Escolar Documentos

Profissional Documentos

Cultura Documentos

Lego's $150 Million Sustainable Plastics Challenge Make Biobased The Norm

Enviado por

Tricia DazaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Lego's $150 Million Sustainable Plastics Challenge Make Biobased The Norm

Enviado por

Tricia DazaDireitos autorais:

Formatos disponíveis

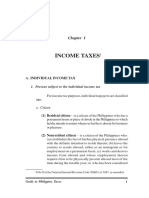

Lego’s $150 Million Sustainable Plastics

Challenge Make Biobased the Norm

Lego is pumping millions of dollars into its quest to find new, sustainable

materials for its

popular plastictoy bricks. While the company’s goal with this initiative is to build

better toys, it may end up shifting the plastics industry away from its oil-based

roots.

“We expect both established and emerging companies within the bio-based

plastics industry to look closely at how their technology may fit in with Lego’s

goal.” Lux Research associate Jennie Lynch told Environmental Leader.

Last year Lego said it would spend 1 billion Danish Krone ($150.5 million) to

develop new sustainable materials for its plastic Lego toys and packaging

materials. This includes the establishment of the Lego Sustainable Materials

Centre in Billund, Denmark.

The company has already hired at least 100 engineers to develop alternatives to

petroleum-based materials and is making good on its promises.

It’s a big deal for Lego, which Fast Company calls “the Apple of toys,” moving

from near bankruptcy in 2003 to briefly beating rival Mattel for a stint in 2014 to

become the biggest toy manufacturer in the world.

Amid its financial success, the company has taken efforts to reduce its carbon

footprint, such as investing in wind farms to offset the energy used in factories

and achieve its goal of using 100 percent renewable energy by 2020.

Between 2013 and 2014, Lego also reduced the size of its boxes by an average of

14 percent to use less cardboard, Lego spokesperson Kathrine Bisgaard Vase

told Environmental Leader. “In 2015, this amounted to approximately 7,000

tonnes less cardboard used,” she said. “In 2015, we also reached the highest

level yet of recycling waste, at 93 percent, and reached our goal of using 100

percent Forest Stewardship Council-certified paper and packaging in our

operations.”

While the company is working to reduce its global footprint across several

initiatives, finding a sustainable material from which to manufacture Legos is a

major one — and the company’s sustainable materials investment is a big deal

for the industry as well.

“It is exciting to see such a well-recognized company rethinking the traditional

supply chain and devoting significant resources to cutting edge research and

development for new materials that are environmentally conscious,” said Kim

Holmes, senior director of recycling and diversion at SPI: The Plastics Industry

Trade Association. “As an industry association, it is our goal that through the

work of innovative brands like Lego, The Coca-Cola Company and others

investing in R&D, sustainability will increasingly become the norm. Many of our

member companies are committed to reducing the environmental footprint of

plastics products from conception to production.”

Coca-Cola, for example, has partnered with three technology developers — Gevo,

Virent and Avantium — to achieve commercial-scale production of it biobased

PlantBottle, a replacement for its conventional plastic bottle. Coca-Cola is also

participating in a new sustainable plastics initiativethat launched last month,

called the New Plastics Economy. It aims to increase recycling and reuse as well

as bioplastics.

So what materials are Lego researchers considering? Bisgaard Vase said that

while it’s still too early to say what materials will replace traditional plastic,

safety and quality will be top priorities. And, she says, the company wants

materials that will not look or feel any different.

“Lego bricks are made from the highest quality plastics, which is very functional

and durable as a material. However, the current raw materials we use for

manufacturing Lego bricks are oil-based, and that is a scarce resource,”

Bisgaard Vase said. “So we are searching for a new material that is not based on

oil.

“Our aim is to have a positive impact on the planet, and that means searching for

new materials in a broader sense to have alternatives to the oil-based plastic

used for bricks and plastic packaging, but also to continue improving our paper-

based boxes to be more sustainable. All of which are significant contributors to

our environmental footprint, and therefore we are focusing on several efforts at

the same time.”

