Escolar Documentos

Profissional Documentos

Cultura Documentos

Separ Filter SWK-2000 Series: Improves Diesel Engine Reliability

Enviado por

Joel AgbekponouTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Separ Filter SWK-2000 Series: Improves Diesel Engine Reliability

Enviado por

Joel AgbekponouDireitos autorais:

Formatos disponíveis

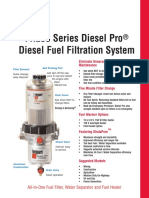

Separ Filter SWK-2000 Series

Improves diesel engine reliability

99.9% Water separation (certified TUV report using

SAE J1839) and removes sludge build-up

Longer element life

Filter separates most debris and large particles

before reaching the element

Less element replacements

User can backlush filter up to 5 times

before replacing element

Low restriction reduces wear on fuel pumps and

ensures full RPMs

Versions for any application

Available with clear or metal bowls. Marine version

includes clear bowl with metal heat deflector.

Diesel Filtration Single Filter with Metal Bowl

and Water Contacts

The Separ 2000 Series is a line of fuel water separators

designed to accommodate newer and more demanding diesel

engines. They are manufactured from high quality, non-

corroding aluminum alloy castings, heavy polycarbonate or

metal bowls and stainless steel hardware. Fuel systems are

protected and engine failure is avoided by the filters’ ability to

separate harmful particulate and water from diesel fuel.

Fuel water separators feature five stages of filtration and are

available with flow rates from 79 to 2,060 GPH for appropriate

integration into any size fuel system. The benefits include a

small physical size, high flow rate, low restriction, multiple

inlet/outlet configurations and long-life filter elements.

Backflushable (cleanable) elements reduce down time and

costly element changes.

Duplex systems contain two filters. When the primary filter

is in need of maintenance, the fuel system can continue to

operate by use of the secondary filter. This reduces down

time and increases dependability.

Duplex Filter System

Separ of the Americas, LLC www.separfilter.com | contact@separfilter.com | Ph: (954) 523-9396

Applications

Typical Installation

• Pleasure boats

• Emergency/standby generators and diesel engines

• Bulk fuel storage on farms and industrial plants

• Reserve storage for vehicle fleets

• Automotive industry - trucks, buses, mobile cranes, etc.

• Construction equipment

• Workboats

Function and Operation

The Separ 2000 filter should be installed on the suction side of the fuel system, between the fuel feed tank and the engine

mounted fuel lift pump. The unit can be mounted directly on the engine as well.

During the filtration process, water and larger, heavier particles settle out of the fuel to the bottom of the bowl and can later

be removed by opening the drain valve. Filters are available with standard or intrinsically safe water sensors to indicate

the need to drain bowl. Fuel then flows through the element to trap smaller particles before exiting the filter and towards

the engine. As a result, the element life is prolonged since it is NOT the sole component of filtration. (Filter size must

accommodate manufacturer’s specified maximum lift pump flow rate and not the burn rate.)

In standard duplex systems, changing filtration from the primary filter to the secondary filter is done by the user turning the

handle between them. An automatic switchable duplex will not require manual switch-over.

Model SWK-2000/5 SWK-2000/5/50 SWK-2000/10 SWK-2000/18 SWK-2000/40 SWK-2000/130

Maximum Flow 79 GPH 79 GPH 158 GPH 285 GPH 630 GPH 2,060 GPH

Capacity (300 LPH) (300 LPH) (600 LPH) (1,080 LPH) (2,400 LPH) (7,800 LPH)

Single or Duplex Filter • • • • • •

Metal Bowl • • • • • •

Clear Bowl • • • •

Water Contacts • • • • • •

Potential-Free probe

• •

Optional

(Metal Bowl only)

Metal Heat Deflector

• • • •

(Clear Bowl only)

Gauge • • • • • •

Separ Filters are certified by:

Version: 1/25/19

Separ of the Americas, LLC www.separfilter.com | contact@separfilter.com | Ph: (954) 523-9396

