Escolar Documentos

Profissional Documentos

Cultura Documentos

Am-01 01 250-Ap2

Enviado por

gianfrancoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Am-01 01 250-Ap2

Enviado por

gianfrancoDireitos autorais:

Formatos disponíveis

KONE EcoSpace and MonoSpace 500

Installation Instruction

K O N E E C O S PA C E A N D M O N O S PA C E 5 0 0 W I T H K C E

E L E C T R I F I C AT I O N

X000032909

© 2013 KONE Corporation 1 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

© 2013 KONE Corporation

All rights reserved.

No part of the contents of this document may be copied, reproduced or transmitted in any form or by any

means, or translated into another language or format, in whole or part, without prior written permission of

KONE Corporation.

Authorization Notice

This publication is for informational p urposes only. All persons participating in the installation and/or

maintenance of KONE equipment and using these instructions must be qualified to perform such work, are

required to have received equipment specific training as specified by KONE and must have KONE

Corporation's authorization to install and maintain KONE equipment.

D I S C L A I M E R O F WA R R A N T I E S A N D L I A B I L I T I E S

KONE reserves the right at any time to alter the product design, specifications and procedures reflected in

this document. NO STATEMENT CONTAINED IN THIS DOCUMENT IS TO BE CONSTRUED AS A

WARRANTY OR CONDITION, EXPRESS OR IMPLIED, AS TO ANY PRODUCT, SPECIFICATION OR

PROCEDURE, ITS MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE OR

QUALITY, OR AS A MODIFICATION OR REPRESENTATION OF THE TERMS OF ANY PURCHASE

AGREEMENT.

KONE DISCLAIMS ANY LIABILITY RESULTING FROM OR IN CONNECTION WITH THE USE OR

DISCLOSURE OF INFORMATION IN THIS DOCUMENT. KONE HAS NO LIABILITY FOR

TYPOGRAPHICAL OR OTHER ERRORS OR OMISSIONS CONTAINED IN THIS DOCUMENT OR

ANYONE'S INTERPRETATION OF THE INSTRUCTIONS. THE USER OF THIS DOCUMENT ASSUMES

ALL RISKS ASSOCIATED WITH THE USE OR DISCLOSURE OF THIS DOCUMENT.

Confidentiality Notice

This proprietary and confidential document is provided to you only for purposes of installing and/or

maintaining KONE products and it may not be used or its contents disclosed for any other purpose without

KONE's prior written permission. Neither this document nor its contents may be copied or disclosed to third

parties for any reason. KONE reserves the right to prosecute any breach of this obligation.

Tr a d e m a r k N o t i c e

"KONE, MonoSpace, MiniSpace, EcoDisc, TranSys, Alta, KoneXion, KONE ECO3000 and all other

product names are trademarks or registered trademarks of KONE Corporation in various countries."

© 2013 KONE Corporation 2 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

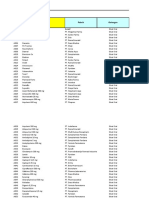

TA B L E O F C O N T E N T S

1 ABOUT THIS DOCUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Translations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Related documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Weight of main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Customer experience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Protecting work areas with safety fences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Public safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3 Warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.4 Minimum required personal protective equipment (PPE) for elevator installation

and commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Personal protection signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6 Man riding hoist sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5 INSTALL MAINTENANCE ACCESS PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.1 Quality requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.2 Maintenance access panel (EN81-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.2.1 Maintenance access panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.2.2 Install maintenance access panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.3 Maintenance access panel (EN81-20). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5.3.1 Maintenance access panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5.3.2 Install maintenance access panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6 ELECTRIFICATION AT TOP OF ELEVATOR SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.1 EcoSpace with KDL16L (EN81-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.1.1 Quality requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.1.2 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.1.3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.1.4 Install drive and THD filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.1.5 Install electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.1.6 Install LWD cable, OSG cable and topmost lighting unit . . . . . . . . . . . . . . . . . . . .27

6.1.7 Connections and earthings with ECB-1 (KDL16L KCE). . . . . . . . . . . . . . . . . . . . .29

6.1.8 Connections and earthings without ECB-1 (KDL16L KCE) . . . . . . . . . . . . . . . . .30

6.1.9 Connect machine cables (KDL16L KCE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.1.10 Connect cables between MAP and drive (KDL16L KCE) . . . . . . . . . . . . . . . . . . .32

6.2 EcoSpace with KDL16L (EN81-20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.2.1 Quality requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.2.2 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.2.3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.2.4 Install drive, THD filter and RBO main unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.2.5 Install electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

© 2013 KONE Corporation 3 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.2.6 Install LWD cable, OSG cable and topmost lighting unit . . . . . . . . . . . . . . . . . . . .41

6.2.7 Connections and earthings with ECB-1 (KDL16L KCE). . . . . . . . . . . . . . . . . . . . .43

6.2.8 Connections and earthings without ECB-1 (KDL16L KCE) . . . . . . . . . . . . . . . . .44

6.2.9 Connect machine cables (KDL16L KCE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.2.10 Connect cables between MAP and drive (KDL16L KCE) . . . . . . . . . . . . . . . . . . .47

6.2.11 Connect RBO cables (KDL16L KCE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.3 MonoSpace 500 with KDL16S (EN81-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.3.1 Quality requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.3.2 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

6.3.3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.3.4 Open KDL16S drive covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