Lynch said recycled or reclaimed plastics may not work for Lego because of

safety and quality concerns. “Challenges associated with identifying the source

of recycled materials, as well as concerns about the reuse of hazardous resins

such as PVC, could present contamination issues for Lego,” she explained. “In

addition, the quality of recycled plastic resin degrades every time it is reused,

meaning this is unlikely to meet the durability requirements set by the company

for its products. With that in mind, the difficulties associated with using recycled

or reclaimed materials highlights an opportunity for emerging technologies to

provide a solution to Lego’s problem.”

There are several companies developing these types of biobased alternatives,

Lynch says. Global Bioenergies, for example, is developing bio-based, drop-in

precursors to acrylonitrile butadiene styrene (ABS) — that’s the plastic from

which Lego blocks are current made.

“Other companies are focused on the production of substitute bio-based

polymers with improved material performance compared to incumbents,” she

says. “For instance, polyhydroxyalkanoate (PHA) producers like Newlight

Technologies, which has partnered with IKEA, claims its AirCarbon PHA has

equal or superior properties to petroleum-derived polymers. And Avantium, which

has partnered with Coca-Cola, positions its superior performing polyethylene

furanoate (PEF) as a replacement to polyterephthalic acid (PET). There are also

more established players in this field, with collaborations between Siemens and

BASF leading to new hybrid materials with the potential to compete with

incumbents.”

The momentum to shift the plastics industry away from oil-based materials

seems to be there. And with a financial boost from companies like Lego with

deep pockets, bringing these new biobased alternatives to market looks

promising.

Você também pode gostar

- Market Potential of Eco-BricksDocumento19 páginasMarket Potential of Eco-BricksMichelle Cruzado Lagumay67% (3)

- Marketing Plan NotplaDocumento14 páginasMarketing Plan NotplaAnkita Vishwakarma100% (2)

- Brick Journal 10 Digital MagazineDocumento85 páginasBrick Journal 10 Digital Magazineflex7867% (6)

- Income Tax Solutions Manual Chapter SummariesDocumento60 páginasIncome Tax Solutions Manual Chapter SummariesPaul Justin Sison Mabao88% (32)

- M4 - Group 3 - The LEGO Group Building StrategyDocumento9 páginasM4 - Group 3 - The LEGO Group Building StrategyCharlie RAinda não há avaliações

- Innovation Turning Methane into Eco-Friendly PlasticDocumento10 páginasInnovation Turning Methane into Eco-Friendly PlasticNavneet KumarAinda não há avaliações

- Lego case study vision strategyDocumento4 páginasLego case study vision strategyCerasella1950% (2)

- CSR ReportDocumento2 páginasCSR ReportKhenith SantosAinda não há avaliações

- Biodegradable Plastic Bags ManufacturingDocumento15 páginasBiodegradable Plastic Bags ManufacturingAli AhmadAinda não há avaliações

- Business Report - Lego GroupDocumento12 páginasBusiness Report - Lego GroupKanchanit BangthamaiAinda não há avaliações

- Financial Accounting Valix and Peralta Volume Three - 2008 Edition 1Documento27 páginasFinancial Accounting Valix and Peralta Volume Three - 2008 Edition 1jamilahpanantaon83% (12)

- Zespri & LEGO Case StrategiesDocumento8 páginasZespri & LEGO Case StrategiesAndrew OnymousAinda não há avaliações

- Lego Serious Play OpensourceDocumento22 páginasLego Serious Play Opensourceapi-183609543Ainda não há avaliações

- Design Process at LEGODocumento5 páginasDesign Process at LEGOkapsarcAinda não há avaliações

- Who Is Legoland Current RM Supplier Now?Documento3 páginasWho Is Legoland Current RM Supplier Now?Nush MhdAinda não há avaliações

