Escolar Documentos

Profissional Documentos

Cultura Documentos

Moxa Cloud Based Remote Access Solution MRC 1

Enviado por

Ngoc Son PhamDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Moxa Cloud Based Remote Access Solution MRC 1

Enviado por

Ngoc Son PhamDireitos autorais:

Formatos disponíveis

WHITE PAPER

Five Key Considerations

When Implementing Secure

Remote Access to Your IIoT

Machines

Blanch Huang

Product Manager

WHITE PAPER Five Key Considerations When Implementing

Secure Remote Access to Your IIoT Machines

Abstract

Industrial IoT (IIoT) and smart factory trends are redefining today’s OEM business model.

Predictive maintenance, improved overall equipment effectiveness (OEE), and zero equipment

downtime are goals that are commonly sought after for industrial machines, and machine

builders are leaving no stone unturned to achieve these for their customers. In order to do so,

machine builders need an effective way to gain visibility into their machines and also need to

be able to remotely connect to and manage their machines at field sites. In this white paper,

we discuss five key elements of a secure remote access solution for industrial equipment and

explain why a cloud-based remote access solution is ideal for machine builders when compared

to traditional VPN and remote desktop solutions.

The IIoT is Driving New OEM Business Models

The IIoT has revolutionized the way business owners view their production environment by

providing the capability to acquire real-time data from machines and devices in the field so

that business owners can efficiently monitor and control production processes. OEE and zero

equipment downtime are no longer just buzzwords because they are the key to a successful

business. In order to increase production efficiency and cut operation costs, business operators

are adopting new technologies and tools to help them gain more insight into their processes

and systems. This new trend is compelling machine builders to provide tools and services that

support the goals of zero downtime and high OEE for business owners’ machines and

equipment. Remote access technology is key to helping machine builders achieve these goals.

Data collected from experienced support engineers indicate that an estimated 60% to 70% of

operational problems in machines simply require a software upgrade or some parameter

changes to fix the problem, and tellingly, these can be done remotely! By adopting remote

access solutions, machine builders can avoid time-consuming and expensive on-site work for

troubleshooting such problems in the field.

Furthermore, with remote access technology, machine builders can acquire real-time data from

machines installed at field sites. And, based on the actual condition of the equipment, machine

builders can predict machine failures before they occur. This ability gives business owners the

opportunity to schedule machine maintenance services in advance, thus enabling them to

improve the availability of their machines, in addition to improving production quality and

speed. Such predictive maintenance services provided by machine builders can dramatically

improve the overall equipment effectiveness of plant machines and equipment.

Released on April 15, 2018

© 2018 Moxa Inc. All rights reserved.

Moxa is a leading provider of edge connectivity, industrial networking, and network infrastructure solutions for enabling

connectivity for the Industrial Internet of Things. With over 30 years of industry experience, Moxa has connected more

than 50 million devices worldwide and has a distribution and service network that reaches customers in more than 70

countries. Moxa delivers lasting business value by empowering industry with reliable networks and sincere service for

industrial communications infrastructures. Information about Moxa’s solutions is available at www.moxa.com.

How to contact Moxa

Tel: 1-714-528-6777

Fax: 1-714-528-6778

© 2018 Moxa Inc.

1

WHITE PAPER Five Key Considerations When Implementing

Secure Remote Access to Your IIoT Machines

Some machine builders have adopted traditional remote access methods such as Virtual

Private Networking (VPN) and Remote Desktop Connection (RDC) to improve their service

levels and to provide quick response times for their customers. However, these traditional

remote access solutions have various limitations and constraints that prevent machine builders

from achieving their maximum service potential.

Challenges for OEMs in Using VPN and RDC Solutions

Virtual Private Networking (VPN) and Remote Desktop Connection (RDC), the latter of which

uses Virtual Network Computing (VNC), are two common methods used to remotely access

machines and equipment at field sites.

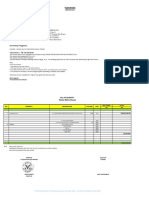

Figure 1: Traditional Remote Management Tools—VPN and RDC

VPN and RDC solutions can facilitate secure connections to remote machines. However, many

of these solutions lack the flexibility or the intelligence to meet the specific needs of industrial

machine builders. The five key elements that such machine builders have to consider when

they use VPN and RDC solutions are:

1. A Time-Consuming Setup Process that Requires Extensive IT

Knowledge

Multiple parameters, including IP address, domain name, key ID, authentication mode, a

suitable encryption algorithm, and an efficient hash function, all need to be configured to

properly establish connectivity with remote machines and to be able to exchange the

necessary authentication keys and data. This process is complex, time consuming, and

requires extensive IT knowledge, which a majority of automation engineers may not be

familiar with.

