 72 % 30 %

Stress Relieved 8 hr 621 °C (1150 °F) 415 MPa (60 ksi) 510 MPa (74 ksi) 72 % 33 %

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

As Welded -46 °C (-50 °F) 141 J (104 ft-lb)

Stress Relieved 8 hr 621 °C (1150 °F) -46 °C (-50 °F) 224 J (165 ft-lb)

Typical Weld Metal Analysis %

C Mn Si S P

0.04 1.30 0.30 0.015 0.014

Deposition Data

Diameter Optimal Amps Amps Deposition Rate Efficiency (%)

2.4 mm (3/32 in.) 90 A 70-100 A 0.8 kg/h (1.7 lb/h) 66.3 %

3.2 mm (1/8 in.) 120 A 90-160 A 1.2 kg/h (2.6 lb/h) 71.6 %

3.2 mm (1/8 in.) 140 A 90-160 A 1.2 kg/h (2.7 lb/h) 70.9 %

4.0 mm (5/32 in.) 140 A 130-220 A 1.4 kg/h (3.1 lb/h) 75 %

4.0 mm (5/32 in.) 170 A 130-220 A 1.7 kg/h (3.8 lb/h) 73.5 %

4.8 mm (3/16 in.) 200 A 200-300 A 2.2 kg/h (4.9 lb/h) 76.4 %

4.8 mm (3/16 in.) 250 A 200-300 A 2.4 kg/h (5.4 lb/h) 74.6 %

5.6 mm (7/32 in.) 250 A 250-350 A 2.9 kg/h (6.5 lb/h) 75 %

14-en_US-FactSheet_Main-01.pdf 10/26/16

5.6 mm (7/32 in.) 300 A 250-350 A 3.3 kg/h (7.2 lb/h) 74 %

6.4 mm (1/4 in.) 300 A 300-400 A 3.5 kg/h (7.7 lb/h) 78 %

6.4 mm (1/4 in.) 350 A 300-400 A 3.9 kg/h (8.7 lb/h) 77 %

esab.com

Você também pode gostar

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Documento1 páginaEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoAinda não há avaliações

- Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)Documento1 páginaEsab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)RodrigoAinda não há avaliações

- Atom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocumento2 páginasAtom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesFranklin Aranda ChacónAinda não há avaliações

- PIPE WELDING ELECTRODEDocumento5 páginasPIPE WELDING ELECTRODEHanny Dewi SaragihAinda não há avaliações

- ESAB Filler Metal GuideDocumento1 páginaESAB Filler Metal GuidekapsarcAinda não há avaliações

- Dual Shiel Ii 101Documento2 páginasDual Shiel Ii 101Robin carcamoAinda não há avaliações

- Low Alloy Flux-Cored Wire GuideDocumento2 páginasLow Alloy Flux-Cored Wire Guideadanmeneses1Ainda não há avaliações

- Low Alloy Flux-Cored Wires for High Strength Steel WeldsDocumento2 páginasLow Alloy Flux-Cored Wires for High Strength Steel Weldsadanmeneses1Ainda não há avaliações

- Coreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresDocumento2 páginasCoreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresJerald GuevarraAinda não há avaliações

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Documento2 páginasEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoAinda não há avaliações

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocumento2 páginasAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaAinda não há avaliações

- Atom Arc 7018-B2L: Typical Tensile PropertiesDocumento1 páginaAtom Arc 7018-B2L: Typical Tensile PropertiesPubcrawlAinda não há avaliações

- FICHADocumento2 páginasFICHAadmisecoinperuAinda não há avaliações

- GAS-SHIELDED FLUX-CORED WIRES (FCAW) LOW ALLOY WIRES Dual Shield II 81-K2Documento2 páginasGAS-SHIELDED FLUX-CORED WIRES (FCAW) LOW ALLOY WIRES Dual Shield II 81-K2MOhammed PatelAinda não há avaliações

- GAS-SHIELDED FLUX-CORED WIRES (FCAW) MILD STEEL WIRES Dual Shield 7100 UltraDocumento3 páginasGAS-SHIELDED FLUX-CORED WIRES (FCAW) MILD STEEL WIRES Dual Shield 7100 Ultraadanmeneses1Ainda não há avaliações

