Escolar Documentos

Profissional Documentos

Cultura Documentos

7.0 Tube To Tubesheet Fabrication: Copper-Nickel Welding and Fabrication - 15

Enviado por

satnamDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

7.0 Tube To Tubesheet Fabrication: Copper-Nickel Welding and Fabrication - 15

Enviado por

satnamDireitos autorais:

Formatos disponíveis

7.

0 Tube to Tubesheet Fabrication

In heat exchangers and condensers, tubes process, either with or without filler • joint crevice leak path size

are joined to tubesheets to prevent leakage metal. Manual welding can be used on requirement

between the tube side and shell side. Often special designs and is often the standard • filler metal requirements

the easiest and least expensive method method for weld repairing; filler metal • tubesheet heat sink

is to expand the tube mechanically into addition is essential here, to avoid weld • structural flexibility

the drilled hole in the tubesheet, usually porosity. While the TIG (GTAW) process is • available equipment

by roller expansion. Ideally, the tubesheet well adapted to make T/TS welds with thin • tube dimensions and fillet size.

should be harder and less galvanically wall tubes, other welding processes may be

noble than the tubes. A mechanically better suited for large diameter and thicker Successful T/TS welding depends critically

expanded joint may be acceptable when: wall tubes. Alternative welding processes on the accurate machining of holes, joint

include MMA (SMAW), MIG (GMAW) or preparation on the tubesheet and cleaning

• service temperatures are under plasma arc. Explosive welding is another all surfaces prior to welding. Accurately

about 200°C joining option, although it is seldom used machined holes are particularly important

• tubesheets are sufficiently thick to in copper-nickel construction. to make sure the tungsten electrode is

allow rolling-in a suitable length of always positioned correctly in the weld

tube There are many different T/TS weld joint joint.

• design pressures are relatively low designs used in industry and each has its

• a weld joint is not needed to support particular advantages and disadvantages. The tubesheet should be cleaned

the tube bundle Figure 3 illustrates the common welds that immediately after drilling and positioned

• a mechanical joint is not used for can be made on the tubesheet face - flush so that, during cleaning, the contaminants

severe services where a leak could tube, recessed tube, trepanned tube sheet, drain from the tubesheet and do not

present a catastophic safety hazard. added-ring and face-side fillet weld. accumulate on one surface. Compressed

air should not be used to blow off the

When a tube-to-tubesheet (T/TS) weld Selection of the particular automatic TIG cleaning solution unless equipment is

is made in a copper-nickel construction, (GTAW) weld joint configuration to use installed to remove moisture and oil

it is most often made by an automatic involves considerations such as: contamination from the air. Dry nitrogen is

gas-shielded tungsten arc (TIG or GTAW) often a good alternative to compressed air.

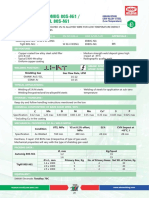

Tube to tubesheet welding of a large heat exchanger using automatic TIG (GTAW) welding heads

(Courtesy Arc Machines Inc)

Copper-Nickel Welding and Fabrication | 15

Você também pode gostar

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- Titanium Heat Exchangers Design IssuesDocumento13 páginasTitanium Heat Exchangers Design Issuesxo123456789Ainda não há avaliações

- Module 4-Part-2Documento76 páginasModule 4-Part-2Renjin J BrightAinda não há avaliações

- About Welding Process 47Documento1 páginaAbout Welding Process 47XerexAinda não há avaliações

- Titanium - Welding and Heat Treating: Topics CoveredDocumento13 páginasTitanium - Welding and Heat Treating: Topics CoveredSisira ChandrasomaAinda não há avaliações

- 13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202)Documento5 páginas13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202)IJAERS JOURNAL100% (1)

- Applying Tig Techniques Hand-OutDocumento12 páginasApplying Tig Techniques Hand-Outjuvy may esbanAinda não há avaliações

- GTAW Chapter 1Documento4 páginasGTAW Chapter 1Renold ElsenAinda não há avaliações

- Workshop Case StudyDocumento13 páginasWorkshop Case Study1071Vishal kumarAinda não há avaliações

- Miller Welding TitaniumDocumento20 páginasMiller Welding TitaniumrcpretoriusAinda não há avaliações

- 13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202) PDFDocumento5 páginas13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202) PDFAshemuAinda não há avaliações