6.3.5 Install drive panel (KDL16S, guide rail fixing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

6.3.6 Install drive panel (KDL16S, wall fixing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

6.3.7 Install electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

6.3.8 Install LWD cable, OSG cable and topmost lighting unit . . . . . . . . . . . . . . . . . . . .58

6.3.9 Connections and earthings with ECB-1 (KDL16S KCE) . . . . . . . . . . . . . . . . . . . .60

6.3.10 Connections and earthings without ECB-1 (KDL16S KCE) . . . . . . . . . . . . . . . . .61

6.3.11 Connect machine cables (KDL16S KCE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

6.3.12 Connect cables between MAP and drive (KDL16S KCE) . . . . . . . . . . . . . . . . . . .62

6.4 MonoSpace 500 with KDL16S (EN81-20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

6.4.1 Quality requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

6.4.2 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

6.4.3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

6.4.4 Open KDL16S drive covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

6.4.5 Install drive and RBO main unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

6.4.6 Install electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

6.4.7 Install LWD cable, OSG cable and topmost lighting unit . . . . . . . . . . . . . . . . . . . .73

6.4.8 Connections and earthings with ECB-1 (KDL16S KCE) . . . . . . . . . . . . . . . . . . . .75

6.4.9 Connections and earthings without ECB-1 (KDL16S KCE) . . . . . . . . . . . . . . . . .76

6.4.10 Connect machine cables (KDL16S KCE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

6.4.11 Connect cables between MAP and drive (KDL16S KCE) . . . . . . . . . . . . . . . . . . .78

6.4.12 Connect RBO cables (KDL16S KCE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

7 MAIN SUPPLY CABLE, MAP AT SECOND TOPMOST FLOOR, GROUP

CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

7.1 Connect main supply cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

7.2 MAP at second topmost floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

7.3 Connect group elevators (duplex / triplex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

8 INSTALL TRAVELING CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

9 ELEVATOR SHAFT WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

9.1 Wiring at top of elevator shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

9.2 Install elevator shaft lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

9.3 Fix connection and protection boxes and wiring at landings . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

9.4 Pit electrification (EN81-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

9.5 Install control station in pit (EN81-20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

9.5.1 Control station in the pit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

9.5.2 Install electrical equipment in pit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

© 2013 KONE Corporation 4 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

9.5.3 Electrical equipment in pit without access door . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

9.6 Install elevator shaft bundle to group elevators with dividing beams OR steel

elevator shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10 ELECTRIFICATION UNDER CAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

11 INSTALL CAR ELECTRIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11.1 Quality requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11.2 Check car roof layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.3 Install alarm unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.4 Install car emergency lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.5 Install door zone sensor (DZS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.6 Install car top connection box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

11.7 Connect wires to car top connection box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

11.7.1 Connectors at KCE car top connection box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

11.7.2 Use spring loaded terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

11.7.3 Connect cables to car top connection box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

11.8 Installing provision for elevator announcer (ACU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

11.8.1 Install ACU box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

11.8.2 Connect ACU (if applicable). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

11.9 Install induction loop (ILS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

11.10 Install positioning magnets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

12 COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

13 APPROVALS AND CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

APPENDIX A ELEVATOR SHAFT WIRING WITH TRUNKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

A.1 Install support channels and trunkings for steel shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

A.2 Trunkings, holes for cable fixings and elevator shaft lighting . . . . . . . . . . . . . . . . . . . . . . . . . 123

A.3 Shaft bundle at topmost floor with trunking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

A.4 Shaft bundle with trunking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

A.5 Routing elevator shaft electrification with trunking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

A.6 Pit electrification with trunking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

© 2013 KONE Corporation 5 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

1 ABOUT THIS DOCUMENT

1.1 Audience

This information is intended to be used by people who are familiar with elevator installation

and have received proper training on methods and safety as specified by KONE.

1.2 Feedback

Click a star button to rate this information, report errors or suggest improvements. This opens

your default e-mail client. Alternatively, send feedback directly to ktd@kone.com.

Excellent

Good

Average

Acceptable

Insufficient

1.3 Tr a n s l a t i o n s

If you need assistance in getting technical information translated, contact ktd@kone.com.

© 2013 KONE Corporation 6 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

2 GENERAL

This instruction describes components and features related to KONE EcoSpace and KONE

MonoSpace elevators with KCE electrification.

Use this instruction in conjunction with AM-01.01.026, AM-01.01.250, AM-01.01.026-AP14

and AM-01.01.500.

2.1 Related documents

In addition to this manual, you can find safety- and product-related information in the following

documents:

– AM-01.01.026 KONE MonoSpace®, Release 2.9, Installation instruction

– AM-01.01.026-AP14 KONE MonoSpace®, Release 2.10 and EcoSpace® 2.3

– AM-01.01.250 MonoSpace ®, Release 3.2, Installation instruction

– AM-01.01.500 EN81-20 code changes affecting elevator products and installation methods

– AM-01.03.009 General instructions for material handling, using transportation and lifting

equipment

– AM-11.65.054 KCE Electrification with KDL16 Drive, Commissioning and Safety Inspection

– AM-11.65.094, KONE MonoSpace and EcoSpace with KDL16L/KDL16S KCE drive (EN

81-20) - commissioning and safety inspection

– AM-13.25.004 Induction Loop Solution

– AM-13.25.011 KONE Remote Monitoring (KRM) for elevators with KCE electrification,

Installation

– AM-13.30.016 EBD10 for KCE, emergency battery drive for elevators with KCE control

system

2.2 We ig h t o f m a in c o m po n e nt s

Component We i g h t

MAP (door type) 24kg

KDL16L/S KCE drive panel 11-14kg

THD filter 5-10kg

Travelling cable, EcoSpace (max travel 35m) 23kg (max)

Travelling cable, MonoSpace500 (max travel 75m) 47kg (max)

Car top connection box 10kg (max)

Emergency Battery Drive EBD06 (optional) 36kg

Autotransformer (optional) 48-68kg

Main unit of electrical brake release device (RBO) 12-15kg

© 2013 KONE Corporation 7 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

2.3 Customer experience

The focus of your work must always be customer satisfaction. To reach and exceed the

customers’ expectations, be polite, constructive and co-operative, and communicate clearly.

Remember that for customers, you represent KONE, so ensure that you handle or at least

communicate all customer requests and feedback to the correct persons.

For more information on how to deliver best-in-class customer experiences through behavior

and communication, see the KONE Ambassador program in KONE intranet (search for

Ambassador) or contact your supervisor.

X000085312 B.5

© 2013 KONE Corporation 8 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

3 SAFETY

For more information on safety, see AM-01.01.026 and AM-01.01.250.

Safe working is based on KONE general safety rules and local regulations. Fitter must use

safety shoes, helmet and protective gloves in all work phases. Additional personal protective

equipment (PPE) must be used when required in instructions.

3.1 Protecting work areas with safety fences

When work is performed at landings, the landings must be protected. Entrance protection /

door must be:

– Fully covered

– Lockable

– Openable without key from inside

– Imperforate or at minimum preventing contact with exposed components that can be a

safety risk

Do not leave the work place unattended when entrance protection is removed or a landing

door is open.

No work at the landing. Closed landing door or fence covering the whole door opening.

X000011548

Work on the car roof or in the pit. Closed landing door or car at landing and fence closing the

landing door area.

© 2013 KONE Corporation 9 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

X000011549

3.2 Public safety

– Keep the working area closed to the public at all times.

– Keep the area outside the working area clean.

– Store materials in designated storage areas. Not on landings or in working area.

– In residential buildings keep to the agreed daily working schedules to avoid unnecessary

disturbance to residents.

– When transporting material into the elevator shaft, segregate other building users from the

transportation route and working areas with additional safety fences or guarding.

X000011865 A.1

3.3 Wa r n i n g s i g n s

Danger Sign Danger Sign

Electric shock Risk of falling

Magnetic field Risk of fire

Corrosion, Entry prohibited

dermatological risk

General hazard Suspended load

warning

Pinching hazard Falling objects

© 2013 KONE Corporation 10 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

3.4 Minimum required personal protective equipment (PPE) for elevator

installation and commissioning

– Protective gloves (cut resistant gloves against sharp objects and if needed gloves against

chemical hazards, cold and heat)

– Working clothes

– High visibility vest

– Safety shoes with ankle protection

– Safety glasses

– Safety helmet

– Hearing protection

– Fall restraint or arrest equipment (if needed)

X000010230

X000034302

For more information on PPE, see AM-01.03.010 Elevator installation — safety manual.