Você também pode gostar

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceAinda não há avaliações

- SEP AppSht SWK2000Series 0119 Email PDFDocumento2 páginasSEP AppSht SWK2000Series 0119 Email PDFJoel AgbekponouAinda não há avaliações

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingNo EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingNota: 5 de 5 estrelas5/5 (3)

- LT32560 - FH233 Series - Diesel Pro2Documento2 páginasLT32560 - FH233 Series - Diesel Pro2Naing Min Htun100% (1)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisNo EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisNota: 5 de 5 estrelas5/5 (1)

- Oil SkimmerDocumento4 páginasOil SkimmerManish KhakhraAinda não há avaliações

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!No EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Nota: 5 de 5 estrelas5/5 (2)

- Oil Grabber Model MB, Multi-Belt Oil Skimmer - Abanaki CorporationDocumento4 páginasOil Grabber Model MB, Multi-Belt Oil Skimmer - Abanaki CorporationKyle ChandlerAinda não há avaliações

- Choke and Kill Manifold Brochure PDFDocumento12 páginasChoke and Kill Manifold Brochure PDFtaloslamomia9417100% (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideNo EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideNota: 4.5 de 5 estrelas4.5/5 (8)

- Sep Catalog 0212Documento30 páginasSep Catalog 0212info2449Ainda não há avaliações

- Duraflo Htc006: Htc006 - Hydraulic Submersible Trash Pump and 1200D Drive UnitDocumento2 páginasDuraflo Htc006: Htc006 - Hydraulic Submersible Trash Pump and 1200D Drive UnitIrpan Fauzy HarahapAinda não há avaliações

- DA Series Diaphragm Accumulators: Previously Known As ELM SeriesDocumento18 páginasDA Series Diaphragm Accumulators: Previously Known As ELM SeriesglobalindosparepartsAinda não há avaliações

- Duraflo htc008Documento2 páginasDuraflo htc008Irpan Fauzy HarahapAinda não há avaliações

- DS OG OilblockDocumento2 páginasDS OG Oilblocksuphanat joomjanAinda não há avaliações

- Diaphragm Accumulators: - AD SeriesDocumento6 páginasDiaphragm Accumulators: - AD SeriesAFG AutomacaoAinda não há avaliações

- Flowrox PC-pump EL-series Datasheet ENGDocumento2 páginasFlowrox PC-pump EL-series Datasheet ENGAlberto Diaz100% (1)

- Filter Solutions English Feb 2019 HR-páginas-1,8-9,25-26Documento5 páginasFilter Solutions English Feb 2019 HR-páginas-1,8-9,25-26samuelAinda não há avaliações

- DeltaStak BrochureDocumento8 páginasDeltaStak Brochurerichard gutierrezAinda não há avaliações

- Selling Kobelt Brake Systems for Drilling ApplicationsDocumento43 páginasSelling Kobelt Brake Systems for Drilling ApplicationsWilson CendalesAinda não há avaliações

- Vcl-24uls 08-12 PDFDocumento2 páginasVcl-24uls 08-12 PDFJulianFootballAinda não há avaliações

- Catalogo GeneralDocumento20 páginasCatalogo Generalmiyagui77Ainda não há avaliações

- 824 Bonded Particle Filters ENDocumento2 páginas824 Bonded Particle Filters ENİsmail Süleyman ŞentürkAinda não há avaliações

- LT32562 - FH232 Series - Diesel ProDocumento2 páginasLT32562 - FH232 Series - Diesel ProShananda SoniAinda não há avaliações

- MAGTECH-Presentation - Main 2020 - CompressedDocumento68 páginasMAGTECH-Presentation - Main 2020 - CompressedMazaharul IslamAinda não há avaliações

- Duraflo Htc004: Htc004 - Hydraulic Submersible Trash Pump and 800D Drive UnitDocumento2 páginasDuraflo Htc004: Htc004 - Hydraulic Submersible Trash Pump and 800D Drive UnitIrpan Fauzy HarahapAinda não há avaliações

- Catalogo RacorDocumento179 páginasCatalogo RacorEdwin Maldonado Castro100% (1)

- CLEARMAX Jetting ToolDocumento2 páginasCLEARMAX Jetting ToolErnest AmadiAinda não há avaliações