- EnvironmentDocumento6 páginasEnvironmentAnna KhoirotunnisaAinda não há avaliações

- Case Study The Lego CaseDocumento1 páginaCase Study The Lego Casecharles ambasAinda não há avaliações

- Sustainability and Responsible Management - LEGODocumento1 páginaSustainability and Responsible Management - LEGOVincent AkormedieAinda não há avaliações

- LEGODocumento4 páginasLEGOluana alexandra albites leonAinda não há avaliações

- English Breakfast 022Documento2 páginasEnglish Breakfast 022Mutiara Canda DesitaAinda não há avaliações

- Caring, Ethical and TransparentDocumento1 páginaCaring, Ethical and TransparentaswinganeshAinda não há avaliações

- Jiaxing, China - Toy Molder Lego A/S Has A New 1.77 Million-Square-FootDocumento4 páginasJiaxing, China - Toy Molder Lego A/S Has A New 1.77 Million-Square-FootJohn Mark LedesmaAinda não há avaliações

- Lesson Proper For Week 14: Relationship of Business To EnvironmentDocumento10 páginasLesson Proper For Week 14: Relationship of Business To EnvironmentMariathess MojicaAinda não há avaliações

- Managing International Business Responsibility - Company AnalysisDocumento8 páginasManaging International Business Responsibility - Company AnalysisPhuong Anh TranAinda não há avaliações

- First Shell Retail Station Built With Eco-Bricks' Rises in Bulacan - BusinessWorldDocumento3 páginasFirst Shell Retail Station Built With Eco-Bricks' Rises in Bulacan - BusinessWorldBenielyn JungcoAinda não há avaliações

- Business Plan for Glowing Eco BricksDocumento10 páginasBusiness Plan for Glowing Eco BricksHarson VelgadoAinda não há avaliações

- Daily Article Paper Bottles Uks2!9!11 Ver 1Documento2 páginasDaily Article Paper Bottles Uks2!9!11 Ver 1borutouzumaki6785Ainda não há avaliações

- CSR InitiativesDocumento6 páginasCSR InitiativesВікторія ОлішевськаAinda não há avaliações

- CSR Case Study On The Lego GroupDocumento10 páginasCSR Case Study On The Lego GroupKobe JenkinsAinda não há avaliações

- MS-WORD - Best Practices (Manuscript) FM 2-4 (GCSR) - Dela Torre, E.Documento11 páginasMS-WORD - Best Practices (Manuscript) FM 2-4 (GCSR) - Dela Torre, E.Eric Balberan Dela Torre Jr.Ainda não há avaliações

- Lego Group: "Only The Best Is Good Enough." - LEGO GroupDocumento20 páginasLego Group: "Only The Best Is Good Enough." - LEGO GroupamconartAinda não há avaliações

- Green Chemistry ProjectDocumento4 páginasGreen Chemistry ProjectShivam SharmaAinda não há avaliações

- Rethinking Bioplastics Future DirectionsDocumento5 páginasRethinking Bioplastics Future DirectionsJohnatan HubsAinda não há avaliações

- Sustainable Packaging CompaniesDocumento16 páginasSustainable Packaging CompaniesSamuel AngelusAinda não há avaliações

- Business Plan ECO-MISTDocumento18 páginasBusiness Plan ECO-MISTAl Sayad ArifAinda não há avaliações

- Implications of BioplasticsDocumento3 páginasImplications of BioplasticsSiti Anis IzzatieAinda não há avaliações

- PITCHINGDocumento1 páginaPITCHINGMary June Torcuato BotangenAinda não há avaliações

- Research Paper On Recycling PlasticDocumento5 páginasResearch Paper On Recycling Plasticoiotxmrhf100% (3)

- The Utility of Starch-Based PlasticsDocumento5 páginasThe Utility of Starch-Based PlasticsVenkata Siva Reddy PoluAinda não há avaliações

