Escolar Documentos

Profissional Documentos

Cultura Documentos

AÇOS VILLARES VF800-AT - Ingles

Enviado por

Amy GriffinDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AÇOS VILLARES VF800-AT - Ingles

Enviado por

Amy GriffinDireitos autorais:

Formatos disponíveis

COLD WORK TOOL STEEL VF800-AT

Brief Description Typical Applications

VF800-AT is a cold work tool steel, with excellent VF800-AT can be largely employed in several

arrange of properties. In relation AISI D series tool cold work tools, including that where both high wear

steels, VF800-AT presents finer structure, which resistance and toughness are necessary. Some

leads to comparative or higher wear resistance and typical applications are:

toughness substantially higher. In service, presents

the following behaviour: Blanking and piercing dies, including punches

- Much higher resistance to cracking or chipping and dies used to cold form metals in an

and much better machinability/grindability than stamping press.

the higher-carbon (1,5% or more) AISI D types, Tools for press forming dies.

such as D2, D3, D6 and D7. Deep drawing dies.

- High resistance to adhesive wear, which is the Thread-rolling dies.

main mechanism in cold work tooling. Blades for cold shearing flat materials, with

- High dimensional stability, even if heat treated to thickness up to 13 mm (1/2 in). Also for cold

hardness as high as 62 HRC. slitting up to 6,5 mm (1/4 in).

- High hardenability, leading to minimum

distortion and very high safety and resistance to Coining dies.

cracking during hardening. Cold rolling mill rolls.

Cold heading dies.

Punches and dies for cold extrusion.

Chemical Composition

Processing operations

C Si Cr Mo V Nb

The following processes can be applied for

0.85 0.90 8.40 2.00 0.50 0.15 producing tools with VF800-AT:

- Machining: grinding, turning or milling. Due to its

Standard Specifications refined structured, VF800-AT good behaviour in

grinding operations, considerably better than

None. D2, D6 and D7 steels. This contributes to

reduce the risk to surface overheating and

cracking.

Physical Property

- Welding: only indicated if a special procedure of

Density at 20 ºC: 7.7 kg/dm3. pre-heating is employed and if the filler material

is from the same grade.

Delivery Conditions - Electrical discharge machining: the white layer

should be mechanically removed, by grinding or

Standard Identification colors: sanding. It is also important to re-temper tools in

white – blue – white. a temperature 50 °C lower than that of the

Forms and hardness: annealed material is previous tempering.

available in round, square or flat bars: 250 HB max.

COLD WORK TOOL STEEL VF800-AT

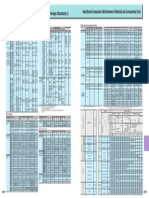

Heat treatment Mechanical Properties

Annealing: soft annealing should be carried out by Typical bend test properties of VF800-AT are

heating between 870 and 900 °C for 2 hours, followed by presented below, compared to AISI D2 and D6, being

slow cooling at 10/20 °C per hour until 650 °C and, then, by toughness related to bend strength. VF800-AT presents

air cooling. In this treatment, the use of protective much higher toughness and is therefore able to reduce

atmosphere is important to avoid surface oxidation and the tendency to falilures by cracking, chipping or

decarburization. spalling. Besides, its higher toughness contribute to

Stress relieving: Intense material removal during improve adhesive wear resistance, which in many

machining of tools can induce considerable stress, which application, is better than that for D2.

may cause distortions after end heat treatment. In order to

4000

avoid this, a stress reliving is recommended to be applied

after machining and before heat treatment. The indicated

Bend Strength (MPa)

procedure is slow heating to 500/600 °C, holding until 3000

complete homogenisation, and cooling (air or furnace) at

least down to 200 °C. 2000

Hardening and Tempering: the indicated heat treatment

temperatures are:

1000

Pre-heating Hardening Tempering

500 - 600 ºC 0

790 – 830 °C 1020 - 1050 °C (see diagram below) VF800-AT AISI D2 AISI D6

Values for specimens taken from the core of a 60 mm round bar, in

After preheating, tools must be carried to another longitudinal orientation. Hardness of 60 HRC.

furnace, holding 30 min after soaking (after tool is fully

heated throughout).