- OLTC BrochureDocumento1 páginaOLTC Brochureefmartin21Ainda não há avaliações

- Solutions For Industrial Applications: Chemineer™ Small MixerDocumento6 páginasSolutions For Industrial Applications: Chemineer™ Small MixerSandeep K TiwariAinda não há avaliações

- Medium Pressure Filters Models 15CN, 40CN, 80CN: P A G EDocumento7 páginasMedium Pressure Filters Models 15CN, 40CN, 80CN: P A G EHidralteka SandelisAinda não há avaliações

- Water Filters Residential 5600SXT Chemical Free Iron Filters ENGLISH Canadian BrochureDocumento4 páginasWater Filters Residential 5600SXT Chemical Free Iron Filters ENGLISH Canadian BrochurePromagEnviro.comAinda não há avaliações

- Samiflex CatDocumento7 páginasSamiflex CatJuan Bernardo NietoAinda não há avaliações

- Ficha Tec. Filter CartsDocumento8 páginasFicha Tec. Filter CartsMakros HRAinda não há avaliações

- Hydrostatic Bailer - Ball TypeDocumento2 páginasHydrostatic Bailer - Ball TypeDias IrsaAinda não há avaliações

- High Performance Applications: Marine Propulsion EngineDocumento2 páginasHigh Performance Applications: Marine Propulsion EngineRocco SilfieddiAinda não há avaliações

- Cartridge and Bag Filter UnitDocumento6 páginasCartridge and Bag Filter UnitDoni KurniawanAinda não há avaliações

- SamiflexDocumento8 páginasSamiflexTIOCA01Ainda não há avaliações

- M Orbitales A PDFDocumento20 páginasM Orbitales A PDFAcu TomeiAinda não há avaliações

- Technical Brochure: Submersible 4" Non-Clog Sewage PumpDocumento4 páginasTechnical Brochure: Submersible 4" Non-Clog Sewage PumpLisandro Torrealba MedranoAinda não há avaliações

- Water Softeners Residential Autotrol 460i-255 Demand Series Softeners US BrochureDocumento4 páginasWater Softeners Residential Autotrol 460i-255 Demand Series Softeners US BrochurePromagEnviro.comAinda não há avaliações

- Velcon FiltersDocumento2 páginasVelcon FiltersLungisani100% (1)

- DeltaValve 2010 Customer VersionDocumento97 páginasDeltaValve 2010 Customer VersionjoseellargoAinda não há avaliações

- DS Og SSDocumento2 páginasDS Og SSDelarenus SianiparAinda não há avaliações

- KOHLER Mobile GeneratorDocumento8 páginasKOHLER Mobile GeneratorRizki Heru HermawanAinda não há avaliações

- Twin FilterDocumento5 páginasTwin Filterjinyuan74Ainda não há avaliações

- Mobile Dual Spin-On SeriesDocumento4 páginasMobile Dual Spin-On SeriesAten HarisAinda não há avaliações

- Brochure Oil Water SeparatorDocumento4 páginasBrochure Oil Water SeparatornorthstarleoAinda não há avaliações

- ALFA LAVAL Oil-Water Separator Stationary-MobileDocumento4 páginasALFA LAVAL Oil-Water Separator Stationary-MobilejpolancosAinda não há avaliações

- Nutsel Filter Press DataDocumento31 páginasNutsel Filter Press DataJay ShethAinda não há avaliações

- Conver Brochure C485 ENG PDF 1Documento12 páginasConver Brochure C485 ENG PDF 1oviAinda não há avaliações

- Filters Features and BenefitsDocumento13 páginasFilters Features and BenefitsGanGker HLAinda não há avaliações

- ZL 440 Product Data SheetDocumento3 páginasZL 440 Product Data SheetVishal ChudasamaAinda não há avaliações

- Proteus RO Type Fresh Water Generators: Seawater Desalination SystemsDocumento2 páginasProteus RO Type Fresh Water Generators: Seawater Desalination SystemsFDAinda não há avaliações