X0000084781 A.7

3.5 Personal protection signs

Mandatory Sign Mandatory Sign

Head protection Overall

Dust mask Hearing protection

© 2013 KONE Corporation 11 ( 1 2 9 ) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

Mandatory Sign Mandatory Sign

Safety shoes with ankle Safety gloves / Rubber

protection gloves

Fall prevention equipment Safety goggles

Fall prevention measures High visibility clothing

3.6 Man riding hoist sign

Informative Sign

Man riding hoist mandatory inspection

X000009573

X0000104842 A.2

X000085313 B.2

© 2013 KONE Corporation 12 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

4 TOO LS

P c s . To o l P c s . To o l

1 Unwinding device 1 Electrostatic Discharge (ESD) kit

KM504610G01 (optional)

KM857505

X000023109

X000024935

1 Working stool 2 Locking set for main switch

KM265173 KM854281

X000085314

X000010443

1 Multimeter (Fluke 179 or equivalent) 1 Manual chain hoist for lifting of EBD

with long insulated test probes (optional)

(minimum length 100 mm) Locally supplied

Locally supplied

X000010454

X000014689

1 Torx screwdriver T10 (to open the Normal hand tools (see KOS-000029,

drive cover plate) KONE hand tools for installation and

maintenance)

X000014894

Locally supplied

1 Electric drill

X000085315 A.1

© 2013 KONE Corporation 13 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

5 I N S TA L L M A I N T E N A N C E A C C E S S PA N E L

5.1 Quality requirements

Quality Requirements:

Maintenance access panel (MAP)

– aligned to frame

– door operation checked

– locks operation checked with key

– no rattling noise during knock & feel test

– all protective plastic paper removed from

joints etc.

– inspected for any sharp edges and de-

burr if necessary

– fire protection installed (if needed)

X000032913

! ! ! C A U T I O N — i s s u e s t h a t a ff e c t SORT

reliability !!! STABILIZE

Incorrectly installed / aligned MAP

causes:

5S SHINE

STANDARDIZE

SUSTAIN

X000028644

– MAP door lock operation failure

Incorrectly installed / adjusted brake Method tools needed:

release cable causes: Man riding hoist

– obstruction with moving parts / damage to Hand tools needed:

cable Battery drill / driver, Phillips screwdriver,

hammer drill, hammer, side cutters, tape

– adjusted too slack = unable to manually

measure, spirit level, ratchet + socket

operate brakes

(19 mm, wall MAP)

– adjusted too tight = potential brake

malfunctions 5S Installation Progress Report

N/A

© 2013 KONE Corporation 14 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

Q D - 1 8 1 . 2 11

N/A

X0000093703 A.3

© 2013 KONE Corporation 15 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

5.2 Maintenance access panel (EN81-1)

5.2.1 Maintenance access panel

1. PE bar

2. Main switch (Q220) and lighting

1 disconnecting switch (Q262)

3. KCEAPM (optional)

2 8 4. Manual brake release lever

5. KCERAL (optional)

6. KCEFUI

7. KCEMSC

8. KCECPU

3 9

9. LED power supply

10. Switch module

11. 24VDC (second one optional)

12. KCEGCL or KCEOPT (optional)

4

13. Traveling cable connection

10

11

6

12

7

13

X000032914

X0000093609 A.2

© 2013 KONE Corporation 16 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

5.2.2 Install maintenance access panel

N O T E : Protect your arms and use dust mask when handling rockwool. When maintenance

access panel (MAP) installation is ongoing, the car roof must be on landing level, the car top

balustrade (if any) must be installed and working area must be closed.

1. Remove the top and bottom covers.

2. Lean the MAP against the wall next to the door frame.

Take care not to damage the cables.

3. Route the cables to the elevator shaft through the top end of the door frame.

4. Install the MAP to the door frame.

5. F i r e r a t e d d o o r s : Fit rockwool pieces to top and bottom consoles.

6. F i r e r a t e d f r o n t t y p e d o o r s : Install the fire protection plates.

7. Install the bottom cover.

N O T E : Install the top cover after main power supply cable installation.

2 3

7

1080833.pdf

X0000085991

X0000093613 A.4

© 2013 KONE Corporation 17 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

5.3 Maintenance access panel (EN81-20)

5.3.1 Maintenance access panel

X0000088791

1. Protective earth (PE) bar 7. KCEMSC

2. Main switch (Q220) and lighting 8. KCECPU

disconnecting switch (Q262)

3. KCEAPM (optional) 9. Switch module

4. Electrical brake release device 10. 24VDC (second one optional)

(RBO)

5. KCERAL (optional) 11. LED power supply

6. KCEFUI 12. KCEGCL or KCEOPT (optional)

13. Overspeed governor by-pass switch

(22BP:1) and by-pass button (22BP:2)

X0000093610 A.2

© 2013 KONE Corporation 18 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

5.3.2 Install maintenance access panel

N O T E : Protect your arms and use dust mask when handling rockwool. When maintenance

access panel (MAP) installation is ongoing, the car roof must be on landing level, the car top

balustrade (if any) must be installed and working area must be closed.

1. Remove the top and bottom covers.

2. Lean the MAP against the wall next to the door frame.

Take care not to damage the cables.

3. Route the cables to the elevator shaft through the top end of the door frame.

4. Install the MAP to the door frame.

5. F i r e r a t e d d o o r s : Fit rockwool pieces to top and bottom consoles.

6. F i r e r a t e d f r o n t t y p e d o o r s : Install the fire protection plates.

7. Install the bottom cover.

N O T E : Install the top cover after main power supply cable installation.

X0000093645

X0000093614 A.3

© 2013 KONE Corporation 19 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6 E L E C T R I F I C AT I O N AT TO P O F E L E VATO R S H A F T

6.1 EcoSpace with KDL16L (EN81-1)

6.1.1 Quality requirements

Quality Requirements:

D r i v e , T H D f i l t e r, t r u n k i n g s , e x t e r n a l

braking resistor (if any)

– installed to correct position according to

layout drawings

Accessories (EBD etc.) KDL16L

– installed to correct position according to

layout drawings

Cables between elevator shaft top

components

– routed and connected, free of obstruction

– encoder cable routed separately (not

grouped with machine cables)

– plugs properly inserted into sockets

– all ‘screw type’ cable terminations

tightened, ensure no loose cable strands

– earthings checked

– cable grounding / shields to be correctly

clamped

– ensure that no damage has occurred

during installation

N O T E : Ensure that all covers are closed

after installation.