For optimizing tool life, a proper heat treatment is

Quenching may be done in: absolutely necessary (see item before). As shown in

a) Salt bath at 500/550 °C. Figure below, incorrect heat hardening or tempering

b) Warm quenching oil. temperatures lead to considerable decrease in

c) Vacuum, with high pressure circulated gas. toughness and substantially reduce tool life.

d) Air blast. 4000 Heat treatment

Bend Strength (MPa)

Tempering temperatures should be suitable to the

3000

required hardness (see diagram), being always higher than

500 °C. Double tempering is required and after each one 2000

tools must cool down to room temperature. After soaking,

holding time of at least 2h is necessary. 1000

65

0

Correct Incorrect

(low tempering

60 temperature)

Hardness (HRC)

Results for specimens taken from the core of a 60 mm round bar, in

longitudinal orientation, correctly and incorrectly tempered to of 60 HRC.

55

Relative Comparison of

Villares Metals Cold Work Tool Steels

50 Wear

Hardening Temp. = 1030 °C Toughness Machinability

Resistance

45 VD2

440 460 480 500 520 540 560 580 600

VF800-AT

Tempering Temperature (°C)

VC131

Surface treatments: VF800-AT is an adequate substrate VA2

for nitriding. As tempering temperatures are higher than

500 ºC, VF800-AT have no risk of decrease in core VND

hardness during nitriding. This is another advantage in VS7

relation to AISI D grades.

PVD or CVD coatings are also available to be applied in VW3

VF800-AT if desired, without decrease in core hardness.

Note: All information presented are intended to provide guidelines of material use.

They do not have relation to warranty of specific properties or contractual obligations.

Você também pode gostar

- Mazak Programing Class BookDocumento510 páginasMazak Programing Class BookBriciu Teofil Mihail100% (7)

- Exp1 Sic180033 PDFDocumento6 páginasExp1 Sic180033 PDFfara basar100% (1)

- FORD WX200 Rev2014Documento4 páginasFORD WX200 Rev2014Amandeep SinghAinda não há avaliações

- Tata Steel - YMPRESS S500MC - Data SheetDocumento2 páginasTata Steel - YMPRESS S500MC - Data SheetpnagarajjAinda não há avaliações

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocumento8 páginasHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziAinda não há avaliações

- Jis D1201Documento38 páginasJis D1201Han Win Aung50% (2)

- Dacromet Coating: World Class Corrosion ProtectionDocumento6 páginasDacromet Coating: World Class Corrosion Protectionmarcelogf74Ainda não há avaliações

- HC-49 Engineering SpecificationDocumento6 páginasHC-49 Engineering SpecificationarunrathikaAinda não há avaliações

- Prog Eia-Iso MP 6200y PDFDocumento356 páginasProg Eia-Iso MP 6200y PDFAmy GriffinAinda não há avaliações

- 2430 & TB2448 ComarisionDocumento6 páginas2430 & TB2448 ComarisionpiyushAinda não há avaliações

- M6x1.0x23 Long HHS Control PlanDocumento2 páginasM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsAinda não há avaliações

- Comaparação A572 G50-A992Documento4 páginasComaparação A572 G50-A992Tiago CastelaniAinda não há avaliações

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Documento13 páginasNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresAinda não há avaliações

- EJOTDocumento200 páginasEJOTJie RongAinda não há avaliações

- Sae J82-2013Documento6 páginasSae J82-2013Marcos RosenbergAinda não há avaliações

- Iso 683-2-2016 2Documento7 páginasIso 683-2-2016 2Saju ShajuAinda não há avaliações

- TL245 English 2004Documento8 páginasTL245 English 2004Elliott RussellAinda não há avaliações

- M 3031 (2013-06)Documento16 páginasM 3031 (2013-06)Hatada FelipeAinda não há avaliações

- International Standard: Stainless Steels For Springs - WireDocumento8 páginasInternational Standard: Stainless Steels For Springs - WireAfzal ImamAinda não há avaliações