- Increase Use of Biodegradable Plastics by 10Documento18 páginasIncrease Use of Biodegradable Plastics by 10Anustha ChoudharyAinda não há avaliações

- Executive Summary: OpportunityDocumento2 páginasExecutive Summary: OpportunityLexico InternationalAinda não há avaliações

- Product PitchDocumento5 páginasProduct PitchCalvin Joshua LacsonAinda não há avaliações

- Green Antz IncDocumento3 páginasGreen Antz IncIcescosttAinda não há avaliações

- ADM and LG Chem To Develop Sustainable Technology For Superabsorbent PolymersDocumento2 páginasADM and LG Chem To Develop Sustainable Technology For Superabsorbent PolymersEng Hau QuaAinda não há avaliações

- MPDFDocumento5 páginasMPDFVenkata Siva Reddy PoluAinda não há avaliações

- Biodegradable Plastic BrochureDocumento4 páginasBiodegradable Plastic BrochureBiodegradablePlastic100% (1)

- readingpracticetest2-v9-18836554Documento16 páginasreadingpracticetest2-v9-18836554buithuytrangkc03Ainda não há avaliações

- PLASTICS CIRCULAR ECONOMY TECHNOLOGY CONVERTING WASTEDocumento6 páginasPLASTICS CIRCULAR ECONOMY TECHNOLOGY CONVERTING WASTEJasmine PutriAinda não há avaliações

- Sustainable Packaging DissertationDocumento6 páginasSustainable Packaging DissertationCollegePaperHelpCanada100% (1)

- Yahy AhDocumento3 páginasYahy Ahjadeshades12Ainda não há avaliações

- Project Profile On PET Bottles: Product Code (NIC Code) : 22203Documento12 páginasProject Profile On PET Bottles: Product Code (NIC Code) : 22203Mr.vijay VaddiAinda não há avaliações

- Industry Focus Advanced MaterialsDocumento51 páginasIndustry Focus Advanced MaterialsCathryn UAinda não há avaliações

- Wepik Building A Sustainable Future The Lego Group039s Ethical Integration and Its Advantages 20231118080236fzlXDocumento12 páginasWepik Building A Sustainable Future The Lego Group039s Ethical Integration and Its Advantages 20231118080236fzlXbarun ghimireAinda não há avaliações

- Reading PracticeDocumento9 páginasReading PracticeAnh Lê ChâuAinda não há avaliações

- 25 Big Companies That Are Going GreenDocumento17 páginas25 Big Companies That Are Going GreenVeron Gochuico JarabeAinda não há avaliações

- Plastics Could Help Build A Sustainable Future - Here's HowDocumento4 páginasPlastics Could Help Build A Sustainable Future - Here's HowanuragAinda não há avaliações

- Empresas Triple Bottom LineDocumento3 páginasEmpresas Triple Bottom LineJHON SEBASTIAN ACERO GUTIERREZAinda não há avaliações

- Individual Proposal FinalDocumento13 páginasIndividual Proposal Finalapi-553166006Ainda não há avaliações

- Article Effect of PlasticsDocumento1 páginaArticle Effect of Plasticstomas zetAinda não há avaliações

- BIOTECH Newsletter-Fall 04Documento9 páginasBIOTECH Newsletter-Fall 04Rakshit MathurAinda não há avaliações

- Cargill S NatureWorks Take Sugar-Derived Plastics To BrazilDocumento1 páginaCargill S NatureWorks Take Sugar-Derived Plastics To BrazilJeanAinda não há avaliações

- Activity in Group - Marketing ProblemDocumento8 páginasActivity in Group - Marketing ProblemCarolina LucínAinda não há avaliações

- Ecos CoDocumento4 páginasEcos CoMaria Jose Mojica TobarAinda não há avaliações

- Introduction To Evs ProjectDocumento26 páginasIntroduction To Evs ProjectShashikant SharmaAinda não há avaliações