X000014890

© 2013 KONE Corporation 20 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

! ! ! C A U T I O N — i s s u e s t h a t a ff e c t SORT

reliability !!! STABILIZE

Incorrectly installed elevator shaft top

electrification causes:

5S SHINE

STANDARDIZE

SUSTAIN

X000028644

– equipment (drive etc.) not installed to

layout drawing position will interfere with Method tools needed:

required running clearance from ropes or Man riding hoist

car

Hand tools needed:

– accessories (EBD etc.) not installed to Tape measure, spirit level, pencil, hammer

layout drawing position will interfere with drill, hammer, side cutters, 2 x spanner (8,

required safety spaces, running 10 mm), ratchet + socket (19 mm, EBD),

clearances spanner (7, 17, 19 mm), allen keys, TORX

Incorrectly installed elevator shaft top screwdriver (T10), electrical terminal

cabling causes: screwdriver, multigrip pliers

– incorrectly routed encoder cable can 5S Installation Progress Report

cause poor encoder reference feedback Lift Controller Installed

due to magnetic field disturbances from

machine cables. This leads to poor ride Q D - 1 8 1 . 2 11

comfort and drive faults QD 7 commenced

– plugs not inserted correctly to sockets

can cause unnecessary disconnections

– earthing / shield clamps not used

correctly will NOT provide the required

grounding to remove signal interference

– loose ‘screw type’ terminals cause

unnecessary disconnections

X0000093803 A.2

6.1.2 Notes

WA R N I N G : During electrification work, the power must be off. Ensure that the power to the

main supply cable cannot be turned on. Remove fuses and lock the main switches. Notice the

separate lighting supplies.

C A U T I O N : When drilling above drive or MAP, protect the panels from dust.

© 2013 KONE Corporation 21 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

C A U T I O N : If there is a danger of condensed water, on the wire or cable

surface, to enter electrical components or connectors in the elevator

shaft, form a loop before the cable entry or connector. This cable loop

X000031161

method is recommended for all installations and mandatory in wet or

humid operating conditions.

X000031162

C A U T I O N : When installing the cables, ensure the following:

o

90

1 Encoder and thermistor cables must be separated from motor supply and

2

>100mm brake control cables. Otherwise there might be disturbances in the

3

4 encoder signals. These cables can cross each other at an angle of

90 degrees. If these cables are routed parallel, the minimum clearance

X000032929

between these two cable groups must be 100 mm.

1 = Encoder cable, 2 = Thermistor cable, 3 = Brake control cable, 4 =

Motor supply cable

N O T E : Fix the cables to the wall in both horizontal and vertical directions. The maximum

distance between wall fixings is 500 mm.

X0000093812 A.2

© 2013 KONE Corporation 22 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.1.3 Overview

X000085318

© 2013 KONE Corporation 23 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

X000032920

X0000093939 A.2

6.1.4 Install drive and THD filter

N O T E : Make sure that you have a good grip when handling heavy items.

1. Assemble required bolts and nuts to the drive fixing bracket.

2. Install the drive module. Align according to the machine type.

© 2013 KONE Corporation 24 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

3. Install the THD filter.

X000032921

N O T E : The drive cover securing wire must not get caught in any component of the moving

car. Shorten the wire using a cable tie if necessary.

X0000145927

X0000094541 A.4

6.1.5 Install electrical components

N O T E : Make sure that you have a good grip when handling heavy items.

© 2013 KONE Corporation 25 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

1. Install the traveling cable hanger.

N O T E : Traveling cable is fixed to the same level as the bottom through hole of the MAP

(also if MAP is at the second topmost floor).

N O T E : Traveling cable hanger must be located above the mid point of the elevator

shaft.

2. Install the DC fuse box (F386:2, optional).

3. Install the braking resistor.

4. Fix the metal plate trunking above the top track.

5. Fix the 2 m piece of trunking (125 × 50 mm) beside the drive.

6. Fix the topmost trunkings for the cables.

7. Install the ECB-1 single line ReGenerative unit (optional).

8. Fix the metal plate trunking below the topmost landing door sill (minimum four screws

per one meter of plate). Fit the plastic end caps over the sharp edges.

9. Install the emergency battery drive unit (EBD, optional).

For more information, see AM-13.30.016.

C A U T I O N : Ensure that there is a minimum 10 mm clearance between the EBD and the

car door operator.

© 2013 KONE Corporation 26 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

10. Install the Site Access Gateway (SAG, optional). Connect the cables to KCEAPM in

MAP.

For more information, see AM-13.25.011.

9

3

10

6

4

2

7

1

X0000085995

X0000094064 A.4

6.1.6 I n s t a l l LW D c a b l e , O S G c a b l e a n d t o p m o s t l i g h t i n g u n i t

1. Route, fix and connect the load weighing device (LWD) sensor cable (140) and

overspeed governor (OSG) cable (127).

Leave minimum 100 mm space between the cables when they are parallel to each

other.

N O T E : LWD cable can be routed together with the thermistor and encoder cables.

2. Install the topmost lighting unit. Route and connect the lighting cable (XH157).

3. Route and connect electric safety chain (P110) and signalization cable (XS2).

© 2013 KONE Corporation 27 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

127

140

100mm

XS2 min.

KDL16L

XH1 XL4

XOSG1

XH157

X000032923

Cable From To

LWD cable Load weighing device KDL16L KCE drive / XL4

OSG cable Overspeed governor MAP / XOSG1

Lighting cable Elevator shaft light MAP / XH157

Electric safety chain cable Electric safety chain of MAP / XH1

elevator shaft

Signalization cable Landing signalization MAP / XS2

X0000094593 A.3

© 2013 KONE Corporation 28 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.1.7 Connections and earthings with ECB-1 (KDL16L KCE)

1 2 3

**

*

6 4 5 11 7 8 10 9

X000032924

*) Only with ECB-1

**) A danger of condensed water, on the wire surface, to enter connectors! Form a loop before

the connector.

1. Braking resistor cable

2. Motor supply cable

3. Brake and thermistor cable

4. DC-link cable (if ECB)

5. Control cable (if ECB)

6. Start permit cable (if ECB)

7. Supply cable

8. Load weighing device cable

9. Drive communication cable

© 2013 KONE Corporation 29 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

10. Encoder cable

11. Start permit cable

X0000094627 A.3

6.1.8 Connections and earthings without ECB-1 (KDL16L KCE)

1 2 3

**

8 4 5 7 6

X000032925

**) A danger of condensed water, on the wire surface, to enter connectors! Form a loop before

the connector.

1. Braking resistor cable

2. Motor supply cable

3. Brake and thermistor cable

4. Supply cable

5. Load weighing device cable

6. Drive communication cable

7. Encoder cable

© 2013 KONE Corporation 30 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

8. Start permit cable

X0000094628 A.3

6.1.9 Connect machine cables (KDL16L KCE)

WA R N I N G : Ensure that the power supply is safely locked off. Refer to AM-01.03.002 Take 5.