- BMS 0000147Documento15 páginasBMS 0000147方綵樺Ainda não há avaliações

- 2370 Ed1 ENDocumento5 páginas2370 Ed1 ENanhthoAinda não há avaliações

- Surface Surface Vehicle Vehicle Recommended Recommended Practice PracticeDocumento19 páginasSurface Surface Vehicle Vehicle Recommended Recommended Practice PracticeGustavo figueiredoAinda não há avaliações

- Silicon Nitride Bearing Balls: Standard Specification ForDocumento8 páginasSilicon Nitride Bearing Balls: Standard Specification ForkrutikAinda não há avaliações

- Jis D0203 PDFDocumento6 páginasJis D0203 PDFsabaris ksAinda não há avaliações

- FCA - PS.50009 (2014) - Ex PS.5570Documento7 páginasFCA - PS.50009 (2014) - Ex PS.5570FeliceAinda não há avaliações

- Coating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetDocumento6 páginasCoating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetROHITAinda não há avaliações

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDocumento9 páginasFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresAinda não há avaliações

- GPS1 enDocumento5 páginasGPS1 enKlocAinda não há avaliações

- Mpaps G-20Documento6 páginasMpaps G-20PANKAJ CHAUHANAinda não há avaliações

- SAE-J423: Distribution Statement ADocumento9 páginasSAE-J423: Distribution Statement Ayorf1989Ainda não há avaliações

- De 82004 0005 BR enDocumento108 páginasDe 82004 0005 BR enAndor Tony CiguAinda não há avaliações

- FT Grease 22Documento2 páginasFT Grease 22Edgar Leonel CortésAinda não há avaliações

- Din71802 PDFDocumento2 páginasDin71802 PDFjudas1432Ainda não há avaliações

- Metallisches Strahlmittel Gerundetes Stahldrahtkorn Bezeichnung, Güteanforderungen, PrüfungenDocumento5 páginasMetallisches Strahlmittel Gerundetes Stahldrahtkorn Bezeichnung, Güteanforderungen, PrüfungenWilmer Quezada MurilloAinda não há avaliações

- Metric Dowel PinsDocumento1 páginaMetric Dowel PinsAbhijeet MitraAinda não há avaliações

- VW 50019 PDFDocumento4 páginasVW 50019 PDFSujay Nahalde100% (1)

- Lss-A286 Astm A453 PDFDocumento2 páginasLss-A286 Astm A453 PDFmazolasboAinda não há avaliações

- E186 RXDocumento3 páginasE186 RXgechaves1Ainda não há avaliações

- 9.57405-Eng - Plating Std.Documento20 páginas9.57405-Eng - Plating Std.Baravkar Auto Parts100% (1)

- Din 908Documento2 páginasDin 908Dani Quirante Flaaut EtcAinda não há avaliações

- CS-11000Documento17 páginasCS-11000Engenharia APedro100% (1)

- Bearing Steel Material Specification Sheet SAE52100Documento1 páginaBearing Steel Material Specification Sheet SAE52100Christy Vijay Roy HenryAinda não há avaliações

- Din 7500 enDocumento10 páginasDin 7500 enCălin Bălăiţă100% (1)

- FW F436 P PDFDocumento2 páginasFW F436 P PDFLuis CarlosAinda não há avaliações

- Iso 9717 2010 en FR - PDF Phosphate CoatingDocumento11 páginasIso 9717 2010 en FR - PDF Phosphate CoatingGANESH AAinda não há avaliações

- Material Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionDocumento1 páginaMaterial Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionRajaSekarsajjaAinda não há avaliações

- Calipers, Micrometers, Indicators (PDFDrive)Documento597 páginasCalipers, Micrometers, Indicators (PDFDrive)Anonymous UXu3EGRAinda não há avaliações

- Astm D 7087 - 2010Documento4 páginasAstm D 7087 - 2010Emmanuel BoquetAinda não há avaliações

- Tabla Ajustes ISO286 2Documento45 páginasTabla Ajustes ISO286 2Shawn MooreAinda não há avaliações

- DIN 55633 Recubrimiento AnclajesDocumento29 páginasDIN 55633 Recubrimiento Anclajesdeybi resarteAinda não há avaliações

- DIN 128 A - Split Spring Washers, Curved, Form ADocumento6 páginasDIN 128 A - Split Spring Washers, Curved, Form ASantosh100% (1)