© 2018 Moxa Inc.

2

WHITE PAPER Five Key Considerations When Implementing

Secure Remote Access to Your IIoT Machines

2. Compromises in Corporate Security Policies Required to Enable

Remote Access to Machines

VPN applications require the VPN server to have a static public IP address, and some specific

network ports need to be configured to permit inbound and outbound traffic. In the inbound

firewall rules, users have to create NAT rules and enable port forwarding to allow inbound VPN

connections. In the outbound firewall, UDP port 500 or UDP port 4500 or some other

designated port has to be configured to allow outbound VPN connections. Most IT departments

are unwilling to implement these changes in their organization’s network because the changes

may create network vulnerabilities and compromise network security. Creating firewall rules

that are secure and flexible at the same time has proven to be a major challenge for most IT

departments, especially those that manage industrial networks.

3. Complexity and the High Cost of Ensuring the Security of Remote

Connections

VPN connections between machine builders and machine operators are usually site-to-site

connections, which typically provide machine builders with remote access to all local devices in

a plant’s network. Plant operators want to restrict the network access of machine builders so

that only a selected set of machines are accessible. For example, plant operators need ways to

restrict access by plant equipment and specify the applications that can be accessed remotely

to prevent unauthorized access to production information and unauthorized or accidental

operation of plant equipment. The only way to mitigate this risk is for IT departments to create

separate end-to-end connections using VPN technology, which as previously noted, is complex

and expensive, thereby drastically increasing setup and maintenance costs.

RDC connections are equally troublesome in that they expose computing equipment on the

plant network to the public network, creating security risks. Computers need regular security-

patch updates, which are carried out when they are connected to a public network such as the

plant’s Wi-Fi network. Plant computers are then vulnerable during such access windows to the

public network, if they are also open to RDC control. They can become targets of network

attacks, and, for example, be susceptible to injection of ransomware. Mitigating these security

issues requires additional resources, both in terms of human resources and maintenance costs.

4. VPN Security is Hard to Manage

One way to achieve a higher-level of security is to have different pre-shared keys or X.509

certificates for each VPN tunnel. When the number of VPN tunnels/connections required are

few, it is easy to manage the keys or certificates for these connections. However, as the

number of VPN tunnels grows, it becomes very hard to manage these keys and certificates.

When VPN servers or client systems are changed, certificates have to be regenerated. When a

certificate expires, a new certificate has to be assigned and reloaded to the system, which

further complicates maintenance.

© 2018 Moxa Inc.

3

WHITE PAPER Five Key Considerations When Implementing

Secure Remote Access to Your IIoT Machines

5. The Scalability and Flexibility of VPN and RDC Come at a High Cost

VPN servers typically have a limitation on the number of VPN tunnels they can support. When

a business grows, more and more machines and devices are connected to the network with an

increasing number of engineers supporting business operations. This leads to an increase in

the number of VPN connections required. Once this number exceeds the VPN server’s

capabilities, machine builders will need to install a new VPN server and go through an

additional time-consuming configuration process.

VPN servers are typically located in the machine builder’s service center. A large number of

VPN clients in remote sites are connected to these VPN servers in the centralized service

center. Support engineers typically do not have access to the server from outside the service

center. In order to have access to the VPN servers from outside the service center—for

example, by using OpenVPN or L2TP over IPsec—VPN servers have to be installed at remote

sites, and each VPN server needs to have a public IP address. This results in high installation

and maintenance costs. In addition, a remote connection requires different network subnets on

the server side as well as on the client side. If engineers want to simultaneously diagnose

remote equipment on different sites, they have to be aware of the IP subnet configurations at

the remote IP sites in order to avoid IP address conflicts and other problems.

Similarly, a remote desktop connection to a PLC/controller is neither straightforward nor

convenient. It requires, at a minimum, a dedicated PC that is connected to the machine and

has all of the relevant software tools installed. As a business grows, the number of dedicated

PCs and the number of software-tool licenses will increase, leading to a steep rise in IT costs.

In addition, one needs to consider the effort to maintain the PCs and the software tools

installed on them. Machine builders tend to prefer identical versions of the software tools to be

installed on both the client and host machines since this simplifies the troubleshooting process.

To do so, the IT engineers assigned for maintenance need to coordinate all updates to software

tools between the server and client sides.

Because of these limitations and restrictions in VPN and RDC-based remote access solutions,

machine builders and equipment manufacturers are looking for easy-to-use, secure, flexible,

and scalable solutions that can be used to remotely manage their machines and equipment.