1. Route and connect.

– Motor supply cable to U, V and W

– Braking resistor cables to XBRE2

– Brake cable to XBR4

– Thermistor cable to XT1

– Encoder cable to XMEN5

2. Check that there is smooth radius from the wall to the drive to avoid the cable leading

humidity or water to the bushings.

3. Check that all connections are clean and clamps are secure. Firm contact between

earthing clamps and cable sleeves is very important.

U, V, W

XMEN5

XBR4

5Nm

XBRE2

XT1

X000032926

X0000094655 A.2

© 2013 KONE Corporation 31 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.1.10 Connect cables between MAP and drive (KDL16L KCE)

1. Route and connect the cables between MAP and drive.

A = THD filter

PE

220 /

2,4,6,8

XS3 XD1

PE

XKDSI1 XD3

T1,T2

T3,PE

A

PE,L1',L2',L3'

L1,L2,L3,PE

X000032927

X0000094657 A.2

© 2013 KONE Corporation 32 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.2 EcoSpace with KDL16L (EN81-20)

6.2.1 Quality requirements

Quality Requirements:

D r i v e , T H D f i l t e r, t r u n k i n g s , e x t e r n a l

braking resistor (if any)

– installed to correct position according to

layout drawings

Accessories (EBD etc.) KDL16L

– installed to correct position according to

layout drawings

Cables between elevator shaft top

components

– routed and connected, free of obstruction

– encoder cable routed separately (not

grouped with machine cables)

– plugs properly inserted into sockets

– all ‘screw type’ cable terminations

tightened, ensure no loose cable strands

– earthings checked

– cable grounding / shields to be correctly

clamped

– ensure that no damage has occurred

during installation

N O T E : Ensure that all covers are closed

after installation.

X000014890

© 2013 KONE Corporation 33 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

! ! ! C A U T I O N — i s s u e s t h a t a ff e c t SORT

reliability !!! STABILIZE

Incorrectly installed elevator shaft top

electrification causes:

5S SHINE

STANDARDIZE

SUSTAIN

X000028644

– equipment (drive etc.) not installed to

layout drawing position will interfere with Method tools needed:

required running clearance from ropes or Man riding hoist

car

Hand tools needed:

– accessories (EBD etc.) not installed to Tape measure, spirit level, pencil, hammer

layout drawing position will interfere with drill, hammer, side cutters, 2 x spanner (8,

required safety spaces, running 10 mm), ratchet + socket (19 mm, EBD),

clearances spanner (7, 17, 19 mm), allen keys, TORX

Incorrectly installed elevator shaft top screwdriver (T10), electrical terminal

cabling causes: screwdriver, multigrip pliers

– incorrectly routed encoder cable can 5S Installation Progress Report

cause poor encoder reference feedback Lift Controller Installed

due to magnetic field disturbances from

machine cables. This leads to poor ride Q D - 1 8 1 . 2 11

comfort and drive faults QD 7 commenced

– plugs not inserted correctly to sockets

can cause unnecessary disconnections

– earthing / shield clamps not used

correctly will NOT provide the required

grounding to remove signal interference

– loose ‘screw type’ terminals cause

unnecessary disconnections

X0000093803 A.2

6.2.2 Notes

WA R N I N G : During electrification work, the power must be off. Ensure that the power to the

main supply cable cannot be turned on. Remove fuses and lock the main switches. Notice the

separate lighting supplies.

C A U T I O N : When drilling above drive or MAP, protect the panels from dust.

© 2013 KONE Corporation 34 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

C A U T I O N : If there is a danger of condensed water, on the wire or cable

surface, to enter electrical components or connectors in the elevator

shaft, form a loop before the cable entry or connector. This cable loop

X000031161

method is recommended for all installations and mandatory in wet or

humid operating conditions.

X000031162

C A U T I O N : When installing the cables, ensure the following:

o

90

1 Encoder and thermistor cables must be separated from motor supply and

2

>100mm brake control cables. Otherwise there might be disturbances in the

3

4 encoder signals. These cables can cross each other at an angle of

90 degrees. If these cables are routed parallel, the minimum clearance

X000032929

between these two cable groups must be 100 mm.

1 = Encoder cable, 2 = Thermistor cable, 3 = Brake control cable, 4 =

Motor supply cable

N O T E : Fix the cables to the wall in both horizontal and vertical directions. The maximum

distance between wall fixings is 500 mm.

X0000093812 A.2

© 2013 KONE Corporation 35 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.2.3 Overview

X0000093979

© 2013 KONE Corporation 36 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

X000032920

X0000093940 A.2

6.2.4 Install drive, THD filter and RBO main unit

N O T E : Make sure that you have a good grip when handling heavy items.

1. Assemble required bolts and nuts to the drive fixing bracket.

© 2013 KONE Corporation 37 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

2. Install the drive panel. Align according to the machine type.

X0000094551

3. Install the THD filter and RBO main unit fixing plate (optional, glass or net shafts) to the

drive fixing bracket.

4. Install the electrical brake release device main unit (RBOMU).

For more information, see AM-10.60.100.

5. Install the THD filter.

MX05 MX06 MX10

430 500 558

448 500 558

X0000136409

Figure 1: Guide rail fixing

© 2013 KONE Corporation 38 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

510 Car DD = 1250 600 680

MX05 550 Car DD = 1300 MX06 MX10

X0000144329

Figure 2: Wall fixing

N O T E : The drive cover securing wire must not get caught in any component of the moving

car. Shorten the wire using a cable tie if necessary.

X0000145927

X0000094518 A.4

6.2.5 Install electrical components

N O T E : Make sure that you have a good grip when handling heavy items.

1. Install the traveling cable hanger.

N O T E : Traveling cable is fixed to the same level as the bottom through hole of the MAP

(also if MAP is at the second topmost floor).

N O T E : Traveling cable hanger must be located above the mid point of the elevator

shaft.

© 2013 KONE Corporation 39 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

2. Install the DC fuse box (F386:2, optional).

3. Install the braking resistor.

4. Fix the metal plate trunking above the top track.

5. Fix the 2 m piece of trunking (125 × 50 mm) beside the drive.

6. Fix the topmost trunkings for the cables.

7. Install the ECB-1 single line ReGenerative unit (optional).

8. Fix the metal plate trunking below the topmost landing door sill (minimum four screws

per one meter of plate). Fit the plastic end caps over the sharp edges.

9. Install the emergency battery drive unit (EBD, optional).

For more information, see AM-13.30.016.

C A U T I O N : Ensure that there is a minimum 10 mm clearance between the EBD and the

car door operator.