- The World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionDocumento2 páginasThe World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionSquidwardAinda não há avaliações

- Iso AnnealingDocumento2 páginasIso AnnealingPurushottam Sutar100% (1)

- Astm A31 (1995)Documento4 páginasAstm A31 (1995)gsb2100% (1)

- Astm A 623 - 08 Tin Mill Products-General RequirementsDocumento38 páginasAstm A 623 - 08 Tin Mill Products-General Requirementsjose_ruben_64Ainda não há avaliações

- 1.4028 enDocumento2 páginas1.4028 ensandeep acharAinda não há avaliações

- Sleipner UddeholmDocumento12 páginasSleipner UddeholmKalipse FerreiraAinda não há avaliações

- FTI VP20ISO InglesDocumento2 páginasFTI VP20ISO InglesepaeseAinda não há avaliações

- 476 Data SheetDocumento1 página476 Data SheetinvidiuoAinda não há avaliações

- 1.4006 en PDFDocumento2 páginas1.4006 en PDFutkuAinda não há avaliações

- Holdax EnglishDocumento8 páginasHoldax EnglishArtemio RsAinda não há avaliações

- Dilli Dur 500Documento4 páginasDilli Dur 500Fernando Alonso Troncos MendivesAinda não há avaliações

- Outokumpu Martensitic Grade 630 Data Sheet17 4Documento2 páginasOutokumpu Martensitic Grade 630 Data Sheet17 4nomecAinda não há avaliações

- Catalogo MITUTOYO INGLÊSDocumento1 páginaCatalogo MITUTOYO INGLÊSAmy GriffinAinda não há avaliações

- Perkins 1104cDocumento140 páginasPerkins 1104cGilvan Junior82% (11)

- Material ComparisonDocumento1 páginaMaterial ComparisonNoir HamannAinda não há avaliações

- QuickFlex DMG Mori Seiki - enDocumento24 páginasQuickFlex DMG Mori Seiki - enAmy GriffinAinda não há avaliações

- Cincom Evolution Line: Sliding Headstock Type Automatic CNC LatheDocumento8 páginasCincom Evolution Line: Sliding Headstock Type Automatic CNC LatheAmy GriffinAinda não há avaliações

- Material ComparisonDocumento1 páginaMaterial ComparisonNoir HamannAinda não há avaliações

- 30 CR Ni Mo 8Documento2 páginas30 CR Ni Mo 8Amy GriffinAinda não há avaliações

- A6-A6M 02b Rolled Steel PDFDocumento64 páginasA6-A6M 02b Rolled Steel PDFJoflAinda não há avaliações

- Perkins 1104cDocumento140 páginasPerkins 1104cGilvan Junior82% (11)

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocumento38 páginasRockwell Hardness of Metallic Materials: Standard Test Methods ForochableAinda não há avaliações

- 36NiCrMo16 PDFDocumento2 páginas36NiCrMo16 PDFAmy GriffinAinda não há avaliações

- Milk - Run Volkswagen PDFDocumento34 páginasMilk - Run Volkswagen PDFAmy GriffinAinda não há avaliações

- 40NiCrMo7 PDFDocumento2 páginas40NiCrMo7 PDFAmy GriffinAinda não há avaliações

- 39NiCrMo3 PDFDocumento2 páginas39NiCrMo3 PDFAmy GriffinAinda não há avaliações

- 34 CR Ni Mo 6Documento2 páginas34 CR Ni Mo 6hp_vijaykAinda não há avaliações

- Astm A350 LF2Documento1 páginaAstm A350 LF2anjangandak2932100% (1)

- 40NiCrMo3 PDFDocumento1 página40NiCrMo3 PDFAmy GriffinAinda não há avaliações

- Astma105 PDFDocumento1 páginaAstma105 PDFAmy GriffinAinda não há avaliações

- AutoCAD 2013Documento264 páginasAutoCAD 2013panosscribd100% (1)

- Manual Fresa Dora Ha AsDocumento143 páginasManual Fresa Dora Ha AsAmy GriffinAinda não há avaliações