- Mobilair M50: 185 CFM at 100 PsigDocumento2 páginasMobilair M50: 185 CFM at 100 PsigDjAinda não há avaliações

- Fulflo Multicartucho GeneralDocumento24 páginasFulflo Multicartucho GeneralZoranAinda não há avaliações

- Contractor Pumps & Generators GuideDocumento32 páginasContractor Pumps & Generators GuideFlores Cesar0% (1)

- 10MFP ParkerDocumento8 páginas10MFP ParkerJoel PalaciosAinda não há avaliações

- OI - OSE - 5 - 10 - 20 - 40 - 80 - 120 EN - tcm11-37378Documento2 páginasOI - OSE - 5 - 10 - 20 - 40 - 80 - 120 EN - tcm11-37378Olga RepetskaAinda não há avaliações

- VolvoDocumento6 páginasVolvoJoel AgbekponouAinda não há avaliações

- VolvoDocumento6 páginasVolvoJoel AgbekponouAinda não há avaliações

- MB Truck Explorer Manual GB PDFDocumento117 páginasMB Truck Explorer Manual GB PDFJoel AgbekponouAinda não há avaliações

- BBG201122ENDocumento438 páginasBBG201122ENGianna FrolaAinda não há avaliações

- IvecoDocumento5 páginasIvecoJoel AgbekponouAinda não há avaliações

- Mbtruck Accessories BrochureDocumento69 páginasMbtruck Accessories BrochureJoel AgbekponouAinda não há avaliações

- BDM 100 TruckDocumento14 páginasBDM 100 TruckPetrescu Ionut100% (1)

- MBDocumento4 páginasMBConstantin CosminAinda não há avaliações

- MAN Presentation 20171027 PDFDocumento43 páginasMAN Presentation 20171027 PDFIceAinda não há avaliações

- Tga GBDocumento175 páginasTga GBMyo Min OoAinda não há avaliações

- Texa Daf Dmci MefiDocumento12 páginasTexa Daf Dmci Mefiinforlex100% (2)

- Infineon-IPP B I80N06S2 08-DS-v01 00-En PDFDocumento8 páginasInfineon-IPP B I80N06S2 08-DS-v01 00-En PDFJoel AgbekponouAinda não há avaliações

- Tga GBDocumento175 páginasTga GBMyo Min OoAinda não há avaliações

- WinOLS 2.24.0.0 + WinOLS ECU File Unlock + DAMOS FilesDocumento1 páginaWinOLS 2.24.0.0 + WinOLS ECU File Unlock + DAMOS FilesJoel AgbekponouAinda não há avaliações

- BBG201122ENDocumento438 páginasBBG201122ENGianna FrolaAinda não há avaliações

- MB Truck Explorer Manual GB PDFDocumento117 páginasMB Truck Explorer Manual GB PDFJoel AgbekponouAinda não há avaliações

- Am29f400bb 90si Amd Datasheet 72825Documento5 páginasAm29f400bb 90si Amd Datasheet 72825Joel AgbekponouAinda não há avaliações

- WinOLS 2.24.0.0 + WinOLS ECU File Unlock + DAMOS FilesDocumento1 páginaWinOLS 2.24.0.0 + WinOLS ECU File Unlock + DAMOS FilesJoel AgbekponouAinda não há avaliações

- Am29f400bb 90si Amd Datasheet 72825Documento5 páginasAm29f400bb 90si Amd Datasheet 72825Joel AgbekponouAinda não há avaliações

- PublicationDocumento89 páginasPublicationCesar Bayes RamosAinda não há avaliações

- Key Programming Manual 12.9Documento77 páginasKey Programming Manual 12.9Joel AgbekponouAinda não há avaliações

- XPROG ManualDocumento19 páginasXPROG ManualLorenna Ruth100% (1)

- Propoxur PMRADocumento2 páginasPropoxur PMRAuncleadolphAinda não há avaliações

- Prlude No BWV in C MinorDocumento3 páginasPrlude No BWV in C MinorFrédéric LemaireAinda não há avaliações

- Seminar Course Report ON Food SafetyDocumento25 páginasSeminar Course Report ON Food SafetyYanAinda não há avaliações