10. Install the Site Access Gateway (SAG, optional). Connect the cables to KCEAPM in

MAP.

For more information, see AM-13.25.011.

© 2013 KONE Corporation 40 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

9

3

10

6

4

7

1

2 8

X0000094473

X0000094065 A.4

6.2.6 I n s t a l l LW D c a b l e , O S G c a b l e a n d t o p m o s t l i g h t i n g u n i t

1. Route, fix and connect the load weighing device (LWD) sensor cable (140) and

overspeed governor (OSG) cable (127).

Leave minimum 100 mm space between the cables when they are parallel to each

other.

N O T E : LWD cable can be routed together with the thermistor and encoder cables.

2. Install the topmost lighting unit. Route and connect the lighting cable (XH157).

3. Route and connect electric safety chain (P110) and signalization cable (XS2).

© 2013 KONE Corporation 41 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

127

140

100mm

XOSG2

min.

XOSG2

XS2 KDL16L

XH1 XL4

XOSG1

XH157

X0000094616

Cable From To

LWD cable Load weighing device KDL16L KCE drive / XL4

OSG cable Overspeed governor MAP / XOSG1 and OSG

adapter cable XOSG2

Lighting cable Elevator shaft light MAP / XH157

Electric safety chain cable Electric safety chain of MAP / XH1

elevator shaft

Signalization cable Landing signalization MAP / XS2

X0000094597 A.4

© 2013 KONE Corporation 42 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.2.7 Connections and earthings with ECB-1 (KDL16L KCE)

1 2 3

**

*

X0000094643

6 4 5 12 11 7 8 10 9

Pos Description Pos Description Pos Description

1 Braking resistor 5 Control cable (if ECB) 9 Drive communication

cable cable

2 Motor supply cable 6 Start permit cable (if 10 Encoder cable

ECB)

3 Brake cable 7 Supply cable 11 Start permit cable

4 DC-link cable (if 8 Load weighing device 12 Thermistor cable

ECB) cable

*) Only with ECB-1

© 2013 KONE Corporation 43 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

**) A danger of condensed water, on the wire surface, to enter connectors! Form a loop before

the connector.

X0000094633 A.4

6.2.8 Connections and earthings without ECB-1 (KDL16L KCE)

1 2 3

**

X0000094645

9 8 4 5 7 6

Pos Description Pos Description Pos Description

1 Braking resistor 4 Supply cable 7 Encoder cable

cable

2 Motor supply cable 5 Load weighing device 8 Start permit cable

cable

3 Brake cable 6 Drive communication 9 Thermistor cable

cable

© 2013 KONE Corporation 44 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

**) A danger of condensed water, on the wire surface, to enter connectors! Form a loop before

the connector.

X0000094635 A.4

6.2.9 Connect machine cables (KDL16L KCE)

N O T E : Ensure that the power supply is safely locked off. Refer to AM-01.03.002 Take 5.

1. Route and connect.

– Motor supply cable to U, V and W

– Braking resistor cables to XBRE2

– Thermistor cable to XT1

– Brake cable from machine to RBO XBR4

– Brake cable from RBO XBD1 to drive XBR4

– Encoder cable from machine to RBO XMEN5

– Encoder cable from RBO XMEN2 to drive XMEN5

2. Check that there is smooth radius from the wall to the drive to avoid the cable leading

humidity or water to the bushings.

© 2013 KONE Corporation 45 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

3. Check that all connections are clean and clamps are secure. Firm contact between

earthing clamps and cable sleeves is very important.

U, V, W

XMEN5

XBR4

XBRE2

XT1

5Nm

XMEN2

XMEN5

XBD1

XBR4

* *

X0000094666

*) Fix the cable shield to the clamp (to ensure uninterrupted cable shielding).

X0000094656 A.2

© 2013 KONE Corporation 46 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.2.10 Connect cables between MAP and drive (KDL16L KCE)

1. Route and connect the cables between the maintenance access panel (MAP) and drive.

A = THD filter

PE

220 /

2,4,6,8

XS3 XD1

PE

XKDSI1 XD3

T1,T2

T3,PE

A

PE,L1',L2',L3'

L1,L2,L3,PE

X0000095204

X0000094658 A.2

© 2013 KONE Corporation 47 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6 . 2 . 11 C o n n e c t R B O c a b l e s ( K D L 1 6 L K C E )

* *

9 OSG

22BP:1

22BP:2

RBOMU

4

XOSG2 11

XF3

XMEN2 X10

RBORC

KCEFCB XMEN5

XF3 XLH32

X10

6 XLH31

10

XBD1 8

XRBO1 XBR4

7

3 KCEMSC

KDL16L

* * XOSG1

XOSGT1

XBR4 XOSGT2

XMEN5 KCE

XRBO1 12

1

2 5

286

X0000088879

From To

1 Main unit / XMEN2* Drive / XMEN5

2 Main unit / XBD1* Drive / XBR4

3 Main unit / XBR4* Hoisting machine brakes

4 Main unit / XMEN5* Hoisting machine encoder

5 Main unit / XRBO1 XRBO1 / KCE

6 Main unit / X10 Remote control unit / X10

7 Main unit / XF3 Shaft bundle / KCEFCB / XF3

8 Remote control unit / XLH32 Maintenance access panel / 22BP:1

© 2013 KONE Corporation 48 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

From To

9 Remote control unit / XOSG2 Overspeed governor

10 Remote control unit / XLH31 KCEMSC

11 Remote control unit / XOSG2 Maintenance access panel /

– bypass switch 22BP:1

– bypass button 22BP:2

Overspeed governor cable

12 Control cable 286L, 286N, PE Maintenance access panel / XRBO1 on

metal bracket

* Fix the cable shield to the clamp (to ensure uninterrupted cable shielding).

X0000095208 A.3

6.3 MonoSpace 500 with KDL16S (EN81-1)

6.3.1 Quality requirements

Quality Requirements:

D r i v e , T H D f i l t e r, t r u n k i n g s , e x t e r n a l

braking resistor (if any)

– installed to correct position according to

layout drawings

Accessories (EBD etc.)

– installed to correct position according to

layout drawings

Cables between elevator shaft top

components

– routed and connected, free of obstruction

– encoder cable routed separately (not

grouped with machine cables)

– plugs properly inserted into sockets

– all ‘screw type’ cable terminations

tightened, ensure no loose cable strands X0000107423

– earthings checked

– cable grounding / shields to be correctly

clamped

– ensure that no damage has occurred

during installation

N O T E : Ensure that all covers are closed

after installation.