- Parker Fluid Power Seal Design Guide 5370Documento300 páginasParker Fluid Power Seal Design Guide 5370edwardsheridan0% (1)

- Proteins and Peptides 20msc01029Documento10 páginasProteins and Peptides 20msc01029Ritu ParmarAinda não há avaliações

- Automated Plate Load Test: Aplt CapabilitiesDocumento2 páginasAutomated Plate Load Test: Aplt CapabilitiesjoseriquAinda não há avaliações

- Calculating The True Cost of SteamDocumento2 páginasCalculating The True Cost of Steamisquare77Ainda não há avaliações

- Prokaryotes and ArchaeaDocumento17 páginasProkaryotes and ArchaeaAngela CanlasAinda não há avaliações

- XII PT-1 Phy KeyDocumento9 páginasXII PT-1 Phy KeyRoshini SAinda não há avaliações

- Chemical Industry ReleasesDocumento152 páginasChemical Industry ReleasesKiran KrishnanAinda não há avaliações

- Chapter 4Documento78 páginasChapter 4Rizky KusumastutiAinda não há avaliações

- Els Week 1Documento13 páginasEls Week 1Paolin Pearl Ortiola RapisuraAinda não há avaliações

- Lasers For Industrial Applications - 56850 - 12Documento15 páginasLasers For Industrial Applications - 56850 - 12ΈλσαΟγκρένιAinda não há avaliações

- Kobel CoDocumento4 páginasKobel CoCesar ZarateAinda não há avaliações

- Dead Molecules and The Live Organism: Moh. Dliyauddin (176090100111019) Rubiyatna Sakaroni (176090100111006)Documento14 páginasDead Molecules and The Live Organism: Moh. Dliyauddin (176090100111019) Rubiyatna Sakaroni (176090100111006)Muhammad DliyauddinAinda não há avaliações

- Science Reviewer 3rd GradingDocumento7 páginasScience Reviewer 3rd GradingSean Irvin MirandaAinda não há avaliações

- Sedimentation and Sedimentation TanksDocumento43 páginasSedimentation and Sedimentation TanksDevendra Sharma80% (10)

- PETSOC-95-09 Towards Optimizing Gas Condensate ReservoirsDocumento18 páginasPETSOC-95-09 Towards Optimizing Gas Condensate ReservoirsMiguel Angel GonzalesAinda não há avaliações

- LAB M Manual 2006Documento163 páginasLAB M Manual 2006Juan José BlesaAinda não há avaliações

- Tetra Pak Particles Processing PDFDocumento1 páginaTetra Pak Particles Processing PDFSergio HernandezAinda não há avaliações

- Ib Chemistry Data BookletDocumento28 páginasIb Chemistry Data BookletPrem AnandAinda não há avaliações

- US6783609Documento13 páginasUS6783609ceyhun kilicAinda não há avaliações

- Us 4207118Documento8 páginasUs 4207118virus40Ainda não há avaliações

- KGL ManualDocumento47 páginasKGL ManualAaron Shane IrvinAinda não há avaliações

- Introduction To Flip ChipDocumento58 páginasIntroduction To Flip ChipLakshman Yandapalli100% (1)

- Evian Bottle Water Quality Report 2020Documento11 páginasEvian Bottle Water Quality Report 2020Lokanathan ArriaAinda não há avaliações

- Iodine Test For StarchDocumento2 páginasIodine Test For StarchNoora MubarakAinda não há avaliações

- 2nd Law of Thermodynamics WorksheetDocumento2 páginas2nd Law of Thermodynamics WorksheetMoa ArmyAinda não há avaliações

- A Study On Numerical Analysis of The Resistance Spot Welding ProcessDocumento6 páginasA Study On Numerical Analysis of The Resistance Spot Welding Processkiran_wakchaureAinda não há avaliações

- Cy 2018Documento16 páginasCy 2018ArvindAinda não há avaliações

- The Mineral Shadows CollectionDocumento6 páginasThe Mineral Shadows CollectionalexkardarAinda não há avaliações

- Corrosion Control - Jack-Up - SP-CO-ENG-CON-06-01Documento37 páginasCorrosion Control - Jack-Up - SP-CO-ENG-CON-06-01evenAinda não há avaliações