Cloud-Based Secure Remote Access

Cloud-based remote access is a new type of remote access solution that enables flexible

remote access to field machines. The network topology of a cloud-based remote access

solution is composed of three components: a remote gateway, a cloud server, and client

software. Remote gateways are connected to field equipment in order to remotely access and

control them. Client software is installed on the engineer’s PC or desktop. The cloud server can

be installed on a cloud-based platform such as Amazon Web Services or Microsoft Azure.

The remote gateway and client software will both initiate outbound secure connection requests

to the cloud server.

© 2018 Moxa Inc.

4

WHITE PAPER Five Key Considerations When Implementing

Secure Remote Access to Your IIoT Machines

The cloud server will map the two connection requests and after successful authentication on

both sides, a connection is established.

Figure 2: Cloud-Based Secure Remote Access

Cloud-based secure remote access solutions implement a network topology that enables the

creation of outbound connections in the form of remote access tunnels, thereby effectively

overcoming the challenges that the traditional VPN and remote desktop control technologies

present. In addition, cloud based remote access brings the following additional benefits to

machine builders.

Ease of Use

a) Plug and play remote access without technical configuration

In a cloud-based remote access solution, security parameters—such as hash functions,

encryption/decryption algorithms, etc.—are configured automatically. Machine builders do

not need to configure these parameters; they just need to click on a button to establish a

remote connection.

b) Virtual IP addresses make multi-point remote access effortless with no field IP

reconfiguration required

Irrespective of the initial IP addresses set up by machine builders, cloud-based solutions

assign a unique virtual IP address to machines. Machine builders can use these virtual IP

addresses to establish multiple simultaneous remote connections. In addition, machine

builders can use identical IP schemes for different field sites without worrying about IP

address conflicts, which helps them cut installation costs substantially.

© 2018 Moxa Inc.

5

WHITE PAPER Five Key Considerations When Implementing

Secure Remote Access to Your IIoT Machines

c) The remote access connection is centrally monitored and managed

In cloud-based remote access solutions, the cloud server is the central point for

establishing and managing remote connections. Administrators can monitor the traffic

status and volume of each connection by connecting to the cloud server. Furthermore,

administrators can easily manage client accounts, remote gateways, and certificates

without the need for frequent reconfiguration. All these management tasks can be done via

an easy to set up cloud-based server portal.

• Client account management: Administrators can create, cancel, or redefine client

access.

• Gateway management: Administrators can add or remove remote gateways and

connected equipment through the centralized cloud-based portal.

• Certificate management: Cloud servers play the role of the centralized certificate

manager, and automatically assign X.509 certificates to each remote access connection.

The cloud servers have the ability to temporarily suspend connections until the

certificates are verified.

Enhanced Security

a) End-to-end encryption prevents data leaks

Cloud-based remote access solutions provide end-to-end data encryption between a piece

of remote equipment and an engineer’s PC. The cloud server only routes the traffic and

does not decrypt or store the data that is passing through

b) On-demand remote access control

Machine builders use remote access solutions to perform troubleshooting, monitoring,

maintenance, and diagnostics. Remote access to machines and equipment is typically not

required on a continuous basis and hence can be used on an as-needed basis to minimize

security issues and reduce costs, especially in cases where remote connectivity is based on

a volume-dependent pricing option, such as with cellular technology. Furthermore, machine

operators want to be able to take measures to prevent machine builders from remotely

accessing all applications on their local network by limiting the scope of remote access to

only applications that machine builders need to access, thereby eliminating the risk of

interference with plant operations.

Cloud-based remote access provides machine operators with the ability to initiate or accept

remote connections. Furthermore, machine operators can create rules as to which services

and applications, such as HTTPS or Telnet, machine builders are authorized to use

remotely. They can also control who has the authority to use them, for example, by

restricting access to a specific set of service engineers.

© 2018 Moxa Inc.

6

WHITE PAPER Five Key Considerations When Implementing

Secure Remote Access to Your IIoT Machines

c) Follow existing IT security policies without any compromises

Cloud-based remote access solutions build outbound connections using the outbound

service port 443 (normally reserved for secure website access using SSL) to access remote

equipment, which does not present any issues for IT departments managing plant

networks. Cloud-based remote access solutions can work in harmony with the IT security

policies of machine operators.