- Plastic Bricks Made From Used Plastic Water BottlesDocumento1 páginaPlastic Bricks Made From Used Plastic Water BottlesMeron GetahunAinda não há avaliações

- Brand Together: Six Principles of Successful Brand PartnershipsNo EverandBrand Together: Six Principles of Successful Brand PartnershipsAinda não há avaliações

- Hairline - Shave (Ahit) - : Hair CUTDocumento1 páginaHairline - Shave (Ahit) - : Hair CUTTricia DazaAinda não há avaliações

- Gracedazaresumebluegray TaclobanDocumento1 páginaGracedazaresumebluegray TaclobanTricia DazaAinda não há avaliações

- Important Reminders: Step 1Documento4 páginasImportant Reminders: Step 1Tricia DazaAinda não há avaliações

- YuklMashud 2010 AdaptiveLeadershipDocumento14 páginasYuklMashud 2010 AdaptiveLeadershipTricia DazaAinda não há avaliações

- Document (1) BradzNBook11Documento20 páginasDocument (1) BradzNBook11Tricia DazaAinda não há avaliações

- Fry de CallopsDocumento8 páginasFry de CallopsTricia DazaAinda não há avaliações

- Categories: All Collections Yarn Needles Notions ToolsDocumento12 páginasCategories: All Collections Yarn Needles Notions ToolsTricia DazaAinda não há avaliações

- We Asked GEL Students and GEL Alumni To Share A Belief in The Form of An EssayDocumento1 páginaWe Asked GEL Students and GEL Alumni To Share A Belief in The Form of An EssayTricia DazaAinda não há avaliações

- Categories: All Collections Yarn Needles Notions ToolsDocumento12 páginasCategories: All Collections Yarn Needles Notions ToolsTricia DazaAinda não há avaliações

- Clarity Assurance Framework 19-04-2010 PDFDocumento39 páginasClarity Assurance Framework 19-04-2010 PDFTricia DazaAinda não há avaliações

- AppendiciesDocumento28 páginasAppendiciesTricia DazaAinda não há avaliações

- Wanted BarberoDocumento1 páginaWanted BarberoTricia DazaAinda não há avaliações

- Categories: All Collections Yarn Needles Notions ToolsDocumento12 páginasCategories: All Collections Yarn Needles Notions ToolsTricia DazaAinda não há avaliações

- Final Cover For BindingDocumento4 páginasFinal Cover For BindingTricia DazaAinda não há avaliações

- Income TaxesDocumento76 páginasIncome TaxesJa FranciscoAinda não há avaliações

- Wanted BarberoDocumento1 páginaWanted BarberoTricia DazaAinda não há avaliações

- Attention Team DinarDocumento1 páginaAttention Team DinarTricia DazaAinda não há avaliações

- ReceiptDocumento1 páginaReceiptTricia DazaAinda não há avaliações

- Letterhead Template 27Documento1 páginaLetterhead Template 27Tricia DazaAinda não há avaliações

- Nature and Extent and Timing Will Vary According To Ksize and Complexity of The EntityDocumento5 páginasNature and Extent and Timing Will Vary According To Ksize and Complexity of The EntityTricia DazaAinda não há avaliações

- Lifecycle Analysis of Computer SystemsDocumento9 páginasLifecycle Analysis of Computer SystemsTricia DazaAinda não há avaliações

- ARTICLE 1458: CONTRACT OF SALE-is A Contract Whereby OneDocumento1 páginaARTICLE 1458: CONTRACT OF SALE-is A Contract Whereby OneTricia DazaAinda não há avaliações

- Leyte Normal University Graduate School Tacloban City: Agency PaperDocumento74 páginasLeyte Normal University Graduate School Tacloban City: Agency PaperTricia DazaAinda não há avaliações

- Chapter 7 Advacc 1 DayagDocumento31 páginasChapter 7 Advacc 1 Dayagchangevela83% (6)