- TIG-welding Gases PDFDocumento2 páginasTIG-welding Gases PDFwenigmaAinda não há avaliações

- Guidelines for Welding Process SelectionDocumento2 páginasGuidelines for Welding Process SelectionAmit SindhyaAinda não há avaliações

- Laser Cladding Vs Other TechnologiesDocumento17 páginasLaser Cladding Vs Other Technologiesvenkat200a100% (2)

- Welding NPTEL Lecturers - Part4Documento30 páginasWelding NPTEL Lecturers - Part4Sai ChaithanyaAinda não há avaliações

- Types of WeldingDocumento66 páginasTypes of WeldingLee Shi HongAinda não há avaliações

- 5 GtawDocumento45 páginas5 GtawPutra Daha PratamaAinda não há avaliações

- 3.4 Crater Pipe: CommentsDocumento1 página3.4 Crater Pipe: CommentsJeevan R NairAinda não há avaliações

- Design - TWIDocumento7 páginasDesign - TWIFreddie KooAinda não há avaliações

- Automation in Sheet Metal Tig Welding Process: A Case StudyDocumento6 páginasAutomation in Sheet Metal Tig Welding Process: A Case StudyseventhsensegroupAinda não há avaliações

- Amta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesDocumento115 páginasAmta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesAbu RectifyAinda não há avaliações

- Not ChingDocumento2 páginasNot ChingjjzoranAinda não há avaliações

- WOWLibrary TIG WeldingDocumento3 páginasWOWLibrary TIG Weldingisaac2408Ainda não há avaliações

- TIG Welding HandbookDocumento88 páginasTIG Welding HandbookBalakumar100% (2)

- Welding Recommendation TS890Documento2 páginasWelding Recommendation TS890max_powerAinda não há avaliações

- Azing Procedure Weld Copper WaterstopDocumento5 páginasAzing Procedure Weld Copper Waterstopzhuxueyun55Ainda não há avaliações

- Welding Hygienic RequirementsDocumento5 páginasWelding Hygienic RequirementsZmanAinda não há avaliações

- Gtaw 03Documento40 páginasGtaw 03பத்மநாபன் ஶ்ரீநிவாஸன்Ainda não há avaliações

- Orbital-Welding Facts enDocumento52 páginasOrbital-Welding Facts ene.vicente.caballeroAinda não há avaliações

- Applying Titanium Alloys in Drilling and Offshore Production SystemsDocumento3 páginasApplying Titanium Alloys in Drilling and Offshore Production SystemsrandyooiscribdAinda não há avaliações

- Tungsten Inert Gas WeldingDocumento2 páginasTungsten Inert Gas WeldingJacques SauAinda não há avaliações

- 5 Crater Cracking: Rev 1 January 2009 TIG Welding © TWI LTD 2009Documento1 página5 Crater Cracking: Rev 1 January 2009 TIG Welding © TWI LTD 2009Gokul RajanAinda não há avaliações

- TIG Welding Process GuideDocumento20 páginasTIG Welding Process GuideEnache DaniAinda não há avaliações

- Titanium 101Documento19 páginasTitanium 101MOHAN100% (2)

- Gas Tungsten Arc WeldingDocumento13 páginasGas Tungsten Arc WeldingEmad A.AhmadAinda não há avaliações

- MigDocumento6 páginasMigPensel KoNtotAinda não há avaliações

- Rotary PipeCLADDocumento7 páginasRotary PipeCLADsafari7Ainda não há avaliações

- Welding MachineDocumento3 páginasWelding MachinetuanAinda não há avaliações

- Koco Koco Kocovvv Koco Koco Kocovv Koco KocoDocumento0 páginaKoco Koco Kocovvv Koco Koco Kocovv Koco KocoSun SunAinda não há avaliações

- WeldOverlayofContinuousDigestersTAPPI2002 PDFDocumento32 páginasWeldOverlayofContinuousDigestersTAPPI2002 PDFดิฐคุณ ผดุงมาศ100% (1)

- Types WeldingDocumento66 páginasTypes WeldingRathnakraja50% (2)

- Applying TIG Welding TechniquesDocumento104 páginasApplying TIG Welding Techniqueshema_avraoAinda não há avaliações

- Proc.-02 GTAW - PAWDocumento37 páginasProc.-02 GTAW - PAWRaghu vamshiAinda não há avaliações