Flexibility and Scalability

a) Client software isn't limited to a specific hardware platform

As long as they have an active client account, users can download the client software to

any laptop/PC and have remote access from anywhere and at any time.

b) Remote access to equipment as if they are locally connected

Cloud-based remote access solutions create a transparent tunnel that connects the client

with the remote equipment as if they were on the same network. So regardless of the

remote equipment being accessed (e.g., a Siemens PLC or a Rockwell controller), and

independent of the protocol used to pull data or for programming (e.g., an L2 broadcast

packet or an L3 IP packet), machine builders can remotely acquire data or program remote

equipment using their own software tools as if the machine builder was sitting next to the

remote equipment.

c) Easy network expansion

Network administrators can easily add and remove equipment and manage client accounts

and certificates as they expand their remote networks.

Conclusion

OEMs and machine builders require a secure, easy-to-use, and scalable remote access solution

to enable on-demand remote access to their machines deployed in the field. Traditional VPN

and RDC solutions are cumbersome and require IT/networking knowledge as well as changes

in security/firewall policies. A remote access solution that is backed by a cloud-based

management infrastructure can provide the ease-of-use, flexibility, and scalability required by

OEMs, without compromising on security. Moxa has designed the Moxa Remote Connect (MRC)

solution specifically for OEMs and machine builders to help them improve their efficiency and

lower operational costs. For additional details, visit Moxa Remote Connect.

Disclaimer

This document is provided for information purposes only, and the contents hereof are subject

to change without notice. This document is not warranted to be error-free, nor subject to any

other warranties or conditions, whether expressed orally or implied by law, including implied

warranties and conditions of merchantability, or fitness for a particular purpose. We specifically

disclaim any liability with respect to this document and no contractual obligations are formed

either directly or indirectly by this document.

© 2018 Moxa Inc.

7

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- 2018 05 DFINITY Technology Overview Series Consensus SystemDocumento16 páginas2018 05 DFINITY Technology Overview Series Consensus SystemNgoc Son PhamAinda não há avaliações

- Urgent - 03 Tester (Manual test, QA QC) : Vũ Thị MếnDocumento7 páginasUrgent - 03 Tester (Manual test, QA QC) : Vũ Thị MếnNgoc Son PhamAinda não há avaliações

- 2017 11 Design Patterns For Smart Contracts in The Ethereum EcosystemDocumento25 páginas2017 11 Design Patterns For Smart Contracts in The Ethereum EcosystemNgoc Son PhamAinda não há avaliações

- 2008 02 Robust De-Anonymization of Large Sparse DatasetsDocumento15 páginas2008 02 Robust De-Anonymization of Large Sparse DatasetsNgoc Son PhamAinda não há avaliações

- 2017 11 Pricing Perpetual Put Options by The Black (Scholes Equation With A Nonlinear Volatility FunctionDocumento18 páginas2017 11 Pricing Perpetual Put Options by The Black (Scholes Equation With A Nonlinear Volatility FunctionNgoc Son PhamAinda não há avaliações

- Name Desc Logo Binance Coin Ethereum Tether SolanaDocumento30 páginasName Desc Logo Binance Coin Ethereum Tether SolanaNgoc Son PhamAinda não há avaliações

- Nguyen Van Dai: Personal DetailsDocumento3 páginasNguyen Van Dai: Personal DetailsNgoc Son PhamAinda não há avaliações

- 2007 03 Volatility and Dividend Risk in Perpetual American OptionsDocumento21 páginas2007 03 Volatility and Dividend Risk in Perpetual American OptionsNgoc Son PhamAinda não há avaliações

- Le Thi Dieu Linh - Curriculum VitaeDocumento2 páginasLe Thi Dieu Linh - Curriculum VitaeNgoc Son PhamAinda não há avaliações

- NVR3616DDocumento1 páginaNVR3616DNgoc Son PhamAinda não há avaliações

- Playing To WinDocumento3 páginasPlaying To WinNgoc Son PhamAinda não há avaliações

- Visual Thinking ArchiveDocumento50 páginasVisual Thinking ArchiveNgoc Son PhamAinda não há avaliações

- Lit 12012371 PDFDocumento120 páginasLit 12012371 PDFNgoc Son PhamAinda não há avaliações

- People Process TechnologyDocumento22 páginasPeople Process TechnologyNgoc Son PhamAinda não há avaliações

- Scanned by CamscannerDocumento28 páginasScanned by CamscannerNgoc Son PhamAinda não há avaliações

- N4 2 - CertTest - APACDocumento17 páginasN4 2 - CertTest - APACNgoc Son Pham100% (1)

- 4090-9120 6-Point IODocumento4 páginas4090-9120 6-Point IONgoc Son PhamAinda não há avaliações

- Iedc Book of The Year 2014Documento42 páginasIedc Book of The Year 2014Ngoc Son PhamAinda não há avaliações