© 2013 KONE Corporation 49 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

! ! ! C A U T I O N — i s s u e s t h a t a ff e c t SORT

reliability !!! STABILIZE

Incorrectly installed elevator shaft top

electrification causes:

5S SHINE

STANDARDIZE

SUSTAIN

X000028644

– equipment (drive etc.) not installed to

layout drawing position will interfere with Method tools needed:

required running clearance from ropes or Man riding hoist

car

Hand tools needed:

– accessories (EBD etc.) not installed to Tape measure, spirit level, pencil, hammer

layout drawing position will interfere with drill, hammer, side cutters, 2 x spanner (8,

required safety spaces, running 10 mm), ratchet + socket (19 mm, EBD),

clearances spanner (7, 17, 19 mm), allen keys, TORX

Incorrectly installed elevator shaft top screwdriver (T10), electrical terminal

cabling causes: screwdriver, multigrip pliers

– incorrectly routed encoder cable can 5S Installation Progress Report

cause poor encoder reference feedback Lift Controller Installed

due to magnetic field disturbances from

machine cables. This leads to poor ride Q D - 1 8 1 . 2 11

comfort and drive faults QD 7 commenced

– plugs not inserted correctly to sockets

can cause unnecessary disconnections

– earthing / shield clamps not used

correctly will NOT provide the required

grounding to remove signal interference

– loose ‘screw type’ terminals cause

unnecessary disconnections

X0000093868 A.3

6.3.2 Notes

WA R N I N G : During electrification work, the power must be off. Ensure that the power to the

main supply cable cannot be turned on. Remove fuses and lock the main switches. Notice the

separate lighting supplies.

C A U T I O N : When drilling above drive or MAP, protect the panels from dust.

© 2013 KONE Corporation 50 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

C A U T I O N : If there is a danger of condensed water, on the wire or cable

surface, to enter electrical components or connectors in the elevator

shaft, form a loop before the cable entry or connector. This cable loop

X000031161

method is recommended for all installations and mandatory in wet or

humid operating conditions.

X000031162

C A U T I O N : When installing the cables, ensure the following:

o

90

1 Encoder and thermistor cables must be separated from motor supply and

2

>100mm brake control cables. Otherwise there might be disturbances in the

3

4 encoder signals. These cables can cross each other at an angle of

90 degrees. If these cables are routed parallel, the minimum clearance

X000032929

between these two cable groups must be 100 mm.

1 = Encoder cable, 2 = Thermistor cable, 3 = Brake control cable, 4 =

Motor supply cable

N O T E : Fix the cables to the wall in both horizontal and vertical directions. The maximum

distance between wall fixings is 500 mm.

X0000093812 A.2

© 2013 KONE Corporation 51 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.3.3 Overview

X000085321

© 2013 KONE Corporation 52 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

X000032920

X0000093941 A.2

6.3.4 Open KDL16S drive covers

N O T E : The covers must be closed when switching the power on.

© 2013 KONE Corporation 53 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

1. Remove the cover plate.

X0000090904

2. Open the slide deck.

Keep the slide deck closed during the drive module installation to prevent damaging the

internal components.

X0000090892

X0000082409 A.3

6.3.5 Install drive panel (KDL16S, guide rail fixing)

N O T E : Make sure that you have a good grip when handling heavy items.

1. Slide the fixing bolts to the C-profile. Fit the locking pins to both ends of the C-profile.

2. Install the drive back plate to the C-profile.

3. Install the guide rail support. Select the support position according to fish plate location.

*) Alternative position for guide rail support fixing.

© 2013 KONE Corporation 54 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

4. Install the drive panel to the back plate.

X000032932

X0000095211 A.2

6.3.6 Install drive panel (KDL16S, wall fixing)

N O T E : Make sure that you have a good grip when handling heavy items.

1. Install the back plate to the elevator shaft wall.

© 2013 KONE Corporation 55 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

2. Install the drive panel to the back plate.

NMX07

128

25

370

NMX11

128

25 370

X000032933

X0000095212 A.2

6.3.7 Install electrical components

1. Install the THD filter. Note two optional fixing positions depending on the filter size.

2. Install the EcoBox DC fuse box (F386:2, optional) to right side of the THD filter.

N O T E : In case of 25 A THD filter, fix DC fuse box to the shaft wall.

3. Install the braking resistor (optional).

4. Fix the metal plate trunking above the top track.

5. Fix the 2 m piece of trunking (125 × 50 mm) beside the drive.

6. Fix the topmost trunkings for the cables.

7. Install the ECB-1 single line ReGenerative unit (optional).

8. Fix the metal plate trunking below the topmost landing door sill (minimum four screws

per one meter of plate). Fit the plastic end caps over the sharp edges.

© 2013 KONE Corporation 56 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

9. Install the emergency battery drive unit (EBD, optional).

For more information, see AM-13.30.016.

C A U T I O N : Ensure that there is a minimum 10 mm clearance between the EBD and the

car door operator.

10. Install the traveling cable hanger.

N O T E : If MAP is at the second topmost floor, the traveling cable is fixed to the same

level as the bottom through hole of the MAP.

N O T E : Traveling cable hanger must be located above the mid point of the elevator

shaft.

11. Install the Site Access Gateway (SAG, optional). Connect the cables to KCEAPM in

MAP.

For more information, see AM-13.25.011.

12. Install the option box. Connect cables to KCEOPT board or KCECPU (XO2) in

controller.

© 2013 KONE Corporation 57 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

9

3

11

6

4

5 2

7

10 12 8

X0000086006

X0000094066 A.2

6.3.8 I n s t a l l LW D c a b l e , O S G c a b l e a n d t o p m o s t l i g h t i n g u n i t

1. Route, fix and connect the load weighing sensor (LWD) cable (140) and overspeed

governor (OSG) cable (127).

Leave minimum 100 mm space between LWD cable and other cables when they are

parallel to each other to prevent possible interference.

N O T E : LWD cable can be routed together with thermistor and encoder cables.

2. Install the topmost lighting unit. Route and connect the lighting cable (XH157).

N O T E : XH157 is connected directly to the maintenance access panel (MAP).

3. Route the shaft safety circuit (P110) and signalization cable (XS1).

© 2013 KONE Corporation 58 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

127

140

100mm

P110

min.