- Dual Shield II 110 Flux-Cored WireDocumento2 páginasDual Shield II 110 Flux-Cored WireRodrigoAinda não há avaliações

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocumento2 páginasDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelAinda não há avaliações

- 274 en - US FactSheet - Main 01Documento2 páginas274 en - US FactSheet - Main 01Luisa FernandaAinda não há avaliações

- Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)Documento1 páginaEsab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)RodrigoAinda não há avaliações

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocumento3 páginasDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelAinda não há avaliações

- Atom Arc 8018Documento2 páginasAtom Arc 8018Jagan TnAinda não há avaliações

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocumento3 páginasDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoAinda não há avaliações

- Tech Data Sheet: Dual Shield T-115Documento3 páginasTech Data Sheet: Dual Shield T-115carlosAinda não há avaliações

- Dual Shield 810X-NI1: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocumento2 páginasDual Shield 810X-NI1: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy Wiresadanmeneses1Ainda não há avaliações

- Tech Data Sheet: Dual Shield Ii 100-D1Documento3 páginasTech Data Sheet: Dual Shield Ii 100-D1carlosAinda não há avaliações

- MIG/MAG wire for welding duplex stainless steelDocumento1 páginaMIG/MAG wire for welding duplex stainless steeljavadmohammadiAinda não há avaliações

- Dual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocumento2 páginasDual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresPEPITO GRILLO2Ainda não há avaliações

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocumento1 páginaSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerAinda não há avaliações

- ESAB ATOM ARC 9015-B9 welding consumable product specsDocumento1 páginaESAB ATOM ARC 9015-B9 welding consumable product specsv ictor manuel MunozAinda não há avaliações

- Dual Shield T-75: Typical Tensile PropertiesDocumento2 páginasDual Shield T-75: Typical Tensile PropertiescfloresAinda não há avaliações

- Tech Data Sheet: DUAL SHIELD 8000-Ni2Documento3 páginasTech Data Sheet: DUAL SHIELD 8000-Ni2carlosAinda não há avaliações

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Documento2 páginasEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoAinda não há avaliações

- COR-1076C Coreweld Brochure 141118Documento28 páginasCOR-1076C Coreweld Brochure 141118Thanh TamAinda não há avaliações

- 278 en US FactSheet Main 01Documento1 página278 en US FactSheet Main 01Jorge Manuel GuillermoAinda não há avaliações

- ATOM ARC LOW HYDROGEN ELECTRODESDocumento2 páginasATOM ARC LOW HYDROGEN ELECTRODESanupmenon menonAinda não há avaliações

- Low Hydrogen Low Alloy Electrodes for High Strength Steel WeldsDocumento2 páginasLow Hydrogen Low Alloy Electrodes for High Strength Steel WeldsFranklin Aranda ChacónAinda não há avaliações

- FabCO 811N1Documento2 páginasFabCO 811N1Sleyda MunozAinda não há avaliações

- Medidores AMERICAN METERSDocumento17 páginasMedidores AMERICAN METERSRaúl PalomoAinda não há avaliações

- SFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Documento2 páginasSFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Slobodan ĐenićAinda não há avaliações

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocumento1 páginaOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136Ainda não há avaliações

- STAR Aromatic Amine Line Pipe High Pressure API 15HR Design Data SheetDocumento4 páginasSTAR Aromatic Amine Line Pipe High Pressure API 15HR Design Data SheetFirasAinda não há avaliações

- MD250MW CAN DataSheet 1642812289Documento1 páginaMD250MW CAN DataSheet 1642812289masAinda não há avaliações

- A 906 - A 906m - 99 - Qtkwni9bota2ts1sruqDocumento8 páginasA 906 - A 906m - 99 - Qtkwni9bota2ts1sruqZam DresAinda não há avaliações

- Compact 550X Electronic Pressure RegulatorDocumento4 páginasCompact 550X Electronic Pressure RegulatorDanang BagasAinda não há avaliações

- OK Tigrod 13.32Documento1 páginaOK Tigrod 13.32Paulo CorreiaAinda não há avaliações

- CSF-71T Technical Report EN - V2Documento7 páginasCSF-71T Technical Report EN - V2Miroslav ThôngAinda não há avaliações

- MILD STEEL WIRE PROPERTIESDocumento4 páginasMILD STEEL WIRE PROPERTIESPoltak SianiparAinda não há avaliações