- Tyco TN17 Tunnel Sprinkler PRDocumento1 páginaTyco TN17 Tunnel Sprinkler PRNgoc Son PhamAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Airline ReportDocumento9 páginasAirline ReportRaheel AhmedAinda não há avaliações

- As 60068.2.17-2003 Environmental Testing Tests - Test Q - SealingDocumento6 páginasAs 60068.2.17-2003 Environmental Testing Tests - Test Q - SealingSAI Global - APACAinda não há avaliações

- Hudgins Fundamental Freedom To TradeDocumento7 páginasHudgins Fundamental Freedom To TradeDenisa StefanAinda não há avaliações

- Memorandum of Association - BRAC 2013 PDFDocumento21 páginasMemorandum of Association - BRAC 2013 PDFNishaAinda não há avaliações

- Malaysian Airline System Berhad Annual Report 04/05 (10601-W)Documento87 páginasMalaysian Airline System Berhad Annual Report 04/05 (10601-W)Nur AfiqahAinda não há avaliações

- Practice Makes Perfect: 28 June 2007 Nottingham Trent UniversityDocumento16 páginasPractice Makes Perfect: 28 June 2007 Nottingham Trent UniversityArjun SinghAinda não há avaliações

- Credit Card DetailsDocumento5 páginasCredit Card Detailsjrbossfps75% (8)

- Breakeven AnalysisDocumento5 páginasBreakeven AnalysismmmugambiAinda não há avaliações

- Cdep Sample SlidesDocumento9 páginasCdep Sample SlidesKarla Kressel CerenoAinda não há avaliações

- HR and Ir Practices in MRK Sugar MillsDocumento107 páginasHR and Ir Practices in MRK Sugar MillsVasanth KumarAinda não há avaliações

- Importance of StatisticsDocumento6 páginasImportance of StatisticsTritoyAinda não há avaliações

- Course Material 1 The Practice of EntrepreneurshipDocumento8 páginasCourse Material 1 The Practice of EntrepreneurshipRenz ZacharielleAinda não há avaliações

- Questionnaire (Filled)Documento3 páginasQuestionnaire (Filled)mayur0072007Ainda não há avaliações

- UNESCO TA AgreementDocumento29 páginasUNESCO TA AgreementSandeep JoshiAinda não há avaliações

- 12 Month Sales ForecastDocumento1 página12 Month Sales ForecastSaulo FernandesAinda não há avaliações

- 2 - Storey 2br/2t&b Newly Renovated Apartment - Quezon CityDocumento4 páginas2 - Storey 2br/2t&b Newly Renovated Apartment - Quezon Cityjust_niceAinda não há avaliações

- RealNetworks Motion For Leave To File Second Amended ComplaintDocumento10 páginasRealNetworks Motion For Leave To File Second Amended ComplaintBen SheffnerAinda não há avaliações

- Advertising and Sales PromotionDocumento69 páginasAdvertising and Sales PromotionnhdAinda não há avaliações

- Arvind MillsDocumento9 páginasArvind MillsPradeep Kumar PandeyAinda não há avaliações

- May 25, 2012 Strathmore TimesDocumento35 páginasMay 25, 2012 Strathmore TimesStrathmore TimesAinda não há avaliações

- CH 10 NotesDocumento13 páginasCH 10 NotesmohamedAinda não há avaliações

- Swift 103-202Documento2 páginasSwift 103-202Akhmad Zaeny100% (11)

- MIS Chapter 1Documento56 páginasMIS Chapter 1Robeir AmirAinda não há avaliações

- Coinbase EulaDocumento4 páginasCoinbase Eulafloorman67Ainda não há avaliações

- Training Organizational Development Manager in United States Resume Donna DelaneyDocumento3 páginasTraining Organizational Development Manager in United States Resume Donna DelaneyDonnaDelaneyAinda não há avaliações

- QUOTATION Harian Boho House 2Documento1 páginaQUOTATION Harian Boho House 2Timothy Integrated Farm07Ainda não há avaliações

- Credit Risk ManagementDocumento23 páginasCredit Risk ManagementRavinder Kumar AroraAinda não há avaliações

- Reliabilityweb Uptime 20131201Documento69 páginasReliabilityweb Uptime 20131201catraioAinda não há avaliações

- Gangar EyenationDocumento10 páginasGangar Eyenationpree09Ainda não há avaliações

- Consumers' Attitude Towards Green Products - An Exploratory Study in Erode DistrictDocumento8 páginasConsumers' Attitude Towards Green Products - An Exploratory Study in Erode DistrictarcherselevatorsAinda não há avaliações