- Design Considerations For WeldingDocumento11 páginasDesign Considerations For WeldingNarender Kundu100% (1)

- HSE PAPER (Soldagem)Documento9 páginasHSE PAPER (Soldagem)Wyllton CandidoAinda não há avaliações

- Weldingfixtures 140919075513 Phpapp02Documento28 páginasWeldingfixtures 140919075513 Phpapp02VJ SharmaAinda não há avaliações

- TIGBook PDFDocumento88 páginasTIGBook PDFMohamad 'Priyo'Ainda não há avaliações

- Fit-Up Preparation and Acceptance Criteria As Per Project RequirementsDocumento6 páginasFit-Up Preparation and Acceptance Criteria As Per Project RequirementsAbdülHak ÖZkaraAinda não há avaliações

- Operation: GTAW Weld AreaDocumento6 páginasOperation: GTAW Weld Areajavier mendezAinda não há avaliações

- Experiment - TIGDocumento5 páginasExperiment - TIGAl Anood Al AmeriAinda não há avaliações

- Gas Tungsten Arc WeldingDocumento12 páginasGas Tungsten Arc WeldingPrasanth NairAinda não há avaliações

- Asi304& Mild SteelDocumento28 páginasAsi304& Mild SteelArnab BhattacharyaAinda não há avaliações

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesNo EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesNota: 1 de 5 estrelas1/5 (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantNo EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantNota: 3.5 de 5 estrelas3.5/5 (3)

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Documento1 páginaAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamAinda não há avaliações

- CWC-BookletF1 59Documento1 páginaCWC-BookletF1 59satnamAinda não há avaliações

- GMAW/GTAW Welding of Aluminium Alloys with ER1100 WireDocumento1 páginaGMAW/GTAW Welding of Aluminium Alloys with ER1100 WiresatnamAinda não há avaliações

- GMAW GTAW MIGINOX 347Si STAINLESS STEELDocumento1 páginaGMAW GTAW MIGINOX 347Si STAINLESS STEELJagannath SahuAinda não há avaliações

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocumento1 páginaAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamAinda não há avaliações

- CWC-BookletF1 36 PDFDocumento1 páginaCWC-BookletF1 36 PDFJagannath SahuAinda não há avaliações

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocumento1 páginaAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamAinda não há avaliações

- GTAW TIGFIL CuNi solid filler rod for welding copper nickel alloysDocumento1 páginaGTAW TIGFIL CuNi solid filler rod for welding copper nickel alloyssatnamAinda não há avaliações

- GMAW Solid Wire for Welding Copper AlloysDocumento1 páginaGMAW Solid Wire for Welding Copper AlloyssatnamAinda não há avaliações

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocumento1 páginaAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamAinda não há avaliações

- Tiginox 385: Classification: en Iso 14343-ADocumento1 páginaTiginox 385: Classification: en Iso 14343-AJagannath SahuAinda não há avaliações

- NiCu-7 solid wire for welding nickel-copper alloysDocumento1 páginaNiCu-7 solid wire for welding nickel-copper alloyssatnamAinda não há avaliações

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 páginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamAinda não há avaliações

- CWC-BookletF1 38 PDFDocumento1 páginaCWC-BookletF1 38 PDFsatnamAinda não há avaliações

- CWC-BookletF1 17Documento1 páginaCWC-BookletF1 17satnamAinda não há avaliações

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 páginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamAinda não há avaliações

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 páginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamAinda não há avaliações

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Documento1 páginaAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamAinda não há avaliações

- CWC-BookletF1 15Documento1 páginaCWC-BookletF1 15satnamAinda não há avaliações

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 páginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamAinda não há avaliações

- CWC-BookletF1 10Documento1 páginaCWC-BookletF1 10satnamAinda não há avaliações

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 páginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamAinda não há avaliações

- CWC-BookletF1 9Documento1 páginaCWC-BookletF1 9satnamAinda não há avaliações

- CWC-BookletF1 12Documento1 páginaCWC-BookletF1 12satnamAinda não há avaliações

- CWC-BookletF1 9Documento1 páginaCWC-BookletF1 9satnamAinda não há avaliações

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Documento1 páginaAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamAinda não há avaliações

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 páginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamAinda não há avaliações