- CH07sDocumento13 páginasCH07sTricia DazaAinda não há avaliações

- Production PlanDocumento7 páginasProduction PlanTricia DazaAinda não há avaliações

- Mark) : Signature Over Printed Name Date - Signature Over Printed Name DateDocumento3 páginasMark) : Signature Over Printed Name Date - Signature Over Printed Name DateAldwin UnisanAinda não há avaliações

- Lego Bricks: Parts List For Base Set #9797Documento3 páginasLego Bricks: Parts List For Base Set #9797Herald FernandoAinda não há avaliações

- Lego Bricklink 910001 Castle in The ForestDocumento566 páginasLego Bricklink 910001 Castle in The ForestJoaoAinda não há avaliações

- Law LEGODocumento105 páginasLaw LEGOVivian Vy LêAinda não há avaliações

- Core Set Product Sheet PDFDocumento2 páginasCore Set Product Sheet PDFCarlos Roman ZarzaAinda não há avaliações

- Case LegoDocumento22 páginasCase LegoAkshat ShahAinda não há avaliações

- List Game WarungGamesPCDocumento163 páginasList Game WarungGamesPCrezadwiirawanAinda não há avaliações

- SMCP Mba Assignment OneDocumento3 páginasSMCP Mba Assignment OneMOhamed Salad Ibrahim100% (1)

- TelegrafoDocumento11 páginasTelegrafoJOSE EDVALDO DA SILVA FRANCAAinda não há avaliações

- 8 1 Book Review 4Documento3 páginas8 1 Book Review 4TinoroAinda não há avaliações

- Kashani - 1989 - Beware The Pitfalls of Global Marketing - StandardisationDocumento18 páginasKashani - 1989 - Beware The Pitfalls of Global Marketing - StandardisationLiAinda não há avaliações

- Lego PDFDocumento28 páginasLego PDFsgraure0% (1)

- LEGO Building Tips and Tricks: LEGO Building Tips and TricksDocumento6 páginasLEGO Building Tips and Tricks: LEGO Building Tips and TricksJesus CarpioAinda não há avaliações

- Built Tribot100Documento59 páginasBuilt Tribot100Felipe MartinezAinda não há avaliações

- 6124045Documento48 páginas6124045David LusignanAinda não há avaliações

- Control a Bulldozer with Touch SensorsDocumento3 páginasControl a Bulldozer with Touch SensorsPika KasillasAinda não há avaliações

- Mindstorms Education 9797Documento72 páginasMindstorms Education 9797Johnny Romero MiliánAinda não há avaliações

- LEGO - Design ReportDocumento30 páginasLEGO - Design Reportsoraya_merrylees06100% (2)

- Appendix 2-LEGO Mind Storms NXT Keypad SchematicDocumento1 páginaAppendix 2-LEGO Mind Storms NXT Keypad SchematicAlfon DeLerínAinda não há avaliações

- FLL Explore Multimedia ConnectionsDocumento9 páginasFLL Explore Multimedia Connectionsapi-454202541Ainda não há avaliações

- Spring 2020 Chronicle Books Frontlist CatalogDocumento180 páginasSpring 2020 Chronicle Books Frontlist CatalogChronicleBooks67% (3)

- LEGO HouseDocumento144 páginasLEGO HouseCarlos Jose Piñero Zeballos100% (4)

- Ev3 SpaceDocumento4 páginasEv3 Spaceapi-317284747Ainda não há avaliações

- Longmont Recreation Summer 2013Documento60 páginasLongmont Recreation Summer 2013City of Longmont, ColoradoAinda não há avaliações

- Lego House InstructionsDocumento13 páginasLego House InstructionsCarmy1625% (4)

- LEGO 100 Ways To Rebuild The World Get Inspired To Make The World An Awesome Place!Documento92 páginasLEGO 100 Ways To Rebuild The World Get Inspired To Make The World An Awesome Place!Fabian LubiszewskiAinda não há avaliações