- Hi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!Documento8 páginasHi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!BS Central, Inc. "The Buzz"Ainda não há avaliações

- Pulse Width ModulationDocumento13 páginasPulse Width Modulationhimanshu jainAinda não há avaliações

- Rapport DharaviDocumento23 páginasRapport DharaviUrbanistes du MondeAinda não há avaliações

- PEDs and InterferenceDocumento28 páginasPEDs and Interferencezakool21Ainda não há avaliações

- Extrajudicial Settlement of Estate Rule 74, Section 1 ChecklistDocumento8 páginasExtrajudicial Settlement of Estate Rule 74, Section 1 ChecklistMsyang Ann Corbo DiazAinda não há avaliações

- Flowmon Ads Enterprise Userguide enDocumento82 páginasFlowmon Ads Enterprise Userguide ennagasatoAinda não há avaliações

- Final Year Project (Product Recommendation)Documento33 páginasFinal Year Project (Product Recommendation)Anurag ChakrabortyAinda não há avaliações

- Weone ProfileDocumento10 páginasWeone ProfileOmair FarooqAinda não há avaliações

- Open Far CasesDocumento8 páginasOpen Far CasesGDoony8553Ainda não há avaliações

- Kaydon Dry Gas SealDocumento12 páginasKaydon Dry Gas Sealxsi666Ainda não há avaliações

- SDS OU1060 IPeptideDocumento6 páginasSDS OU1060 IPeptideSaowalak PhonseeAinda não há avaliações

- Condition Based Monitoring System Using IoTDocumento5 páginasCondition Based Monitoring System Using IoTKaranMuvvalaRaoAinda não há avaliações

- Kate Elizabeth Bokan-Smith ThesisDocumento262 páginasKate Elizabeth Bokan-Smith ThesisOlyaGumenAinda não há avaliações

- Flexible Regression and Smoothing - Using GAMLSS in RDocumento572 páginasFlexible Regression and Smoothing - Using GAMLSS in RDavid50% (2)

- Revision Worksheet - Matrices and DeterminantsDocumento2 páginasRevision Worksheet - Matrices and DeterminantsAryaAinda não há avaliações

- United-nations-Organization-uno Solved MCQs (Set-4)Documento8 páginasUnited-nations-Organization-uno Solved MCQs (Set-4)SãñÂt SûRÿá MishraAinda não há avaliações

- Oxgen Sensor Cat WEBDocumento184 páginasOxgen Sensor Cat WEBBuddy Davis100% (2)

- Assignment Gen PsyDocumento3 páginasAssignment Gen PsyHelenAinda não há avaliações

- Listening Exercise 1Documento1 páginaListening Exercise 1Ma. Luiggie Teresita PerezAinda não há avaliações

- The Service Marketing Plan On " Expert Personalized Chef": Presented byDocumento27 páginasThe Service Marketing Plan On " Expert Personalized Chef": Presented byA.S. ShuvoAinda não há avaliações

- Joining Instruction 4 Years 22 23Documento11 páginasJoining Instruction 4 Years 22 23Salmini ShamteAinda não há avaliações

- Critical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentDocumento3 páginasCritical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentJatin KaushikAinda não há avaliações

- Kalley Ltdn40k221twam Chassis msd6308 SM PDFDocumento49 páginasKalley Ltdn40k221twam Chassis msd6308 SM PDFjulio cesar calveteAinda não há avaliações

- The Smith Generator BlueprintsDocumento36 páginasThe Smith Generator BlueprintsZoran AleksicAinda não há avaliações

- Baobab MenuDocumento4 páginasBaobab Menuperseverence mahlamvanaAinda não há avaliações

- LIST OF ENROLLED MEMBERS OF SAHIWAL CHAMBER OF COMMERCEDocumento126 páginasLIST OF ENROLLED MEMBERS OF SAHIWAL CHAMBER OF COMMERCEBASIT Ali KhanAinda não há avaliações

- Uniform-Section Disk Spring AnalysisDocumento10 páginasUniform-Section Disk Spring Analysischristos032Ainda não há avaliações