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 páginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamAinda não há avaliações

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 páginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamAinda não há avaliações

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 páginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamAinda não há avaliações

- Rac NotesDocumento16 páginasRac NotesJohnRay LominoqueAinda não há avaliações

- Applications and Interpretation Standard SpecimensDocumento56 páginasApplications and Interpretation Standard SpecimensNahir ClaraAinda não há avaliações

- Toraiz SP-16Documento89 páginasToraiz SP-16ScappinAinda não há avaliações

- Knight Boiler ManualDocumento80 páginasKnight Boiler ManualAnonymous 7xHNgoKE6eAinda não há avaliações

- Jurnal IlmiahDocumento12 páginasJurnal IlmiahROSSITAAinda não há avaliações

- Ws2 PascalDocumento3 páginasWs2 PascalsalahadamAinda não há avaliações

- Viscosity Vs ConsistencyDocumento6 páginasViscosity Vs Consistencysontakke manmathAinda não há avaliações

- AMCP 706-185, Military Pyrotechnics - Theory and ApplicationDocumento270 páginasAMCP 706-185, Military Pyrotechnics - Theory and ApplicationASDAFF ASADAinda não há avaliações

- What Is XRF ?: Prepared by Lusi Mustika SariDocumento34 páginasWhat Is XRF ?: Prepared by Lusi Mustika SariBayuAinda não há avaliações

- An Intelligent Algorithm For The Protection of Smart Power SystemsDocumento8 páginasAn Intelligent Algorithm For The Protection of Smart Power SystemsAhmed WestministerAinda não há avaliações

- ASME - Performance Test CodesDocumento1 páginaASME - Performance Test CodesanoopkntpcAinda não há avaliações

- Modular Forms Exam - Homework RewriteDocumento2 páginasModular Forms Exam - Homework RewritejhqwhgadsAinda não há avaliações

- 384 TungaloyDocumento32 páginas384 Tungaloyp.designAinda não há avaliações

- Connective TissueDocumento6 páginasConnective TissuecrtgyhujikAinda não há avaliações

- Preparation of Gases in LaboratoryDocumento7 páginasPreparation of Gases in LaboratoryChu Wai Seng50% (2)

- Live load and wind pressure on sloping roofsDocumento11 páginasLive load and wind pressure on sloping roofsAbel BerhanemeskelAinda não há avaliações

- Mathematics Class 10 CBSE (NCERT)Documento369 páginasMathematics Class 10 CBSE (NCERT)LinoAinda não há avaliações

- Guaranteed Restore Points Oracle 11g - Flash Back to SCN or RP (39Documento2 páginasGuaranteed Restore Points Oracle 11g - Flash Back to SCN or RP (39PraveenAinda não há avaliações

- Ansoff Matrix Template User GuideDocumento6 páginasAnsoff Matrix Template User Guidebernardo95Ainda não há avaliações

- Jm-10 Operation Manual Rev02 UnlockedDocumento121 páginasJm-10 Operation Manual Rev02 UnlockedAlan Jimenez GonzalezAinda não há avaliações

- Heat Combustion Laboratory ReportDocumento8 páginasHeat Combustion Laboratory ReportSteven Lee100% (1)

- The World of Chemistry Video Guide SetDocumento10 páginasThe World of Chemistry Video Guide SetrkvAinda não há avaliações

- Kidney AnatomyDocumento55 páginasKidney AnatomyMohammad zreadAinda não há avaliações

- DebugDocumento14 páginasDebugMigui94Ainda não há avaliações

- Compact GSM II: Installation and Application ManualDocumento22 páginasCompact GSM II: Installation and Application ManualleonardseniorAinda não há avaliações

- Unit Testing in Delphi by Nick Hodges 110214Documento36 páginasUnit Testing in Delphi by Nick Hodges 110214air4gbAinda não há avaliações

- Financial Accounting IIDocumento16 páginasFinancial Accounting IIMiguel BuenoAinda não há avaliações

- B. Solving Quadratic EquationsDocumento23 páginasB. Solving Quadratic EquationsHasnain -GamerAinda não há avaliações

- Forrester Roi StudyDocumento30 páginasForrester Roi StudymcgettsAinda não há avaliações

- Presentation On Power Grid InertiaDocumento47 páginasPresentation On Power Grid InertiajorjijonAinda não há avaliações