XS1

KDL16S

XL4

XOSG1

XH157

X000032935

Cable From To

LWD cable Load weighing device KDL16S KCE drive / XL4

OSG cable Overspeed governor MAP / XOSG1

Lighting cable Shaft light MAP / XH157

Safety circuit cable Elevator shaft safety circuit MAP / XH1

Signalization cable Landing signalization MAP / XS1

X0000095213 A.2

© 2013 KONE Corporation 59 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.3.9 Connections and earthings with ECB-1 (KDL16S KCE)

16

XSD1

XEC01

XMF1

XMEN5 XW1 XKDSI1 XL4 XT1

17

U V W T1 T2 T3

XG3

XS3

XBR4

XEC02

XBRE2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

X000032936

1. Motor supply cable (cables from machine or du/dt filter)

2. Motor fan cable

3. Earth wire of the mains supply (PE, optional)

4. Supply cable

5. ECB-1 cable

6. Encoder cable

7. Load weighing device cable (optional)

8. Start permit cable

9. ECB-1 cable

10. Drive communication cable

11. Brake cable

12. Thermistor cable

13. Braking resistor cable

14. Load weighing device cable

15. ECB-1 cable

16. SD card

17. Battery tool connector

X0000082432 B.3

© 2013 KONE Corporation 60 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.3.10 Connections and earthings without ECB-1 (KDL16S KCE)

13

XSD1

XMF1

XMEN5 XW1 XKDSI1 XL4 XT1

14

U V W T1 T2 T3

XG3

XBRE2

XS3 XBR4

1 2 3 4 5 6 7 8 9 10 11 12

X000032937

1. Motor supply cable (cables from machine or du/dt filter)

2. Motor fan cable

3. Earth wire of the mains supply (PE, optional)

4. Supply cable

5. Encoder cable

6. Load weighing device cable (optional)

7. Start permit cable

8. Drive communication cable

9. Brake cable

10. Thermistor cable

11. Braking resistor cable

12. Load weighing device cable

13. SD card

14. Battery tool connector

X0000082433 B.3

6 . 3 . 11 C o n n e c t m a c h i n e c a b l e s ( K D L 1 6 S K C E )

WA R N I N G : Ensure that the power supply is safely locked off. Refer to AM-01.03.002 Take 5.

© 2013 KONE Corporation 61 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

1. Route and connect (and bundle together) following cables.

– Motor supply cable to U, V and W

– Braking resistor cable (if delivered) to XBR2

– Brake cable to XBR4

N O T E : Motor supply cable and brake control cable can be routed between the car

guide rail and drive, if there is not enough space between drive and elevator shaft front

wall.

2. Route and connect (and bundle together) following cables.

– Thermistor cable to XT1

– Encoder cable to XMEN5

N O T E : Thermistor cable and encoder cable can be routed together with load weighing

device (LWD) cable.

3. Check that there is smooth radius from the wall to the drive to avoid the cable leading

humidity or water to the bushings.

4. Check that all connections are clean and clamps are secure. Firm contact between

earthing clamps and cable sleeves is very important.

XMEN5

XT1

U,V,W

XBR4

XBR2

PE

X000032938

X0000095217 A.2

6.3.12 Connect cables between MAP and drive (KDL16S KCE)

N O T E : Always connect the PE cable first.

© 2013 KONE Corporation 62 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

1. Route and connect the cables between the maintenance access panel (MAP) and drive.

A = THD filter, Load (L1’, L2’, L3’, PE) to drive, Line (L1, L2, L3, PE) to MAP

PE

XKDSI1

T1,T2,T3

220 /

2,4,6,8

XS3

XD1

PE

XD3

L1,L2,L3 PE L1',L2',L3'

A

X000032939

X0000095224 A.2

© 2013 KONE Corporation 63 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.4 MonoSpace 500 with KDL16S (EN81-20)

6.4.1 Quality requirements

Quality Requirements:

D r i v e , T H D f i l t e r, t r u n k i n g s , e x t e r n a l

braking resistor (if any)

– installed to correct position according to

layout drawings

Accessories (EBD etc.)

– installed to correct position according to

layout drawings

Cables between elevator shaft top

components

– routed and connected, free of obstruction

– encoder cable routed separately (not

grouped with machine cables)

– plugs properly inserted into sockets

– all ‘screw type’ cable terminations

tightened, ensure no loose cable strands X0000107423

– earthings checked

– cable grounding / shields to be correctly

clamped

– ensure that no damage has occurred

during installation

N O T E : Ensure that all covers are closed

after installation.

© 2013 KONE Corporation 64 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

! ! ! C A U T I O N — i s s u e s t h a t a ff e c t SORT

reliability !!! STABILIZE

Incorrectly installed elevator shaft top

electrification causes:

5S SHINE

STANDARDIZE

SUSTAIN

X000028644

– equipment (drive etc.) not installed to

layout drawing position will interfere with Method tools needed:

required running clearance from ropes or Man riding hoist

car

Hand tools needed:

– accessories (EBD etc.) not installed to Tape measure, spirit level, pencil, hammer

layout drawing position will interfere with drill, hammer, side cutters, 2 x spanner (8,

required safety spaces, running 10 mm), ratchet + socket (19 mm, EBD),

clearances spanner (7, 17, 19 mm), allen keys, TORX

Incorrectly installed elevator shaft top screwdriver (T10), electrical terminal

cabling causes: screwdriver, multigrip pliers

– incorrectly routed encoder cable can 5S Installation Progress Report

cause poor encoder reference feedback Lift Controller Installed

due to magnetic field disturbances from

machine cables. This leads to poor ride Q D - 1 8 1 . 2 11

comfort and drive faults QD 7 commenced

– plugs not inserted correctly to sockets

can cause unnecessary disconnections

– earthing / shield clamps not used

correctly will NOT provide the required

grounding to remove signal interference

– loose ‘screw type’ terminals cause

unnecessary disconnections

X0000093868 A.3

6.4.2 Notes

WA R N I N G : During electrification work, the power must be off. Ensure that the power to the

main supply cable cannot be turned on. Remove fuses and lock the main switches. Notice the

separate lighting supplies.

C A U T I O N : When drilling above drive or MAP, protect the panels from dust.

© 2013 KONE Corporation 65 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

C A U T I O N : If there is a danger of condensed water, on the wire or cable

surface, to enter electrical components or connectors in the elevator

shaft, form a loop before the cable entry or connector. This cable loop

X000031161

method is recommended for all installations and mandatory in wet or

humid operating conditions.

X000031162

C A U T I O N : When installing the cables, ensure the following:

o

90

1 Encoder and thermistor cables must be separated from motor supply and

2

>100mm brake control cables. Otherwise there might be disturbances in the

3

4 encoder signals. These cables can cross each other at an angle of

90 degrees. If these cables are routed parallel, the minimum clearance

X000032929

between these two cable groups must be 100 mm.

1 = Encoder cable, 2 = Thermistor cable, 3 = Brake control cable, 4 =

Motor supply cable

N O T E : Fix the cables to the wall in both horizontal and vertical directions. The maximum

distance between wall fixings is 500 mm.

X0000093812 A.2

© 2013 KONE Corporation 66 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

6.4.3 Overview

X0000093981

© 2013 KONE Corporation 67 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

X000032920

X0000093942 A.2

6.4.4 Open KDL16S drive covers

N O T E : The covers must be closed when switching the power on.

© 2013 KONE Corporation 68 (129) AM-01.01.250-AP2

All rights reserved (B) 2017-04-06

KONE EcoSpace and MonoSpace 500

Installation Instruction

1. Remove the cover plate.

X0000090904

2. Open the slide deck.