- ESAB Dual Shield 7100 UltraDocumento3 páginasESAB Dual Shield 7100 UltrahaldunAinda não há avaliações

- Specifications of Rebar Grade: As Per ASTM StandardDocumento2 páginasSpecifications of Rebar Grade: As Per ASTM StandardMyat SuAinda não há avaliações

- Dual Shield II 80-Ni1 h4 Data SheetDocumento3 páginasDual Shield II 80-Ni1 h4 Data SheetNicolas MaximilianoAinda não há avaliações

- ASM Catalysts ceramic and alumina support ball data sheetDocumento1 páginaASM Catalysts ceramic and alumina support ball data sheetBamrung SungnoenAinda não há avaliações

- Saudi Cable Catalogue - Low VoltageDocumento1 páginaSaudi Cable Catalogue - Low VoltageMd SaquibAinda não há avaliações

- Esab E7018-1-H4r Ebds1-Ok 55Documento2 páginasEsab E7018-1-H4r Ebds1-Ok 55PubcrawlAinda não há avaliações

- RS 250 M Welding MachineDocumento1 páginaRS 250 M Welding MachineLucioAinda não há avaliações

- COVERED ELECTRODES FOR MILD STEEL WELDINGDocumento1 páginaCOVERED ELECTRODES FOR MILD STEEL WELDINGRys Multiventas SacAinda não há avaliações

- HOB FC86R045X33 SpecSheetDocumento2 páginasHOB FC86R045X33 SpecSheetJohn AltasAinda não há avaliações

- m8083 sc86c14 Spec SheetDocumento2 páginasm8083 sc86c14 Spec SheetJamal HabbasAinda não há avaliações

- Op Amps: Design, Application, and TroubleshootingNo EverandOp Amps: Design, Application, and TroubleshootingNota: 5 de 5 estrelas5/5 (2)

- Ropa2000 307Documento4 páginasRopa2000 307HORACIOAinda não há avaliações

- 307 A2020 MAT AAA FDagenda 08 18Documento75 páginas307 A2020 MAT AAA FDagenda 08 18HORACIOAinda não há avaliações

- General Requirements For Steel Plates For Pressure VesselsDocumento34 páginasGeneral Requirements For Steel Plates For Pressure VesselsIndira BanerjeeAinda não há avaliações

- Appendix 1 Part 8 Eddy Current Inspector 4th Edition February 2016Documento13 páginasAppendix 1 Part 8 Eddy Current Inspector 4th Edition February 2016Kiriakos PappoutasAinda não há avaliações

- NDT Handbook Vol 9 Visual Testing Handbook-3Ed-ASNTDocumento347 páginasNDT Handbook Vol 9 Visual Testing Handbook-3Ed-ASNTDavid Andres Cañas Suarez87% (30)

- General Requirements For Steel Plates For Pressure VesselsDocumento34 páginasGeneral Requirements For Steel Plates For Pressure VesselsIndira BanerjeeAinda não há avaliações

- ASNT Handbook Volume 2 Liquid Penetrant TestingDocumento498 páginasASNT Handbook Volume 2 Liquid Penetrant TestingJosé Juan Jiménez Alejandro94% (32)

- Appendix 1 Part 8 Eddy Current Inspector 4th Edition February 2016Documento13 páginasAppendix 1 Part 8 Eddy Current Inspector 4th Edition February 2016Kiriakos PappoutasAinda não há avaliações

- Astm d660 Checking o CuarteamientoDocumento9 páginasAstm d660 Checking o CuarteamientoMelissa Edith Vega ReynosoAinda não há avaliações

- ASNT Liquid Penetrant Testing Level - II Questions and AnswersDocumento6 páginasASNT Liquid Penetrant Testing Level - II Questions and Answers003suresh87% (23)

- Ring Spinning MachineDocumento25 páginasRing Spinning Machinemahmuda chowdhuryAinda não há avaliações

- Chemistry Investigatory File Handmade NewDocumento17 páginasChemistry Investigatory File Handmade NewMadhusudan PeriwalAinda não há avaliações

- GAS-RELEASE CALCULATORDocumento3 páginasGAS-RELEASE CALCULATOREduardo Paulini VillanuevaAinda não há avaliações

- SQL Injection Attack Detection and Preve PDFDocumento12 páginasSQL Injection Attack Detection and Preve PDFPramono PramonoAinda não há avaliações

- Manual Fuji TemperaturaDocumento40 páginasManual Fuji TemperaturaMartínAinda não há avaliações

- Managing Economies of Scale in Supply ChainsDocumento25 páginasManaging Economies of Scale in Supply ChainsWei JunAinda não há avaliações

- 4-1 E Handbook 2013-14Documento53 páginas4-1 E Handbook 2013-14Siva Reddy KunduruAinda não há avaliações

- Innovative Lesson PlanDocumento12 páginasInnovative Lesson PlanMurali Sambhu33% (3)

- 2024 Quiz Bee Math 7Documento1 página2024 Quiz Bee Math 7Jabez Magda GenorgaAinda não há avaliações

- Driver MC34152Documento4 páginasDriver MC34152William RamírezAinda não há avaliações

- AVR R448: SpecificationDocumento2 páginasAVR R448: SpecificationAish MohammedAinda não há avaliações

- PDF Ecs h81h3 Ad DDDocumento37 páginasPDF Ecs h81h3 Ad DDsanak tiuhAinda não há avaliações

- Hikmayanto Hartawan PurchDocumento12 páginasHikmayanto Hartawan PurchelinAinda não há avaliações

- Class XI Chemistry Question BankDocumento71 páginasClass XI Chemistry Question BankNirmalaAinda não há avaliações

- VPRS-4300D Catalogue PDFDocumento4 páginasVPRS-4300D Catalogue PDFHoàngTrầnAinda não há avaliações

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Documento52 páginasSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanAinda não há avaliações

- Lec11 Amortized Loans Homework SolutionsDocumento3 páginasLec11 Amortized Loans Homework SolutionsJerickson MauricioAinda não há avaliações

- Bahir Dar University Introduction to Logic Final ExamDocumento6 páginasBahir Dar University Introduction to Logic Final ExamEskinder TeferiAinda não há avaliações

- Fundamental of Database: Madda Walabu University College of Computing Department of Information TechnologyDocumento46 páginasFundamental of Database: Madda Walabu University College of Computing Department of Information TechnologychalaAinda não há avaliações

- I) All Questions Are Compulsory. Ii) Figure To The Right Indicate Full Marks. Iii) Assume Suitable Data Wherever NecessaryDocumento1 páginaI) All Questions Are Compulsory. Ii) Figure To The Right Indicate Full Marks. Iii) Assume Suitable Data Wherever Necessarythamizharasi arulAinda não há avaliações

- MetaLINK Info r456Documento5 páginasMetaLINK Info r456Milan AntovicAinda não há avaliações

- Lumion PRO 5Documento6 páginasLumion PRO 5paparock34Ainda não há avaliações

- Week 3: Experimental Design Energy Transfer (Mug Experiment)Documento3 páginasWeek 3: Experimental Design Energy Transfer (Mug Experiment)Kuhoo UAinda não há avaliações

- STATS Shortcut FormulaDocumento3 páginasSTATS Shortcut Formulajeet sighAinda não há avaliações

- Sky Telescope 201304Documento90 páginasSky Telescope 201304Haydn BassarathAinda não há avaliações

- Development and Validation of UV Spectrophotometric Method For The Estimation of Curcumin in Bulk Drug and Pharmaceutical Dosage FormsDocumento6 páginasDevelopment and Validation of UV Spectrophotometric Method For The Estimation of Curcumin in Bulk Drug and Pharmaceutical Dosage FormswiracanaAinda não há avaliações

- Manage expenses and group contributions with Expense ManagerDocumento29 páginasManage expenses and group contributions with Expense ManagerPt Kamal SharmaAinda não há avaliações

- Clustering Methods for Data MiningDocumento60 páginasClustering Methods for Data MiningSuchithra SalilanAinda não há avaliações

- 25 Most Frequently Asked DSA Questions in MAANGDocumento17 páginas25 Most Frequently Asked DSA Questions in MAANGPranjalAinda não há avaliações

- Vorplex - MST - Airblowing and Water FlushingDocumento14 páginasVorplex - MST - Airblowing and Water FlushingAmirHakimRusliAinda não há avaliações